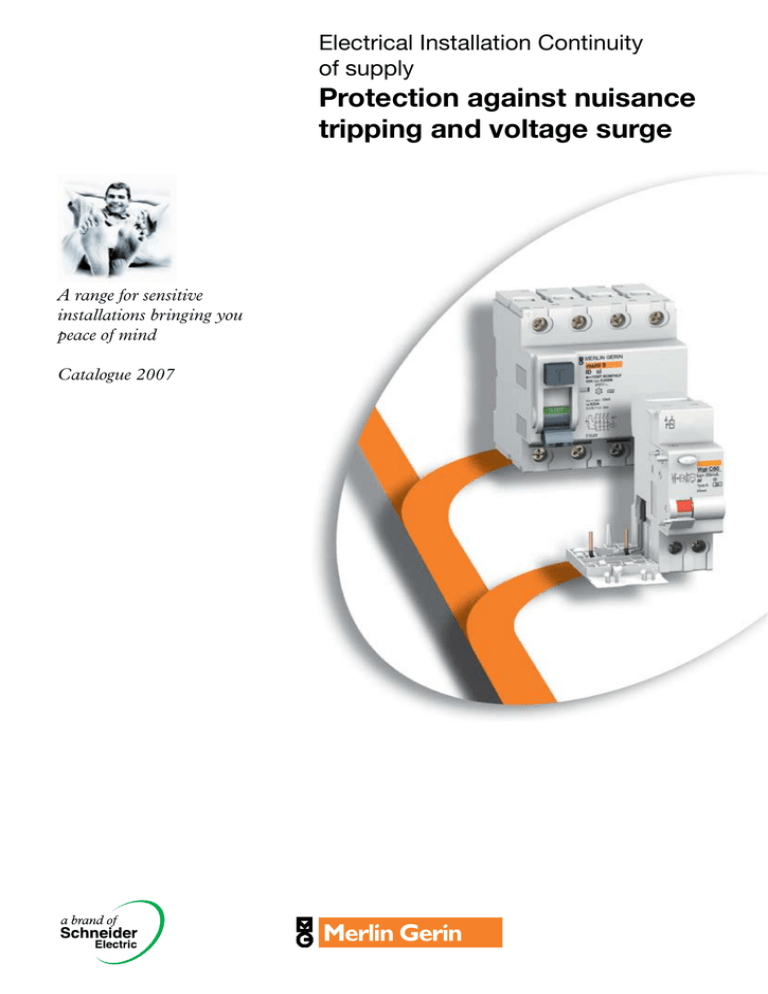

Electrical Installation Continuity

of supply

Protection against nuisance

tripping and voltage surge

A range for sensitive

installations bringing you

peace of mind

Catalogue 2007

november 2006

1

Content

1. Nuisance tripping and continuity of supply

2. Disturbances in distribution systems

2

PAGE

5

6-11

3. The different technologies

3.1. Standard RCD and RCCB

3.2. Super Immune RCD and RCCB, Si and SiE

3.3. Type B RCD

3.4. Automatic Recloser

3.5. Advanced earth leakage protection: Vigirex

12-18

12

13

14

15

16-18

4. The Applications

4.1. Lighting and priority loads

4.2. People safety in low temperature conditions

4.3. Computer and nuisance tripping

4.4. Lighting and nuisance tripping

4.5. Variale speed controllers and nuisance tripping

4.6. Continuity of supply in hazardous environment

4.7. Remote sites and transient faults

4.8. Advanced earth leakage protection

19-23

19

19

20

21

22

23

23

23

5. Which protection to use?

24-25

6. Catalogue numbers

6.1. Si and SiE ranges

6.2. Type B range

6.3. RED range

6.4. REDs range

6.5. REDtest range

6.6. Vigirex range

26-57

26-29

30-32

33-37

38-41

42-46

48-57

7. Voltage surges

58-62

8. Lightning risk

63-66

9. Overvoltage protection devices

67-73

10. Surge protection selection guide

74-75

11. Chosing surge arresters for LV networks

76-89

12. Catalogue numbers surge arresters

12.1. Fixed type 2 LV surge arresters

12.2. Withdrawable type 2 LV surge arresters

12.3. Type 1 surge arresters

12.4. Telecommunication and computer

equipments surge arresters

12.5. Connection kit for surge arresters

12.6. Dimensions surge arresters

Index

90-104

90-93

94-97

98-101

3

4

5

6

7

8

9

10

11

102

103-104

105-107

108

12

1

1

1. Nuisance tripping and

continuity of supply

Disturbances on low voltage electrical networks

and earth leakage protection

Low voltage electrical networks are increasingly subject to disturbances which

deform the distributed sine wave.

These disturbances can be:

b External, coming from the medium or low voltage upstream network.

b Internal, on the low voltage network.

These disturbances interfere with the operation of devices connected to the

network, especially electronic devices, but also standard residual current devices

(RCD).

Residual current devices are an efficient means for ensuring people’s protection

against low voltage electrical risks resulting from direct or indirect contact.

The disturbances can have two effects on the residual current devices:

b Nuisance tripping, when people’s safety is not threatened:

deterioration in continuity of supply

Blinding, that is residual current devices failing to trip when there is a danger to

b people’s safety downstream:

people’s safety is no longer guaranteed

In the face of these relatively new risks, users are increasingly demanding.

As blinding is obviously critical, since it affects people’s lives, nuisance tripping

can have major consequences.

Example: stoppage of industrial processes, motors, cold rooms, etc.

Data center

Hospital

Industrial plant

2. Disturbances in distribution

systems

2

Residual current devices detect earth leakage

currents.

Earth leakage currents can be caused by different types of disturbances which

make the residual current devices sensitive:

-25

b External disturbances, essentially surges and harmonics, such as:

v lightning surges, the amplitude of which is among the greatest.

v switching surges, linked to the opening and closing of capacitive circuits

(capacitor banks) or inductive circuits (motors) located on other installations.

v power frequency surges, such as:

- phase-to-phase insulation faults,

- cable breaks,

- flashover of an MV spark-gap,

v harmonic voltages produced by the devices connected to the MV network,

such as:

- arc furnaces,

- saturated reactors, etc..

b Another external disturbance:

v very low temperature (-25°C) causing the desensitisation of the residual

current devices.

b Internal disturbances, on the LV network are the cause of earth leakage currents:

v switching surges, such as: short-circuit current breaking and the opening and

closing of RLC circuits cause transient surges.

constant load leakage currents, both at power frequency and high frequency,

v in the presence of high frequency generators.

harmonic currents and voltages generated by an increasing number of loads.

v Example of loads and environments causing disturbances:

b Some loads generate:

v 50 Hz constant leakage currents: standard fluorescent lighting or with electronic ballast, household appliances, convectors, Hi-fis, videos, computers, etc.

high frequency transient leakage currents: fluorescent lighting with electronic

v ballast, luminous signs, computers, etc.,

v leakage currents with pulsed DC type component:

variable speed, lighting and power controllers, power electronics, etc

b Lightening and the operation of upstream power devices generate transient

surges.

Loads generating high frequency currents (higher than several kHz) do not in

themselves present any electrocution risk for people. However, they can cause

the blinding of the residual current device and prevent it from working when there

are other faults, which can then call people’s safety into question.

These disturbances cause risks:

b Of nuisance tripping deteriorating continuity of supply.

b Of non-tripping which means that people’s safety can no longer be guaranteed.

Disturbances

Nuisance tripping

50 Hz constant

leakage currents

n

HF transient leakage currents

n

Leakage currents with

pulsed DC component

n

Lightening surges

n

Switching surges

n

Very low temperatures

Blinding

(non tripping)

n

n

n

Disturbances in distribution

systems

Earth-leakage current

Cable leakage capacitance

The stray capacitance of the cables is the cause of a continuous leakage current,

called the “natural leakage current”, because a part of the current in the capacitors

does not return to the source in the live conductors.

Continuous leakage current due to stray capacitances of conductors (dotted lines).

This leakage current “spreads” throughout the entire installation.

The general level of the capacitance between a cable and earth is 150 pF/m.

For three-phase equipment, any dissymmetry between the phases reinforces these

phenomena.

