EMI / EMC Requirements for Navy Shipboard and Submarine

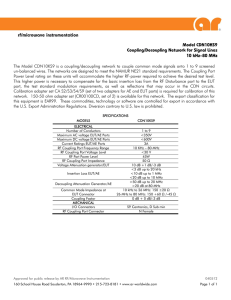

advertisement

EMI / EMC Requirements Navy Shipboard & Submarines Presented by Jeffrey Viel, EMI/EMC Director, NTS jeffrey.viel@nts.com Welcome Jeff Viel, Director of Technology, EMI / EMC • Mr. Viel is a degreed electrical engineer and Subject Matter Expert in electromagnetic interference design and compatibility testing. • For over 20 years Mr. Viel has been providing test planning and procedure development, project engineering/management, technical training, product design consultation services. His primary areas of expertise reside within the related EMI/EMC Defense, Aerospace, Department of Energy, and Telecommunications markets. • As NTS Director of Technology, EMI / EMC, he is responsible for overseeing 10 fully compliant EMI/EMC test laboratories worldwide. As SME he provides EMI/EMC training for NTS employees, clients and colleagues including the NYCT where he is recognized by the Practicing Institute of Engineering Inc. (PIE) for the state of NY as an EMI course instructor. • Mr. Viel is a 9 year veteran of the United States Marine Reserves and holds a BSEE from Northeastern University. He is a member of the IEEE and participates on many technical committees, including SC135 RTCA DO160, and SAE International where he is a voting member of the EMC standards committee. 2 Shipboard & Submarine General EMI/EMC Requirements MIL-STD-461 (Subsystem level) • Guidance Document which provides general EMI/EMC requirements for all electrical and electronic based equipment and subsystems required by all branches of the DoD. • Permits tailoring of test criteria determined on a case-by-case basis. • Addresses Emissions and Susceptibility criteria. – All inclusive document including test methods, limits, and levels. – Also includes a detailed appendix for detailed test descriptions, and tailoring activities. 3 Applicability Matrix Naval Shipboard EMI / EMC Requirements This is a general applicability list and does not address limited or specified type tests. MIL-STD-461F Description Applicability CE101 Conducted Emissions, Current 30 Hz to 10 kHz Input Power Lines CE102 Conducted Emissions, Voltage 10 kHz to 10 MHz Input Power Lines CS101 Conducted Susceptibility, Voltage 30 Hz to 150 kHz Input Power Lines CS106 Conducted Susceptibility, Transients Input Power Lines CS109 (Subs only) Conducted Susceptibility, Structure Current 60 Hz to 100 kHz Enclosure CS114 Conducted Susceptibility, BCI 4 kHz to 200 MHz All interconnecting cables CS116 Conducted Susceptibility, Damped Sinusoidal Transients 10 kHz to 100 MHz All interconnecting cables RE101 Radiated Emissions, Magnetic Field 30 Hz to 100 kHz Enclosure RE102 Radiated Emissions, Electric Field, 10 kHz to 18 GHz Enclosure RS101 Radiated Susceptibility, Magnetic Field 30 Hz to 100 kHz Enclosure RS103 Radiated Susceptibility, Electric Field 2 MHz to 18 GHz Enclosure 4 EMI / EMC Test Requirements An approved Electromagnetic Interference Test Plan (EMITP) is required prior to conducting formal testing per DI-EMCS-80201C . • Detailed step by step procedures of each applicable test method. • Limits (emissions tests), Levels (susceptibility tests). • Justification for any tailored activities, exceptions, or exclusions. • Detailed description of the equipment being tested • Purpose and intended function of the equipment under test (EUT). • Parametrics (size, weight, power requirements, etc…) • Configuration (number of cables, types of cables, length of cables expected in the installation, grounding configuration, & operational parameters. EMI / EMC Test Requirements • EUT cabling must be representative of the actual installation! • Equipment cabling plays a major roll in EMI/EMC compliance to MIL-STD-461. The type of cable used may impact both emissions and susceptibility test results. • Twisted or untwisted unshielded pairs • Shielded or unshielded cabling • Cable shields grounded at one or both ends. 6 EUT Cable Lengths are Specified Input Power Cables Defined as any input lead that obtains power from a shared utility source (not part of the EUT). • 2 meters routed to front edge of set up from EUT to the LISN termination. Shall not exceed 2.5 meters in total length. Interconnecting Leads and Cables Defined as any electrically conductive lead or cable that interfaces with the EUT (communication, alarm, or power). • Shall be the actual installation length. If greater than 10 meters, at least 10 meters will be required. • If actual length is unknown or un-specified, then at least 2 meters shall be provided. 