EXPERIMENTAL INVESTIGATION OF FILM COOLING

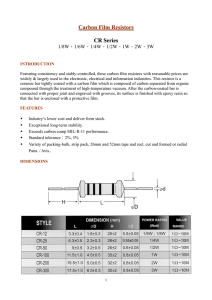

advertisement