Load leakage capacitance

Non-linear loads, primarily those with static rectifiers, draw low-frequency and highfrequency harmonics. To limit the electromagnetic disturbances and comply with

the EM requirements contained in the IEC 61000 standards, these loads are

equipped with RFI filters that are directly earthed.

These filters increase the continuous earth-leakage current.

This leakage current is called the “intentional leakage current”.

Note: this phenomenon is amplified by the presence of low-frequency harmonic voltages which

increase the flow of common-mode currents.

Capacitances between live conductors and earth.

The capacitors installed at the input of electronic equipment have a capacitance of

approximately 10 to 100 nF.

Note: in the IT system, additional precautions must be taken when installing RFI filters.

Leakage capacitance / approximate values

Component

Differential-mode

capacitance

Common-mode

capacitance

Standard cable (not shielded)20 pF/m

150 pF/m

Shielded cable

Shielded cable

30 pF/m

30 pF/m

200 pF/m

200 pF/m

Frequency converter

x 100 µF

(with rectifier)

10 to 100 nF

PC, printer, cash register

x 10 µF

(with rectifier)

10 nF

Fluorescent lighting

1 µF /10 W

1 nF

(compensation capacitor)(electronic ballast)

2

The environment and the loads of a low-voltage electrical distribution system

generate three major types of disturbances that impact on the earth-leakage

currents in the system.

n Overvoltages

Lightning, switching overvoltages

Residual current following operation of a switch.

Example of a common-mode disturbance.

Overvoltages / approximate values

Type

Amplitude (xUn)

Duration

or kV

Frequency

or rise time

Insulation fault

y 1.7

30 - 1000 ms

50 Hz

Switching

2 - 4

1 - 100 ms

1 - 200 kHz

Lightning

2 to 8 kV (1)

1 - 100 µs

1 µs

Electrostatic

8 kV

1 - 10 µs

25 µs

(1) Depending on the position in the installation.

Harmonic spectrum of the current.

These overvoltages, via the natural leakage capacitance of the system, cause more

or less high transient leakage currents.

n Harmonic currents

These low and high-frequency currents may reach high values (see the harmonic

spectrum in the diagram opposite). These harmonic currents must be taken into

account when calculating the natural and/or intentional earth-leakage current and

setting a threshold for RCDs that does not provoke malfunctions.

n Waveform of the fault currents

In addition to the earth-leakage current problems, fault currents with a DC

component may arise if an insulation fault occurs. The RCD must not be “disturbed”

or “blinded” by this type of fault.

Consequences for use of RCDs

These phenomena create considerable earth-leakage currents (transient or continuous).

The RCD must not react to these leakage currents when they are not dangerous.

It is necessary to adjust the protection setting for people for indirect contacts,

taking into account the prospective leakage current.

Disturbances in distribution

systems

RCD-device settings in installations with high

leakage current.

TT system

n maximum current setting I∆n1

It is first necessary to check the earthing resistance (RT) of the exposed conductive

parts of the connected loads. The maximum setting value for RCD I∆n1 is provided

by UL/RT (where UL is equal to 50 V for standard environments and 25 V for humid

environments).

n minimum current setting I∆n2

It is then necessary to determine for the various parts of the installation protected

by a given RCD the natural leakage current (low because the leakage capacitances

are balanced) and the intentional leakage current (caused by the load filters). The

table below provides typical values for the leakage currents of loads causing

particularly high levels of disturbances.

If II is the value in question, the minimum setting I∆n2 of the RCDs is 2 II.

Note: with the specific factory setting and the operating tolerances under worst-case conditions

(temperature, auxiliary-source voltage, etc.), Vigirex can be used with a guaranteed nonoperating threshold of 0.8 I∆n . The minimum setting for a Vigirex devices can be as low as II

/0.8, i.e. 1.25 x II .

n table for leakage currents

Electrical equipment

Measured leakage current (mA)

Fax machine

Printer

Workstation

(UC, screen and printer)

Photocopy

machine

Floor heating

Single-phase and three-phase filters

0.5 to 1

<1

1 to 3

0.5 to 1.5

1 mA / kW

1 mA / load

Electrical equipment

Measured leakage current (mA)

Class II

Class I

Class I

Class I

0.25

0.75

3.5

3.5 or 5 % In

All equipment

Portable

A-type fixed or mobile

B-type fixed

n I∆n2 << I∆n1 (slightly disturbed system)

There are no problems with malfunctions if the discrimination rules are observed.

n I∆n2 ≈ I∆n1 to avoid nuisance tripping. There are three possible solutions:

segment the installation to reduce the leakage currents in each part

v v install an isolating transformer for sets of loads causing particularly high levels

of disturbances

set up the TN-S system for all or a part of the installation. This is possible if the

v disturbing loads can be identified and located (the case for computer

equipment).

10

2

IT system

The major characteristic of the IT system is its capacity to continue operation after a

first insulation fault. However, this insulation fault, though not dangerous, causes a

leakage current in the natural capacitances (high because unbalanced) and

intentional capacitances. This current may reach or exceed 1 A. If RCDs are

required, they must imperatively be set to a value double that of the leakage current

(see § 531.2.5 of standard IEC 60364-553).

n table for leakage currents depending on system capacitance

System leakage capacitance (mF)

1st fault current (A)

1

5

30

0.07

0.36

2.17

Table drawn from figure 5 in the Cahier Technique document 178.

Note: 1 ∆F is the typical leakage capacitance of 1 km of four-core cable.

For a load causing high leakage currents, the installation segmenting technique

mentioned above is often used.

Distribution system in a factory with a TNS segment for the management IT system.

IMD: insulation-monitoring device.

11

3. The different technologies

Ph

relay

N

Operation

NC contact

toroid

3.1. Standard residual current devices

actuator

n Principle:

v measurement of the sum of currents flowing through the conductors in a

circuit,

v opening the contacts on the residual current device if this vector sum goes

over a pre-determined value: sensitivity I∆n = 30 mA, 100 mA, 300 mA, etc.

Technical data

The majority of the residual current devices in the multi9 range have their own current technology, with the power of the fault causing the tripping.

This is a safer solution which does not depend on an external source likely to fail.

Principle of the standard range

The hysteresis curve

It represents the energy

which can be generated

within the magnetic

materials by the residual

current. Each material

has its own hysteresis

curve. Each type of RCD

has its own curve.

I

leak

AC

B

t

DC

∆Φ 2

Mono half wave

∆Φ 1

Standard RCD toroid curve

12

n Standard RCD toroids

These only detect classic alternating earth leakage currents. They are insensitive

to rectified (pulsed) currents with or without DC component. These currents are

as dangerous as alternating currents because they generate the same contact

voltage.

According to the Faraday law, any ∆Φ2 variations in the flux generated by the

magnetic field causes an induced voltage:

The curve in figure 1 shows a leakage of alternating current (AC) generating a ∆Φ1

variation which creates a residual current high enough to activate the relay.

A leakage of rectified DC current does not have a negative component. The toroid’s hysteresis cycle is incomplete and ∆Φ2 too weak to generate a voltage high

enough to activate the relay.

dφ

E = -N

dt

FIGURE 1

H

RCDs are made up of three main parts:

n v The toroid, in ferromagnetic material, detects and senses the power and

determines the fault current. Its primary winding is made up of one or several

phases and the neutrol phase to be protected. It works as follows:

In normal mode, the vector sum of the currents in this circuit is zero. If there is

a fault, it ceases being zero, a current is induced into the secondary coil and

acts on the tripping relay if it is higher than the sensitivity threshold.

v An eventual interface which deals with the recovered image of the fault

current.

v An electromechanical relay which allows the tripping and therefore the

­opening of the contacts.

n Protection against surges leading to overcurrents in common mode

All of Merlin Gerin’s standard residual current devices are protected against surges

in accordance with the UNE-EN 61008 and UNE-EN 61009 standards, which

request the following tests:

v 0.5µ/100kHz type standardised dampened overcurrent wave corresponding

to the type of current which is leaking through the installation capacitors in the

case of surges due to the connection of capacitive circuits.

v test of 8/20µs type standardised impulse current following surges caused by

a 1.2/50µs type lightening stroke. In concrete terms, instantaneous standard

devices withstand tests involving current peaks from 250 A 8/20µs type to

3,000 A (selective).