7 EUT Installation Requirements Equipment Cable Routing • All electrical cabling is elevated above the ground plane by 5 cm to minimize capacitive coupling effects. • Cables are routed to the front edge of the test setup for 2 meters and separated by 2 cm. • The cable closest to the front edge shall be spaced 10 cm from the front edge of the ground plane. 8 EUT Installation Requirements: Orientation & Loading • EUTs shall be oriented such that surfaces which produce maximum radiated emissions and/or respond most readily to radiated signals face the measurement antennas. (door seams, large apertures, ventilation ducts, connector panels, video displays, etc…) • All EUT electrical interfaces shall be terminated with either the actual equipment from the platform installation or representative loads which simulate the electrical properties. • Generally, the maximum load is selected to represent the installation environment (within reason). • Equipment orientation and loading are generally determined by analysis or test. 9 EUT Installation Requirements: Bonding and Grounding • Only the provisions included in the design of the EUT shall be used to bond units such as equipment case and mounting bases together, or to the ground plane. • When bonding straps are required, they shall be identical to those specified in the installation drawings. • Shock or vibration isolators shall be used if required in the installation. • The bonding straps shall only be used when furnished with the mounting base. Grounding strap 10 EMI/EMC Test Requirements • Precautions are commonly taken to ensure electrical support/monitoring and loading circuits do not interfere with emissions measurements, or become susceptible when interface cabling is subjected to EM exposure tests. • Cables shield terminations at the feed-through port, or EMI filtering of unshielded lines are commonly required. However, potential effects of these precautions must be considered. 11 CE101 Conducted Emissions Current Test Method • Applicable to AC or DC input power leads that obtain power from sources not considered part of the EUT. • Current measurement (dBµA) made between 30 Hz – 10 kHz. • Pass fail criteria based upon set (not to exceed) limits. • Limits are based on the current waveform measurement criteria specified in MIL-STD-1399 section 300A. 12 CE101 Conducted Emissions Current Test Method • 60 Hz power limits for Surface Ships & Submarines are based on power demand (i.e., < 1kVA, or ≥ 1kVA). • The basic < 1kVA limit is based on a fundamental current draw of 1 amp 120 dBµA decaying to 76 dBµA at 10 kHz (20 dB/decade slope rate). • The limit is relaxed/extrapolated where EUT fundamental currents exceed 1 amp, but less than 1 kVA Limit Relaxation: 20*log (rms current) 13 CE101 Conducted Emissions Current Test Method • The basic ≥ 1kVA limit is also based an a 1 amp current draw. • Limiting harmonic currents to 3% of fundamental current draw of 1 amp from the 2nd harmonic to the 32nd harmonic, then decaying at a rate of 20 dB/decade to 10 kHz. • Limit is also relaxed using 20*log( current) over 1 amp. 14 CE101 Conducted Emissions Current Test Method • Submarines also have a CE101 limit for DC power applications. 15 CE101 Design Considerations • Odd Harmonic orders currents can be problematic for power conversion technologies used in power supplies, VFD’s and motor controllers. • Internal filtering is designed assuming maximum load currents which becomes less effective at lower current draws. • Additional filtering is commonly needed for high current systems operating a loads < 60% of full rated capacity. Conventional low pass EMI filters are ineffective in suppressing harmonic currents due to their low frequency cut off. 16 CE102 Conducted Emissions Voltage Test Method • Voltage measurement (dBµV) 10 kHz to 10 MHz. • Applicable to AC or DC power leads that obtain power from sources not part of the EUT. • Measurement made off of each 50 µH Line impedance stabilization Network (LISN). • • Derived from the ANSI C63.4 low frequency & high frequency circuits. Impedance value can be tailored to best match the product and installation. 