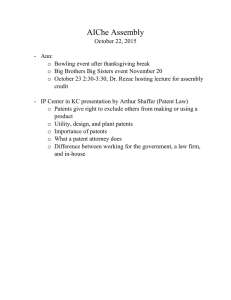

The Role of the National Science Foundation in the Origin and

advertisement