Slides_Part 3

advertisement

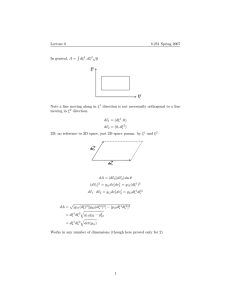

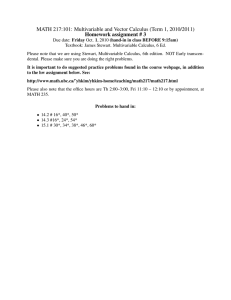

PART-3 KNU/EECS/ELEC 835001 Decentralized control for MIMO processes Multivariable Control Dr. Kalyana C. Veluvolu Outline - Module 5.3 Decentralized control for MIMO processes – – – – – – – – Multi-loop vs. Multivariable Control Loop Decomposition RGA detuning factor Biggest Log Modulus Method Design based on Loop Decomposition IMC Design Sequential Loop closing method Simultaneous Equation Solving Method Multivariable Control Dr. Kalyana C. Veluvolu 2 Multi-loop Control Systems Differences in SISO and interactive MIMO systems: The manipulated variables that satisfy the desired controlled variables must be determined simultaneously. Differences between single-variable and multivariable behavior increase as the transmission interaction increases. Sensitivity of adjustments in manipulated variables to model changes can be much greater in multi-loop than in single-loop systems. Multivariable Control Dr. Kalyana C. Veluvolu 3 Loop Decomposition The decentralized system is diagonally paired, for any loop ul ( s ) = g cl ( s )[rl ( s ) − yl ( s )] Focusing on the loop u j ( s ) − yi ( s ) only set-point change at u j ( s ) then n yi ( s ) = gij ( s )u j ( s ) − ∑ gil ( s ) gcl ( s ) yl ( s ) l =1,l ≠ j y i ( s) = g ij ( s )u j ( s ) + aij ( s )u j ( s) yk ( s ) = d kj ( s )u j ( s ), Multivariable Control ∀k , k ≠ i Dr. Kalyana C. Veluvolu 4 y1,sp - + TITO Process GC1 u1 G11(s) G12(s) - GC2 u2 G22(s) y2 ++ + y2,sp Control Loop 2 c ( s) g12 ( s ) g 21 ( s ) a11 ( s ) = − 2 1 + c 2 ( s ) g 22 ( s ) d 21 ( s ) = y1 G21(s) c ( s) g12 ( s) g 21 ( s) y1 ( s) = g11 ( s) − 2 1 + c2 ( s) g 22 ( s) u1 ( s) y 2 ( s) g 21 ( s) = d 21 ( s) = 1 + c 2 ( s) g 22 ( s) u1 ( s ) ++ Control Loop 1 g 21 ( s ) 1 + c2 ( s ) g 22 ( s ) Similarly a22 ( s ) = − d12 ( s) = Multivariable Control c1 ( s ) g12 ( s ) g 21 ( s ) 1 + c1 ( s ) g11 ( s ) g12 ( s) 1 + c1 ( s) g11 ( s ) Dr. Kalyana C. Veluvolu 5 TITO Process Continued The closed-loop transfer functions y1 ( s ) g c1 ( s ) g11 ( s ) + g c1 ( s ) g c 2 ( s )[ g11 ( s ) g 22 ( s ) − g12 ( s ) g 21 ( s )] = r1 ( s ) gCL ( s ) y2 ( s ) g c 2 ( s ) g 22 ( s ) + g c1 ( s ) g c 2 ( s )[ g11 ( s ) g 22 ( s ) − g12 ( s ) g 21 ( s )] = r2 ( s ) gCL ( s ) y1 ( s ) g c 2 ( s ) g12 ( s ) = r2 ( s ) gCL ( s ) y2 ( s ) g c1 ( s ) g 21 ( s ) = r1 ( s ) gCL ( s ) with gCL ( s ) = det [ I + G ( s )GC ( s ) ] 0 g ( s ) g12 ( s ) g c1 ( s ) = det I + 11 g c1 ( s ) g 21 ( s ) g 22 ( s ) 0 = 1 + g c1 ( s ) g11 ( s ) + g c 2 ( s ) g 22 ( s ) + g c1 ( s ) g c 2 ( s )[ g11 ( s ) g 22 ( s ) − g12 ( s) g 21 ( s )] Multivariable Control Dr. Kalyana C. Veluvolu 6 Design by Detuning Factor Extend RGA with