17 CE102 Conducted Emissions Voltage Test Method 18 CE102 Conducted Emissions Voltage Test Method • One basic curve is used for all applications (based on 28 Volts), then relaxed based upon the specific operating voltage. • The 28 V curve is place 20 dB lower than the MIL-STD-704 Power quality curve to minimize additive noise contributions from platform equipment, and to account for platform bus impedance variances. • The relaxation for other voltages is based on the relative control levels for ripple voltage. 19 CE102 Design Considerations • EMI power line filters are commonly required to comply with CE102. • Be aware of the EMI filter selected, not all are created equally! • MIL-STD-461 starts at 10 kHz • FCC/CE Mark starts at 150 kHz • MIL-STD filters are generally larger/heavier, and more expensive. • Be aware of the Navy shipboard requirement for common mode capacitance! • 0.1 µF for 60 Hz • 0.02 µF for 400 Hz • 0.03 µF for DC loads < 500W on Submarines • 0.075 µF/kW of connected load >500W on submarines • Do not assume a device that meets FCC or CE Mark Criteria will comply with MIL-STD-461. • MIL-STD-461 requires peak data (worst case) • FCC/CE Mark requires quasi-peak , and average data. (modulated noise contribution). 20 RE101 Radiated Magnetic Field Emissions Test Method • Note that the limit does not take into account magnetic effects from equipment such as magnetic launchers, magnetic guns and the like. Amplitude (dBpT) • Near field radiated Magnetic field emissions test performed from 30 Hz to 100 kHz. • Intended to limit the low frequency magnetic field emissions from equipment due to the close proximity of electronic and electrical systems and associated cables installed on the Navy platforms, and the sensitivity of low frequency sensors and systems. (low frequency acoustic systems, ELF, VLF/LF communications systems and sensors that have sensitivities in the nV range). 21 RE101 Radiated Magnetic Field Emissions Test Method • Magnetic field measurements made with a electrostatically shielded loop antenna (13.3cm diameter). • Measurements made 7 cm from all faces of the EUT, and connectors to locate and maximize the magnetic field level. • Minimum of 2 frequencies per octave below 200 Hz • Minimum of 3 frequencies per octave above 200 Hz • If the specified emissions limits are exceeded, the measurement distance is increased until the emissions fall within the limit. • EUT Still needs to meet the criteria at 7 cm distance. 22 RE101 Design Considerations • Position high magnetic field emitters as far away from enclosure walls. • Try to minimize loop lengths, loop diameters. • Magnetic field intensity is proportionate to the distance from the source. • Use steel versus aluminum cabinets or enclosures to minimize magnetic field readings. • Use small patches of ferrous material to redirect and dissipate field currents. • Ferrous materials like steel, or Mu metals possess high absorptive properties which can be used to reduce magnetic emissions 23 RE102 Radiated Electric Field Emissions Test Method • Measures the electric field emissions radiated from equipment enclosures and cables from 10 kHz – 18 GHz. • • Testing is required up to 1 GHz or 10x highest clock to 18 GHz. RE102 Testing not required above 18GHz. • Measurement are made with linearly polarized antennas. • • • Vertically polarized fields measured <30MHz (using rod antennas) Horizontally and vertically polarized fields measured >30MHz. Specific Antenna types: 10kHz – 30 MHz 104 cm (41 in) rod, with impedance matching balun. 30 MHz – 200 MHz Biconical (137 cm) tip to tip 200 MHz – 1GHz Double ridge horn 69 cm by 64.5 cm opening 1 GHz – 18 GHz Double ridge horn 24.2 cm by 13.6 cm opening • Log spiral antennas, and Log periodic antennas are not permitted. 24 RE102 Radiated Electric Field Emissions Test Method • All measurements are made from a distance of 1 meter. • Number of antenna positions are to be determined. • Below 200 MHz- the test boundary is divided by 3 and rounded up to nearest integer. • Between 200 – 1000 MHz entire width of EUT, plus first 35 cm of cables must be within 3 dB beamwidth. • Above 1 GHz entire width of EUT, plus first 7 cm of cables must be within 3 dB beamwidth. 