Roof Systems Manual

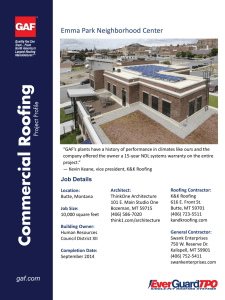

advertisement