frequency dependant terms λ ( s) = – replacing steady-state gain with transfer function 1 G ( s )G21 ( s) 1 − 12 G11 ( s )G22 ( s) GCL ( s ) = 1 + Gc1 ( s )G11 ( s ) + Gc 2 ( s )G22 ( s ) + G ( s )G21 ( s ) +Gc1 ( s )Gc 2 ( s )G11 ( s )G22 ( s ) 1 − 12 G11 ( s )G22 ( s ) For analysis of loop 1divided by 1 + Gc 2 ( s)G22 ( s) results Gc1 ( s )Gc 2 ( s )G11 ( s )G22 ( s ) λ ( s) 1 + Gc 2 ( s )G22 ( s ) 1 + Gc 2 ( s )G22 ( s ) + Gc1 ( s )G11 ( s ) + GCL ( s ) = 1 + Gc 2 ( s )G22 ( s ) λ ( s ) = 1 + Gc1 ( s )G11 ( s ) 1 + Gc 2 ( s )G22 ( s ) Multivariable Control Dr. Kalyana C. Veluvolu 7 Loop 1 much faster than loop 2 At the loop 1 critical frequency Gc 2 ( jω )G22 ( jω ) → 0 as amplitude ratios decrease rapidly after comer frequency. λ11 is not a strong function of frequency 1 + Gc 2 ( jω )G22 ( jω ) λ11 = 1.0 1 + Gc 2 ( jω )G22 ( jω ) tuned like a single-loop controller without interaction. GCL ( jω ) ≈ 1 + Gc1 ( jω )G11 ( jω ) Multivariable Control Dr. Kalyana C. Veluvolu 8 Loop 1 Much Slower Than Loop 2 Gc 2 ( jω )G22 ( jω ) The fast loop, very large at loop 1 critical frequency big at a frequency much less than loop 2 critical frequency Gc 2 ( jω )G22 ( jω ) >> 1.0 The characteristic equation in loop 1 can be simplified to GCL ( jω ) ≈ 1 + Gc1 ( jω )G11 ( jω ) ≈ 1 + Gc1 ( jω ) Gc 2 ( jω )G22 ( jω ) λ11 ( jω )Gc 2 ( jω )G22 ( jω ) G11 ( jω ) G ( jω ) ≈ 1 + Gc1 ( jω ) 11 λ11 ( jω ) λ11 The gain of the process is changed. the controller gain has to be adjusted. The phase lag unaffected, the integral time same. It affect only the closed-loop process gain. Multivariable Control Dr. Kalyana C. Veluvolu 9 Same Dynamics for Loops 1 and 2 GCL ( s ) = 1 + Gc 2 ( s )G22 ( s ) + Gc1 ( s )G11 ( s ) + Gc1 ( s )Gc 2 ( s )G11 ( s )G22 ( s ) λ = 1 + 2Λ ( s ) + Λ 2 ( s ) λ11 System stability 1 + 2Λ ( s) + Λ 2 ( s) λ =0 To determine the closed-loop stability 1 + 2Λ( s) + Multivariable Control Λ 2 ( s) λ Λ ( s) Λ ( s) 1 = 1 + + 2 2 λ + λ − λ λ − λ − λ Dr. Kalyana C. Veluvolu 10 λ > 1.0 Case 1: 1 + 2Λ( s) + Λ( s) Λ( s) = 1 + 1+ 2 2 λ + λ − λ λ − λ − λ Λ 2 ( s) λ ωu1I = ωu1 Has real solution, ultimate frequency is unaffected by the interaction the ultimate gain can be calculated from ku1I g11 = λ − λ 2 − λ ωu 1 I k u1 I = ⇒ λ − λ2 − λ ωu 1 I g11 By the definition of gain margin k u1 = 1 ⇒ g11 ω ) ( ku1I = λ − λ 2 − λ ku1 u1 Multivariable Control Dr. Kalyana C. Veluvolu 11 Case 2: λ < 1.0 1 + 2Λ( s) + Λ 2 ( s) λ Λ ( s) Λ ( s) = 1 + 1+ 2 2 λ + λ − λ λ − λ − λ The factor with complex constant λ + λ 2 − λ the gain margin calculated from K u1I = determine the stability limit λ + λ2 − λ ωu 1 I g11 both phase and gain affected, for FOPDT process, can be approximated. ku1 I ( tan −1 1 − 1 λ = λ 1 − π Multivariable Control ) k ( u1 . 