25 RE102 Design Considerations • A device that has met FCC or CISPR radiated emissions requirements may not meet RE102. • MIL-STD-461 requires peak measurements made at 1 meter, FCC and CISPR requires quasi peak and average measurements made from either 3 or 10 meters. • Differences in test methodologies make comparing results difficult. • Cables contributors to radiated emissions not just equipment enclosures. • 2 meters of cabling is intended to maximize radiated coupling from 10 kHz – 18 GHz. – < 150 MHz noise problems are generally related to cable issues. – > 150 MHz noise problems are generally related to enclosure issues. • Shielded cables and/or integrated EMI filtering are common solutions. • Good electrical Bonding and grounding schemes will help reduce most RE102 issues. Per MIL-STD-464C: • 10 milliohms or less from the equipment enclosure to system structure, including the cumulative effect of all faying surface interfaces. • 15 milliohms or less from cable shields to the equipment enclosure, including the cumulative effect of all connector and accessory interfaces. • 2.5 milliohms or less across individual faying interfaces within the equipment, such as between subassemblies or sections. 26 RS101 Radiated Magnetic Field Susceptibility Test Method • Ensures equipment performance does not degraded when exposed to magnetic fields radiated from 30 Hz to100 kHz. – Applicable to all Navy Shipboard equipment. – For submarines, only applicable to equipment operating at 100 kHz or less and with an operating sensitivity of 1 μV or less. • The Navy limit was established by measurement of magnetic field radiation from power distribution components (transformers and cables), and the magnetic field environment of Navy platforms. 27 RS101 Radiated Magnetic Field Susceptibility Test Method • A 12 cm transmit loop consisting of 20 loops of 12 AWG. Wire. • The loop is oriented in the parallel axis 5 cm from EUT. • It is Positioned every 30 cm x 30 cm (1 foot ²) area over each face including each connector interface. • Initially field levels 10 dB greater than specified are produced (not to exceed 15 amps) to quickly detect potential susceptibility issues. 28 RS101 Design Considerations • Similar to the RE101 design considerations. • Position sensitive magnetic field receivers away from enclosure walls. • Try to minimize loop lengths, loop diameters. • Magnetic field intensity is proportionate to the distance from the source. • Use steel versus aluminum cabinets or enclosures to minimize magnetic field readings. • Use small patches of ferrous material to redirect and dissipate field currents. • Ferrous materials like steel, or Mu metals possess high absorptive properties which can be used to reduce magnetic emissions 29 RS103 Radiated Susceptibility Electric Field Test Method • RS103 ensures that equipment will operate without degradation in the presence of electromagnetic fields present at the installation platform. • RS103 is required to 18 GHz, but may be extended to 40GHz by the procuring agency. • Driven by the platform EME, & Risk of exposure to intentional radiators (above decks, located external to ships or subs hull). • RS103 levels are simply based on levels expected to be encountered during the service life of the equipment. – – – – Ships internal, Below Decks- Metallic Hull – 10 V/M Ships internal, Below Decks- Non-Metallic Hull – 50 V/M <30 MHz, 10 V/m >30MHz Submarines Internal – 5 V/m <30 MHz, 10 V/M >30 MHz Ships & Submarines External – 200 V/m Note * Equipment located external to the pressure hull of a submarine but within the superstructure, use the Ships (metallic) below decks limit (10 V/m) • These test level do not necessarily represent the worst-case environment to which the equipment may be exposed. RF environments can be highly variable, particularly for emitters not located on the platform. 30 RS103 Radiated Susceptibility Electric Field Test Method • Antenna positioning similar to RE102 methods. • Transmit antenna set at a distance of 1 meter for EUT & cabling. • Number of antenna positions are to be determined. – Below 200 MHz- the test boundary is divided by 3 – – and rounded up to nearest integer. Between 200 – 1000 MHz entire width of EUT, plus first 35 cm of cables must be within 3 dB beamwidth. Above 1 GHz entire width of EUT, plus first 7 cm of cables must be within 3 dB beamwidth. 