18 SG with Round Rotor Design

advertisement

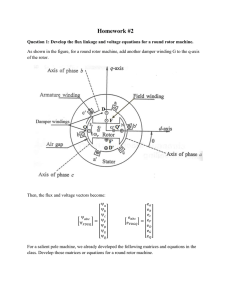

Design of Synchronous Generator with Round Rotor Part 1 – General Considerations Synchronous Generator System Rotor Peripheral Speed The maximum allowable peripheral speed of the rotor is a central consideration in machine design. With present-day steel alloys, rotor peripheral speeds of 50,000 ft/min (or about 250 m/s) represent the design limit. 1 ft/min = 0.0051 m/s Resistivity of Copper vs Temperature The resistivity of copper versus temperature can be calculated using the following formula: Cu (T ) Cu (T0 ) Cu (T T0 ) where T0 is a reference temperature and give by Cu is a constant Cu 2.668 10 9 in/ o C or: Cu 6.775 10 11 m/ o C At T0 20 o C , we have Cu (T0 ) 0.679 10 6 in/ o C or: Cu (T0 ) 1.724 10 8 m/ o C Part 2 – Armature Design Number of Armature Slots For a m-phase synchronous machine, the number of armature slots (S) must be multiples of m. This will guarantee all the phases are balanced. A. Integral S/P S is multiples of mP. Example: For a 2 pole, 3 phase machine, the number of slots can be 6,12,18,24,30,36… For a 4 pole, 3 phase machine, the number of slots can be 12, 24,36,48,60… Integral S/P may cause extensive cogging or detent torque since all pole faces will line up with slot openings at the same time. Cogging torque: torque from the interactions between rotor poles and stator teeth. Use slot skew or fractional S/P can reduce it. B. Fractional S/P S/P takes a fractional number. Number of Turns per Coil V , rated where 2 f e Nˆ a g , pk 4 .44 f e Nˆ a g , pk g , pk 2Bg , pk Dl P Nˆ a kw Na / 1.1 kw k p kd ks Na PqNc / C Na is the number of series turns per phase of armature winding C is the number of parallel circuits of armature winding Nc 1 .1V , rated C 2 2 f e qk w B g , pk Dl To consider leakage flux Number of Conductor Positions per Slot on Stator Cs 2N ca for double layer winding. In the above expression, Cs includes hollow conductor positions for cooling (about 25%) and additional 15% - 25% of both height and width tolerance of conductors (for insulation, slot liner, etc.) in factor a. a can take about 1.6 – 2. Cs 1.1aV , rated C 2 f e qk w B g , pk Dl Maximum and Average Flux Density Average flux per pole: g , av 0 g , pk sin ae d ae g , pk 2 g , pk 0 Average flux density per pole: B g , av g , av Dl / P DlB g , av 2 g , pk P 2 Dl 2 or: g , pk 2P Specific magnetic loading g , pk Since B g , av 4 2 B g , pk 2Bg , pk Dl P 0 .4 B g , pk Typically, take B g , av 0 . 6 T or B g , pk 1 . 5T in design. Machine Size (1) Specific electric loading: rms current per unit length of the armature circumference m (2 N a C )( I A,rated / C ) 2 mN a I A,rated Ka D D Na is the number of series turns per phase of armature winding C is the number of parallel circuits of armature winding I A , rated DK a 2 mN a Machine Size (2) Apparent power S rated mV , rated I A , rated 2 f e Nˆ a g , pk V , rated S rated g , pk 2Bg , pk Dl P 2 B pk Dl DK ˆ m 2 f e N a P 2 mN S rated a S rated 2 2 2 k w K a Bg , pk m 2 ( D l ) nm 120 60 proportional to power density 2mN a Nˆ a k w N a a D 2l 2 f e B g , pk k w K a P 2 I A,rated DK a nm P fe 120 where m k w K a Bg , pk 2 Defined as: magnetic shear stress Machine Size (3) 60 2 S rated D l 2 k w nm K a Bg , pk 2 Volume of Machine Discussions: The more advanced cooling technology (larger Ka), the smaller the volume. The larger the rated apparent power Srated, the larger the volume. The faster the machine speed nm , the smaller the volume. The larger the gap magnetic field Bg,pk (through using advanced materials with larger magnetic saturation, etc.), the smaller the volume. Generator Size - Experience 1 1 D 2l depends on cooling C0 , C0 2 2 f e m K a S rated P C0 1400 in 3 /MVA (air - cooled) C0 700 in 