HVTECK SPECIFICATIONS

CSA HVTECK AL 3/C 90EPR TS PVC AIA PVC 5KV 100% 133%

PRODUCT HIGHLIGHTS

Southwire's 5KV HVTECK is a CSA approved armoured cable for industrial and commercial medium voltage applications. FT4, -40C, HL and 105°C rated for use in harsh Canadian

environments. Rated for installation in cable trays, duct banks, direct burial, troughs, continuous rigid cable supports, and concrete encaseable.

CONSTRUCTION

Conductor:

• Class B compact stranded 8000 Series aluminum ACM

Copper Tape Shield:

• Helically wrapped 5 mil copper tape with 25% overlap

Conductor Shield:

• Extruded semi-conducting thermosetting polymeric layer

• Class B compressed or compact stranded bare copper

Grounding Conductor:

- in accordance with ASTM B3 and B8

Insulation:

Fillers:

• Non-wicking, non-hygroscopic

• No-Lead EPR (ethylene propylene rubber)

• Thickness:

0.090" (2.3 mm) - nominal

• Insulation Level: 100% / 133% - ungrounded system

• 105°C rated

Print Legend:

• SOUTHWIRE [symbol - lightning bolt] #P# CSA 3/C

Inner Jacket:

[AWG 2 to 750 kcmil] CPT AL 90EPR AIA 5KV

100% / 133% INS LEVEL 25%TS, SUN RES 105°C FT4 HL

LTGG [-40°C] RoHS YEAR (NESC) SEQUENTIAL

METER MARKS

• Black PVC

Insulation Shield:

• Thickness:

- #2AWG to #2/0 AWG = 0.080" (2.0 mm)

- #3/0 AWG to 500 kcmil = 0.110" (2.8 mm)

- 750 kcmil = 0.145" (3.7 mm)

• Extruded semi-conducting thermosetting polymeric layer

• CSA 68.10 - Shield removal/termination requirements are

printed on the surface

• Phase identification as per ICEA Method 3, using printed

Overall Jacket:

• Orange PVC (optional colours available)

• Thickness:

- #2AWG to 4/0AWG kcmil = 0.060" (1.5 mm)

- 250 kcmil to 500 kcmil = 0.075" (1.9 mm)

- 750 kcmil = 0.085" (2.2mm)

Armour:

circuit numbers

• Meets requirement of ICEA, but built to CSA standards

• Aluminum Interlocked Armour (AIA)

• Optional Galvanized Steel Interlocked Armour (GSIA)