The different technologies

Ph

relay

N

3.2. Super immune type residual current devices

Operation

NC contact

toroid

interface

n Principle:

The technology of the "Si" and "SiE" range, based on the same operating principle as the technology of the standard range, is specially designed to withstand increasingly frequent disturbances.

Technical data

n "

Si" and "SiE" type RCD toroids

Principe of the "Si" and

These solve the problem of non-activation of the relay in the case of a leakage of

pulsated DC current. Figure 2 shows an operating diagram for a magnetic toroid

core with a flat, longer hysteresis curve, which increases the following ratio:

∆Φ2

∆Φ1

FIGURE 2

In this case, the residual current generated is high enough to activate the relay.

This is one of the features of the "Si" and "SiE" type residual current devices.

Variations close to the alternating or pulsed residual current are high enough to

generate the same amount of power.

∆Φ 2

H

∆Φ 2

n Electronic filtering

t

B

∆Φ 1

∆Φ 1 : under single-alternating current

∆Φ 2 : under alternating fault current

"Si" and "SiE" type RCD toroid

curve

Clean room, electronics, etc.

The technology of the "Si"

and "SiE" range presents

significant advantages

in terms of withstanding

disturbances thanks to its main

developments on toroids and

electronic filtering.

It therefore reaches higher

performance levels than those

defined in standards.

Major upgrading of the electronic filtering system for the treatment of the electrical

signal in the range of Merlin Gerin "Si" and "SiE" type residual current devices has

improved performance compared with standard products in the following areas:

v Influence of surges

The new instantaneous residual current devices in the "Si" and "SiE" range

can withstand levels much higher than those defined in the IEC 61008 and

IEC 61009 standards and can withstand the majority of transient overcurrents

caused by lightening discharges without tripping. This circuit means that the

most common types of nuisance tripping, caused by operations on the network

which, like the preceeding operations, are transmitted by the line capacitors

and load filters, can be avoided.

v Influence of high frequencies

These are generated and sent to earth by the filters on some loads, such as

fluorescent lighting electronic reactors, motor variable speed controllers, electronic dimmers, etc.

Two problems may arise with standard residual current devices, depending on

the number of loads installed:

- nuisance tripping,

- non-tripping through blinding.

The high frequency filters in the new "Si" and "SiE" range mean that nuisance

tripping can be avoided. The EMC design of the interface means that blinding

in the presence of high frequencies can be avoided.

v Tripping relays

The tripping relay on the residual current device continuously receives an

­electrical signal from the toroidal transformer which presents a continuous risk

of nuisance tripping or blocking.

In the "Si" and "SiE" range, the signal will not reach the relay unless all of the

filters "authorise" the tripping. The final tripping action is managed by the

­verification and tripping circuit.

v The stability of the trip threshold in relation to low temperatures is guaranteed by the choice of the toroid’s magnetic material as well as an appropriate

electronics/relay configuration.

13

3

The different technologies

v "SiE" type RCD range

The live parts of the relay are insensitive to corrosion thanks to a dual protective barrier:

- a patented anti-corrosion coating (amorphous carbon) on the live parts of

the relay ensures reliable products irrespective of the polluting or corrosive

substances present in the environment,

- a seal for tightness protects the relay from aggressive environments.

After tests conducted as per standard IEC 68-2-60 (gas mixtures - industrial

environment), chloramine tests (swimming pool environment) and damp heat

tests (greenhouse environment), the SiE RCDs have a withstand that is 100

times greater than conventional solutions.

3.3. Type B RCD technology:

n Fault with a DC component: B type earth leakage protection

Conventional protection devices are suitable for measuring AC fault currents.

However, fault currents with a DC component may arise if an insulation fault

occurs with three-phase rectified current . The RCD must not be "disturbed" or

"blinded" by this type of fault.

The main difficulty is to measure the fault current with a DC component, as this

can saturate the magnetic circuit and reduce the sensitivity of measurements. In

this case, there is the risk that a dangerous fault current might not be detected. To

avoid this problem and ensure that the toroid provides an accurate output signal, it

is necessary to use a magnetic material that does not have a horizontal saturation

curve, with low residual induction. With such a technology, RCD device will not be

blinded by this DC component : this is the B type earth leakege protection.

Leakage current between 1 phase and earth

These devices are suitable for all types of current and are required, in particular,

for rectified three-phase currents.

Those currents can be created by :

– regulators and variable speed drives

– UPS and battery chargers

And the main applications for B type RCDs will then be :

– mobile installations (cranes)

– chargers, UPS, machine tool, equipments laboratory

– elevators, escalators

– buildings for medical care (ex: x-ray equipment)

3-phase

14

Leakage current between 1 phase and earth - linked to a D

C leakage current, this explaining why it is not crossing the

zeroline

3.4. Recloser Automatic Device: the RED technology

Increasingly more installations are isolated and do not have any supervisory personnel (telecom relay, cold room, second home). Should a protection device trip,

downtime is lengthy and maintenance costs high.

A large number of trippings are due to transient faults. The RED provides a solution

to quickly put the installation back into operation, in optimum safety conditions

Transient faults are often due to environmental conditions that damage insulation

on a temporary basis (humidity, arcing due to dust, nuisance animals, etc.)

At the time of the fault there is a real danger. Tripping is thus normal (when the

fault has disappeared, the danger also disappears).

However, tripping of the earth leakage protection device and the power supply breaking that follows appearance of this fault may be a problem if it is not

detected quickly enough or in the absence of human presence. Automatic resetting allows reclosing of the earth leakage protection device and restoration of the

power supply without operator action.

Prior to any attempt to put back into operation, the RED tests insulation. Safety

conditions are thus optimum.

If the fault has disappeared, the installation can be put back into operation.

If the fault persists, the circuit remains open and an alarm indicates this fact.

Automatic reset operating principle

Check

No fault

4. Resumption of

operation

1. Tripping on an

insulation fault

2. Insulation

monitoring

3. Resetting

OFF + indication

After 3

unsuccessful

attempts

OFF + indication

1. Tripping of the earth leakage protection further to a fault.

2. Checking leakage current absence (setting to faulty status if permanent fault).

Most rival offers do not perform such preliminary insulation monitoring.

The RED calculates downstream circuit insulation resistance. This value must

be greater than the critical threshold:

• RED 30 mA : 120 kOhm

• REDtest 30 mA: 120 kOhm

• REDs 30 mA: 10 kOhm

• REDs 300 mA: 2 kOhm

3. Automatic resetting if the fault has disappeared.

RED set to faulty status and alarm after 3 unsuccessful resetting attempts. The

circuit then remains open.

4. Installation put back into operation without human intervention.

15

3

The different technologies

3.5. Advanced earth leakage protection:

the Vigirex technology

Vigirex residual-current devices (RCDs) with appropriate settings provide effective

protection of life and property. The characteristics of the relay / toroid combination

ensure reliable measurements.

Schneider Electric guarantees the safe clearing of faults by Vigirex relays set to 30

mA and combined with any of its circuit breakers rated up to 630 A. The reinforced

insulation of Vigirex relays (overvoltage category IV, the most severe) makes direct

connection possible at the head of the installation or on the upstream busbars

without any additional galvanic isolation.

Vigirex has a self-testing capabilities. Failure of the detection circuit is signalled

and may be used to trip the circuit breaker. The LEDs in front can also be used to

check operation at any time.

Vigirex also come with advance feature that can greatly improve electrical continuity

of service:

Reduced tripping tolerances

Vigirex relays trip between 0.8 and 1 x I∆n, thus increasing immunity to nuisance

tripping by 60 % compared to the residualcurrent protection requirements of

standard IEC 60947-2 annex M.

The standards indicate the preferred values for the residual operating current

settings.

Operating current I∆n in A:

0.006 – 0.01 – 0.03 – 0.1 – 0.3 – 0.5 – 1 – 3 – 10 – 30.

