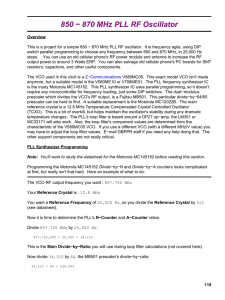

LMK61E2 Ultra-Low Jitter Programmable Clock Oscillator with

advertisement