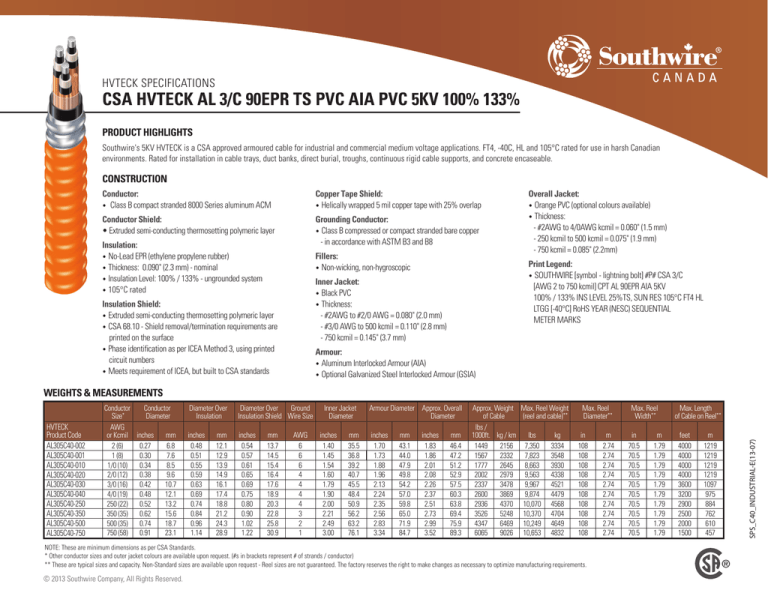

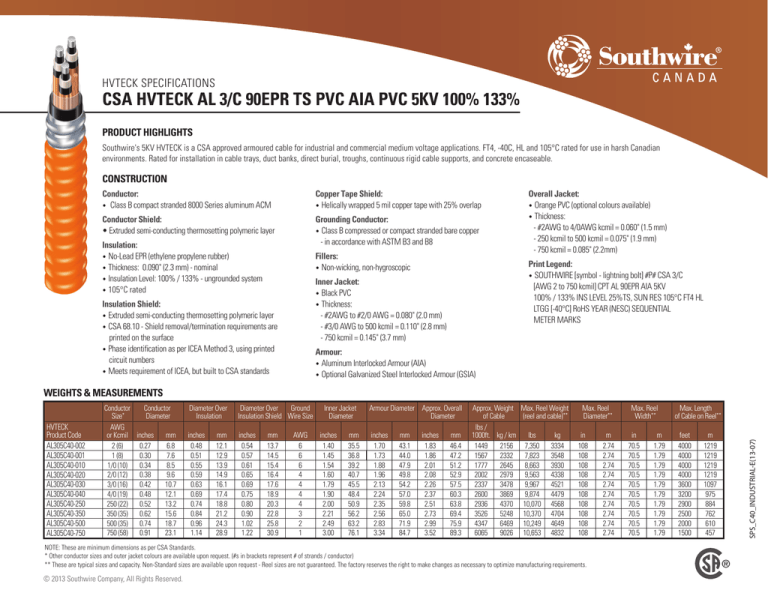

WEIGHTS & MEASUREMENTS

Diameter Over

Insulation

Diameter Over

Ground

Insulation Shield Wire Size

inches

0.48

0.51

0.55

0.59

0.63

0.69

0.74

0.84

0.96

1.14

inches

0.54

0.57

0.61

0.65

0.69

0.75

0.80

0.90

1.02

1.22

mm

12.1

12.9

13.9

14.9

16.1

17.4

18.8

21.2

24.3

28.9

mm

13.7

14.5

15.4

16.4

17.6

18.9

20.3

22.8

25.8

30.9

AWG

6

6

6

4

4

4

4

3

2

1

Inner Jacket

Diameter

inches

1.40

1.45

1.54

1.60

1.79

1.90

2.00

2.21

2.49

3.00

mm

35.5

36.8

39.2

40.7

45.5

48.4

50.9

56.2

63.2

76.1

Armour Diameter Approx. Overall

Diameter

inches

1.70

1.73

1.88

1.96

2.13

2.24

2.35

2.56

2.83

3.34

mm

43.1

44.0

47.9

49.8

54.2

57.0

59.8

65.0

71.9

84.7

inches

1.83

1.86

2.01

2.08

2.26

2.37

2.51

2.73

2.99

3.52

mm

46.4

47.2

51.2

52.9

57.5

60.3

63.8

69.4

75.9

89.3

Approx. Weight

of Cable

lbs /

1000ft. kg / km

1449

2156

1567

2332

1777

2645

2002

2979

2337

3478

2600

3869

2936

4370

3526

5248

4347

6469

6065

9026

Max. Reel Weight

(reel and cable)**

lbs

7,350

7,823

8,663

9,563

9,967

9,874

10,070

10,370

10,249

10,653

kg

3334

3548

3930

4338

4521

4479

4568

4704

4649

4832

Max. Reel

Diameter**

in

108

108

108

108

108

108

108

108

108

108

NOTE: These are minimum dimensions as per CSA Standards.

* Other conductor sizes and outer jacket colours are available upon request. (#s in brackets represent # of strands / conductor)

** These are typical sizes and capacity. Non-Standard sizes are available upon request - Reel sizes are not guaranteed. The factory reserves the right to make changes as necessary to optimize manufacturing requirements.

© 2013 Southwire Company, All Rights Reserved.

m

2.74

2.74

2.74

2.74

2.74

2.74

2.74

2.74

2.74

2.74

Max. Reel

Width**

in

70.5

70.5

70.5

70.5

70.5

70.5

70.5

70.5

70.5

70.5

m

1.79

1.79

1.79

1.79

1.79

1.79

1.79

1.79

1.79

1.79

Max. Length

of Cable on Reel**

feet

4000

4000

4000

4000

3600

3200

2900

2500

2000

1500

m

1219

1219

1219

1219

1097

975

884

762

610

457

SPS_C40_INDUSTRIAL-E(13-07)

HVTECK

Product Code

AL305C40-002

AL305C40-001

AL305C40-010

AL305C40-020

AL305C40-030

AL305C40-040

AL305C40-250

AL305C40-350

AL305C40-500

AL305C40-750

Conductor

Conductor

Size*

Diameter

AWG

or Kcmil inches

mm

2 (6)

0.27

6.8

1 (8)

0.30

7.6

1/0 (10)

0.34

8.5

2/0 (12)

0.38

9.6

3/0 (16)

0.42

10.7

4/0 (19)

0.48

12.1

250 (22)

0.52

13.2

350 (35)

0.62

15.6

500 (35)

0.74

18.7

750 (58)

0.91

23.1

HVTECK SPECIFICATIONS

CSA HVTECK AL 3/C 90EPR TS PVC AIA PVC 5KV 100% 133%

DESIGN

Qualification Standards:

• CSA C68.10 - Shielded Power Cables for Commercial and

Industrial Applications - 5 - 46 KV

• CSA C68.3 - Shielded & Concentric Neutral Power Cable 5 to 46 kV

• CSA C22.2 No. 174 - Cables in Hazardous Locations

• ICEA S-93-639 (NEMA WC 74) 5 to 46 kV - Shielded Power Cable

• AEIC CS-8 - Qualification Testing Requirements

Flame Test Ratings:

• FT1 - Flame Test (1,706 BTU/Hr nominal - Vertical Wire

Flame Test)

• FT4 - Flame Test (70,000 BTU/Hr - Vertical Tray Flame Test)

• IEEE 1202 - Flame Test (70,000 BTU/Hr - Vertical Tray Test)

• IEEE 383 - Flame Test (70,000 BTU/Hr)

• ICEA T-29-520 - Vertical Cable Tray Flame Test (210,000 BTU/Hr)

Product Ratings:

• CSA C22.2 No. 2556 & No. 0.3. - Wire and Cable Test Methods

• CSA LTGG [-40°C] - as per C68.10 - for Cold Bend and

Impact rating

• CSA HL - for Hazardous Locations rating

• CSA FT4 - for Flame Retardancy rating

• CSA SUN RES - for Sunlight Resistant rating

ALUMINUM CONDUCTOR

Operating Temperatures:

• -40°C - CSA Cold Bend and Impact Temp.