3 /MVA (hydrogen- cooled) C0 375 in 3 /MVA (liquid - cooled) fe = 60 Hz common steel Length/Diameter Ratio (1) The length/diameter ratio of a machine is defined as the ratio of the length and the stator bore diameter: rlD Discussions: l D For fixed mechanical speed, the machine power rating depends on D2l. •As the l/D increases, the rotor diameter decreases and thus the moment of inertia decreases. Also the rotor peripheral speed decreases. •As the l/D increases, the machine length increases and the rotor is prone to exhibit critical frequencies at lower speeds that can result in shaft flexure to the point that the rotor strikes the stator bore. • If the l/D is too large, it is difficult to cool. • If the l/D is too small, the leakage inductance of end turns can severely affects machine performance. Length/Diameter Ratio (2) Some people use aspect ratio, which is defined as the ratio of the length and the pole pitch: rasp l where P P D P We can find the relationship between aspect ratio and length/diameter ratio: rasp l P l P P rlD D Stator Core Diameter Stator Core diameter (outer diameter) D0 Two-pole: D0 2.1D Four-pole: D0 1.7 D Stator Slot Design s D S 0.4 s bs 0.6 s 3bs d s 7bs t s s bs Use 65 V/mil ground insulation Use 0.375-in slot wedge Use 0.125-in coil separator and top stick Stator Conductor Size I A,rated / C Js aAa where Aa is stator (armature) conductor cross section area and can be determined from the above formula together with: Air-cooled: J s 2500 A rms /in 2 Hydrogen-cooled: J s 4000 A rms /in 2 Water-cooled: J s 7000 A rms /in 2 1 A/in2 = 0.00155 A/mm2 J. J. Cathey, Electric Machines: Analysis and Design Applying MatLab, pp. 482, McGraw Hill, 2001. Round Wire Structure This figure shows the wire structure, including the bare conductor, an insulation layer and an optional bonding layer. dwb: bare conductor diameter dwc: covered wire diameter Awb: bare conductor cross section area Awc: covered conductor cross section area American Wire Gauge (AWG) d wb 8.251463 0.8905257 G Or d wb log 8.251463 G log 0.8905257 G: wire gauge (typically an integer) dwb: bare wire diameter in mm. Relative Wire Resistance versus Wire Gauge Increasing wire gauge by 1, increases copper loss by 26%. Decreasing wire gauge by 1, decreases copper loss to about 79% of the previous gauge. Current Capacity versus Wire Gauge The maximum allowable current density varies roughly between 1 Arms/mm2 to 10 Arms/mm2. In confined volumes, the lower limit 1Arms/mm2 may be too high. Similarly, with active cooling, the upper limit 10 Arms/mm2 may be too conservative. Round Wire with Film Insulation (1) Round Wire with Film Insulation (2) Square Wire with Film Insulation Air Gap Size From Ba , pk 4 0 Nˆ a 1.5 2 I A,rated g eff P g eff k c g An empirical formula for effective air gap size: g eff 4 0 Nˆ a 1.5 2 I A,rated Ba , pk P g g eff / k c The actual air gap size can be further tuned using an electromagnetic simulation software. Part 3 – Round Rotor Design for Generator with Field Winding Number of Poles For round rotor machine with field winding, take P = 2 or 4. Phasor Diagram EA jX S I A E A V jX s I A V IA Pick up torque angle (T full load =Tmaxsin ) and power factor pf cos . From X s I A cos E A sin E A K B X s I A , K B cos / sin Example: If =30 o , pf=0.85 lagging, K B 1.7. Steady E A K B X s I A B Steady K B f , pk B a , pk V E A cos X s I A sin ( K B cos sin ) X s I A Ba , pk B g , pk X sIA 1 V K B cos sin Rotor Slot Selection (1) total number of slots on rotor N r 2nr P nr is integer N slots on rotor per pole half : n r r 2P D r rotor pole pitch : r P pole width : 0.2 r W f 0.3 r Angular slot pitch (in elec. radian) : Dr PW f 1 P Dr PW f 2 2n r P ( Dr / 2) 2 2 Dr n r 2 Dr Arc length between two adjacentslots : t P rotor slot width : 