31 RS103 Radiated Susceptibility Electric Field Test Method • The frequency range can be swept or stepped – Each discrete stepped frequency shall be dwelled for a time based on the equipment operating cycle, but for no less than are 3 seconds . • The step size above 1 GHz has been relaxed to expedite testing . However critical frequencies that would not be covered must be specifically included in the RS103 test range. Susceptibility Thresholding • Susceptibility and operational anomalies are not acceptable. • When EUT susceptibility is detected, a threshold level shall be determined where the susceptible condition is no longer present. • • • reduce the interference signal until the EUT recovers. Reduce the interference signal by an additional 6 dB. Gradually increase the interference signal until the susceptibility condition reoccurs. 32 RS103 Radiated Design Considerations • RS103 Design considerations are similar to those described for RE102. • Radiated susceptibility can be caused by cabling as well as equipment enclosures. • 2 meters of cabling is intended to maximize radiated coupling from 10 kHz – 18 GHz. – Susceptibility issues < 150 MHz are generally related to cable issues. – Susceptibility issues > 150 MHz are generally related to enclosure issues. • Shielded cables and/or integrated EMI filtering are common solutions. • Seems, slots, and apertures are points of entry and potential causes for susceptibility. • • 360 degree cable shield terminations, filtered connector assemblies, or PCB mount filtering will improve cable induced susceptibility issues. The use of EMI compression gaskets around doors, and panels will improve enclosure induced susceptibility issues. • Low transfer impedance and high shielding effectiveness of cables and enclosures will reduce internal noise from getting out, and external noise from getting in. • • IEEE 299 describes test methods for evaluating shielding effectiveness of enclosures Test standards, IEC 61196-1 , IEC 62153-4-6 describe methods for evaluating transfer impedance and shielding effectiveness for shielded coaxial cables. 33 CS101 Conducted Susceptibility Voltage Test Method • Injects a swept AC signal onto EUT input power leads (high sides only) . • • Test Levels are based on input voltage level • • Intended to ensure that equipment performance is not degraded from differential mode ripple voltages associated with allowable distortion of shared utility sources. • no requirement to test output power leads. Either Curve#1 > 28V, or Curve#2 ≤28V • 30 Hz – 150 kHz ( DC power leads) • 2nd harmonic – 150 kHz (AC leads) CS101 limits are based on the spectral content requirements of MIL-STD-704. • Curve#1 is approximately 6 dB above typical power quality limits, although the limit has been somewhat generalized to avoid complex curves. • The difference between the limits for CE102 and CS101 of approximately 26 dB should not be viewed as a margin. • The CE102 limit is placed so that ripple voltages do not exceed that allowed by the power quality standards due to interference contributions from multiple EUTs. 34 CS101 Conducted Susceptibility Voltage Test Method • The test voltage is coupled to the input power through a coupling transformer. • The signal generation equipment must be capable of achieving the voltage into a .5 ohm load (80 Watts), while maintaining a sinusoidal waveform. • Test can also be performed on 3 phase systems (one phase tested at a time). • Performed on system current draws up to 100 amps. • Voltage Threshold verification is performed where susceptibility is detected. 35 CS106 Conducted Susceptibility Transient Test Method • A test which simulates voltage transients experienced on shipboard power systems coupling to interface wiring inside enclosures. • Typically caused by switching of inductive loads, circuit breaker (or relay) bounce, and load feedback onto the power distribution system. • Applicable to submarine and surface ship equipment and subsystem AC and DC input power leads, not including grounds and neutrals. 