ABTQ-103 rev 01

advertisement

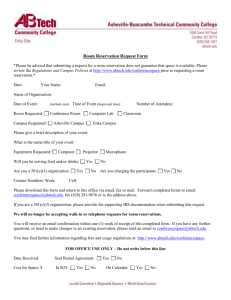

ABTQ-103 rev 01 Last review: 21-02-12 INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS FOR ABTECH ‘PCS’ Control Station Purpose of Instructions • • • Working in hazardous areas, the safety of personnel and plant depends on complying with all relevant safety regulations. Installation and maintenance personnel working on installed product have a particular responsibility to ensure any applicable standards and regulations are complied with. These instructions give a brief summary of the most important safety measures. It should be read in conjunction with the product certificate and any applicable national and local regulations. Safety Instructions • • • • • • The PCS control station should be used only for its intended purpose. PCS control stations are not suitable for Zone 0 hazardous areas! No alterations to the apparatus is permitted. The PCS control station should not be used if damaged Any damage may invalidate the Ex protection. Observe the following during installation and operation: o Any relevant National safety regulations; o Local safety regulations: o International installation regulations(e.g. IEC 60079-14); o The following installation instructions contained in this manual o Any values or instruction printed on the apparatus label. The PCS control stations are designed, manufactured and tested in accordance with ISO 9001. The PCS control stations complies the following standards: IEC60079-0:2004 EN60079-0:2006 IEC60079-1:2003 EN60079-1:2004 IEC60079-7:2001 EN60079-7:2003 IEC61241-0:2004 EN61241-0:2006 IEC 61241-0:2004 EN61241-0:2006 Applicable Scope The function of the apparatus is based on the performance and use of built-in components. The permissible Ex components can be used as following: • CZ0201 Series Explosion-proof switch module. This module can be used in the PCS control station when installed in a circuit where rated working voltage is AC250V (+28%) or below to control electromagnetic starter, contactor, relay and other electric circuits. • CZ0202 Series Explosion-proof signal lamp. Lamp modules can be used in the PCS control station where working voltage is AC24240V or DC24-36V. The correct module should be chosen for the applicable working voltage. • CZ0205 Series Explosion-proof ammeter module. The ammeter module can be used to measure or display the current in an ac circuit. Technical Data • Coding: o • • • • • • Control station with ammeter only: II 2GD Ex e IIC T6/Ex tD A21 IP66 T80ºC -40°C≤Tamb≤40°C II 2GD Ex de IIC T6/Ex tD A21 IP66 T80ºC -40°C≤Tamb≤40°C o Control station(except with ammeter only): Certificate no.: DNV 12 ATEX 13746 Degree of protection: IP66 Ambient temperature: -40°C≤Tamb≤40°C Material of enclosure: Polyamide Tightening torque for cover screws: 2.0Nm Internal earthing: Terminal 2x 2.5mm² (tightening torque: 1.1Nm) Abtech Limited, Sheffield, S9 2UA, United Kingdom www.abtech.eu 1/5 ABTQ-103 rev 01 Last review: 21-02-12 • Main technical data of built-in Ex components: o CZ0201 Series Explosion-proof switch module Ex- mark: G ll 2G Ex de llC Test certificate: IECEx CQM 08.0005U DNV-2008-0SL-ATEX-21657U Degree of protection : IP20 Rated voltage: 250V; Rated current: 16A max. Rated insulation voltage: 690V Rated withstand voltage: 6KV (Uimp) Conventional closed heating current: -55ºC≤Ta≤40°C - Ithe16A; -55ºC≤Ta≤60ºC - Ithe - 10A Breaking capacity: Rated voltage 250V 250V 110V 24V Utilisation category: AC12 AC15 DC13 DC13 Rated current: 16A 10A 0.5A 1A Contact type: 1N0+1NC, 2NC, 2N0 6 Mechanical life: 10 times (3600/h) Connection type: Terminal 2 x 2.5mm²(With spring washer). Terminal material 304 stainless Connecting lead: 2 x 2.5mm² (tightening torque: 1.1Nm) o CZ0202 Series Explosion-proof signal lamp module Ex- mark: G ll 2G Ex de llC Test certificate: IECEx CQM 08.0006U DNV-2008-0SL-ATEX-21658U Degree