MF300 Remodel Trimless Installation Instructions

advertisement

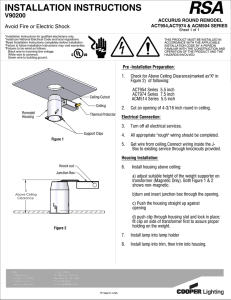

MF300 TRIMLESS REMODEL INSTALLATION INSTRUCTION Warnings: • Risk of fire or electric shock. • Disconnect all power before installing or servicing. ­• Installation Instructions for qualified electricians only. • Install per National Electrical Code and local regulations. • Read Installation Instructions completely before installation. • Failure to follow Installation Instructions may void warranties. • Always use correct lamp type and wattages. C Required Measurement Driver Compartment Quick Connect Spring Latch Ceiling Material Drywall Screws THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED. ® US FIXTURE MOUNTING: Housing Compartment IMPORTANT: Precise measurements of the housing O.D. (Not including the flange return) are required prior to installation. 1. Make ceiling cut-out .0625” wider than housing measurements as Deep Sleeve noted above. Swing-Out Adjustable Tabs (Qualified electricians only). Flange Return housing wall. 2. Make all necessary electrical connections to driver compartment Swing-out Tabs Adjustment Screw 3. Insert housing through opening with swing-out tabs parallel to 4. Turn the swing-out tab adjustment screw. The tab will swing out over the ceiling material, continue to adjust until tabs captures the ceiling between it and the housing flange return. 5. Plug in the power supply line to the light source using the quick connects provided. 6. Compress the torsion springs at each end of trimless frame and Torsion Springs place into spring latches located on each side of the inner housing. This will capture the trimless frame to the ceiling material. Mud Plate 7. Fasten each corner of the perforated mud plate into the ceiling material countersinking the screw into the perforated screen to allow for a smooth screed finish transition from ceiling to edge of trimless collar. Screed Finish Trimless Collar Fasten each corner using drywall screws Perforated Mud Plate LED PRODUCTS: • LEDs are ESD (Electro Static Discharge) sensitive devices that can be easily damaged if the proper ESD mitigating steps are not taken. • LEDs are very sensitive to mechanical damage. CAUTION MUST BE TAKEN TO AVOID DAMAGE TO THE LEDs. • ESD or mechanical damage voids all warranties. NOTE: ALL WORK MUST BE DONE WITH CIRCUIT OFF AND COMPONENTS SHOULD NOT BE INSTALLED WHEN ENERGIZED. It is IMPORTANT TO READ instruction sheet completely before installation. ©2016 LF ILLUMINATION LLC HEADQUARTERS Telephone: 818-885-1335 We reserve the right to change or 9200 Deering Avenue Toll Free: 855-885-1335 withdraw specifications without prior notice. Chatsworth CA 91311 Fax: 818-576-1335 www.lfillumination.com 05.27.16