1.5 tan −1 1 − 1 λ ωu1I = 1 − π Dr. Kalyana C. Veluvolu ) ω u1 12 Case 2: Correction factor λ < 1.0 For 0.5 < λ < 1.0 ωu1I = ( 0.85λ + 0.1) ωu1 ku1I = ( 0.62λ + 0.3) ku1 Check Table 3.2.1 of the lecture notes for the summary of the detuning rules for all three cases Multivariable Control Dr. Kalyana C. Veluvolu 13 Example: WB Distillation Column 12.8e − s G ( s ) = 16.7 s−+7 s1 6.6e 10.9 s + 1 − 18.9e −3 s 21.0 s + 1 − 19.4e −3 s 14.4 s + 1 2.0 − 1.0 Λ= − 1.0 2.0 other loop open Multivariable Control NI > 0 other loop closed Dr. Kalyana C. Veluvolu 14 Example: Continued dynamic of the two loops are almost the same λ>1=2 controller gains detuned by (λ − ) λ 2 − λ = (2 − 2) ≈ 0.59 Multivariable Control Dr. Kalyana C. Veluvolu 15 BLM Method Review Nyquist (Bode or Nichols) plot g (iω ) g c (iω ) made as ω from zero to infinity Number of encirclements of (-1, 0) equal to number of closed-loop characteristic equations roots lie in the right half of the s plane if the open-loop system is stable. If (-1, 0) is encircled, closed-loop system is unstable. closed-loop log modulus (Lcmax) Lc = 20 log gg c 1 + gg c measure distance g (iω ) g c (iω ) from the (-1, 0) point Farther away from (-1, 0), more stable A commonly used specification is +2 dB for Lcmax Multivariable Control Dr. Kalyana C. Veluvolu 16 BLM Method for MIMO Processes Design procedure 1. Calculate the Ziegler-Nichols setting for each individual loop. The ultimate gain Ku and ultimate frequency ωu of each diagonal transfer function gii ( s ) calculated in SISO way. g ci ( s ) = K ci (1 + 1 τ Ii s K ZNi = ) K ui 2.2 τ ZN = i 2π 1.2ωui 2. Specify factor F, vary from 2 to 5, all feedback controllers gains (Kc) and integral constant τ I calculated by correcting as K ci = Multivariable Control K ZNi τ Ii = Fτ ZN F i Dr. Kalyana C. Veluvolu 17 BLM Method for MIMO Processes 3. Define a scalar function W ( s ) = −1 + det( I + G ( s )Gc ( s )) Multivariable closed-loop log modulus Lcm Lcm = 20 log W 1+ W 4. For MIMO processes, the best tuning criterion ( Lcm ) max = 2n Multivariable Control Dr. Kalyana C. Veluvolu 18 Example: WB Distillation Column 12.8e − s G (s ) = 16.7 s−+7 s1 6.6e 10.9s + 1 − 18.9e −3 s 21.0s + 1 −3 s − 19.4e 14.4s + 1 τ i ,ii Controller Kc,ii Loop 1 0.375 8.29 Loop 2 -0.075 23.6 Multivariable Control ( Lcm ) max = 4 Dr. Kalyana C. Veluvolu 19 Structure Decomposition The transfer function seen by controllers g1 ( s ) = g11 ( s ) − g12 ( s ) g21 ( s ) gc 2 ( s ) 1 + g22 ( s ) gc 2 ( s ) g2 ( s ) = g22 ( s ) − g12 ( s ) g21 ( s ) gc1 ( s ) 1 + g11 ( s ) gc1 ( s ) The system can be separated into two SISO systems The tuning of one controller depends on the other controller. A set-point change on one loop seen as a disturbance by the other. Multivariable Control