To take into account the tolerances (temperature, dispersion of components, etc.),

the standards indicate that an RCD device set to an I∆n value must:

v not operate for all fault currents y I∆n/2

v operate for all fault currents u I∆n.

The technologies employed for Vigirex devices guarantee dependable nonoperation up to 0.8 I∆n.

Standard IEC 60947-2 annex M allows manufacturers to indicate the level of nonoperation if it differs from the general rule.

16

Filtering of harmonic frequencies

Frequency converters, such as variable speed drives, generate high levels of high

frequency leakage currents. During normal operation, these leakage currents are

not a danger to users. Frequency filtering by Vigirex residual current relays ensures

maximum protection against insulation faults and a particularly high level of continuity of service.

non-dangerous leakage currents

n v frequency converters cause the most specific leakage currents to analyse.

The voltage waveform generated by the frequency converter and in particular

the voltage fronts caused by IGBT switching result in the flow of high-frequency

leakage currents in the supply cables.

Flow of leakage currents in a frequency converter.

These currents may reach levels of several tens or hundreds of milliamperes (rms

value).

n dangerous faults

Standard IEC 60479 indicates the sensitivity of the human body depending on the

frequency. Consequently, the table in question shows that:

p

v rotection for people at the power frequencies 50/60 Hz is the most critical

case

v the use of filters corresponding to the “desensitisation curve” ensures perfect

safety.

The figure below shows the result of the filters on Vigirex in reducing the effects of

the harmonic currents and malfunctions due to transient currents.

Frequency factor for the fibrillation threshold (IEC 60749-2).

Limiting values of the natural leakage currents downstream of a rectifier.

17

3

Rms measurements

Vigirex devices carry out rms measurements on the zero-sequence currents.

This is the means to: n accurately measure the harmonic currents and avoid nuisance tripping due to

non-dangerous currents with high crest factors

n correctly calibrate the energies of the fault currents because, for both fire

hazards and the protection of property, it is the energy of the fault current that

must be taken into account.

Inverse-time tripping curve

During circuit energisation, the inverse-time tripping curve makes it possible to

avoid nuisance tripping of the residual-current protection system by false zero

phase sequence currents caused by:

n high transient currents of certain loads (e.g. motors, LV/LV transformers, etc.)

the charging of capacitances between active conductors and earth.

n Protection for people requires the use of non-delay type relays. These relays must

comply with standards to ensure safety.

Standards IEC 60947-2 annex M and IEC 60755 indicate the preferred values for

the operating-current setting.

They stipulate the maximum break time depending on the residual fault current.

See table B in B.4.2.4.1 in standard IEC 60947-2 annex M.

If =

Time Tps

I∆n

0.3 s

2 I∆n

0.15 s

5 I ∆n

0.04 s

10 I∆n

0.04 s

Key:

Standardised RCD response curve as per the table.

Time Tps: total time required to break the current (including the time for the associated

protection device to open)

If: leakage current

I∆n: residual operating current setting

Leakage-current curve for switching in of a load with

leakage capacitance.

For devices set to 30 mA, 5 I∆n can be replaced by 0.25 A, in which case 10 I∆n is

replaced by 0.5 A.

Vigirex uses this type of response curve to manage the false fault currents caused

by switching in of loads (transformers, motors).

Schneider guarantees all the above break times for a Vigirex combined with its

circuit breakers rated up to y 630 A, particularly when set to 30 mA.

Guaranteed non-operation up to 0.8 I∆n

This function equipping Vigirex relays significantly increases (from 0.5 I∆n to 0.8 I∆n)

the immunity of relays to continuous leakage currents, both natural and intentional.

18

4. The applications

4.1. Lightning and priority loads

Comfortable operation and peace of mind

Circuit breaker with

selective 300/500

mA RCD

ID 30 mA

Protect

your priority loads

(freezer, PC, etc.)

from tripping linked to

lightening.

ID 30 mA

4

ID 300 mA

Surge arrester

Circuit

breakers

Essential circuits

(Freezer, PC, etc.)

Circuit

breakers

Specialised circuits

(washing machine,

dishwasher, etc.)

Circuit

breakers

Other circuits

n Extreme atmospheric conditions

When lightening falls close to a block of flats or building, the network is subjected to

a voltage wave which generates transient leakage currents through cables or filters.

These leakage currents can cause nuisance tripping, depending on the intensity, the

closeness of impact and the characteristics of the electrical installation.

n Solutions:

To ensure continuity of supply on essential circuits, while at the same time

ensuring safety in the case of atmospheric disturbances, the following must be

combined:

v a surge arrester, which protects sensitive loads against lightening surges,

v a circuit breaker with upstream selective s 300/500 mA RCD, to ensure

complete differential discrimination,

v a downstream 30 mA Si type residual current device, which is insensitive to

this type of leakage.

4.2. Ensuring people’s safety in low-temperature

conditions

Si range has been designed to ensure people’s safety by preventing the residual

current device from blocking at low temperatures.

n Extreme atmospheric conditions

Examples: outdoor domestic enclosures and winter caravan camping, etc..

n Solutions:

The residual current devices in the range work in temperature of up to -25°C.

This range therefore means more comfort and safety for users.

19

4.3. Computing and nuisance tripping

Economical installation and operating peace of mind

Standard

Recommended

Circuit breaker with

selective s 300/500

mA RCD

Circuit

ID

30 mA

"Si"

type 30

mA ID

Circuit

breakers

Circuit

breakers

2 computer stations max.

Increasing the number

of computer loads per

circuit and avoiding

information losses

linked to power cuts.

Up to 5 workstations

Installations including computers, printers or office workstations

n Phenomenon:

In order to be in line with European directives on electromagnetic compatibility,

several manufacturers have included interference filters in their computers. These

filters generate constant leakage currents of 50Hz, of the order of 0.5 to 1.5 mA

per device, depending on the type and brand. When there are several loads of this

type on the same phase, the leakage currents add up vectorially.

In the case of 3 phase loads, 2 phase leakages can be cancelled out depending

on their balance and the leakages caused on each phase.

Consequences: nuisance tripping

n When the sum of the constant leakages reaches approximately 30% of the residual current device’s rated sensibitivity threshold, any small surge or current peak

(caused for example by the switching on of one or several computers on the same

or another circuit) can cause nuisance tripping.

n Solutions: v dividing up the circuits

Dividing up the circuits prevents a surplus of loads depending on the same

conventional, single-phase residual current device. The figure of a maximum

of 6 loads is achieved by starting from the following consideration: in the worst

case, a leakage of 1.5 mA for each load, the total leakage is of 9 mA or 30% of the

sensitivity threshold for the 30 mA residual current device.

v using si residual current devices

Thanks to its behaviour faced with transient currents, the "Si" range is specially

recommended for installations with computer equipment.

It means that a greater number of machines can be installed (a maximum of

around 12 machines) with the same residual current device, without any nuisance

20

In concrete terms:

Thanks to "Si" type

residual current devices,

you can increase the

number of computer

stations connected from

2 to 5.

The applications

4.4. Lighting and nuisance tripping

Fluorescent lighting with electronic ballasts

Standard

Circuit breaker with

selective 300/500

mA RCD

ID 30 mA

Recommended

Circuit breaker with

selective 300/500

mA RCD

4

ID "Si" 30 mA

Circuit

breakers

Increase the number of

lighting loads per circuit

and prevent effects linked to

lighting power cuts

(panic, inconvenience, etc.)

20 ballasts max.

up to 50 ballasts

n Phenomenon:

Electronic ballasts can be at the root of two types of problem:

high frequencies:

v Generating high-frequency currents injected into the network or escaping to

earth can cause the blinding of the relay which in turn can bring about:

– a risk for people if there is a 50Hz fault at the same time.

– nuisance tripping without any risks to people (no more continuity of supply).

switching peaks when switching on or off.

v If these high-frequency currents are weak (and do not block the residual current

device), they will cause the tripping relay to be pre-sensibilised.

If other ballast circuits are switched on, discharges occur between the capacitors

of these circuits through frames connected to earth. A definitive sensitivity could

then manifest itself which could cause nuisance tripping or the tripping of the

residual current device.

