Primary Pedestal / Sectionalizing Cabinet Sample Specification 1

advertisement

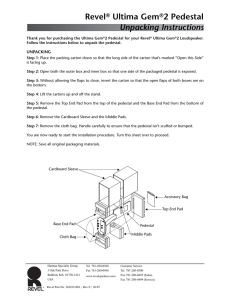

Primary Pedestal / Sectionalizing Cabinet Sample Specification 1. Scope This specification covers the minimum requirements for cable junction pedestals designed for single and three phase service applications. 2. Pedestal Materials Pedestal shall be made of fiberglass reinforced polymer with nominal thicknesses as shown in Table 2.1 Table 2.1 Component Cover Pad Mount Base Direct Bury Base Nominal Thickness 3/16" (4.8 mm) 3/16" (4.8 mm) 1/4" (6.4 mm) All externally facing fiberglass reinforced polymer shall be gel coated. Gel coat color shall be Willow green (light) or Munsell green (7GY3.29/1.5). The fiberglass reinforced polymer shall be made with fire retardant resin and shall have a flammability rating of HB per UL-94 The fiberglass reinforced polymer shall be resistant to typical roadside chemicals. The fiberglass material shall conform to the chemical resistance criteria listed in the latest revision of ANSI/SCTE 77. Specimens shall be exposed to the chemicals as listed in Table 2.2. Table 2.2 Chemical Common Use Concentration Sodium Chloride Road De-Icer 5% Battery Acid 0.1N Sulfuric Acid Water Softener 0.1N Sodium Carbonate Detergents 0.1N Sodium Sulfate Mineral Acid / Cleaner 0.2N Hydrochloric Acid Lye / Caustic Soda 0.1N Sodium Hydroxide Solvent / Vinegar 5% Acetic Acid Jet Fuel Per ASTM D543 Kerosene Mineral Oil Per ASTM D543 Transformer Oil Road De-Icer 5% Magnesium Chloride The pedestal locking device shall be of cast aluminum-bronze or silicon-bronze with captive 188 stainless steel hardware. The locking device shall have provisions for a padlock. The junction mounting assembly shall be made of hot-dip galvanized steel, 5000 or 6000 series aluminum, or 18-8 stainless steel. Parking clips shall be made of 18-8 stainless steel. All interior and exterior hardware shall be made of 18-8 stainless steel. 3. Testing & Compliance Certified test data for any criteria listed shall be made available upon request. 4. Design The pedestal shall meet all criteria set forth in ANSI C57.12.28, Pad-mounted Equipment Enclosure Integrity Standard. The pedestal cover shall open 90° and base sidewalls shall be of a cut-away type to allow unobstructed access to internal hardware. The pedestal base shall be designed to withstand a sidewall pressure of 130 psf (6.2 kPa) without cracking. This will simulate soil pressure placed on the pedestal. Both the pedestal base and cover shall be of a female mold design for security and aesthetic purposes. The pedestal shall have 4 lifting eyes for hoist slings. The cover shall be supplied with locking devices to prevent accidental closure. The weight of the cover is not sufficient to be considered a locking device. The junction mounting bar shall be designed to accommodate junctions and elbows which conform to IEEE 386. The junction mounting assembly shall be able to withstand a 400 lb (1780 N) pulling or pushing force along the cable junction axis anywhere along the mounting bar without damage or permanent distortion. 5. Dimensions Single phase cabinets used in 200 Amp applications shall have nominal dimensions as listed in Figure 4.1. Figure 4.1 25"[635mm] 34"[890mm] 21.5"[545mm] Height Dim A 36"[915mm] 42"[1065mm] 48"[1220mm] A B Bury Depth Dim B 12"[305mm] 18"[457mm] 24"[610mm] Three phase cabinets used in 200 Amp applications shall have nominal dimensions as listed in Figure 4.2. Figure 4.2 25"[635mm] 58"[1475mm] A B Height Dim A 42"[1065mm] 48"[1220mm] 54"[1370mm] Bury Depth Dim B 12"[305mm] 18"[457mm] 24"[610mm] Three phase cabinets used in 600 Amp applications shall have nominal dimensions as listed in Figure 4.3. Figure 4.3 32"[810mm] 78"[1980mm] 54"[1370mm] 24"[610mm]