TSI

Terminal set interface protection and diode bridge

Features

■

Stand-off voltage from 62 V to 265 V

■

Peak pulse current: 30 A (10/1000 µs)

■

Maximum DC current: IF = 0.2 A

■

Holding current: 150 mA

SO-8

Benefits

■

Trisil™ technology is not subject to ageing and

provides a fail safe mode in short circuit for a

better protection.

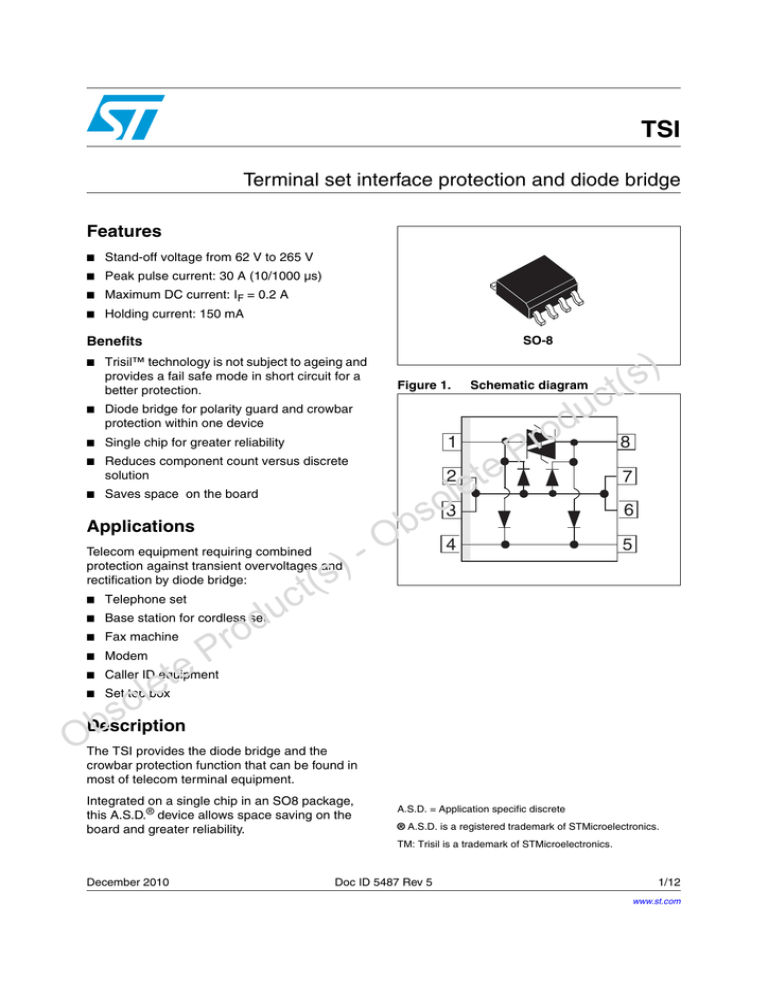

Figure 1.

Schematic diagram

■

Diode bridge for polarity guard and crowbar

protection within one device

■

Single chip for greater reliability

1

■

Reduces component count versus discrete

solution

2

■

Saves space on the board

Applications

Telecom equipment requiring combined

protection against transient overvoltages and

rectification by diode bridge:

■

Telephone set

■

Base station for cordless set

■

Fax machine

■

Modem

■

Caller ID equipment

■

Set top box

)

s

(

ct

e

t

le

c

u

d

o

r

P

o3

s

b 4

O

-

)

s

t(

8

7

6

5

u

d

o

r

P

e

t

e

l

o

s

b

O

Description

The TSI provides the diode bridge and the

crowbar protection function that can be found in

most of telecom terminal equipment.

Integrated on a single chip in an SO8 package,

this A.S.D.® device allows space saving on the

board and greater reliability.

A.S.D. = Application specific discrete

® A.S.D. is a registered trademark of STMicroelectronics.

TM: Trisil is a trademark of STMicroelectronics.