Possible consequences (when conventional residual current devices are

n used):

non-tripping

v There is a risk of non-tripping when a high level of high-frequency current is

reached for a single standard residual current device (corresponding to a large

number of electronic ballasts, for example over 20 per single-phase circuit),

v nuisance tripping

This occurs when the switching peaks or high frequency levels are high

(due to an overly large number of ballasts).

n Solutions:

v using "Si" type residual current devices

These have been designed to prevent non-tripping and nuisance tripping in the

case of high-frequency currents. The number of ballasts per residual current

device is increased to 50 per phase.

v limiting the number of ballasts on each standard residual current device

whenever necessary (less than 20 per phase).

21

The applications

Circuit breaker with

selective 300/500

mA RCD

ID

Loads and phenomena generating current peaks

"Si"for 1P and

"B" for 3P ID

ID

Circuit

breakers

Motor

circuit-breaker

Lighting

Controller

Altivar

9978 VR 01

4887 KI 69

5612 KL 21

9978 VR 01

9978 VR 01

1151 TR 73

3335 YU 56

5612 KL 21

4131 BU 57

9978 VR 01

4887 KI 69

3335 YU 56

5612 KL 21

8910 AD 28

1151 TR 73

5123 CE 66

5612 KL 21

8910 AD 28

9978 VR 01

4887 KI 69

4.5. Choosing safety and operating peace of mind

for your variable speed controllers

8951 GH 56

n Switching on the low voltage network

Sudden changes in voltage are caused by:

v the switching on or off of conventional fluorescent devices (over 10 or 20

ballasts cause problems),

v sudden operations on the network,

v the tripping of an automatic device on another circuit,

a fuse blowing,

v v any electrical arc generated on the network (motor, contactor, switch, etc.).

All of the capacities of an installation (loads’ electronic filters), associated with the

cable capacities, convey a transient leakage current with each sudden change in

voltage, thus giving rise to nuisance tripping.

The residual current devices in the "Si" range are perfect for this type of installation because they can withstand high levels of transient current

and therefore avoid nuisance tripping.

n Starting up motors

The high peaks generated when a motor is started up cause the nuisance tripping

of the residual current device. We recommend that you use the "Si" range

(when the start up peak is 6 times higher than the normal current) and that you

increase the calibration of the residual current device (if the peaks are 10 times

higher than the rated current).

Ventilator

Variable motor speed controllers, dimmers, etc.

n Phenomenon:

v High frequencies in the installation

High frequencies, sent to earth or transmitted onto the network, can be responsible for the residual current device not tripping. They are also the cause of nuisance

tripping when their RMS value is low and they are superimposed with constant 50

Hz leakages. Variable motor speed controllers are loads which can generate highfrequency current leakages and transmit them onto the network.

Dimmers can give rise to the same phenomenon, especially when the power goes

over 3,000 W in terms of light dimming. In some installations, several types of

loads can cause high frequencies, even if the power of each load is not very high.

The effects of each of the loads add up and lead to the residual current device’s

inability to operate.

v These loads bring about the risk of faults on pulsed DC currents.

n Possible consequences:

v nuisance tripping,

v non-tripping.

n Solutions:

v dividing up the circuit

It is recommended that the circuit be divided up whenever possible.

v "Si" or "B" type protection

The "Si" and "B" ranges are the only ones designed to ensure safety and continuity of supply at the same time while preventing the residual current device’s

inability to operate and nuisance tripping.u

v put the "Si" or "B" type protection upstream from the controller

– "Si" type for single phase circuit

– "B" type for three phase circuit

22

The applications

4.6. Continuity of supply in hazardous ­environment

Example of sites exposed External influences

Iron and steel industry, steel works. Presence of sulphur,

sulphur containing fumes,

hydrogen sulphide.

Marinas, ships, dockyards. trading ports, salty environments,

seasides damp outside environments,

low temperatures.

Swimming pools, hospitals, food-processing.

Chlorinated compounds.

Petrochemistry. Hydrogen,

combustion gases,

nitrogen oxides.

Breeding farms, dumps. Sulphur-containing hydrogen.

4

CONSEQUENCES

Corrosion

Standard residual current relay contact weiding

Non-tripping of the RCD

DANGER

For such applications, the SiE type will provide safe protection to the people,

while still being immune to nuisance tripping.

4.7. Remote sites and transient faults

Transient faults affecting remote sites can cause serious electrical continuity

problems, especially when those are not supervised. An automatic recloser RED

will prove useful for :

Telecom relays

Water or gas distribution

Computer servers

Secondary homes

RED can be a simple and efficient solution where power outage can not be

­ ccepted :

a

Cold room and food store protection

Lift protetion

Public lighting, alarms

Bank cash point ….

4.8. Advance earth leakage protection applications

The advance features of Vigirex allow perfect protection of people and goods

while improving continuity of service. Its features can be useful for sensitive building or process such as :

Hospitals

Airports

Pulp and Paper industry

Steel plants

Petrochemical plants

Data centers

Semiconductor plants

23

Which protection to use?

Protection device

Type

Applications

Current uses

Electronic loads, rectifiers, instruments, switch mode power supplies, variable speed controllers, etc...

Environment

Disturbed networks with: Risk of nuisance

Lightning stroke, switchgear

tripping due to transient operating on the network...

voltage surges

High risk of nuisance Close lightning strokes, IT earthing

Enhanced

tripping(*)

system, equipment incorporating

continuity

interference filters (lighting, computer of supply

systems), variable speed controllers,

frequency converters, electronic

lighting ballasts

Sources of blindness Presence of harmonics or high

Enhanced

frequency rejections

earth

leakage

protection

A

A si

A SIE

b

b

b

b

b

b

b

-

-

b

b

-

-

b

b

-

b

b

b

Use: -25°C

Swimming pools, marinas, agri-food industries, water

treatment plants, industrial production sites, etc...

-

b

-

b

-

b

b

Whether they are applied quickly or increased slowly

b

b

b

b

-

b

b

b

Presence of DC components:

equipment incorporating diodes,

thyristors, triacs (single phase)

Presence of DC components:

equipment incorporating diodes,

thyristors, triacs (three phase)

Low temperatures

Humid atmospheres and/

or atmospheres polluted

by aggressive agents

Tripping

Due to sinusoidal AC

residual currents

Due to continuous pulsed

residual currents

AC

-

Optimum contininuity of supply

Hospitals, Airports, Pulp and paper, Data centers, Petro

Reduced tolerances

Chemical plant, Steel industry Semi conductors

Inverse time monitoring

Frequency filtering

RMS measurement

( ) Those nuisance tripping are an indirect efect of a close lightning stroke. However, direct effect of lightning which strokes directly on power lines can destroy

*

equipment connected to it. In that case, only surge protection devices will protect the equipment.

Indirect effect of lightning --> nuisance tripping --> use of super-immune protection

Direct effect of lightning --> dangerous voltage surge --> use of surge protection device

24

B

RED

b

Vigirex

b

b

b

b

b

5

b

b ()

*

b

Vigi module

b

b

b

b

b

b

b

b

b

b

b

b

b

Vigirex module

( ) Schneider Exclusivity: Type B additional

*

coordination with Telemecanique variable speed drives

to avoid nuisance tripping due to EMC problems

25

Catalogue

Numbers

6. The "Si" and "SiE" range

Technical data

The Merlin Gerin range has characteristics which are highly superior to those of

the standard range and is therefore more capable of withstanding disturbances.

Product characteristics

DPN N Vigi

ID

"Si" and "SiE"

"Si" and "SiE"

Vigi C60 Vigi C120 "Si" and "SiE" "Si" and "SiE"

≤ 80A

Vigi NG 125

"Si"

100/125A

Electrical data

Curve

C

-

-

IDm (A) residual breaking capacity

6,000

2,500

same as associated circuit-breaker

Icn (A) rated breaking capacity

6,000

-

same as associated circuit-breaker

Icu ultimate breaking capacity in 7.5

-

accordance with IEC 60947.2 (KA) - Insulation voltage (kV) -

-

2 (NF C-150)

-

690

Degree of protection

- of terminal IP 20

IP 20

IP 20

IP 20B

- of front face IP 40

IP 40

IP 40

IP 40D

Current limiting class

3

3

-

Test operating limit 115/264 (2P) 102/176

90

176/456 (4P) 115/240

(V CA) (min./max.)

