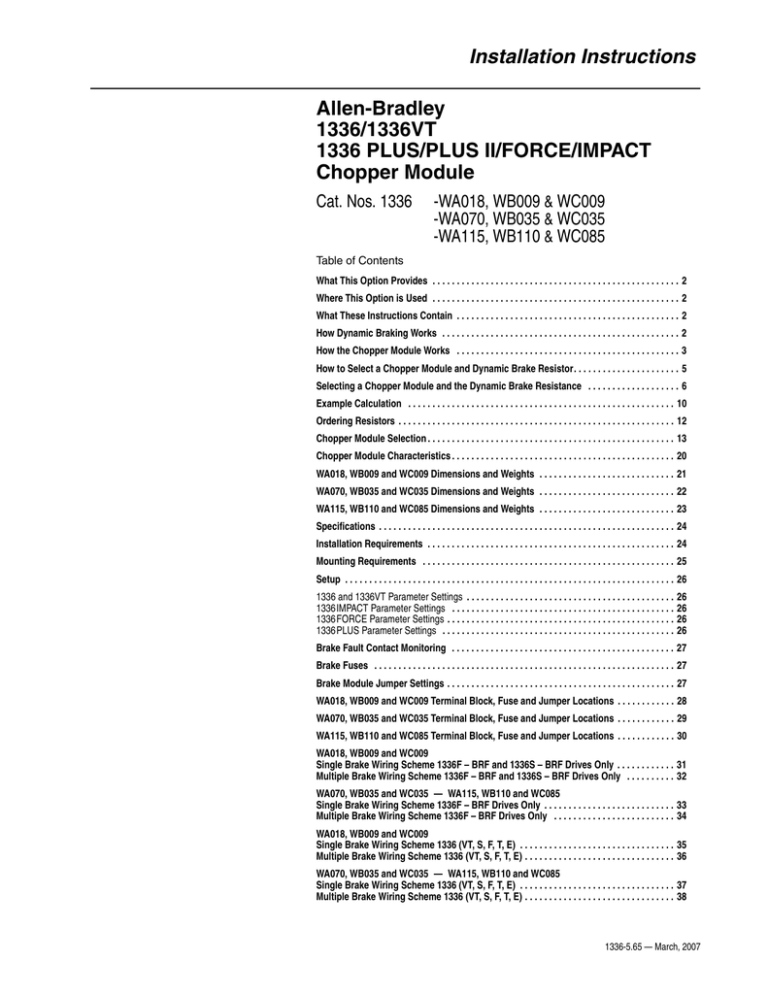

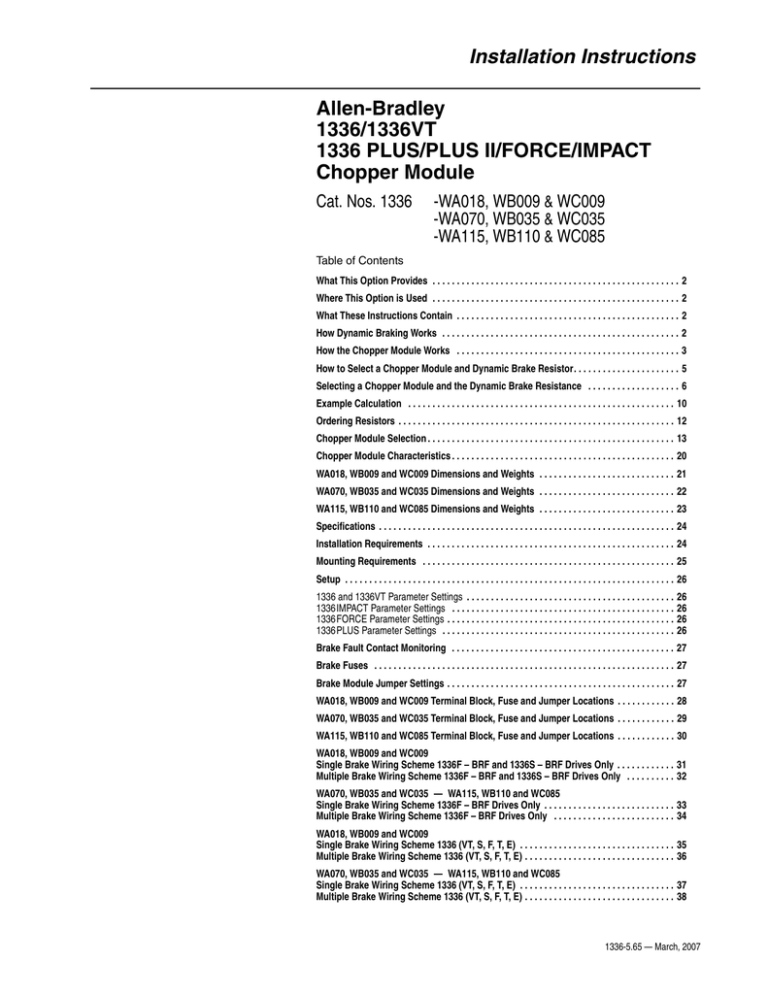

Installation Instructions

Allen-Bradley

1336/1336VT

1336 PLUS/PLUS II/FORCE/IMPACT

Chopper Module

Cat. Nos. 1336

-WA018, WB009 & WC009

-WA070, WB035 & WC035

-WA115, WB110 & WC085

Table of Contents

What This Option Provides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Where This Option is Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

What These Instructions Contain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

How Dynamic Braking Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

How the Chopper Module Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

How to Select a Chopper Module and Dynamic Brake Resistor. . . . . . . . . . . . . . . . . . . . . . 5

Selecting a Chopper Module and the Dynamic Brake Resistance . . . . . . . . . . . . . . . . . . . 6

Example Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ordering Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chopper Module Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chopper Module Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

WA018, WB009 and WC009 Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

WA070, WB035 and WC035 Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

WA115, WB110 and WC085 Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Mounting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1336 and 1336VT Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1336IMPACT Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1336FORCE Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1336PLUS Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26

26

26

26

Brake Fault Contact Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Brake Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Brake Module Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

WA018, WB009 and WC009 Terminal Block, Fuse and Jumper Locations . . . . . . . . . . . . 28

WA070, WB035 and WC035 Terminal Block, Fuse and Jumper Locations . . . . . . . . . . . . 29

WA115, WB110 and WC085 Terminal Block, Fuse and Jumper Locations . . . . . . . . . . . . 30

WA018, WB009 and WC009

Single Brake Wiring Scheme 1336F – BRF and 1336S – BRF Drives Only . . . . . . . . . . . . 31

Multiple Brake Wiring Scheme 1336F – BRF and 1336S – BRF Drives Only . . . . . . . . . . 32

WA070, WB035 and WC035 — WA115, WB110 and WC085

Single Brake Wiring Scheme 1336F – BRF Drives Only . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Multiple Brake Wiring Scheme 1336F – BRF Drives Only . . . . . . . . . . . . . . . . . . . . . . . . . 34

WA018, WB009 and WC009

Single Brake Wiring Scheme 1336 (VT, S, F, T, E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Multiple Brake Wiring Scheme 1336 (VT, S, F, T, E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

WA070, WB035 and WC035 — WA115, WB110 and WC085

Single Brake Wiring Scheme 1336 (VT, S, F, T, E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Multiple Brake Wiring Scheme 1336 (VT, S, F, T, E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1336-5.65 — March, 2007

2

Heavy Duty Dynamic Braking

What This Option Provides

The brake chopper module is an open style assembly that together with

customer supplied braking resistors can increase the braking torque

capability of a 1336, 1336VT, 1336PLUS, 1336PLUSII, 1336FORCE or

1336IMPACT drive from approximately 10 to 100%.