of protection : IP20 Rated insulation voltage: 300V; Rated service voltage: AC24 ~ 240V DC24 ~ 36V 5 Electrical life: 10 working hours Ambient temperature: -55ºC≤Ta≤60ºC Connection type: Terminal 2 x 2.5mm²(With spring washer). Terminal material 304 stainless Connecting lead: 2 x 2.5mm² (tightening torque: 1.1Nm) o CZ0205 Series Explosion-proof ammeter module Ex- mark: G ll 2G Ex e ll Test certificate: IECEx CQM 08.0007U DNV-2008-0SL-ATEX-21659U Rated insulation voltage: 690V Accuracy class: 1.5 Operation type: Electromagnetic Ambient temperature: -40ºC≤Ta≤60ºC Connection type: Terminal 2 x 2.5mm²(With spring washer). Terminal material 304 stainless Connecting lead: 2 x 2.5mm² (tightening torque: 1.2Nm) o P/K/L Switch Operators Ex- mark: G ll 2GD Ex e ll Ex tD A21 Test certificate: IECEx CQM 08.0012U DNV-2008-0SL-ATEX-46028U Degree of protection: IP66 Ambient temperature: -40ºC≤Ta≤55ºC Tightening torque: 5Nm (operator retaining nut) o Cable Glands: Certification level: Degree of protection: Ambient temperature: Tightening torque: G ll 2GD Ex e ll Ex tD A21 (Atex certified) IP66 -40ºC≤Ta≤55ºC M20 x 1.5p – 3.0Nm; M25 x 1.5p – 4.0Nm Abtech Limited, Sheffield, S9 2UA, United Kingdom www.abtech.eu 2/5 ABTQ-103 rev 01 Last review: 21-02-12 PCS Control Station Dimensions PCS01 PCS02 PCS03 PCS05 PCS06 - PCS01 95 X 86 x 76 135 x 86x 76 175x86x 76 175x 100 x 76 215x 100 x 76 PCS02 PCS03 PCS05 PCS06 PCS51 Type P1 P2 P3 P4 Y0 Y1 Operator Pushbutton (rubber) Double Pushbutton (Rubber) Emergency Stop Black Mushroom Head Red Mushroom Head (key) Pushbutton (key) L (mm) 15.5 15.5 41.2 41.2 24.0 28.0 Type K4 – K8 S4 – S8 L P/B1 DW EXM Operator Selector Switch (small) Selector Switch (large) Signal Lamp Bezel Illuminated Pushbutton/Stopping Plug Potentiometer Head Ammeter Window L = Height of operator head from front face of control station (mm) Abtech Limited, Sheffield, S9 2UA, United Kingdom www.abtech.eu 3/5 L (mm) 30.5 30.5 22.6 17.5 30.5 12.0 ABTQ-103 rev 01 Last review: 21-02-12 Operation & Installation • Transport and storage in original packaging only. Any national or local safety and/or installation regulations and good engineering practice must be observed when mounting and operating this equipment. • The user shall observe the following conditions in order to ensure the safe operation of the PCS control station. o The Abtech PCS control station is suitable for use in hazardous areas, zone 1, 2 and 21, 22. o The Abtech PCS control station should be used under the following atmospheric/ambient conditions: The pressure is 80kPa(0.8bar)-110kPa(1.1bar) The volume ratio of standard oxygen content is 21% air; The Ambient relative humidity is less than: 95%; The PCS control station is designed for use subjected to normal industrial levels of vibration. It should not be mounted such that it is exposed to excessive levels of vibration or shock. o Conductors must be connected with due care, e.g. multi stranded conductors should be fitted with a ferrule o Insulation must be stripped back no more than 1mm from throat of terminal; o Damaged conductors or conductors with damaged insulation should not be used; o All screws, used and unused, on the connection terminals, must be fully tightened. This should be checked prior to commissioning; o The earth conductor should be at least the same cross sectional area as the live conductors; o It is the users responsibility to ensure the IP rating of the apparatus is maintained; o Caution: de-energize before opening! • Cable gland & stopping plug o Only certified cable glands and stopping plugs should be used with this apparatus. o If a cable gland or stopping plug with degree of protection lower than IP66 is used, the IP rating of the apparatus will be reduced to that of the entry device. (Cable gland or stopping plug must have minimum IP rating: IP54) o The installation, operation and maintenance instructions