104/264

Supply voltage tolerance

-15% +10%

-15% + 10%

-15% +10%

-20% +10%

-20% +10%

Operating frequency (Hz)

50… 60

50… 60

50

AC class: 50… 60

50… 60

Electrical endurance

≤ 20 A: 20,000 10,000

20,000 -

10,000

10,000

(O/C cycles)

25 A: 25,000

32 A: 10,000

40 A: 6,000

Level of RCDs’ electromagnetic compatibility- Protection against disturbances

test

standard level

test

(IEC 61543)

required

result

Standard class

approved instantaneous

RCD

Voltage wave: 1.2/50µ

(IEC 61000-4-5)

Differential mode:

4 kV under 2 Ω

5.1.2

Common mode:

5 kV under 2 Ω

(T2.3)

Rapid transient (IEC 61000-4-4)

bursts (T2.2)

4 kV

5.1.2

Dampened current

(IEC 61008-61009)

sine wave (T2.4)

200 A

5.1.4

Current wave (IEC 61008-61009)

8/20 µs for s type only 5.1.2

10/1,000 µs

-

Electrostatic

(IEC 61000-4-2)

discharges

in the air: 8 kV

5.1.3

(T3.1)

on contact: 6 kV

26

internal level required

Standard class Instantaneous

s type RCD

RCD "Si" type

s type RCD

"Si" type

5 kV

8 kV

5 kV

8 kV

5 kV

8 kV

5 kV

8 kV

4 kV

4 kV

4 kV

4 kV

200 A

400 A

400 A

400 A

250 Â

0 Â

3 kÂ

10 Â

3 kÂ

1.5 Â

5 kÂ

> 200 Â

8 kV

6 kV

8 kV

6 kV

8 kV

6 kV

8 kV

6 kV

Product characteristics (cont.)

DPN N Vigi "Si" and "SiE"

ID "Si" and "SiE"

≤ 80A

100/125A

Vigi C60

Vigi C120

"Si" and "SiE" "Si" and "SiE"

Vigi NG125 "Si"

Mechanical data

Tunnel terminals with guard

35 mm2 50 mm2

1.5 to 35 mm2 35 mm2

-flexible cable

10 mm

2

≤ 25 16 mm

≤ 63

25 mm2

-hard cable

16 mm2

50 mm2 -

1 to 50 mm2 50 mm2

≤ 25

25 mm2

≤ 63

-

35 mm2

Tightening torque (N.m)

3.5

3.5

3.5

≤ 25 A: 2

≤ 63 A:

-

3.5

Mounting method:

on 35 mm symmetrical rail

n

n on mounting plate

n

n on mounting plate

Self-extinguishing:

- on insulating parts connected to a

potential in accordance with

IEC 60695-2-1

960°C, 30 s

960°C, 30 s

960°C, 30 s

960°C, 30 s

- on insulating parts not connected

to a potential in accordance with

IEC 60695-2-1

650°C, 30 s

650°C, 30 s

650°C, 30 s

650°C, 30 s

Mechanical withstand capacity IEC 60947-2

- against impacts:

in accordance with IEC 60068-2-6 n

n n

- against shaking:

in accordance with IEC 60068-2-6 n

n

n

Mechanical endurance (O/C cycles)

20,000

- off-load, IEC 60947-1

20,000

20,000 5,000

20,000

- on-load, IEC 61008, In x 0.9

10,000 - by test action, NF C 61-150

20,000 - by fault current, NF C 61-150

20,000 Fast closing

n

n -

n

n

Isolation with positive

break indication

n

n

n

n

Environment

Operating temperature

Storing temperature

Damp heat in accordance

with IEC 61008

Tropicalisation

-25°C to +60°C

-40°C to +70°C

-25°C to +40°C

-40°C to +70°C

-25°C to +40°C -25 °C to +60°C

-25°C to +60°C -40 °C to +70°C

n

n

n

treatment 2 (95% of relative humidity at 55°C in accordance with IEC 60068-2-30)

-10 °C to +60 °C

-40 °C to +70 °C

n

Auxiliaries and accessories

Merlin Gerin offers you a whole range of add-on auxiliaries and accessories which can be simply and easily

integrated into electrical systems:

Auxiliaries

Accessories

O/F auxiliary contact (open/closed)

SD fault indicating switch

MX + OF shunt release

MN or MNs undervoltage release

Please contact your representative for more information.

Comb busbar

Bars of clip-on markers

Padlocking facility

Terminal shield

Screw shield

27

6

6.1. Selection tables

"Si" and "SiE" type RCCB-ID

type

voltage

(V CA)

rating

(A)

sensitivity

cat. no.

(mA)

width

(module: 9 mm)

2P

240

25

30

40

30

N 1

40

300 s

63

30

T

R

63

300 s

80 300 s

N 2

"Si"

"SiE"

23523 23300

23524 23307

-

23314

23525 23352

23363 23355

23372

4

4

4

4

4

4

4P

415

N 1 3 5

T

R

N 2 4 6

30

30

300 s

30

300 s

30

300 s

23526 23377

23529 23379

-

23398

23530 23383

23392 23401

23390

23394

8

8

8

8

8

8

8

sensitivity

cat. no. 25

40

40

63

63

80

80

A class RCCB-ID

type

voltage

28

rating

(A)

(mA)

width

(module: 9 mm)

2P

230

16

10

23415

4

25

10

23353

4

30

23354

4

N

1

300

23356

4

40

30

23358

4

T

R

300

23360

4

N

2

300 s

23265

4

63

30

23362

4

300

23364

4

300 s

23370

4

500 s

23371

4

80

300 s

23272

4

100

300 s

23279

4

4P

230/400 25

30

23378

8

300

23380

8

500

23381

8

N 1 3 5

40

30

23382

8

T

100

23304

8

R

100 s

23490

8

N 2 4 6

300

23384

8

300 s

23399

8

500

23385

8

63

30

23386

8

100 s

23494

8

300

23388

8

300 s

23402

8

500

23389

8

80

300

23326

8

300 s

23284

8

500 s

23376

8

100

300 s

23294

8

C60, C120 and NG 125 "Si" and "SiE" type Vigi modules

type

voltage

(V)

rating

(A)

sensitivitycat. no. width

(mA)

2P

C60

"Si"

(module: 9 mm)

"SiE"

230… 415

≤ 25 30 1 3

≤ 40 30 T

≤ 40 300 s ≤ 63 30 300 s

2 4

1000 s

26747 26700

26761 26701

-

26716

26774 26702

26779 26706

26806

3

3

3

4

4

4

C120

230… 415

120

1 3

T

2 4

18591

18592

18556

18593

18557

7

7

7

7

7

26747

30

300

300 s

500

1,000 s

18592

6

3P

C60

230… 415

≤ 25

1 3 5

≤ 40

T

≤ 63

2

18594

6

C120

230… 415

120

1 3 5

T

2

26756

19004

4

4

6

30 26751

30 26764 26691

30 26789 26721

300 s 26794

1000 s 26807

30

300

300 s

500

1,000 s

18594 18676

18595 18677

18558

18596

18559

6

6

7

7

10

10

10

10

10

NG 125

220… 415

125 30 19100

9

adjustable

19106

9

4P

C60

230… 415

≤ 25

≤ 40

1 3 5 7

T

≤ 40

≤ 63

2 4 6 8

30 30 300 s 30 300 s

1000 s

26756

26767

-

26799

26804

26808

C120

230… 415

120

1 3 5 7

T

30

300

300 s

500

1,000 s

18597 18602

18598 18678 10

18560 18600 10

18599

10

18561 18601 10

30 adjustable

19101

19107

2

NG 125

4

6

26703

26704

26730

26705

26707

26708

6

6

6

7

7

7

8

220… 415

125

9

9

29

Catalogue

Numbers

PB101616-55-1

Protection of people against direct and

indirect contacts.

Protection of installations against

insulation faults.

