Installing the Rack Mount

ET 350 Monitor (Model 350R), ET 3170 Terminal, and ET 3200 Series Computers

Intended Use

CAUTION

When properly installed using the materials provided, and

according to these instructions, the rack mount is intended

to mount the 3M DynaproTM ET 350 monitor, the ET 3170

terminal, and ET 3200 series computers for use in a

standard 19-inch EIA rack.

To reduce the risks associated with fire which, if not

avoided, may result in minor or moderate injury or cause

property damage.

!

Installation of the ET unit in a rack should be such that the

amount of air flow required for safe operation of the unit is not

compromised.

Product safety information

Equipment

Read and understand all safety information in this

document before installing and using the rack mount.

Materials supplied

The Rack Mount Kit comes with the following items:

WARNING

!

To reduce the risks associated with fire and explosion

which, if not avoided, could result in death or serious injury

and/or property damage.

!

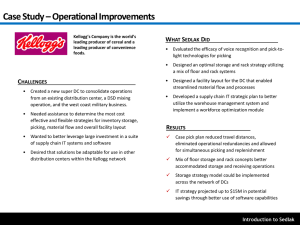

1 rack adapter (the example illustrated below is the

adapter for the ET 3170 terminal or ET 3210

computer)

Use the materials provided so that installation of the ET unit will

not result in a hazardous condition due to uneven mechanical

loading.

WARNING

To reduce the risks associated with electrical shock or fire

which, if not avoided, may result in death or serious injury

and/or property damage:

!

Follow all product and accessory installation instructions.

WARNING

73145_a

To reduce the risks associated with electrical shock or fire

which, if not avoided, could result in death or serious injury

and/or property damage:

!

!

Reliable earthing of rack-mounted equipment should be

maintained. Particular attention should be given to supply

connections other than direct connections to the branch circuit

(e.g., use of power strips).

Consideration should be given to the connection of the ET unit to

the supply circuit and the effect that overloading of the circuits

might have on overcurrent protection and supply wiring.

Appropriate consideration of equipment nameplate ratings

should be used when addressing this concern.

!

8 clip nuts

!

12 Phillips #10-32 x ½ inch panhead machine screws

!

12 flat washers

!

12 lock washers

!

8 slotted #10-32 x 5/8 inch countersunk machine

screws

!

8 cup washers

Tools Required

!

No. 2 Phillips screwdriver

!

Large flat-blade screwdriver

3M Touch Systems Proprietary Information

1

Installing the Rack Mount

Mounting steps

4.

On each of the twelve #10-32 panhead machine

screws, first put on a lock washer and then put on a

flat washer.

5.

Using a No. 2. Phillips screwdriver, attach each screw

(with lock washer and flat washer) through the holes

in the rack adapter and into the back of the bezel of

the ET unit.

6.

Tighten each screw to a torque of 12 inch-pounds.

7.

If your unit requires security screws (available as an

option from 3M Touch Systems), insert them.

8.

Pick up the rack adapter with the ET unit attached and

fit it to the rack. Position it to match the locations of

the clips installed earlier.

9.

Fasten the adapter/ET unit to the clip nuts in the rack

with the eight slotted #10-32 x 5/8-inch countersunk

machine screws with a cup washer on each screw.

Important

If installed in a closed or multi-unit rack assembly, the operating

ambient temperature of the rack environment may be greater

than room ambient temperature. Therefore, consideration should

be given to installing the equipment in an environment

compatible with the manufacturer’s maximum rated ambient

temperature.

To install the rack adapter in the 19-inch rack, follow

these steps:

1.

To determine where to attach the clip nuts to the rack,

hold the rack adapter in the rack where you want to

mount the ET unit. Fasten the clip nuts on the rack so

that they match the locations of the slots in the sides

of the rack adapter.

The clip nuts will “clip” to the rack. Screws and

washers are not required.

2.

Place the ET unit face down on a padded bench or

other protected surface.

3.

Fit the rack adapter over the back of the ET unit,

against the back of the bezel.

10. Connect data and power cables.

3M Touch Systems Proprietary Information

2

Copyright

This manual is © 3M 2002. All rights reserved.

Reproduction of the contents of this copyrighted manual in

whole or in part, by any means, electronic or mechanical,

for any purpose, without written permission of 3M Touch

Systems, a subsidiary of 3M, is prohibited.

Notice

Given the variety of factors that can affect the use and

performance of a 3M Touch Systems Product (the

“Product”), including that solid state equipment has

operation characteristics different from electromechanical

equipment, some of which factors are uniquely within

User’s knowledge and control, it is essential that User

evaluate the 3M Touch Systems Product and software to

determine whether it is suitable for User’s particular

purpose and suitable for User’s method of application. 3M

Touch Systems’ statements, engineering/technical

information, and recommendations are provided for User’s

convenience, but their accuracy or completeness is not

warranted. 3M Touch Systems products and software are

not specifically designed for use in medical devices as

defined by United States federal law. 3M Touch Systems

products and software should not be used in such

applications without 3M Touch Systems’ express written

consent. User should contact its sales representative if

User’s opportunity involves a medical device application.

Important notice to purchaser

Specifications are subject to change without notice. These

3M Touch Systems’ Products and software are warranted

to meet their published specifications from the date of

shipment and for the period stated in the specification.

3M Touch Systems

3M Optical Systems Division

800 Carleton Court

Annacis Island

New Westminster, BC

Canada V3M 6L3

www.3Mtouch.com

3M Touch Systems makes no additional warranties,

express or implied, including but not limited to any

implied warranties of merchantability or fitness for a

particular purpose.

User is responsible for determining whether the 3M Touch

Systems Products and software are fit for User’s particular

purpose and suitable for its method of production,

including intellectual property liability for User's

application. If the Product, software or software media is

proven not to have met 3M Touch Systems’ warranty, then

3M Touch Systems’ sole obligation and User’s and

Purchaser’s exclusive remedy, will be, at 3M Touch

Systems’ option, to repair or replace that Product quantity

or software media or to refund its purchase price. 3M

Touch Systems has no obligation under 3M Touch

Systems’ warranty for any Product, software or software

media that has been modified or damaged through misuse,

accident, neglect, or subsequent manufacturing operations

or assemblies by anyone other than 3M Touch Systems.

3M Touch Systems shall not be liable in any action

against it in any way related to the Products or software

for any loss or damages, whether non-specified direct,

indirect, special, incidental or consequential (including

downtime, loss of profits or goodwill) regardless of the

legal theory asserted.

Edition

Second edition: October 2002

Document Number: 19916 (Rev. 1.0)

(Supersedes 80-0453)

Trademark

3M Dynapro is a trademark of 3M.

For more information on 3M touch products, visit

3Mtouch.com or call toll-free 1-800-667-0374.

Worldwide Manufacturing Plants

Methuen, Massachusetts

Milwaukee, Wisconsin

Vancouver, BC, Canada

© 3M 2002

19916 (Rev. 1.0)