LC-tank CMOS Voltage-Controlled Oscillators using High Quality

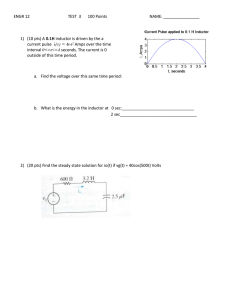

advertisement