ArcelorMittal USA Plate Steel Specification Guide 2015-2016

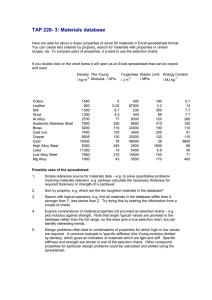

advertisement