Where This Option is Used

B003-B250 and C003-C250 1336 Drives.

B003-B250 1336VT Drives.

AQF05-A125, BRF05-B600 and CWF10-C600 1336PLUS and

1336PLUSII Drives.

A001-A125, B001-B600 and C001-C650 1336FORCE and 1336IMPACT

Drives.

1336 — W

B

009

1336

1336VT

1336PLUS

1336PLUS II

1336FORCE

Brake Chopper Module

Voltage Rating

Continuous Amp Rating

A = 230VAC

018 = 375VDC, 18.0ADC

070 = 375VDC, 70.0ADC

115 = 375VDC, 115.0ADC

B = 380/415/460VAC 009 = 750VDC, 9.0ADC

035 = 750VDC, 35.0ADC

110 = 750VDC, 110.0ADC

C = 575VAC

What These Instructions

Contain

009 = 935VDC, 9.0ADC

035 = 935VDC, 35.0ADC

085 = 935VDC, 85.0ADC

These instructions contain the necessary information to select, configure

and install dynamic braking. By completing Selecting a Chopper Module

and the Maximum Dynamic Brake Resistance first you will be able to

determine:

1. Whether or not dynamic braking is required for your application.

2. If dynamic braking is required, the rating and quantity of chopper

modules required as well as the size and type of braking resistors

required.

How Dynamic Braking Works

When an induction motor’s rotor is turning slower than the synchronous

speed set by the drive’s output power, the motor is transforming electrical

energy obtained from the drive into mechanical energy available at the drive

shaft of the motor. This process is referred to as motoring. When the rotor

is turning faster than the synchronous speed set by the drive’s output power,

the motor is transforming mechanical energy available at the drive shaft of

the motor into electrical energy that can be transferred back into the utility

grid. This process is referred to as regeneration.

Most AC PWM drives convert AC power from the fixed frequency utility

grid into DC power by means of a diode rectifier bridge or controlled SCR

bridge before it is inverted into variable frequency AC power. Diode and

SCR bridges are cost effective, but can only handle power in the motoring

direction. Therefore, if the motor is regenerating, the bridge cannot conduct

1336-5.65 — March, 2007

Heavy Duty Dynamic Braking

3

the necessary negative DC current, the DC bus voltage will increase and

cause a Bus Overvoltage trip at the drive.

Expensive bridge configurations use SCRs or transistors that can transform

DC regenerative electrical energy into fixed frequency utility electrical

energy. A more cost effective solution is to provide a Transistor Chopper

on the DC Bus of the AC PWM drive that feeds a power resistor which

transforms the regenerative electrical energy into thermal energy. This is

generally referred to as Dynamic Braking.

How the Chopper Module

Works

Figure 1 shows a simplified schematic of a Chopper Module with Dynamic

Brake Resistor. The Chopper Module is shown connected to the positive

and negative conductors of an AC PWM Drive. The two series connected

Bus Caps are part of the DC Bus filter of the AC Drive.

A Chopper Module contains five significant power components:

Protective fuses are sized to work in conjunction with a Crowbar SCR.

Sensing circuitry within the Chopper Transistor Voltage Control determines

if an abnormal conditions exist within the Chopper Module, such as a

shorted Chopper Transistor. When an abnormal condition is sensed, the

Chopper Transistor Voltage Control will fire the Crowbar SCR, shorting

the DC Bus, and melting the fuse links. This action isolates the Chopper

Module from the DC Bus until the problem can be resolved.

The Chopper Transistor is an Insulated Gate Bipolar Transistor (IGBT). The

Chopper Transistor is either ON or OFF, connecting the Dynamic Brake

Resistor to the DC Bus and dissipating power, or isolating the resistor from

the DC Bus. There are several transistor ratings that are used in the various

Chopper Module ratings. The most important rating is the collector current

rating of the Chopper Transistor that helps to determine the minimum ohmic

value used for the Dynamic Brake Resistor.

Chopper Transistor Voltage Control (hysteretic voltage comparator)

regulates the voltage of the DC Bus during regeneration. The average values

of DC Bus voltages are:

• 375V DC (for 230V AC input)

• 750V DC (for 460V AC input)

• 937.5V DC (for 575V AC input)

Voltage dividers reduce the DC Bus voltage to a value that is usable in signal

circuit isolation and control. The DC Bus feedback voltage from the voltage

dividers is compared to a reference voltage to actuate the Chopper

Transistor.

The Freewheel Diode (FWD), in parallel with the Dynamic Brake Resistor,

allows any magnetic energy stored in the parasitic inductance of that circuit

to be safely dissipated during turn off of the Chopper Transistor.

1336-5.65 — March, 2007

4

Heavy Duty Dynamic Braking

Figure 1

Schematic of Chopper Module and Dynamic Brake Resistor

+ DC Bus

Fuse

Bus Caps

FWD

To

Voltage Dividers

Voltage

Divider

Dynamic

Brake

Resistor

To

Voltage

Control

Signal

Common

Chopper

Transistor

FWD

Chopper Transistor

Voltage Control

Crowbar

SCR

Voltage

Divider

Fuse

To

Crowbar

SCR Gate

To

Voltage

Control

Bus Caps

To

Voltage

Control

– DC Bus

Chopper Modules are designed to be applied in parallel if the current rating

is insufficient for the application. One Chopper Module is the designated

Master Chopper Module, while any other Modules are the designated

Follower Modules.

Two lights are provided on the front of the enclosure to indicate operation.

• DC Power light illuminates when DC power has been applied to the

Chopper Module.

• Brake On light flickers when the Chopper Module is operating

(chopping).

1336-5.65 — March, 2007

Heavy Duty Dynamic Braking

How to Select a Chopper

Module and Dynamic Brake

Resistor

5

As a rule, a Chopper Module can be specified when regenerative energy is

dissipated on an occasional or periodic basis. In general, the motor power

rating, speed, torque, and details regarding the regenerative mode of

operation will be needed in order to estimate what Chopper Module rating

and Dynamic Brake Resistor value to use. If a drive is consistently operating

in the regenerative mode of operation, serious consideration should be given

to equipment that will transform the electrical energy back to the fixed

frequency utility.

In order to select the appropriate Chopper Module and Dynamic Brake

Resistor for your application, the following data must be calculated.

Peak Regenerative Power of the Drive (Expressed in watts of power.)

This value is used to determine:

• The minimum current rating of the Chopper Module

Choose the actual current rating from the selection tables.

• The estimated maximum ohmic value of the Dynamic Brake Resistor

If this value is greater than the maximum imposed by the peak

regenerative power of the drive, the drive can trip off due to transient

DC Bus overvoltage problems.

Minimum Dynamic Brake Resistance

If a Dynamic Brake Resistance value that is less than the minimum imposed

by the choice of the Chopper Module is applied, damage can occur to the

Chopper Transistor.

Dynamic Brake Resistor’s Allowable Ohmic Value Range

(Use the Chopper Module current rating to determine this range.)

These values range between the minimum value set by the Chopper

Transistor current rating and the maximum value set by the peak

regenerative power developed by the drive in order to decelerate or satisfy

other regenerative applications.

