LAWA Commissioning Forms

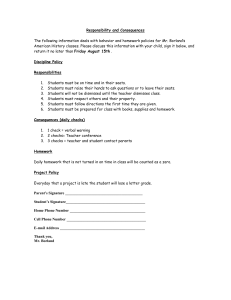

advertisement