Dr. Kalyana C. Veluvolu 20 Approximation One g1 ( s ) = g11 ( s ) − g12 ( s ) g21 ( s ) g c 2 ( s ) 1 + g22 ( s ) gc 2 ( s ) g2 ( s ) = g22 ( s ) − g12 ( s ) g 21 ( s ) g c1 ( s ) 1 + g11 ( s ) g c1 ( s ) The diagonal transfer functions contain no unstable zero Both delay shorter than L12 (s) + L21 (s) frequencies lower than the cross-over frequency g1 ( s ) = g11 ( s ) − g12 ( s ) g 21 ( s ) g 22 ( s ) for g 22 ( s ) gc 2 ( s ) > 1 g 2 ( s ) = g 22 ( s ) − g12 ( s ) g 21 ( s ) g11 ( s ) for g11 ( s ) gc1 ( s ) > 1 ω co Argument 2: controllers designed so two loops have perfect control with infinite bandwidth or infinite control gains g c1 ( s ) g11 ( s ) = 1; 1 + g c1 ( s ) g11 ( s ) Multivariable Control g c 2 ( s ) g 22 ( s ) =1 1 + g c 2 ( s ) g 22 ( s ) Dr. Kalyana C. Veluvolu 21 Approximation Two •The transfer functions contain an unstable zero •or a delay longer than L12 ( s) + L21 ( s ) the following approximation can be used Multivariable Control g1 ( s ) = g11 ( s ) − g12 ( s ) g 21 ( s ) K 22 g 2 ( s ) = g 22 ( s ) − g12 ( s ) g21 ( s ) K11 Dr. Kalyana C. Veluvolu 22 Gain and phase margin design G(s) = Gc ( s ) = b0 e − Ls a2 s + a1s + 1 gc ( s) = K p + 2 K d s 2 + K p s + Ki Ki + Kd s s b As 2 + Bs + C =k ⇒ Gc ( s )G ( s ) = k 0 e − sL s s s Phase cross Over frequency Am Gc ( jωg )G ( jωg ) = 1 arg Gc ( jω g )G ( jω g ) = −π Gain cross Over frequency Φ m = π + arg Gc ( jω p )G ( jω p ) Gc ( jω p )G ( jω p ) = 1 Multivariable Control Dr. Kalyana C. Veluvolu 23 Gain and phase margin design Gc ( s )G ( s ) = k k= arg Gc ( jωg ) G ( jωg ) = −π Am × Gc ( jωg ) G ( jωg ) = 1 G ( jω ) G ( jω ) = 1 p p c Φ m = π + arg Gc ( jω p ) G ( jω p ) b0 − sL e s π 2 Am Lb0 Φm = PID parameters Multivariable Control π 2 (1 − 1 ) Am ⇒ ωg L = ⇒ Am = 2 ωg k ⇒ k = ωp ⇒ Φm = K p K = π i 2 A Lb 0 m K d Dr. Kalyana C. Veluvolu π π 2 − ωp L a1 1 a2 24 Example: WB Distillation Column 12.8e − s 1.Find the equivalent transfer function G ( s ) = 16.7 s−+7 s1 6.6e 10.9 s + 1 g12 ( s ) g 21 ( s ) 12.8e − s 6.43(14.4 s + 1)e −7 s g1 ( s ) = g11 ( s ) − = − g 22 ( s ) 16.7 s + 1 (21.0s + 1)(10.9 s + 1) − 18.9e −3s 21.0s + 1 − 19.4e −3s 14.4 s + 1 g12 ( s ) g 21 ( s ) −19.4e −3s 9.75(16.7 s + 1)e −9 s g2 ( s ) = g 22 ( s ) − = + g11 ( s ) 14.4 s + 1 (21.0s + 1)(10.9 s + 1) not FOPTD transfer functions, a model reduction is required. After model reduction, Controller be designed Gain and phase margin method: gain margin 3, phase margin π 3 Gc1 ( s) = 0.4660 + 0.1208 s Multivariable Control Gc2 ( s) = −0.2122 − 0.0343 s Dr. Kalyana C. Veluvolu 25 Dr. Kalyana C. Veluvolu 26 Simulation Detuning method (dotted line) better performance on load disturbance rejection. Independent design method (solid line) better set-point tracking Multivariable Control