Wattage Rating of the Dynamic Brake Resistor

This rating is estimated by applying what is known about the drive’s

motoring and regenerating modes of operation. The average power

dissipation of the regenerative mode must be estimated and the wattage of

the Dynamic Brake Resistor chosen to be greater than the average

regenerative power dissipation of the drive.

Dynamic Brake Resistors with large thermodynamic heat capacities,

defined as thermal time constants less than 5 seconds, are able to absorb a

large amount of energy without the temperature of the resistor element

exceeding the operational temperature rating. Thermal time constants in

the order of 50 seconds and higher satisfy the criteria of large heat capacities

for these applications. If a resistor has a small heat capacity, the temperature

of the resistor element could exceed maximum temperature limits during

the application of pulse power to the element.

1336-5.65 — March, 2007

6

Heavy Duty Dynamic Braking

Selecting a Chopper Module

and the Maximum Dynamic

Brake Resistance

The following calculations are demonstrated using The International

System of Units (SI).

Gather the following information:

• Power rating from motor nameplate in watts, kilowatts, or horsepower

• Speed rating from motor nameplate in rpm or rps (radians per second)

• Motor inertia and load inertia in kg-m2 or lb-ft2

• Gear ratio (GR) if a gear is present between the motor and load

• Motor shaft speed, torque, and power profile of the drive application

Figure 2 shows the speed, torque, and power profiles of the drive as a

function of time for a particular cyclic application that is periodic over t4

seconds. The desired time to decelerate is known or calculable and is within

the drive performance limits. In Figure 2, the following variables are

defined:

ω(t) = Motor shaft speed in radians per second (rps)

ω✕

2πN

Rad

=

60

s

N(t)

= Motor shaft speed in Revolutions Per Minute (RPM)

T(t)

= Motor shaft torque in Newton-meters

1.0 lb-ft = 1.355818 N-m

P(t)

= Motor shaft power in watts

1.0 HP = 746 watts

-Pb

1336-5.65 — March, 2007

= Motor shaft peak regenerative power in watts

Heavy Duty Dynamic Braking

7

Figure 2

Application Speed, Torque and Power Profiles

ω(t)

ωb

ωo

0

t1

t2

t3

t4

t 1 + t4

t

0

t1

t2

t3

t4

t 1 + t4

t

t1

t2

t3

t4

t 1 + t4

t

T(t)

P(t)

0

-Pb

1336-5.65 — March, 2007

8

Heavy Duty Dynamic Braking

Step 1 — Determine Gear Ratio

Turns of Load

Turns of Motor

GR=

GR = _________

Step 2 — Determine the Total Inertia

JT = Jm + GR2 ✕ JL

JT

= Total inertia reflected to the motor shaft (kg-m2 or lb-ft2)

Jm = Motor inertia (kg-m2 or lb-ft2)

GR = Gear ratio of any gear between motor and load

(dimensionless)

JL

JT = [

+

= Load inertia (kg-m2 or lb-ft2)

1.0 lb-ft2 = 0.04214011 kg-m2

]✕[

JT = __________ kg-m2 or lb-ft2

]

Step 3 — Calculate the Peak Braking Power

Pb =

JT ✕ ωb (ωb - ωo)

(t3 - t2)

JT

= Total inertia reflected to the motor shaft (kg-m2)

ωb = Rated angular rotational speed (Rad / s = 2πNb / 60)

ωo = Angular rotational speed,

Nb

less than rated speed down to zero (Rad / s)

= Rated motor speed (RPM)

t3 - t2 = Deceleration time from ωb to ωo (seconds)

Pb

Pb =

= Peak braking power (watts)

1.0 HP = 746 watts

[

✕

[

(

–

)]

]

Pb = __________watts

Compare the peak braking power to that of the rated motor power. If the

peak braking power is greater that 1.5 times that of the motor, then the

deceleration time (t3 - t2) needs to be increased so that the drive does not

go into current limit.

1336-5.65 — March, 2007

Heavy Duty Dynamic Braking

9

Step 4 — Calculate the Maximum Dynamic Brake Resistance Value

Vd 2

Rdb1 =

Rdb1 = Maximum allowable value for the dynamic brake

resistor (ohms)

Vd = DC Bus voltage the chopper module regulates to

(375V DC, 750V DC, or 937.5V DC)

Pb = Peak braking power calculated in Step 2 (watts)

Pb

[

Rdb1 =

]

✕

[

]

Rdb1 = _________ ohms

The choice of the Dynamic Brake resistance value should be less than the

value calculated in Step 4. If the resistance value is greater than the value

calculated in Step 4, the drive can trip on DC Bus overvoltage.

Step 5 — Calculate the Minimum Chopper Module Current Rating

Id1 =

Vd

Id1

= Minimum current flow through Chopper Transistor

Rdb1

Vd

= Value of DC Bus voltage chosen in Step 3

Rdb1 = Value of Dynamic Brake Resistor calculated in Step 3

Id1 =

[

[

]

]

Id1 = __________ amps

The value of Id1 sets the minimum current rating for the Chopper Module.

When choosing a Chopper Module, the current rating for the Chopper

Transistor must be greater than or equal to the value calculated for Id1.

Step 6 — Calculate the Minimum Dynamic Brake Resistor Value

Rdb2 =

Rdb2 =

Rdb2 = Minimum ohmic value of the Dynamic Brake Resistor

Vd

0.75 ✕ Id2

[

[

]

]

Vd

= Value of DC Bus voltage chosen in Step 3

Id2

= Value of Chopper Module current rating

Rdb2 = __________ ohms

This step calculates the minimum resistance value that the Dynamic Brake

Resistor can have. If a lower resistance were to be used with the Chopper

Module of choice, the IGBT could be damaged from overcurrent.

1336-5.65 — March, 2007

10

Heavy Duty Dynamic Braking

Step 7 — Choose the Dynamic Brake Resistance Value

Use to Table 1a, 2a, or 3a to choose the correct table based on the Chopper

Module’s regulating voltage.

1. Find the column that lists the value of Dynamic Brake Resistance for

the various Dynamic Brake Resistor assemblies.

2. Choose the resistor value that lies between Rdb1 and Rdb2.

Preferred resistance values are as close Rdb1 as possible.

Step 8 — Estimate the Minimum Wattage Requirements for the Dynamic

Brake Resistor

It is assumed that the application exhibits a periodic function of acceleration

and deceleration. If (t3 - t2) equals the time in seconds necessary for

deceleration from rated speed to 0 speed, and t4 is the time in seconds before

the process repeats itself, then the average duty cycle is (t3 - t2)/t4. The

power as a function of time is a linearly decreasing function from a value

equal to the peak regenerative power to 0 after (t3 - t2) seconds have elapsed.

The average power regenerated over the interval of (t3 - t2) seconds is Pb/2.

The average power in watts regenerated over the period t4 is:

Pav =

[t3 - t2]

t4

✕

Pb

2

(

ωb + ωo

ωb

)

Pav = Average dynamic brake resister dissipation (watts)

t3 - t2 = Deceleration time from ωb to ωo (seconds)

t4

= Total cycle time or period of process (seconds)

Pb

= Peak braking power (watts)

ωb = Rated motor speed (Rad / s)

ωo = A lower motor speed (Rad / s)

Pav =

[

–

[

]

]

✕

[

]

2

Pav = _________ watts

The Dynamic Brake Resistor power rating, in watts, that is chosen should

be equal to or greater than the value calculated in Step 8.

Example Calculation

Application Information

A 100 HP, 460 Volt motor and drive is accelerating and decelerating as

depicted in Figure 2.

