Lightning Transient Suppression Circuit Design for Avionics

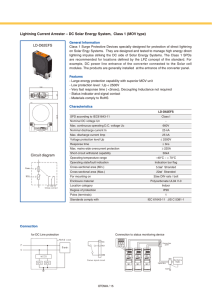

advertisement

Lightning Transient Suppression Circuit Design for Avionics Equipment Presented by: Clay McCreary Outline • • • • • Background Design Challenges Design Technique Summary Applicable Waveform Equations Current Calculation Outline • • • • • • Series Resistor MOV/GDT TVS Trace Size Example Miniaturization References Background • Due to the environment in which they operate, aircraft are often struck by lightning. • While only external devices (ie. antennas) are susceptible to the direct effects of the lightning strike, all electronic devices installed in the aircraft are exposed to the indirect effects. • Thus, Airworthiness Authorities have mandated that all avionics must pass tests verifying immunity to applicable lightning levels. Background • Due to nearly all new airframes being constructed using Carbon Composite material, avionics equipment are being required to tolerate much higher lightning levels. – This is due to greater “Structural IR (current x resistance) Coupling”. Background • Most avionics have been changed to smaller form factors throughout the years, so they cannot accommodate the larger components associated with existing design techniques to tolerate the new lightning levels required by customers. – Thus, there is a need to minimize the area required for lightning protection while providing increased protection. Background – Structural IR Coupling Signal Line EUT Load Signal Return Structural IR Coupling Current Flow (blue) Avionics in one area of the airframe may be connected to equipment in another area. Both are grounded to their respective local grounds. The airframe appears as a large resistor between the local grounds. Lightning attaches at one local ground, flows through the airframe and detaches from the airframe. Thus, a large transient is applied to the contact connecting the two pieces of avionics equipment. Background • The transient applied to the airframe to determine test levels is a 200kA double exponential waveform. Background • Composite aircraft distort this transient through resistive and capacitive effects resulting in a test waveform with 40µs rise time and 120µs pulse width, WF5A. Background • A voltage gradient is established throughout the airframe and used to create “zones”. – Each “zone” has a voltage associated with it. • The test level for a signal pin on the electronic devices interface is determined by routing of the cable to the load to which it is connected. • The voltages for every zone through which the cable passes through are added together and then doubled to determine test levels. Background • Lightning protection has been considered a nearly trivial matter in the past for several reasons: – Aluminum airframes result in negligible Structural IR Coupling. • There are other types of coupling, so there were still testing requirements, but they are not as severe. – Avionics equipment was large with low signal density, so there was room for large devices. Design Challenges • The basic suppression circuit consists of a series resistor and shunt suppression device Design Challenges • Series resistor – The pulsed power handling capabilities are either not specified on the datasheet or rated with a rectangular pulse • Suppression Device – Suppression devices are rated using a variety of standard test transients • None of the transients used for rating these components are experienced during lightning testing Design Challenges • Printed Circuit Board (PCB) Traces – Very little guidance is available for determining the minimum trace sizing for transients • The transients used to rate the components and the lack of guidance for trace sizing has resulted in a “trial and error” attitude towards lightning suppression circuit design Design Technique Summary • The techniques presented assume that the following parameters have been determined either by requirement, downstream component ratings, or experimentation: – Series impedance – Clamping voltage – Lightning test waveform • WF5A will only be presented here – Lightning test level Applicable Waveform Equations • Double Exponential Current Equation • Coefficients – WF5A: – 8 x 20 µs: – 10 x tp µs : . • This is used for transient voltage suppressor (TVS) selection tp is a variable pulse width Current Calculation • The current used for all the subsequent calculations is calculated by: • Zsource for WF5A is 1 Ω Series Resistor • Suitable resistors for this application are: – Untrimmed thick film – Carbon composite – Wirewound Series Resistor • The KOA SPEER “SG73” model is an example of an untrimmed thick film resistor with the pulse handling capability rated on the datasheet Series Resistor • The graph on the previous slide rates the pulse handling capability of each of the physical sizes of resistor offered under this model • The pulse handling capability is rated using rectangular pulses of varying pulse widths Series Resistor • To determine the suitability of a resistor for this application, the transient to which the resistor is exposed is transformed into a rectangular pulse – The transformation is performed by calculating the peak power and total energy dissipated by the resistor during the lightning test transient and calculating the pulse width of a rectangular pulse having the same peak power that dissipates the equivalent energy Series Resistor • Plot the resultant point (tp , Ppk) on the graph, the limit lines that lie above the point represent the physical sizes of resistors that are suitable for this application Series Resistor • Some models of carbon composite resistors also have similar pulse power rating graphs on the datasheets Series Resistor • The 1 W surface mount wire wound “WSC” model offered by Vishay has been found empirically to open when exposed to a 200 µs rectangular pulse resulting in the dissipation of 1.2 J of energy – 60 % derating (multiply 1.2 J/W by 0.6 resulting in 0.72 J/W) of this model of resistor has shown the resistor to reliably tolerate the transient without changing resistance value Series Resistor • Thumbrule: – 0.72 J/W (joules per watt of rated power) for the “WSC” model of surface mount wire wound resistor • Empirically, this relationship has been found to be linear – ie. 2W resistor can tolerate a lightning test transient resulting in