0.4t b f 0.5t rotor toot h width : t f t b f Number of Conductors in Rotor (1) The length of the ith field coil:L fi 2(l W f i 2 Dr P ) Assume the number of conductors (Cf ) are the same in the each slot Total length of the field winding: Note: use single layer concentric winding on rotor. nr 2 Dr i 1 P LF C f P 2(l W f i ) Number of Conductors in Rotor (2) LF C f X f nr 2 Dr i 1 P where X f P 2(l W f i 0.7VF max I F ,rated ) 2nr P(l W f ) 2 Dr nr (nr 1) LF J f C f X f Af where Af is the cross section area of the field conductor, J f is the allowable current density, and is the resistivity of copper at working temperature. 0.7VF max Cf J f X f The calculated results will be rounded to an integer. Jf depends on rotor cooling. See next slide Rotor Cooling 1 A/in2 = 0.00155 A/mm2 Rotor Rated Field Current and Slot Size Empirical design requires maximum magnetic field from field winding is about KB times maximum magnetic field from armature winding: Steady B Steady K B f , pk B a , pk 4 0 Nˆ a Steady 1.5 2 I A,rated Ba , pk g eff P 4 0 kwf N f Steady B f , pk I geff P f ,rated I f ,rated K B 1.5 2 Nˆ a I A,rated 2.12 K B Nˆ a I A,rated kwf N f kwf N f where Nf is total number of series turns in field winding: kwf is rotor winding factor given is next page. rotor slot cross section area Af : Af I f ,rated Jf N f PC f nr Round Rotor Winding Factor This is the case when sr is even. sr 2nr nr kwf N cos[(2 1) 1 r nr N 1 If N1 N 2 N nr nr kwf cos[(2 1) 1 nr r / 2] / 2] Comprehensive Design Example Design a 3 phase turboalternator with the following specifications: 500 MVA Y connected 24 kV (terminal voltage) 60 Hz 3600 rpm 2 pole 0.85 pf lagging Maximum allowable rotor peripheral speed 50,000 ft/min for 20% overspeed Directly cooled stator (water) Directly cooled rotor (hydrogen) In the design, initially picked up 48 stator slots, 20 rotor slots 5/6 stator coil pitch Vfmax = 600V Not skewed Details in sgDesign.m Part 4 – Round Rotor Design for Surface Mount Permanent Magnet Generator Magnetic Circuit Analysis For a multi-pole surface mount rotor dm Da D g Poles gH g H m d m 0 gBg 0 H m d m 0 dm Bm Am g 0 H m Ag Bm Am Bg Ag Working Point for Permanent Magnetics (1) Maximum Energy Point B Br BmR 0 Hc 0 HmR Br B (H H c ) Hc To get (BH) max 0 H Br BH (H H c )H Hc ( BH ) Br Hc 0 Bm ,Hm H 2 2 Working Point for Permanent Magnetics (2) rm Br 0 H c 1 rm 1.2 Load Line: Bm d m Ag 0 H m g Am Pc 0 H m Define: Bm m Br H m (1 m ) H c Typically pick up: m 0.5 0.8 Pc is called permeance coefficient Ag / g d m Ag R m Pg Pc g Am Am / d m R g Pm Pc Bm m rm 0H m 1 m Airgap Magnetic Field from PM Rotor PM embrace: B g , rotor PM PM Bm Bm PM PM 2 2 B g , rotor h 1,3,5... 2 electrical angle PM 2 2 PM 2 2 de de B Rh B Rh B rh cos( h de ) B rh cos( h PM P d ) 2 PM /2 2 PM /2 B h d cos( ) ( Bm ) cos( h ae ) d ae m ae ae /2 /2 PM 2 PM sin h PM 4 2 Bm h Brh pitch factor for the hth harmonic k ph sin h PM 2 P d 2 Phasor Diagram EA jX S I A E A V jX s I A V IA Pick up torque angle (T full load =Tmaxsin ) and power factor pf cos . From X s I A cos E A sin E A K B X s I A , K B cos / sin Example: If =30 o , pf=0.85 lagging, K B 1.7. Steady E A K B X s I A B Steady K B f , pk B a , pk V E A cos X s I A sin ( K B cos sin ) X s I A Ba , pk B g , pk X sIA 1 V K B cos sin Air Gap Size and PM Thickness From: Ba , pk 4 0 Nˆ a 1.5 2 I A,rated gˆ total P Initial total effective air gap size: gˆ total From: gˆ total k c g 'total 4 0 Nˆ a 1.5 2 I A,rated Ba , pk P g 'total g d m / rm dm Pc g Pc Carter’s coefficient g (1 m ) g 'total d m m g 'total rm ( Ag Am ) m rm 1 m Effective Air Gap gˆ total kc g 'total where the Carter’s coefficient kc s 2 b s 0 bs 0 g ' total atan ln s 1 2 g ' total bs 0 2 b s 0 2 ' g total approximately kc s bs20 s 5 g ' total bs 0 ts g total bs0 s ds0ds1 ds