December 2010

Doc ID 5487 Rev 5

1/12

www.st.com

12

Characteristics

1

TSI

Characteristics

Table 1.

Compliant with the following standards

Peak surge

Voltage

Required peak

Current

voltage (V) waveform (µs)(1)

current (A)

waveform (µs)(1)

Standard

ITT K17 - K20

1500

VDE 0433

10/700

2000

38

5/310

(2)

10/700

5/310

40A

1. See Figure 2.

2. With series resistors or PTC

Table 2.

Absolute maximum ratings (Tamb = 25 °C)

Symbol

Parameter

Peak pulse current(1)

10/1000 µs

5/310 µs

2/10 µs

IPP

Non repetitive surge peak on-state current

(F = 50 Hz)

Tstg

Tj

Storage temperature range

Maximum junction temperature range

Table 3.

Thermal resistance

Symbol

Rth(j-a)

Figure 2.

e

t

le

o

r

P

o

s

b

O

Parameter

(s)

Junction to ambient

t

c

u

Pulse waveform

d

o

r

P

e

2/12

c

u

d

t = 10ms

t = 1s

Maximum lead temperature for soldering during 10 s

1. See Figure 2.

s

b

O

30

40

75

ITSM

TL

t

e

l

o

Value

% I

PP

Repetitive peak pulse current

10 0

tr = rise time (µs)

tp = pulse duration time (µs)

50

0

tr

tp

Doc ID 5487 Rev 5

t

5

3.5

Unit

)

s

t(

A

A

- 55 to + 150

°C

260

°C

Value

Unit

170

°C/W

TSI

Characteristics

Table 4.

Electrical characteristics - definitions (Tamb = 25 °C)

Symbol

Parameter

VRM

Stand-off voltage

VBO

Breakover voltage

VBR

Breakdown voltage

IBO

IH

IH

Holding current

IBO

Breakover current

IRM

Leakage current at VRM

IPP

Peak pulse current

IRM

Capacitance

αT

Temperature coefficient

Electrical characteristics - values (Tamb = 25 °C)

IRM @ VRM

Order code

VBO(1)

IH

max.

min.

min.

mA

max.

TSI220B1

µA

V

V

mA

1

5

50

220

330

150

2. VR = 0 V, F = 1 MHz, between pins 1 and 8

Thermal resistances

Symbol

VF (for one diode)

o

s

b

O

Parameter

(s)

IF = 20 mA

IF = 100 mA

t

c

u

50

VBO

)

s

t(

C(2)

IBO(1)

r

P

e

t

le

1. Measured at 50 Hz, one cycle

Table 6.

V

VRM

C

Table 5.

I

IPP

uc

max.

od

typ.

mA

pF

400

200

Value

Unit

0.9

1.1

V

d

o

r

P

e

t

e

l

o

s

b

O

Doc ID 5487 Rev 5

3/12

Typical application

2

TSI

Typical application

Figure 3.

Application schematic

PTC

TSI

Ligne A

Hook

Speech

dialing

ringer

Ligne B

c

u

d

)

s

t(

Telecom terminals have a diode bridge for polarity guard located at the line interface stage.

They also have above this diode bridge one crowbar protection device that is mandatory to

prevent atmospheric effects and AC mains disturbances from damaging the electronic

circuitry that follows the diode bridge.

o

r

P

STMicroelectonics proposes a single-chip device that includes both protection and the diode

bridge. This is the concept of the TSI devices.

Figure 4.

e

t

le

o

s

b

O

-

Uses of the TSI in a conventional telecom network

)

s

(

ct

Central office

Telephone set

Answering

machine

u

d

o

r

P

e

PABX

Exchange

Answering

machine

t

e

l

o

s

b

O

Modem

Computer

WLL

4/12

Telephone set

Doc ID 5487 Rev 5

TSI

Electrical parameters

3

Electrical parameters

The VRM value corresponds to the maximum voltage of the application in normal operation.