• -25°C - Min. Installation Temp.

• 105°C - Max. Continuous Operating Temp.

• 140°C for Emergency Overload Temp.

• 250°C for Short Circuit Temp.

INSULATION

CONDUCTOR SHIELD

INSULATION SHIELD

COPPER TAPE SHIELD

POLY TAPE

GROUND CONDUCTOR

INNER PVC JACKET

FILLER

ALUMINUM INTERLOCK ARMOUR

End View

OVERALL PVC JACKET

Conductor

Size*

HVTECK

Product Code

AL305C40-002

AL305C40-001

AL305C40-010

AL305C40-020

AL305C40-030

AL305C40-040

AL305C40-250

AL305C40-350

AL305C40-500

AL305C40-750

AWG

or Kcmil

2 (6)

1 (8)

1/0 (10)

2/0 (12)

3/0 (16)

4/0 (19)

250 (22)

350 (35)

500 (35)

750 (58)

Minimum

Bend Radius

inches

12.8

13.0

14.1

14.6

15.8

16.6

17.6

19.1

20.9

24.6

mm

324

331

358

370

402

422

447

486

532

625

Maximum

Pulling Tension

AC Resistance Rac

DC Resistance Rdc Ratios @ 90°C & 60Hz

@ 25°C

(each conductor)

Ω/

lbs Newtons 1000ft

1194

5313

0.2650

1506

6701

0.2110

1901

8455

0.1680

2396 10657 0.1330

3020 13435 0.1050

3809 16942 0.0836

4500 20017 0.0707

6300 28024 0.0505

9000 40034 0.0354

13500 60051 0.0236

Ω/

km

0.8695

0.6923

0.5512

0.4364

0.3445

0.2743

0.2320

0.1657

0.1161

0.0774

Ω/

1000ft

0.3350

0.2660

0.2110

0.1670

0.1330

0.1070

0.0908

0.0654

0.0472

0.0333

Ω/

km

1.0991

0.8727

0.6923

0.5479

0.4364

0.3511

0.2979

0.2146

0.1549

0.1093

* Other conductor sizes and outer jacket colours are available upon request. (#s in brackets represent # of strands / conductor)

† Ampacities are based on Table 4 of the 2012 Canadian Electrical Code Part I (30°C Ambient Temperature)

‡ Ampacities are based on Table D13A and Detail 1 of Diagram B4-3 of the 2012 Canadian Electrical Code Part I

© 2013 Southwire Company, All Rights Reserved.

Inductance

L

mH/

1000ft

0.0928

0.0900

0.0872

0.0846

0.0821

0.0799

0.0791

0.0762

0.0735

0.0713

mH/

km

0.3046

0.2953

0.2860

0.2776

0.2695

0.2621

0.2595

0.2500

0.2412

0.2340

Capacitance (each

phase conductor)

C

µF/

1000ft

0.0849

0.0924

0.1012

0.1108

0.1219

0.1342

0.1393

0.1609

0.1879

0.2177

µF/

km

0.2787

0.3031

0.3321

0.3634

0.4000

0.4404

0.4570

0.5280

0.6166

0.7142

Inductive Reactance Capacitive Reactance Short Circuit

(each phase

@60Hz

Current (each

conductor)

XC

Φ conductor)

XL

(wrt grounded shield)

@60Hz

Ω/

1000ft

0.0350

0.0339

0.0329

0.0319

0.0310

0.0301

0.0298

0.0287

0.0277

0.0269

Ω/

km

0.115

0.111

0.108

0.105

0.102

0.099

0.098

0.094

0.091

0.088

MΩ•

1000ft

0.0312

0.0287

0.0262

0.0239

0.0218

0.0198

0.0190

0.0165

0.0141

0.0122

MΩ•

km

0.0095

0.0088

0.0080

0.0073

0.0066

0.0060

0.0058

0.0050

0.0043

0.0037

Amps

2940

3707

4678

5896

7434

9374

11075

15505

22150

33225

Allowable

Ampacities in

Raceway or

Cable†

Allowable

Ampacities

Directly Buried

in Earth‡

Amps

100

115

135

150

175

205

230

280

350

435

Amps

~

~

190

217

242

280

304

366

440

540

SPS_C40_INDUSTRIAL-E(13-07)

SLS_15KV PRIMARY

UD_ENERGY-E(12-09)

TABLE 2 - ENGINEERING SPECIFICATIONS