Control and isolation of on-load

electrical circuits already protected

against overloads and short-circuits.

RCCB-ID 25...125 A, B type

6.2. Description B type

B type

The RCCB-ID B type residual current circuit-breakers provide specific protection of

three-phase installations and people even in the presence of DC fault currents on

the network generated by:

n three-phase controllers and variable speed drives

n three-phase battery chargers and inverters

n three-phase backed-up power supplies.

They are a requirement for three-phase supplied applications, when class l

equipment installed downstream from the RCCB-ID are likely to produce DC

component fault currents (pure DC fault)

.

They include and also guarantee protection against fault currents:

n sinusoidal AC residual currents

(AC type)

n pulsed DC residual currents

(A type).

They can be adapted, without exception, to all the application cases defined in

standards IEC 60364 and EN 50178.

The B type RCCB-ID combination with variable speed drives of the Telemecanique

brand has been successfully tested and validated.

Instantaneous

It ensures instantaneous tripping (without time delay).

16766

Selective s

It ensures total discrimination with a non-selective RCD placed downstream.

RCCB-ID 25...125 A, B type

Technical data

Compliance with standards

IEC 61008, EN 61008, VDE 0664

Voltage rating

230/400 V AC, +10%, -15%

Frequency rating

50 Hz

Current rating (In)

25, 40, 63, 80 or 125 A

Making and breaking capacity,

10 In with 500 A minimum

rated residual current (I∆m = Im)

as per standard IEC 61008

Protected against nuisance tripping due to transient overvoltages (lightning stroke,

device switching on the network, etc.)

Level of immunity in 8/20 µs wave

3 kÂ

Tripping time

Short-circuit current withstand

(I∆c = Inc)

Number of operating cycles (O-C)

Releases with fixed sensitivities

for all ratings

Test button

Indication of RCCB-ID status

Tropicalisation

Operating temperature

Storage temperature

Weight (g)

Degree of protection

Connection by tunnel terminal

30

I∆n: ≤ 300 ms

5I∆n: ≤ 40 ms

See the circuit-breaker or fuse coordination

table with B type RCCB-ID

Mechanical: > 5 000

Electrical: > 2 000

Instantaneous release

Selective release s: allows total vertical

discrimination with the 30 mA RCDs placed

downstream

Checks proper operation of the tripping

mechanism

Working range: 185...440 V AC

By 3-position toggle and mechanical

indicator on the front face: closed (red

indicator) tripped on fault (red indicator)

open (green indicator) By OFsp auxiliary

switch (optional)

Treatment 2 (relative humidity 95% at 55°C)

-25°C to +40°C

-40°C to +60°C

500

IP40 on front face

IP20 at terminals

Flexible or rigid cable: 1 x 1.5 to 50 mm2 or

2 x 1.5 to 16 mm2

RCCB-ID 25...125 A, B type

Catalogue numbers

Type

16766

Voltage

Rating

Sensitivity

(V AC)

(A)

(mA)

RCCB-ID residual current circuit-breakers

4P

230/400

25

30

300

40

30

300

300s

500

63

30

300

300s

500

80

30

300

300s

125

30

300

300s

500

Width in

Cat. no.

mod. of 9 mm

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

16750

16751

16752

16753

16754

16755

16756

16757

16758

16759

16760

16761

16762

16763

16764

16765

16766

OFsp auxiliary

Electrical indication: by OFsp auxiliary mounted to the left. It has a double changeover switch

indicating the “open” or “closed” position of the B type RCCB-ID

Weight (g)

Connection by tunnel terminal

40

Flexible or rigid cable: 0.5 to 1.5 mm2

Type

Voltage

(V AC)

Contact Width in

Cat. no.

(A)

mod. of 9 mm

OFsp

230 V AC (AC15)

230 V DC (DC13)

6

1

16940

22

12 14

21

11

16940

1

Accessory

4-pole sealable screw shield

Degree of protection

16939

Prevents contact with device terminal screws

IP40

Type

Screw shield (set of 10 parts) upstream/downstream

Number of

poles

4

Cat. no.

16939

31

6

RCCB-ID 25...125 A, B type

Coordination tables, max. short-circuit current

(kA rms)

Circuit-breakers / B type RCCB-ID coordination (IEC 60947-3)

Circuit-breaker

RCCB-ID, B type

400/415 25 A

V network 40 A

63 A

80 A

125 A

multi 9

Compact

C60N C60H C60L NG125a C120N NG125N NG125H NS100 NS160

C120H

NG125L

10

10

10

15

15

15

25

20

15

7

7

7

5

5

7

7

7

7

5

15

15

15

15

10

15

15

15

15

4

4

4

4

4

4

4

4

Fuses / B type RCCB-ID coordination (IEC 60947-3)

gl or gG

fuse (A)

RCCB-ID, B type

400/415 V 25 A

network

40 A

63 A

80 A

125 A

16

25

32

40

50

63

80

100

125

100

100

100

100

100

100

100

100

100

100

100

100

100

100

80

80

80

80

50

50

50

30

30

30

20

20

10

10

Ut > 1000 V

d To perform the

dielectric test, disconnect

terminals 3, 5, 7 and 4, 6, 8.

32

Catalogue

Numbers

RED, REDs, REDtest

Selection table

The RED, REDs and REDtest REsidual current Devices offer the following

functions:

n protection of people against direct and indirect contacts

n protection of installations against insulation faults

n disconnection of on-load electric circuits, already protected against overloads

and short-circuits

n automatic restart after insulation monitoring of the downstream circuit

n automatic and periodical test of the device, without breaking downstream

circuit (REDtest).

Selection table

REDtest

PB101781-50

REDs

PB101780-50

RED

PB101779-50

Type

6

Technical data

Earth leakage protection compliance with standards IEC 61008, EN 61008

b

b

b

Current rating (In)

Sensibility

Type

25, 40, 63 A

30 mA

A

25, 40, 63 A

30, 300 mA

A

25, 40 A

30 mA

A

b

b with prolonged insulation monitoring

b

Recloser

Autotest

Power supply

From the top

From the

bottom

Indication

Mechanical

Luminous

Remote

b

-

b

b

b

b

b

By O-l (open-closed) 2-position lever

1 LED

-

By O-l (open-closed) 2-position lever

2 LEDs

1 built-in auxiliary contact

By O-l (open-closed) 2-position lever

2 LEDs

1 built-in auxiliary contact

-

33

RED 25...63 A, A type

30 mA

PB101779-50

6.3. Description RED type

The RED, REsidual current Device recloser, is made up of a residual current device

and a recloser.

A type

The RED phase-to-neutral residual current devices provide A type earth leakage

protection: tripping due to sinusoidal AC residual currents as well as by continuous

pulsed residual currents, whether they are applied quickly or increased slowly.

RED 25...63 A, A type

Common technical data

18681

Power supply

Voltage rating (Ue)

Frequency rating

Current rating (ln)

Impulse withstand voltage (Uimp)

Insulation voltage (Ui)

8/20 µs wave immunity level

Tropicalisation

Operating temperature

Storage temperature

Weight (g)

Protection class

Connection by tunnel terminal with guard

From top and bottom

230 V AC, +10 %, -15 %

50 Hz

25, 40, 63 A

4 kV

500 V

250 Â

Treatment 2 (relative humidity: 95 % at 55°C)

-5°C to +40°C

-20°C to +60°C

350

IP20 at terminals

25 mm2 flexible cable or 35 mm2 rigid cable

Mounting

On DIN rail

Residual current device

Compliance with standards

Making and breaking capacity, rated

residual current (I∆m=Im)

Breaking capacity in association with

protection device

Tripping time

Short-circuit current withstand

(I∆c = Inc)

Number of cycles (O-C)

Fixed sensitivity releases for all ratings

Test button min operating voltage

IEC 61008, EN 61008

630 A

10.000 A (gL 63 A)

I∆n : ≤ 300 ms

5I∆n : ≤ 40 ms

See coordination table of circuit-breaker or fuse

with A type RED

Mechanical: 1,000

Instantaneous release

100 V

Recloser technical data

Max duration of a restart cycle

Number of restart operations

Maximum number of consecutive restart

attempts (if no earth fault)

Min interval between 2 closings

Insulation fault presence monitoring

Restart in event of transient insulation

fault

Stopping restart cycle if insulation fault

present

90 s

15/hour

3

180 s

Yes

Yes

Yes

Indication

RED status indication

34

Mechanical:

by O-l (open-closed) 2-position lever

Electrical: by 1 red indicator light on the front panel

RED 25...63 A, A type

30 mA

Catalogue numbers

Type

Voltage

Rating

(V AC)

(A)

RED residual current devices

2P

230

25

40

63

Sensitivity

(mA)

Width in

mod. of 9 mm

Cat. no.