For instance, if the maximum line voltage is ranging between 100 VRMS of ringing plus 48 V

of battery voltage, then the protection chosen for this application shall have a VRM close to

200 V.

VBO is the triggering voltage. This indicates the voltage limit for which the component shortcircuits. Passing this VBO makes the device turn on.

IBO is the current that makes the device turn on. Indeed, if we want a Trisil to be turned on

not only the voltage across it shall pass the VBO value but the current through it shall also

pass the IBO value.

In other words, if a voltage surge occurring on the line is higher than the VBO value of a

Trisil, but the line surge current is limited to a value that does not exceed the Trisil’s IBO

value, then the Trisil will never turn into a short-circuit. At this time the surge will be clamped

by the Trisil.

)

s

t(

The electronic circuitry located after the Trisil will always be protected whatever the Trisil

state is (crowbar or clamping mode).

c

u

d

IH is the holding current. When the Trisil is turned on, as soon as the crossing current surge

gets lower than this IH value, the Trisil protection device turns back in its idle state. For this

reason the Trisil’s IH value shall be chosen to be higher than the maximum telecom line

current can be.

o

r

P

3.1

e

t

TSI behavior with regard to surge standard

le

o

s

b

O

)

s

(

t

c

u

d

o

r

P

ete

The TSI replaces both diode bridge and usual discrete protection on telecom terminals.

Furthermore, it complies with the ITT K17 recommendations:

●

10/700 µs waveform surge test ±1.5 kV

●

AC power induction test

●

AC power contact test

Figure 5.

Test circuit for the ITT K17 recommendations

PTC

b

O

l

o

s

10 Ω

Surge

generator

LA

TSI

Telecom

line side

LB

Doc ID 5487 Rev 5

5/12

Electrical parameters

3.1.1

TSI

10/700 µs waveform surge - lightning simulation

This test concerns the 10/700 µs waveform surge ±1.5 kV.The surge generator used for the

test has the following circuitry (Figure 6).

Figure 6.

10/700 µs waveform surge generator circuit

W

W

W

)

s

t(

The behaviour of the TSI to this lightning surge is given below (Figure 7 and Figure 8).

Figure 7.

c

u

d

Voltage across + and - terminals of Figure 8.

TSI and current for 1.5 kV positive

surge

Voltage (50 V /div)

Voltage across + and - terminals of

TSI and current for 1.5 kV negative

surge

Voltage (50 V /div)

e

t

le

(t s)

o

r

P

o

s

b

O

-

2 µs/div

uc

Current (5 A/div)

2 µs/div

Current (5 A/div)

d

o

r

P

e

t

e

l

o

s

b

O

2 µs/div

2 µs/div

These curves show the peak voltage the surge generates across the TSI + and - terminals.

This lasts a short time ( 2 μs) and after, as the internal protection behaves like a short circuit,

the voltage drop across the TS1 becomes a few volts. In the meantime all the surge current

flows through the protection device.

As far as the 10/700 µs waveform surge test is concerned,the TSI withstands the ±1.5 kV

test.

6/12

Doc ID 5487 Rev 5

TSI

3.1.2

Electrical parameters

AC power induction test

This test simulates the induction phenomena that can happen between telecom lines and

AC mains lines (Figure 9).

Figure 9.

AC power induction test circuit

I

PTC

R

LA

10 W

TSI

T

Telecom

ligne side

Vrms

50 Hz

V

LB

Part 1

c

u

d

Test conditions:

●

VRMS = 240 V

●

R = 600 Ω

●

t = 0.2 s

e

t

le

Part 2

Test condition :

●

VRMS = 600 V

●

R = 600 Ω

●

t = 0.2 s

)

s

(

ct

)

s

t(

o

r

P

o

s

b

O

-

Figure 10. Voltage across + and - terminals of TSI and current during test part 1

u

d

o

Voltage (50 V/div)

r

P

e

s

b

O

t

e

l

o

5 ms/div

Current (0.2 A/div)

5 ms/div

The TSI withstands the AC power induction test in both cases.