• Cycle period (t4) is 60 seconds

•

•

•

•

Rated speed is 1785 RPM

Deceleration time from rated speed to 0 speed is 6.0 seconds

Motor load can be considered purely as an inertia

All power expended or absorbed by the motor is absorbed by the

motor and load inertia

• Load inertia is directly coupled to the motor

• Motor inertia plus load inertia is given as 9.61 kg-m2

1336-5.65 — March, 2007

Heavy Duty Dynamic Braking

11

Calculate Application Values

Use the Application Information to calculate the necessary values to choose

an acceptable Chopper Module and Dynamic Brake Resistor.

Rated Power of Motor = 100 HP × 746 = 74.6 kW

This information is given and must be known before the calculation process

begins. If this rating is given in horsepower, convert to watts before using

in the equations.

Rated Speed = 1785 RPM = 2π × 1785/60 = 186.93 Rad/s = ω

This information is given and must be known before the calculation process

begins. If this rating is given in RPM, convert to radians per second before

using in the equations.

Total Inertia = 9.61 kg-m2 = JT

If this value is given in lb-ft2 or Wk2, convert to kg-m2 before using in the

equations. Total inertia is given and does not need further calculations as

outlined in Step 2.

Deceleration Time = 6.0 seconds = (t3 - t2)

Period of Cycle = 60 seconds = t4

DC Bus Voltage = 750 Volts = Vd

This is known because the drive is rated at 460 Volts rms.

If a drive is rated 230 Volts rms, Vd = 375 Volts.

If a drive is rated 575 Volts rms, Vd = 937.5 Volts.

Select the Correct Chopper Module

Peak Braking Power = JTω2/(t3 - t2) = 55.96 kW = Pb

This is 75% rated power and is less than the maximum drive limit of 150%

current limit. This calculation is the result of Step 3 and determines the peak

power that must be dissipated by the Dynamic Brake Resistor.

Maximum Dynamic Brake Resistance = Vd2/Pb = 10.5 ohms = Rdb1

This calculation is the result of Step 4 and determines the maximum ohmic

value of the Dynamic Brake Resistor. Note that a choice of Vd = 750 Volts

DC was made based on the premise that the drive is rated at 460 Volts.

Minimum Current Flow = Vd/Rdb1 = 74.62 amps = Id1

This calculation is the result of Step 5. This is the minimum value of current

that will flow through the Dynamic Brake Resistor when the Chopper

Module Transistor is turned on. Refer to Table 2b in the Installation

Instructions for the Brake Chopper Module, Publication 1336-5.65. Choose

the Brake Chopper Module whose peak current capacity is greater than

74.62 amps. The correct choice must be the WB035 Chopper Module

because it has a current rating greater than 74.62 amps.

1336-5.65 — March, 2007

12

Heavy Duty Dynamic Braking

Minimum Dynamic Brake Resistance = Vd/Id2 = 10 ohms = Rdb2

This is the result of Step 6 and is also included as a value in Table 2b.

Choose the 10.4 ohms resistor, type T10F4R2K97, rated at 2.97 kW from

Table 2a.

Average Power Dissipation = [(t3 - t2)/t4]Pb/2 = 2.8 kW = Pav

This is the result of calculating the average power dissipation as outlined

in Step 8. Verify that the power rating of the Dynamic Brake Resistor chosen

in Step 7 is greater than the value calculated in Step 8. Note that the actual

resistor wattage rating is much greater than what is needed. The type

T10F4R2K97 assembly is the best choice based on resistance and wattage

values.

Ordering Resistors

Resistor assemblies listed are manufactured by IPC Power Resistors

International Incorporated and Powerohm Resistors Incorporated and have

been tested with Allen-Bradley Chopper Modules.

Available resistor assembly options include an overtemperature switch (see

Wiring Schemes), auxiliary terminal blocks and custom enclosures.

For purchase information, contact:

IPC Power Resistors International Inc.

167 Gap Way

Erlanger, KY 41018

Tel. 859-282-2900 Fax. (859) 282-2904

www.ipcresistors.com

Powerohm Resistors Inc.