30

30

30

8

8

8

18681

18683

18685

Coordination table, max short-circuit current (kA rms)

Multi 9 circuit-breaker, fuse / A type RED coordination

RED A type

Network 25 A

230 V

40 A

L/N

63 A

Multi 9 circuit-breakers

C32 K60 DT40 DT40N

C60

C120

NG125

Fuse

gL 63

4.5

4.5

-

6

6

6

10

10

10

10

10

10

6

6

6

6

6

-

6

6

-

6

6

-

6

Operation

Recloser

The built-in automatic recloser automatically recloses the residual current device

after checking insulation of the downstream circuit. If the circuit is faulty, then RCD

reclosing is prohibited.

Fig.1

Residual current device

The RED operates in the residual current device mode without automatic restart

when the sliding cover is open, i.e. to the right in the Auto Off position (Fig. 1).

The automatic restart mode is activated when the sliding cover is closed, i.e. to the

left in the Auto On position (Fig. 2).

Fig.2

Test

bthis is only possible in manual mode, i.e. sliding cover open in the Auto Off

position. You can then manually test the device by pressing the Test key. The

downstream installation is then temporarily broken. You must then manually reclose

the RED, by activating the O-l lever to power supply the downstream circuit.

35

RED 25...63 A, A type

30 mA

Operation (cont.)

Recloser

Operating diagram of the recloser

+

ON

LED :

OFF

FAULT

No

?

OFF

F = 1 Hz

Yes

CLACK

R

OFF

R

CHECK

R

FAULT

R

3 min

Yes

FAULT

?

FAULT

No

No

RCD

reclosing

OK

Yes

3rd reclosing

attempt

? No

R

? Yes

OK

END

Operating and indicating diagram of a restart cycle:

Faulty installation

Healthy installation

Power contact

Monitoring phase

Installation test

Operating spring loading

Flashing

LED (operating status)

36

Sliding cover

opening

Permanent fault

detection and

blocking

Fault

Restart

Restart

cycle start

Transient tripping

fault

Downstream voltage

RED 25...63 A, A type

30 mA

Dimensions

6

37

REDs 25...63 A, A type

30 mA and 300mA

Protection of people against direct and indirect

contacts.

Protection of installations against insulation faults.

Disconnection of on-load electric circuits, already

protected against overloads and short-circuits.

Automatic restart after insulation monitoring of the

downstream circuit.

6.4. Description REDs

PB10178+-50

Catalogue

Numbers

18688

The REDs, REsidual current Device recloser, is made up of a residual current device

and a recloser.

A type

The REDs phase-to-neutral residual current devices provide A type earth leakage

protection: tripping due to sinusoidal AC residual currents as well as by continuous

pulsed residual currents, whether they are applied quickly or increased slowly.

REDs 25...63 A, A type

Common technical data

Power supply

Voltage rating (Ue)

Frequency rating

Current rating (ln)

Impulse withstand voltage (Uimp)

Insulation voltage (Ui)

8/20 µs wave immunity level

Tropicalisation

Operating temperature

Storage temperature

Weight (g)

Protection class

Connection by tunnel terminal with guard

Mounting

From top and bottom

230 V AC, +10 %, -15 %

50 Hz

25, 40, 63 A

4 kV

500 V

250 Â

Treatment 2 (relative humidity: 95 % at 55°C)

-5°C to +40°C

-20°C to +60°C

360

IP20 at terminals

25 mm2 flexible cable or 35 mm2 rigid cable

On DIN rail

Residual current device

Compliance with standards

Making and breaking capacity, rated

residual current (I∆m=Im)

Breaking capacity in association with

protection device

Tripping time

Short-circuit current withstand

(I∆c = Inc)

Number of cycles (O-C)

Fixed sensitivity releases for all ratings

Test button min operating voltage

IEC 61008, EN 61008

630 A

10.000 A (gL 63 A)

I∆n : £ 300 ms

5I∆n : £ 40 ms

See coordination table of circuit-breaker or

fuse with A type REDs

Mechanical: 1,000

Instantaneous release

100 V

Recloser technical data

Max duration of a restart cycle

Number of restart operations

Maximum number of consecutive restart

attempts (if no earth fault)

Min interval between 2 closings

Insulation fault presence monitoring

Restart in event of transient insulation fault

Stopping restart cycle if insulation fault

present

90 s

15/hour

3

180 s

Yes

Yes

Yes, during 15 minutes

Indication

REDs status indication

Mechanical:

by O-l (open-closed) 2-position lever

Electrical: by 2 indicator lights on the front panel:

left: red LED

right: green LED

Remote: by 1 built-in auxiliary contact

Auxiliary contact technical data

Voltage rating (Ue)

Insulation voltage (Ui)

Current rating (ln)

Type

Connection by tunnel terminal

38

5...230 V AC/DC

350 V

Min: 0.6 mA

Max: 100 mA, power factor = 1

Configurable : NO or NC or intermittent 1 Hz

Flexible or rigid cable: max 2.5 mm2

REDs 25...63 A, A type 30 mA

Catalogue numbers

Type

Voltage

Rating

(V AC)

(A)

REDs residual current devices

2P

230

25

Sensitivity

(mA)

Width in

Cat. no.

mod. of 9 mm

30

300

30

300

30

300

40

63

8

8

8

8

8

8

18687

18688

18689

18690

18691

18692

Coordination table, max short-circuit current (kA rms)

Multi 9 circuit-breakers

C32 K60 DT40 DT40N

REDs A type

Network 25 A

230 V

40 A

L/N

63 A

4.5

4.5

-

6

6

-

6

6

-

6

6

-

C60

10

10

10

C120

10

10

10

NG125

10

10

10

Fuse

gL 63

6

6

6

6

DB109806

Operation

Fig. 1

Recloser

The built-in automatic recloser automatically recloses the residual current device

after checking insulation of the downstream circuit. If the circuit is faulty, then RCD

reclosing is prohibited. After a 15-minute time delay, downstream circuit insulation

is checked again.

There are then two possibilities:

the installation is still faulty: in this case a new check will be carried out in

n 15 minutes.

The sequence is locally reported by a 5-second intermittent red Led and remotely

reported by the auxiliary contact.

the fault was temporary and has disappeared: the recloser automatically

n recloses the RCD.

DB109806

Residual current device

The REDs operates in the residual current device mode without automatic restart

when the sliding cover is open, i.e. to the right in the Auto Off position (Fig. 1).

The automatic restart mode is activated when the sliding cover is closed, i.e. to the

left in the Auto On position (Fig. 2).

Test

this is only possible in manual mode, i.e. sliding cover open in the Auto Off

n position. You can then manually test the device by pressing the Test key. The

downstream installation is then temporarily broken. You must then manually

reclose the REDs by activating the O-l lever to power supply the downstream

circuit.

39

REDs 25...63 A, A type

30 mA and 300mA

Operation (cont.)

Recloser

Operating diagram of the recloser

+

ON

LEDs :

OFF

FAULT

No

OFF

Yes

CLACK

F = 1 Hz

?

R

OFF

5s 5s

5s

R

CHECK

R

R

G

R

Yes

FAULT

15 min

3 min

?

No

FAULT

No

RCD

reclosing

OK

? No

Yes

OK

END

3rd reclosing

attempt

?

R

Yes

G

Operating and indicating diagram of a restart cycle:

Faulty installation

(3rd reclosig attempt)

Healthy installation

Power contact

Monitoring phase

Installation test

Operating spring loading

Flashing

Right LED (voltage presence)

Left LED (operating status)