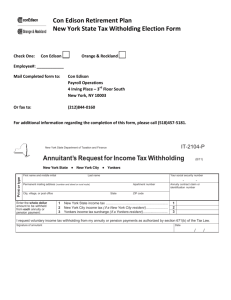

High Tension Service Welcome Kit

advertisement

Introduction This Information Guide has been prepared by Con Edison (the Company) for customers who are planning to install high tension substations. It provides a high-level, non-technical introduction to the sequence of events involved in the construction of a high-tension substation. Included are a high level schedule showing how major Customer and Con Edison activities are sequenced and key points of information to assist our customers in the development of their design and construction schedule. This information guide is a companion to Con Edison’s Company specification EO-2022 “General Specification for High Tension service” which provides detailed technical requirements.. This document is not intended as a design specification or an instruction manual. This document is for informational purposes only and Consolidated Edison Company of New York shall not be held liable for indirect, special, incidental, punitive or consequential damages of any kind including loss of profits, arising under or in connection with the use of this Information Guide. Description of High Tension Service Con Edison provides service to high tension service Customers at a nominal voltage of 4kV, 13kV, 27kV or 33kV depending on location. To achieve this, the Company extends 4kV, 13kV, 27kV or 33kV feeders to a manhole at the Customer property line1 (or to a pole at the Customer property line). The Company owns and maintains its feeders up to the property line manhole and the Customer will design, install, own and operate all equipment from the property line termination point (manhole or splice chamber), including cables, circuit breakers, transformers, and associated equipment (see figure 1). While the Customer owns the substation, Con Edison evaluates the design and construction of the substation to ensure that they will not have an adverse impact on the electric distribution system. As will be shown later, Con Edison’s contribution to the project is primarily the performance of design reviews and extension of its feeders to the customer premises. 1 The Company works with the Customer to select a convenient position for the property line manhole to minimize the amount of street construction needed to extend the primary feeder to the customer. Where the Customer prefers another location, they are usually required to pay the difference in cost. 2 Figure 1 - Diagram of a Typical 4 Feeder High Tension Service Communication between the Customer and Con Edison Several departments within the Company will be involved in the High Tension project. Some departments will be assessing the Customer’s design while others will be making system changes to provide service. It is important that these groups are aware of the Customer’s schedule and that the Customer is made aware of certain scheduling constraints. For example, the Company does not typically perform work in the summer that requires an outage on a feeder, as this is the period of peak electricity demand. The customer and Company need to work together to ensure that tasks are scheduled, and completed, in a time windows that minimize delays. The Company will appoint a Customer Project Manager (CPM) who will act as the liaison between the Customer and the Company. The CPM will ensure that the requirements of each department are clearly communicated to the Customer and that the Customer’s questions are directed to the appropriate internal department that can provide the answer. 2 Depending on load being served, between three and six feeders may be required. - High Tension Service Customer Guide: September 2010 - 1 While the Customer may delegate the day to day management of the project to a consultant, we encourage the Customer to periodically meet with the CPM to discuss the progress of the project. Figure 2- Typical Interactions between a customer and Con Edison The Process There are a number key milestones involved in a high tension project. The Customer’s consultant should include these in the project timeline and the schedule should be updated after each milestone has been reached. Submission of Load letter to Con Edison Preliminary Design Review Kickoff Meeting Receipt of Signed Con Edison HT specification (EO-2022) Design Review Complete Customer Conduit and Manhole Installation Manufacturers’ Design Package Review Final Design Review Customer’s Electrical Equipment Installed Con Edison Cables Installed Pre-Operational Testing Completed Metering/Energization - High Tension Service Customer Guide: September 2010 - 2 Experience shows that the duration of a High Tension project is largely determined by the pace of the design and construction of Customer facilities. Con Edison’s construction activities will be coordinated to accommodate the customer’s schedule. Figure 3 - Major HT Project Milestones As you review the high-level schedule outlined in figure 3, keep in mind that the design is not typically fully completed before construction starts. Construction begins once design of major items is completed and detailed items are defined as the project progresses. The duration of a High Tension project varies based on the complexity of the project, based on factors such as number of feeders, green field construction vs. modification of an existing facility. The timeline shown in figure 3 indicate the recommended sequence of major milestones that have a Con Edison involvement. It is recommended that the Customer include these milestones in their project plan that is submitted to Con Edison - High Tension Service Customer Guide: September 2010 - 3 Submit load letter to Con Edison The initial service request (load letter) is typically delivered to the Customer Project Manager (CPM) indicating the customer’s desire to obtain service at a certain location. The service request will include a breakdown of the individual loads at the service location. After internal engineering review, the CPM will provide a service ruling indicating the service voltage, the