5713 13th Street

Katy, TX 77493

Tel. 800-838-4694 Fax. (859) 384-8099

www.powerohm.com

1336-5.65 — March, 2007

Heavy Duty Dynamic Braking

13

Chopper Module Selection

Ohms

Watts

Catalog

Watt

Seconds

Manufacturer

Ohms

Watts

Catalog

Watt

Seconds

Manufacturer

956

956

956

956

956

695

695

695

695

695

695

615

615

615

615

615

615

546

546

546

546

546

546

439

439

439

439

439

439

364

364

364

364

364

364

342

342

342

342

342

342

283

283

283

283

283

283

237

237

237

237

237

237

196

196

196

196

196

196

181

181

181

181

181

181

242

400

597

605

915

248

333

553

825

832

1258

180

242

404

602

605

915

316

424

707

1055

1059

1601

254

339

568

847

848

1281

477

635

1065

1588

1590

2402

329

435

734

1088

1096

1645

614

817

1372

2043

2048

3089

473

628

1057

1570

1577

2373

890

1180

1987

2950

2965

4460

620

822

1385

2055

2068

3108

552-1

555-1A

550-1A

555-1

550-1

552-2A

552-2

555-2A

550-2A

555-2

550-2

442-1A

442-1

445-1A

440-1A

445-1

440-1

552-3A

552-3

555-3A

550-3A

555-3

550-3

442-2A

442-2

445-2A

445-2

440-2A

440-2

552-4A

552-4

555-4A

555-4

550-4A

550-4

442-3A

442-3

445-3A

445-3

440-3A

440-3

552-5A

552-5

555-5A

555-5

550-5A

550-5

442-4A

442-4

445-4A

445-4

440-4A

440-4

552-6A

552-6

555-6A

555-6

550-6A

550-6

442-5A

442-5

445-5A

445-5

440-5A

440-5

4225

6260

6260

6260

6260

4929

4929

7981

7981

7981

15258

4225

4225

4225

13302

13615

13302

5634

12050

12050

23004

23004

36619

2973

2973

2973

11267

9389

24647

3990

15336

24412

38496

38496

39514

3677

3677

14397

23473

22534

36306

19092

19092

30046

48120

47338

76680

5321

15649

25351

38496

39748

61422

20970

33567

53519

83096

83096

130669

19248

19248

30985

77853

77853

77775

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

154

154

154

154

154

154

150

150

150

150

150

150

150

150

150

150

150

150

128

128

128

128

128

128

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

117

117

117

117

117

117

117

117

110

110

110

110

110

110

100

100

100

100

100

100

100

100

100

100

100

100

182

242

408

604

610

913

400

800

1200

1600

2000

2400

2800

3200

3600

4000

5200

5600

874

1162

1951

2906

2912

4395

400

800

1200

1386

1600

1850

2000

3095

3600

4000

4620

4625

6994

7200

7600

300

600

900

1200

1500

2100

2700

3000

255

338

570

845

850

1278

400

800

1200

1600

2000

2400

2800

3600

4000

4800

5200

5600

222-1A

222-1

225-1A

225-1

220-1A

220-1

PF150R400W

PF150R800W

PF150R1K20

PF150R1K60

PF150R2K00

PF150R2K40

PF150R2K80

PF150R3K20

PF150R3K60

PF150R4K00

PF150R5K20

PF150R5K60

442-6A

442-6

445-6A

445-6

440-6A

440-6

PF125R400W

PF125R800W

PF125R1K20

552-7A

PF125R1K60

552-7

PF125R2K00

555-7A

PF125R3K60

PF125R4K00

550-7A

555-7

550-7

PF125R7K20

PF125R7K60

T117R300W

T117R600W

T117R900W

T117R1K2

T117R1K5

T117R2K1

T117R2K7

T117R3K0

222-2A

222-2

225-2A

225-2

220-2A

220-2

PF100R400W

PF100R800W

PF100R1K20

PF100R1K60

PF100R2K00

PF100R2K40

PF100R2K80

PF100R3K60

PF100R4K00

PF100R4K80

PF100R5K20

PF100R5K60

6416

6416

6416

16431

16431

16431

7700

12100

30000

54200

53500

82500

132000

136500

196200

192400

333400

329100

22065

32863

55397

86382

82626

138024

6500

18300

25200

32863

44200

51954

68700

130903

161600

277800

208131

208131

212513

341300

344600

7950

10100

10600

12500

15800

18600

14300

20800

7511

7511

18779

18779

18779

46947

5200

20000

35300

55000

89800

130800

125700

211600

205200

285500

275000

273100

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

IPC

Powerohm

IPC

Powerohm

IPC

Powerohm

Powerohm

IPC

IPC

IPC

Powerohm

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

1336-5.65 — March, 2007

14

Heavy Duty Dynamic Braking

Ohms

Watts

Catalog

Watt

Seconds

Manufacturer

Ohms

Watts

Catalog

Watt

Seconds

Manufacturer

100

100

100

97

97

97

97

97

97

97

97

97

97

85

85

85

85

85

85

85

85

85

85

85

85

85

85

85

85

85

85

85

85

85

85

85

85

85

81

81

81

81

81

81

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

77

77

6800

8000

9200

300

600

900

1200

1500

2100

2700

3000

3600

4200

326

400

438

730

800

1089

1094

1200

1600

1654

2000

2056

2720

2800

3600

4592

5200

5600

6800

6801

6854

7200

10000

10285

11200

1389

1837

3102

4592

4629

6944

300

400

600

800

900

1200

1200

1500

2000

2100

2700

3000

3600

4000

4200

4500

5700

7600

8000

9000

9300

300

600

PF100R6K80

PF100R8K00

PF100R9K20

T97R300W

T97R600W

T97R900W

T97R1K2

T97R1K5

T97R2K1

T97R2K7

T97R3K0

T97R3K6

T97R4K2

222-3A

PF85R400W

222-3

225-3A

PF85R800W

220-3A

225-3

PF85R1K20

PF85R1K60

220-3

PF85R2K00

552-8A

552-8

PF85R2K80

PF85R3K60

555-8A

PF85R5K20

PF85R5K60

PF85R6K80

555-8

550-8A

PF85R7K20

PF85R10K0

550-8

PF85R11K2

442-7A

442-7

445-7A

445-7

440-7A

440-7

T80R300W

PF80R400W

T80R600W

PF80R800W

T80R900W

T80R1K2

PF80R1K20

T80R1K5

PF80R2K00

T80R2K1

T80R2K7

T80R3K0

T80R3K6

PF80R4K00

T80R4K2

T80R4K5

T80R5K7

PF80R7K60

PF80R8K00

T80R9K0

T80R9K3

T77R300W

T77R600W

450100

692400

676300

10300

13400

13800

16500

20800

15400

19100

16800

22400

19100

9076

6900

9076

23004

17200

36384

36384

46200

75400

57901

109000

57588

92016

179500

173600

233795

379200

383300

588500

231135

231135

578500

934100

361490

923100

34975

55084

55319

224640

221432

221276

8530

6500

10900

16000

18500

13700

44600

17500

102600

19100

24600

22100

18500

229300

25100

23300

29400

545700

897500

209000

230000

8210

10600

Powerohm

Powerohm

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

IPC

IPC

Powerohm

IPC

IPC

Powerohm

Powerohm

IPC

Powerohm

IPC

IPC

Powerohm

Powerohm

IPC

Powerohm

Powerohm

Powerohm

IPC

IPC

Powerohm

Powerohm

IPC

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

IPC

Powerohm

IPC

IPC

Powerohm

IPC

Powerohm

IPC

IPC

IPC

IPC

Powerohm

IPC

IPC

IPC

Powerohm

Powerohm

IPC

IPC

IPC

IPC

77

77

77

77

77

77

77

77

77

77

77

77

70

70

70

70

70

70

70

70

70

70

70

70

65

65

65

65

65

65

65

65

65

65

60

60

60

60

60

60

60

60

60

60

60

60

60

60

60

60

59

59

59

59

59

59

56

56

56

56

56

56

55

55

52