applicable to the cable gland or stopping plug must be adhered to. o Ensure that the cable gland, appropriate for the cable diameter and type is used. o Unused operator holes and cable entry holes must be closed with a certified blanking plug appropriate for the hole diameter in order to ensure the required minimum protection category. o IMPORTANT: Cable glands and stopping plugs should be tightened according to the manufacturers instructions. Care should be taken not to over tighten of cable glands or blanking plugs as this may impair the ingress protection properties of the device. Component Installation Contact Block/Lamp Module The required contact block/lamp module (item 1) should be snapped onto the plastic rail moulded into the body (item 2) ensuring that it clicks into one of the spacing slots. Plastic Moulded Earth Terminal Plastic earth terminal (item 3) can be fitted to either the top or bottom of the enclosure (item 2) Metal Earth Plate Where metallic cable glands or stopping plugs are used they should be fitted to the metal earth plate (item 4) The metal earth plate is threaded to suit the appropriate cable gland or stopping plug. Combining Enclosures It is permissible to join two enclosures together using the connecting bolt (item 5) and locknut (item 6). Corresponding 25mm diameter holes should be drilled in the adjoining faces of the enclosures to be connected and the seal (item 7) clamped between the two enclosures. Abtech Limited, Sheffield, S9 2UA, United Kingdom www.abtech.eu 4/5 ABTQ-103 rev 01 Last review: 21-02-12 Installation of Operator/Lamp Bezel The operator/lamp bezel (item 8) should be fitted to the cover, ensuring that the tab on the operator is aligned with the keyway in the cover hole. The locknut (item 10) should be fitted to the rear of the operator and tightened using the appropriate socket spanner (item 9) to the recommended torque of 5Nm. Ensure that the actuating pins of the operator align with the plungers in the contact block or the lamp bezel aligns with the lamp module. Operator Label The labels (item 11) fitted to the operator heads may be changed by placing screwdriver or other implement behind label and levering off. New label is push into slots. Tag Labels Tag labels may be fitted to the top of the enclosure as shown. IP Cover Key operated pushbuttons may be supplied with an IP cover which should be replaced when the key is not being used in order to maintain the IP rating of the enclosure. Components and Spare Parts Only, operators, bezels, contact blocks and lamp modules supplied by Abtech should be fitted to the PCS control stations. Similarly, only spare parts supplied by Abtech should be used. Maintenance The conditions of certification and any special conditions for safe use, noted in the certificate should be strictly adhered to, along with the instructions laid down in this manual. The apparatus must be de-energised prior to removing the cover or replacing any parts. This work must be carried out by a competent person. The following should be checked during maintenance: • Check for compliance of the apparatus with respect to ambient temperatures. • Check for any damage to seals and gaskets. • Check for any damage to contact block/lamp module and operator head/lamp bezel. • Check contact block/lamp module is securely positioned in enclosure • Check contact block/lamp module terminals for tightness • Check condition of conductors and wiring insulation • Check earth connection • Check cable glands/stopping plugs as per manufacturers recommendations. • Clean exterior of enclosure with a damp cloth to remove any build up of dust. Disposal/Recycling Any local or national regulations regarding the disposal of this equipment should be adhered to. For further information please contact Abtech technical department. Abtech Limited, Sheffield, S9 2UA, United Kingdom www.abtech.eu 5/5