Doc ID 5487 Rev 5

7/12

Electrical parameters

3.1.3

TSI

AC power contact test

This test simulates the direct contact between the telecom lines and the AC mains lines.

The AC power contact test consists in applying 240 VRMS through a 10 Ω PTC for 15

minutes to the device under test. The ITT K17 recommendation specifies an internal

generator impedance allowing 10 ARMS when in short circuit.

The behavior of the TSI with respect to this surge is given in Figure 11.

Figure 11. Voltage across + and - terminals of TSI and current during the test

Voltage (50 V/div)

50 ms/div

c

u

d

Current (5 A/div)

e

t

le

so

b

O

-

)

s

t(

o

r

P

50 ms/div

Figure 11 shows that after 250 ms there is no current flowing through the TSI device. This is

due to the action of the serial PTC that limits the current through the line. This PTC is

mandatory for this test. It can also be replaced by a fuse or any other serial protection that

“opens” the line loop under AC contact test.

)

s

(

ct

u

d

o

r

P

e

t

e

l

o

s

b

O

8/12

Doc ID 5487 Rev 5

TSI

4

Ordering information scheme

Ordering information scheme

Figure 12. Ordering information scheme

TPN 220 B 1 RL

Terminal set interface

Breakdown voltage

220 = 220 V

Package

1 = SO-8 plastic

Packing

RL = Tape and reel

Blank = Tube

c

u

d

e

t

le

)

s

(

ct

)

s

t(

o

r

P

o

s

b

O

-

u

d

o

r

P

e

t

e

l

o

s

b

O

Doc ID 5487 Rev 5

9/12

Package information

5

TSI

Package information

●

Epoxy meets UL94, V0

●

Lead-free package

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK® packages, depending on their level of environmental compliance. ECOPACK®

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK® is an ST trademark.

Table 7.

SO-8 dimensions

Dimensions

Ref.

Min.

Seating

Plane

C

A2

A

L

k

ppp C

L1

D

A1

0.1

A2

1.25

b

0.28

C

0.17

D

4.80

so

E

e

4

1

(s)

h

b

O

-

ct

u

d

o

t

e

l

o

s

b

O

10/12

Typ.

Max.

L

o

r

P

0.23

4.90

5.00

0.011

)

s

t(

0.010

c

u

d

0.049

0.007

0.019

0.009

0.189 0.193 0.197

5.80

6.00

6.20

0.228 0.236 0.244

3.90

4.00

0.150 0.154 0.157

1.27

0.25

0.40

0.050

0.50

0.010

1.27

0.016

1.04

0°

ppp

0.6

(0.024)

4.2

(0.165)

1.27

(0.050)

0.020

0.050

0.041

8°

0.10

6.8

(0.268)

Doc ID 5487 Rev 5

0.004

3.80

L1

k

0.069

0.48

Figure 13. Footprint, dimensions in mm (inches)

r

P

e

Min.

0.25

e

t

le

E1

E1

Max.

1.75

E

5

8

Typ.

Inches

h x 45°

C

A1

e

b

A

Millimeters

0°

8°

0.004

TSI

6

Ordering information

Ordering information

Table 8.

7

Ordering information

Ordering code

Marking

Package

Weight

TSI220B1

TSI220

SO-8

0.08g

Revision history

Table 9.

Document revision history

Date

Revision

Changes

Oct-2003

4

Last release

14-Dec-2010

5

Updated trademark statements. Removed order codes that are no longer

available.

c

u

d

e

t

le

)

s

(

ct

)

s

t(

o

r

P

o

s

b

O

-

u

d

o

r

P

e

t

e

l

o

s

b

O

Doc ID 5487 Rev 5

11/12

TSI

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

)

s

t(

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

c

u

d

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

e

t

le

o

r

P

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

o

s

b

O

-

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

)

s

(

ct

u

d

o

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

r

P

e

t

e

l

o

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

bs

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

O

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

12/12

Doc ID 5487 Rev 5