52

52

900

1200

1500

2100

2700

3000

3600

4200

4500

5700

9000

9300

400

800

1200

2400

2527

3303

4800

5643

8258

8424

9600

12489

400

800

1200

2000

2400

3600

4000

7200

7600

16640

300

400

600

800

900

1200

1500

2000

2700

3600

4000

4500

6900

8000

11000

15896

473

631

1056

1576

1577

2384

2010

2657

4490

6642

6702

10045

400

800

400

800

1200

T77R900W

T77R1K2

T77R1K5

T77R2K1

T77R2K7

T77R3K0

T77R3K6

T77R4K2

T77R4K5

T77R5K7

T77R9K0

T77R9K3

PF70R400W

PF70R800W

PF70R1K20

PF70R2K40

552-9A

552-9

PF70R4K80

555-9A

555-9

550-9A

PF70R9K60

550-9

PF65R400W

PF65R800W

PF65R1K20

PF65R2K00

PF65R2K40

PF65R3K60

PF65R4K00

PF65R7K20

PF65R7K60

PF65R16K6

T60R300W

PF60R400W

T60R600W

PF60R800W

T60R900W

T60R1K2

T60R1K5

PF60R2K00

T60R2K7

T60R3K6

PF60R4K00

T60R4K5

T60R6K9

PF60R8K00

T60R11K0

PF60R15K8

222-4A

222-4

225-4A

225-4

220-4A

220-4

442-8A

442-8

445-8A

445-8

440-8A

440-8

PF55R400W

PF55R800W

PF52R400W

PF52R800W

PF52R1K20

17900

20800

16400

19100

23800

21300

28100

24200

22400

28700

209000

230000

5700

25000

62000

153900

76680

144048

308300

189665

297173

295765

1249300

482144

9500

23600

59300

138900

141100

178100

291700

712100

709900

690800

10300

8700

13000

21400

13700

16400

20800

128300

18500

22000

269300

28000

164000

659400

448000

690800

10094

25038

39201

64161

64161

99762

61344

154455

245062

245375

245375

388094

8000

30800

10400

28600

65400

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

Powerohm

IPC

IPC

Powerohm

IPC

IPC

IPC

Powerohm

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

IPC

Powerohm

IPC

Powerohm

IPC

IPC

IPC

Powerohm

IPC

IPC

Powerohm

IPC

IPC

Powerohm

IPC

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

1336-5.65 — March, 2007

Heavy Duty Dynamic Braking

15

Ohms

Watts

Catalog

Watt

Seconds

Manufacturer

Ohms

Watts

Catalog

Watt

Seconds

Manufacturer

52

52

52

52

52

52

52

52

52

52

48

48

48

48

48

48

48

48

48

48

48

48

48

48

48

48

48

48

48

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

44

44

44

44

44

44

44

44

44

44

44

44

44

44

44

1600

2400

2800

3200

4800

5600

6000

9600

13312

18625

300

400

600

800

900

1200

1200

1500

2000

2700

3000

3600

3600

4200

5670

6600

12600

19100

20400

300

600

617

827

1200

1378

1500

2056

2066

2100

2700

3000

3125

3600

3883

5138

6000

8672

12600

12846

12943

19100

19427

400

800

1200

2000

2561

2800

3381

3600

4000

5600

5720

7200

7600

8454

8537

PF52R1K60

PF52R2K40

PF52R2K80

PF52R3K20

PF52R4K80

PF52R5K60

PF52R6K00

PF52R9K60

PF52R13K3

PF52R18K6

T48R300W

PF48R400W

T48R600W

PF48R800W

T48R900W

T48R1K2

PF48R1K20

T48R1K5

PF48R2K00

T48R2K7

T48R3K0

T48R3K6

PF48R3K60

T48R4K2

T48R5K67

T48R6K6

T48R12K6

T48R19K1

T48R20K4

T45R300W

T45R600W

222-5A

222-5

T45R1K2

225-5A

T45R1K5

220-5A

225-5

T45R2K1

T45R2K7

T45R3K0

220-5

T45R3K6

552-10A

552-10

T45R6K0

555-10A

T45R12K6

555-10

550-10A

T45R19K1

550-10

PF44R400W

PF44R800W

PF44R1K20

PF44R2K00

442-9A

PF44R2K80

442-9

PF44R3K60

PF44R4K00

PF44R5K60

445-9A

PF44R7K20

PF44R7K60

445-9

440-9A

111200

149600

142400

233400

352900

569300

577000

598400

621800

583500

13100

9600

16500

26400

17500

20800

61600

16600

98500

23300

21100

28000

86200

23800

131000

131000

359000

656000

716000

12300

15800

30828

30828

19100

49529

24900

124800

124800

28100

22000

19800

197177

26600

120810

308128

125000

370410

359000

409420

409420

656000

563362

8800

39500

57700

126100

121670

197900

190604

79000

300900

477000

184031

793400

775400

305624

302807

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

IPC

Powerohm

IPC

Powerohm

IPC

IPC

Powerohm

IPC

Powerohm

IPC

IPC

IPC

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

Powerohm

IPC

Powerohm

IPC

Powerohm

Powerohm

Powerohm

IPC

Powerohm

Powerohm

IPC

IPC

44

44

44

44

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

36

36

36

36

36

36

36

36

36

36

36

36

36

36

35

35

34

34

34

34

34

34

34

34

34

34

34

34

34

34

32

32

32

32

32

32

32

32

32

32

32

11264

12784

15000

23276

300

400

800

900

1200

1200

1800

2000

3200

4000

4000

6000

10000

10240

11000

11429

16000

16000

17000

19000

22000

22858

400

800

1200

1600

2000

2400

4000

4400

9216

11298

16517

16863

19044

24978

5058

6423

300

900

1800

2400

3600

4000

8000

9000

13000

15000

17000

18000

19000

26000

300

400

600

800

875

900

1162

1200

1500

1600

1955

PF44R11K2

440-9

PF44R15K0

PF44R23K2

T40R300W

PF40R400W

PF40R800W

T40R900W

T40R1K2

PF40R1K20

T40R1K8

PF40R2K00

PF40R3K20

T40R4K0

PF40R4K00

PF40R6K00

T40R10K0

PF40R10K2

T40R11K0

PF40R11K4

T40R16K0

PF40R16K0

T40R17K0

T40R19K0

T40R22K0

PF40R22K8

PF36R400W

PF36R800W

PF36R1K20

PF36R1K60

PF36R2K00

PF36R2K40

PF36R4K00

PF36R4K40

PF36R9K21

555-11A

555-11

550-11A

PF36R19K0

550-11

552-11A

552-11

T34R300W

T34R900W

T34R1K8

T34R2K4

T34R3K6

T34R4K0

T34R8K0

T34R9K0

T34R13K0

T34R15K0

T34R17K0

T34R18K0

T34R19K0

T34R26K0

T32R300W

PF32R400W

T32R600W

PF32R800W

222-6A

T32R900W

222-6

PF32R1K20

T32R1K5

PF32R1K60

225-6A

483600

369388

495000

1263600

10900

8000

35900

14300

17300

83400

18500

114700

277000

105000

448800

727000

309000

414500

333000

440000

521000

638700

574000

568000

1202000

1130600

12900

32400

77000

103200

99000

79200

395700

399000

414500

316618

449907

449907

1064100

1321116

157272

249757

14700

19100

25100

30100

93000

98600

262000

285000

456000

456000

990000

1017000

1048000

1591000

13800

11400

17500

41100

35054

19100

55162

70600

28100

91800

88573

Powerohm

IPC

Powerohm

Powerohm

IPC

Powerohm

Powerohm

IPC

IPC

Powerohm

IPC

Powerohm

Powerohm

IPC

Powerohm

Powerohm

IPC

Powerohm

IPC

Powerohm

IPC

Powerohm

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

IPC

IPC

IPC

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

IPC

Powerohm

IPC

IPC

IPC

Powerohm

IPC

Powerohm

IPC

1336-5.65 — March, 2007

16

Heavy Duty Dynamic Braking

Ohms

Watts

Catalog

Watt

Seconds

Manufacturer

Ohms

Watts

Catalog

Watt

Seconds

Manufacturer

32

32

32

32

32

32

32

32

32

32

32

32

32

32

32

32

32

32

32

32

32

32

32

32

32

29