36 CS106 Conducted Transient Test Method • The 400 volt peak, 5 microsecond pulse represents the typical transient observed on 115V and 440V power distribution systems. • Measurements of transients on Navy platforms have shown the transient durations (widths) are predominantly in the 1 – 10 microsecond range. • The large majority (> 90%) of the transients measured on both the 115 volt and 440 volt ac power distribution systems were between 50 and 500 volts peak. 37 CS106 Conducted Transient Test Method CS106 Single phase test setup 38 CS109 Structure Current • Applicable to equipment and subsystems that have an operating frequency of 100 kHz or less and an operating sensitivity of 1 μV or better (such as 0.5 μV). • Handheld equipment is exempt from this requirement. • This test procedure is used to verify the ability of the EUT to withstand structure currents up to 1 amp. 39 CS109 Structure Current Test Configuration • • • AC sources are isolated Safety grounds are disconnected A single point ground condition is established. Equipment that will not be rack mounted: At diagonal extremes across only the mounting surface. Rack mounted equipment: At diagonal extremes across all surfaces of the equipment. Deck resting equipment: At diagonal extremes across all surfaces of the equipment. Bulkhead mounted equipment: At diagonal extremes across rear surface of the equipment. Cables (all mounting methods): Between cable armor, which is terminated at the EUT, and the single point ground established for the test setup. 40 CS114 Conducted Susceptibility BCI Test Method • Simulates currents that will be developed on platform cabling from EMI fields generated by antenna transmissions (RS103) both on and off the platform. • CS114 provides data that can be directly related to induced current levels measured during platform-level evaluations. • CS114 is performed on all power & signal cables. • Additionally, EUT’s intended to be installed on ships or submarines, testing from 4 kHz to 1 MHz shall be performed on complete power cables (common mode test). 41 CS114 Conducted Susceptibility BCI Test Method CS114 Test Levels for Navy Ships All Ships & Subs (common mode) Metallic Ships Below decks Metallic Ships Above decks 42 CS114 Conducted Susceptibility BCI Test Method CS114 Calibration CS114 Test 43 CS116 Conducted Susceptibility Sinusoidal Transient Test Method • Simulates damped sinusoidal transients occurring in platforms from excitation of natural cable resonances. • Caused by both external stimuli (lightning and electromagnetic pulse) and from platform electrical switching phenomena. • Broad frequency coverage (10 kHz – 100 MHz) to account for a wide range of conditions. Applicable to all interconnecting cables (I/O, power cables), including individual high side power leads. • Power returns and neutrals need not be tested individually. 44 CS116 Conducted Susceptibility Sinusoidal Transient Test Method • Performed at 10 kHz, 100 kHz, 1 MHz, 10 MHz, 30 MHz, and 100 MHz. • Additional specific resonance frequencies can be selected if known. • Transients between1 MHz and 30 MHz Can reach up to 10 Amps peak • Required for all procurements (Air Force used to be 5 amps) • Applied at a 1-2 pps rate for 5 minutes per cable. • Performed during for each mode of operation. • “Powered Off” testing requirement was removed. 45 CS116 Conducted Susceptibility Sinusoidal Transient Test Method • Pulses are inductive coupled to each line. • Induced Currents are monitored during the test. • Method similar to CS114 and CS115. • A threshold analysis is required at each frequency where susceptibility is observed. 46 Conducted Susceptibility Design Considerations • Robust cable shielding and proper ground terminations are common design implementations for MIL-STD 461 compliance. • Low impedance terminations (transfer impedance < 15 milliohms). • High Shielding Effectiveness (SE = > 60 dB). • Installing low pass EMI filters and properly rated surge protection devices on power lines and unshielded lines is highly recommended. • EMI Filters should be designed to provide between 40 and 60 dB of insertion loss at 10 kHz. However, some product designs will allow 20 dB. • Be cognizant of the Navy common mode capacitance limitations for power entry filtering. Inductive filters are commonly used. • Metal Oxide Varistors, and/or zenor diode type transient suppressors 47 Thank You For more information please visit www.nts.com. Follow us for updates and articles!