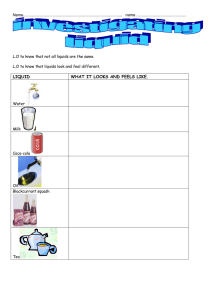

flammable and combustible liquids

advertisement