29

29

29

29

29

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

27

27

27

27

27

27

27

27

27

27

27

27

25

2000

2100

2400

2700

2800

2906

2918

3600

4000

4395

4500

4800

5200

8420

9144

10368

12700

13545

17100

18000

18286

21632

26000

27090

28000

3800

5130

8487

12667

12826

19396

400

800

1200

1600

2000

2800

4000

4400

5600

6096

7501

8258

9072

11200

13615

15001

18928

20321

20646

23548

30001

30492

36288

300

600

900

1200

1500

2100

3300

8420

11500

15000

21600

27400

300

PF32R2K00

T32R2K1

PF32R2K40

T32R2K7

PF32R2K80

225-6

220-6A

PF32R3K60

T32R4K0

220-6

T32R4K5

PF32R4K80

PF32R5K20

T32R8K42

PF32R9K14

PF32R10K3

T32R12K7

PF32R13K5

T32R17K1

T32R18K0

PF32R18K2

PF32R21K6

T32R26K0

PF32R27K0

T32R28K0

442-10A

442-10

445-10A

440-10A

445-10

440-10

PF28R400W

PF28R800W

PF28R1K20

PF28R1K60

PF28R2K00

PF28R2K80

PF28R4K00

PF28R4K40

PF28R5K60

552-12A

PF28R7K50

552-12

PF28R9K07

PF28R11K2

555-12A

PF28R15K0

PF28R18K9

550-12A

555-12

PF28R23K5

PF28R30K0

550-12

PF28R36K2

T27R300W

T27R600W

T27R900W

T27R1K2

T27R1K5

T27R2K1

T27R3K3

T27R8K42

T27R11K5

T27R15K0

T27R21K6

T27R27K4

T25R300W

143600

20200

113100

25200

220200

82626

82626

102600

83300

222215

105000

581600

583400

246000

345400

385000

410000

511000

931000

1017000

931100

1203600

1591000

2541900

2304000

127069

199993

253840

359925

359925

615920

15400

35900

57300

77000

124100

314200

502600

493600

320400

299521

345400

237463

330000

447100

359925

846300

1132800

1100930

1033301

2224200

3042600

2138364

4610000

18500

15400

24900

18800

23700

27300

73900

358000

391000

931000

1346000

2075000

17200

Powerohm

IPC

Powerohm

IPC

Powerohm

IPC

IPC

Powerohm

IPC

IPC

IPC

Powerohm

Powerohm

IPC

Powerohm

Powerohm

IPC

Powerohm

IPC

IPC

Powerohm

Powerohm

IPC

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

IPC

Powerohm

IPC

Powerohm

Powerohm

IPC

Powerohm

Powerohm

IPC

IPC

Powerohm

Powerohm

IPC

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

24

24

24

24

24

24

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

21

21

21

21

21

21

21

21

21

21

21

21

21

21

21

21

21

20

400

600

800

900

1200

1200

1500

1600

2000

2400

2800

3200

3300

3900

6876

8420

10158

13751

21025

25600

32400

40632

55001

7340

9635

16393

24086

24468

36710

300

600

800

900

1200

1500

1600

2000

2100

3600

4982

6310

6469

7452

7490

10200

11125

15548

16172

29808

400

800

1200

1600

2000

2400

3200

4000

5626

7426

8400

11251

17661

22501

33600

45001

70644

300

PF25R400W

T25R600W

PF25R800W

T25R900W

T25R1K2

PF25R1K20

T25R1K5

PF25R1K60

PF25R2K00

PF25R2K40

PF25R2K80

PF25R3K20

T25R3K3

T25R3K9

PF25R6K87

T25R8K42

PF25R10K1

PF25R13K7

PF25R21K0

PF25R25K6

PF25R32K4

PF25R40K6

PF25R55K0

552-13A

552-13

555-13A

555-13

550-13A

550-13

T23R300W

T23R600W

PF23R800W

T23R900W

PF23R1K20

T23R1K5

PF23R1K60

PF23R2K00

T23R2K1

PF23R3K60

442-11A

T23R6K31

442-11

PF23R7K45

T23R7K49

T23R10K2

445-11A

PF23R15K5

445-11

PF23R29K8

PF21R400W

PF21R800W

PF21R1K20

PF21R1K60

PF21R2K00

PF21R2K40

PF21R3K20

PF21R4K00

PF21R5K62

PF21R7K42

PF21R8K40

PF21R11K2

PF21R17K6

PF21R22K5

PF21R33K6

PF21R45K0

PF21R70K6

T20R300W

13800

14300

55600

23000

27700

71400

22000

55000

173100

130800

277000

272600

73900

190000

276400

328000

383200

752200

2012300

2789000

4149000

1445600

2926300

211079

299938

533797

1173670

1871068

844315

15800

20800

51300

21300

63500

20200

82600

157300

23100

185800

254295

179000

399830

275000

328000

310000

492736

900900

825698

3841600

18900

47100

57700

75400

143600

107700

373400

240800

236100

234800

319400

564200

1694600

2282000

5992900

2394200

6778300

13700

Powerohm

IPC

Powerohm

IPC

IPC

Powerohm

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

IPC

IPC

Powerohm

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

IPC

Powerohm

IPC

Powerohm

Powerohm

IPC

Powerohm

IPC

IPC

IPC

Powerohm

IPC

IPC

IPC

Powerohm

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

IPC

1336-5.65 — March, 2007

Heavy Duty Dynamic Braking

17

Ohms

Watts

Catalog

Watt

Seconds

Manufacturer

Ohms

Watts

Catalog

Watt

Seconds

Manufacturer

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

18

18

18

18

18

18

15.4

15.4

15.4

15.4

15.4

15.4

15.4

15

15

15

15

15

15

15

15

15

15

15

15

600

900

1372

1500

1860

3063

4572

4650

5940

7031

8920

10700

15200

16605

20600

24910

28400

34600

400

800

1200

1600

2000

2800

3200

4864

6716

8213

9540

10051

12170

13613

16425

19456

21305

30400

31798

31965

40204

47709

63916

77824

6184

8266

13810

20612

20664

30910

800

1200

2400

5063

10410

20251

41642

300

600

900

1500

4210

6160

7132

8570

9919

11400

12112

15927

T20R600W

T20R900W

222-7A

T20R1K5

222-7

225-7A

220-7A

225-7

T20R5K94

220-7

T20R8K92

T20R10K7

T20R15K2

440-11A

T20R20K6

440-11

T20R28K4

T20R34K6

PF19R400W

PF19R800W

PF19R1K20

PF19R1K60

PF19R2K00

PF19R2K80

PF19R3K20

PF19R4K86

PF19R6K71

PF19R8K21

552-14A

PF19R10K0

552-14

PF19R13K6

PF19R16K4

PF19R19K4

555-14A

PF19R30K4

550-14A

555-14

PF19R40K2

550-14

PF19R63K9

PF19R77K8

442-12A

442-12

445-12A

440-12A

445-12

440-12

PF15F4R800W

PF15F4R1K20

PF15F4R2K40

PF15F4R5K06

PF15F4R10K4

PF15F4R20K2

PF15F4R41K6

T15R300W

T15R600W

T15R900W

T15R1K5

T15R4K21

T15R6K16

442-13A

T15R8K57

442-13

T15R11K4

552-15A

445-13A

17300

18500

87086

28000

55084

138493

222215

221432

260000

169227

267000

582000

924000

825698

1602000

1781970

1066000

1148000

17100

39000

84900

68300

213200

339300

344700

207300

220000

272600

410613

564200

410613

700700

1497400

2155200

1514674

5393600

3029900

2913365

2128200

5953399

6142800

8113500

152850

234734

660558

1336477

1336477

899814

42400

106000

123100

165000

600600

2612300

2407200

16400

20800

22000

38800

143000

232000

179963

466000

328491

734000

550465

1158280

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

IPC

Powerohm

IPC

Powerohm

Powerohm

Powerohm

IPC

Powerohm

IPC

IPC

Powerohm

IPC

Powerohm

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

15

15

15

15

15

15

15

15

14

14

14

14

14

14

14

14

14

14

14

14

14

14

13

13

13

13