the dissipation of 1.44 J MOV/GDT • Metal Oxide Varistors (MOV) and Gas Discharge Tubes (GDT) are typically rated using the 8 x 20 µs current waveform • MOVs also may be rated using energy dissipated when exposed to a 10 x 1000 µs current waveform – This rating should not be used for this application MOV/GDT • There is a plateau for shorter pulses on the pulse rating graph for the SG73 resistor, indicating that resistors are rated for less energy for shorter transients – This is due to the entire transient being dissipated in the film because there is not enough time for the heat to transfer to the component body • This may be extended to MOVs – Since lighting test transients are much shorter than 10 x 1000 µs, this energy rating is not representative of the lightning transient, so it does not produce accurate results MOV/GDT • To transform the current from the lightning test transient is transformed to the 8 x 20 µs the coefficient I0 is found using the following equation: • This equation is generalized to find the coefficient for any double exponential – Here, α and β for the 8 x 20 µs waveform are used MOV/GDT • Substitute I0 into the following equation to calculate the 8 x 20 µs peak current • If the resultant peak current is less than the current rating on the datasheet, the MOV or GDT is suitable TVS TVS • Selection of a TVS is similar to the selection of a resistor having its pulse power handling capability specified • Most TVS datasheets contain a graph of peak power vs. pulse width • However, the test transient used to rate TVSs is a double exponential waveform with 10 µs rise time TVS • The rating graph is in terms of power, but the test transient is in terms of current • ¼ of the peak power corresponds to ½ of the peak current, so this is used for calculation of the pulse width of the current test transient • Since the rise time is short when compared to the fall time, the following equation is a sufficient approximation for α for a given pulse width TVS • The point to be plotted on the peak power vs. pulse width can be found recursively using the equations on the next slide by starting with 11 µs pulse width and widening it until energydesired ≈ energyoriginal • Plot the point on the graph • If the point is below the limit line, the TVS is suitable TVS _ . . _ Trace Size • D. Brooks, “Fusing Current – When Traces Melt Without a Trace”, Printed Circuit Design, a Miller Freeman publication, December 1998. – This paper presents equations to calculate steady state current handling capability of a given trace size – These equations calculate the fusing current and the time required for the trace to fuse with that current applied Trace Size • Using the fusing current, the time to fuse and the resistance of the trace; the energy required to fuse a trace can be calculated • The fusing trace width for a given copper weight (trace thickness) can be determined recursively using the equations on the next slide by starting with 1 mil wide trace and widening it until the energyoriginal ≈ energyfuse Trace Size . _ . Use the longest trace length _ Trace Size • Doubling the resultant trace width results in a trace width that is robust to the lightning test transient – Have designed over 1000 traces with none fusing – Currently researching simpler algorithms for accurately predicting fusing trace width – Also researching the required design margin for robust design Example Miniaturization Surface mount MOV Through‐ Hole MOV • Surface mount (SMT) Metal Oxide Varistor (MOV) compared to a Though‐Hole MOV with the same clamping voltage rating Example Miniaturization Data sheet comparison • Used algorithms detailed in this presentation to determine that the SMT part could be used in place of the through‐hole part Example Miniaturization Data sheet comparison – Max Peak Pulse (8x20µs) Current is the parameter used to select MOVs • Through‐hole rated at 4500A • Surface mount rated at 50A for 100 surges (non‐ repetitive), 80A for 20 surges, 100A for 10 surges, and 200A for 2 surges • Testing subjects unit to 20 surges, 10 positive, 10 negative – Algorithm results for this transient is 69.4A • The DC Resistance of the common mode choke is 0.2Ω Example Miniaturization • Test results using the following circuit Yellow Plot (V) Blue Plot (I) Green Plot (V) Purple Plot (V) Example Miniaturization • For the following test plots, the plots are as follows: – Yellow ‐ Voltage at injection point – Blue ‐ Current – Red ‐ Common Mode MOV on the Neutral side – Green ‐ Common Mode MOV on the Hot side • WF5A 500/500 and 1500/15 were tested • Through‐hole plots on the left and SMT on the right for side‐by‐side comparison Test Results Significance • The protection capability and ability to tolerate the transient of the Through‐ Hole MOV and the SMT MOV are compared. – The blue and green traces are the most significant. – The blue demonstrates ability to tolerate the transient – The green demonstrates the protection provided. Example Miniaturization 500V/500A Through Hole MOV SMT MOV Example Miniaturization 500V/500A Through Hole MOV SMT MOV Example Miniaturization 1500V/15A Through Hole MOV SMT MOV Example Miniaturization 1500V/15A Through Hole MOV SMT MOV References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. “Environmental Conditions and Test Procedures for Airborne Equipment”, RTCA/DO‐ 160E, RTCA Inc. December 9, 2004. “Aircraft Lightning Environment and Related Test Waveforms”, SAE ARP5412, Nov. 1999 C. A. McCreary and B. A. Lail, “Lightning Transient Suppression Circuit Design for Avionics Equipment”, EMC International Symposium on Electromagnetic Compatibility, 2012, pp. 93‐98, http://ieeexplore.ieee.org/xpl/articleDetails.jsp?tp=&arnumber=6351804&contentTy pe=Conference+Publications&refinements%3D4291944822%26ranges%3D2012_201 2_p_Publication_Year%26searchField%3DSearch_All%26queryText%3Dmccreary T. Ardley, “First Principles of a Gas Discharge Tube (GDT) Primary Protector”, www.bourns.com. D. Brooks, “Fusing Current – When Traces Melt Without a Trace”, Printed Circuit Design, a Miller Freeman publication, December 1998. “P6SMB6.8AT3”, Datasheet, ON Semiconductor Inc. February 2007. “SG73”, Datasheet, KOA SPEER Inc. January 23, 2008. “RCWP”, Datasheet, Vishay Inc. July 22, 2009. “WSC, WSN”, Datasheet, Vishay Inc. August 3, 2007 “Varistor Testing”, Application Note: AN9773, Littelfuse Inc. January 1998.