13

12

12

12

12

12

12

12

12

12

12

12

12

11.5

11.5

11.5

11.5

11.5

11.5

11.5

11.5

11.5

11.5

11.5

11.5

11.5

11.5

11.5

11.5

11.5

11

11

11

11

11

11

10.4

10.4

10.4

10.4

10.4

18173

23772

23894

27060

35663

40388

40587

60579

300

600

900

1200

1800

2012

2657

4495

6160

6642

6708

10045

11400

12700

800

1600

2800

5457

11000

9641

12398

13780

20673

21531

30776

32136

32297

45934

46170

48204

68911

400

800

1600

2000

2944

3726

4600

6083

7774

9671

11776

14904

18400

24334

31096

59616

110001

2561

3381

5720

8454

8537

12784

300

600

900

1500

2970

552-15

440-13A

445-13

555-15A

440-13

550-15A

555-15

550-15

T14R300W

T14R600W

T14R900W

T14R1K2

T14R1K8

222-8A

222-8

225-8A

T14R6K16

225-8

220-8A

220-8

T14R11K4

T14R12K7

PF13R800W

PF13R1K60

PF13R2K80

PF13R5K45

PF13R11K0

442-14A

442-14

552-16A

552-16

445-14A

555-16A

440-14A

445-14

550-16A

555-16

440-14

550-16

PF11F5R400W

PF11F5R800W

PF11F5R1K60

PF11F5R2K00

PF11F5R2K94

PF11F5R3K72

PF11F5R4K60

PF11F5R6K08

PF11F5R7K77

PF11F5R9K67

PF11F5R11K7

PF11F5R14K9

PF11F5R18K4

PF11F5R24K3

PF11F5R31K0

PF11F5R59K6

PF11F5R110K0

222-9A

222-9

225-9A

225-9

220-9A

220-9

T10F4R300W

T10F4R600W

T10F4R900W

T10F4R1K5

T10F4R2K97

1158280

719851

719851

719851

1313963

1300276

1313963

7591398

15400

19400

20700

24500

27800

61344

154455

117367

232000

172138

172138

523728

734000

1038000

58400

111200

238800

191600

1048200

440372

890985

890985

599876

1924486

1040221

1040221

1040221

2387466

2247026

1314510

10015318

25700

41300

102600

206500

146900

140900

191600

321100

500500

898500

1254700

1955300

3196300

1330100

1840800

7683200

11663100

121123

100080

237243

407344

407344

890985

17300

22900

24500

25400

95100

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

1336-5.65 — March, 2007

18

Heavy Duty Dynamic Braking

Ohms

Watts

Catalog

Watt

Seconds

Manufacturer

Ohms

Watts

Catalog

Watt

Seconds

Manufacturer

10.4

10.4

10.4

10.4

10.4

10.4

10.4

10.4

10.4

10.4

10.1

10.1

10.1

10

10

10

10

10

9.5

9.5

9.5

9.5

9.5

9.5

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

8

8

8

8

8

8

8

8

8

8

7.3

7.3

7.3

7.3

7.3

7.3

7

7

7

7

5360

6040

8890

11000

15500

18900

26000

35600

43900

72300

400

800

1200

17713

26569

39559

59043

59339

11926

17890

26636

39755

39955

59635

400

800

1200

1600

2000

2355

2981

3751

4867

6601

7737

9421

11923

15001

19467

24876

30948

37683

47693

58880

69635

90001

132480

14093

21143

23427

31474

35138

46977

47219

52321

70477

78475

3826

5095

8545

12738

12754

19264

400

800

1200

1600

T10F4R5K36

T10F4R6K4

T10F4R8K89

T10F4R11K0

T10F4R15K5

T10F4R18K9

T10F4R26K0

T10F4R35K6

T10F4R43K9

T10F4R72K3

PF10F1R400W

PF10F1R800W

PF10F1R1K20

552-17A

552-17

555-17A

550-17A

555-17

442-15A

442-15

445-15A

440-15A

445-15

440-15

PF9F2R400W

PF9F2R800W

PF9F2R1K20

PF9F2R1K60

PF9F2R2K00

PF9F2R2K35

PF9F2R2K98

PF9F2R3K75

PF9F2R4K86

PF9F2R6K60

PF9F2R7K73

PF9F2R9K42

PF9F2R11K9

PF9F2R15K0

PF9F2R19K4

PF9F2R24K8

PF9F2R30K9

PF9F2R37K6

PF9F2R47K6

PF9F2R58K8

PF9F2R69K6

PF9F2R90K0

PF9F2R132K2

442-16A

442-16

552-18A

445-16A

552-18

440-16A

445-16

555-18A

440-16

555-18

222-10A

222-10

225-10A

225-10

220-10A

220-10

PF7R400W

PF7R800W

PF7R1K20

PF7R1K60

329000

489000

801000

359000

1742000

1991000

2002000

1230000

1367000

4620000

20600

35900

112100

479901

903350

1956117

1950414

1950414

316618

479901

3000513

2851152

1079776

1820386

18900

32400

102200

75500

161600

98000

116700

135600

282100

341800

748700

1075400

1520800

545200

1064100

1416000

2965500

4056800

6146600

10387700

6672400

9127700

23372300

401656

693480

1211023

1564893

2494758

2966898

1560331

1559677

3325398

5345909

164245

267369

566990

359925

359925

656981

19300

35900

123900

77000

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

Powerohm

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

6.5

6.5

6.5

6.5

6.5

6.5

6.5

6.4

6.4

6.4

6.4

6.4

6

6

6

5.7

5.7

5.7

5.7

5.7

5.7

5.4

5.4

5.4

5.4

5.4

5.4

5.4

5.4

5.4

5.4

5.4

5.4

5.1

5.1

5.1

5.1

5.1

5.1

5.1

5.1

5.1

5.1

5.1

5.1

5.1

5.1

2268

2800

3703

4732

6240

7383

9307

11251

14812

18928

23548

28672

36912

45001

55001

64512

81648

110001

127575

157500

2106

2600

3438

4394

5466

6656

8424

17529

26292

39148

58430

58718

28008

42015

62551

4938

6525

11029

16314

16461

24694

1670

2680

5080

5780

7280

12000

20300

22000

37700

48100

51900

104000

400

800

1600

2704

3448

4290

5408

6610

8160

10791

13790

17156

27501

32640

PF7R2K26

PF7R2K80

PF7R3K70

PF7R4K73

PF7R6K23

PF7R7K38

PF7R9K30

PF7R11K2

PF7R14K8

PF7R18K9

PF7R23K5

PF7R28K6

PF7R36K9

PF7R45K0

PF7R55K0

PF7R64K5

PF7R81K6

PF7R110K0

PF7R127K7

PF7R157K7

PF6F5R2K10

PF6F5R2K60

PF6F5R3K43

PF6F5R4K39

PF6F5R5K46

PF6F5R6K65

PF6F5R8K42

442-17A

442-17

445-17A

440-17A

445-17

552-19A

552-19

555-19A

222-11A

222-11

225-11A

225-11

220-11A

220-11

T5F4R1K67

T5F4R2K68

T5F4R5K8

T5F4R5K78

T5F4R7K28

T5F4R12K0

T5F4R20K3

T5F4R22K0

T5F4R37K7

T5F4R48K1

T5F4R51K9

T5F4R104K0

PF5F1R400W

PF5F1R800W

PF5F1R1K60

PF5F1R2K70

PF5F1R3K44

PF5F1R4K29

PF5F1R5K40

PF5F1R6K60

PF5F1R8K16

PF5F1R10K7

PF5F1R13K7

PF5F1R17K1

PF5F1R27K5

PF5F1R32K6

77800

107500

199600

300300

599000

765100

1303500

436200

802700

1132800

2330100

3042600

4610000

7990600

5083700

6845800

10141900

17978700

21021300

34493700

92600

90400

188100

256400

599000

717000

1086300

574859

719851

1231840

4818224

4929414

1960167

1981674

2135190

260816

421193

905640

880744

880744

1781970

55700

185000

401000

169000

328000

699000

738000

717000

2310000

1845000

1953000

3444000

35400

41100

141300

158300

212400

449300

537700

869000

1412200

564200

800800

1694600

3380700

5992900

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

IPC

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

Powerohm

1336-5.65 — March, 2007

Heavy Duty Dynamic Braking

19

Ohms

Watts

Catalog

Watt

Seconds

Manufacturer

Ohms

Watts

Catalog

Watt

Seconds

Manufacturer

5.1

5.1

5

5

5

5

5

5

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.6

4.6

4.6

4.6

4.6

4.6

4.6

4.6

4.6

4.6

4.6

4.6

4.6

4.6

4.6

4.6