number of feeders, the preferred point of entry, etc. The Customer will use this information to develop the Customer’s preliminary one-line diagram. Preliminary Design Review Once the customer has developed a one-line diagram, it is recommended that they send it to Con Edison for a preliminary review. Kickoff Meeting [Approximately 1 month after the initial inquiry] After completing an initial review of the Customer’s One-Line diagram, the CPM will schedule a meeting between Con Edison’s engineering group and the customer’s engineering staff to discuss Con Edison’s high tension service requirements and any site specific issues. During the course of this meeting, the Customer’s project schedule and expected completion date will be discussed with respect to how the Company-related portions of the project can be optimally sequenced. At this meeting, the customer is expected to present a signed copy of the Company’s specification EO-2022, which commits the Customer to meet the Company’s standards. Design Reviews [ Dependent on customer progress] The Customer will be required to develop their substation design to meet the Company’s interconnection requirements as identified by the preliminary One-Line, the site specific design specification and associated Company’s general high tension specification EO-2022. The Customer should submit their design documents when the design is approximately 30% complete and again when the design is approximately 60% complete. Experience has shown that such periodic review ensures that the Customer is incorporating the necessary requirements and greatly reduces the need for changes and the consequential delays in the project] The first design submittal for review is at approximately 30% completion of the substation design. At this stage we expect to see general equipment layout, cable routing, etc. At the end of this review construction of switchgear rooms, ducts and associated work will typically proceed, and major items such as switchgear and transformers are ordered. This submittal shall at a minimum include the following drawings: AC One-Line Diagram AC Three-Line Diagram Substation Floor Plan (including room layouts) Substation primary conduit plans and arrangements Substation Grounding Plan and associated calculations - High Tension Service Customer Guide: September 2010 - 4 Primary Switchgear Arrangements (Both Service and Utilization Voltage) Transformer Vault Design AC and DC Circuit Breaker control Schematics (Both Service and Utilization Voltage) DC Control Battery One-Line diagram detailing the battery and charger types, distribution panels, transfer switches, relaying and alarms, and associated calculations Site Plan Showing Incoming Service Duct Arrangements and P/L MHs Emergency generator details and arrangements (if applicable). The Company shall issue comments subsequent to this review. The Customer should meet with the Company’s engineering forces to discuss the design. The Customer will be expected to address the comments issued by modifying these drawings as appropriate and re-submitting these revised drawings for Company review and acceptance. The second design submittal, at approximately 60% completion and will add detail to the items submitted in the 30% review. At this stage we expect to see protection calculations, vendor drawings of major equipment already ordered (but not yet delivered), cable terminations etc. This submittal will include the following: Bill of Materials - including all relays, voltage & current transformers (showing ratios and connections), fuses, and interrupting & grounding devices A relay coordination study and proposed protective relay settings Termination Compartment equipment showing the arrangement of the cable terminations, neon indicators and ground studs Metering compartment equipment showing the physical layout & clearances, barriers, and phasing facilities Bus, Cables & Terminations (manufacturer's specifications) Ground & Test Devices or Ground Switches - manufacturer, detailed description of operation, equipment drawings, specifications, and interlocks Vendor drawings and specifications Emergency Generator - interlocking procedures, load to be supplied, and testing schedule The Customer shall subsequently submit the manufacturer’s design drawings for the following equipment: High Tension Switchgear (both Service and Utilization voltage) Ground and Test Device arrangement drawings Service/Isolation Transformer nameplate and arrangement drawings Remote Control Monitoring Panel drawings The customer’s Bill of Materials Prior to final inspection and testing, the Customer shall submit final design documents for review. Pre Operational Testing [4-8 weeks] - High Tension Service Customer Guide: September 2010 - 5 This includes such activities as relay testing, switchgear inspection and operational tests, cable tests, completing meter installations, etc. Feeder Energization Customer Documentation - Prior to energization the Customer shall resubmit to Energy Services their final submittal package corrected and marked final and stamped by a Professional Engineer for Company record. Outage Scheduling [1 week per feeder] Once all testing is completed and the required documentation is in place, the CPM will schedule the outages and initiate the splicing of the customer’s cable to Company cable in the customer property line manhole. This is not typically done during the summer as this is the period of peak electricity demand. The project schedule should ensure that this point is arrived at outside summer months. - High Tension Service Customer Guide: September 2010 - 6 Key Points of Information The city of New York places an embargo on non-emergency street excavations during the winter holiday period to minimize traffic disruptions. Company does not typically perform non-emergency work on primary feeders between May 15 and September 15. Customer property line manholes need to be completed before the ducts can be built for the extension of primary feeders to the customer. The customer should ensure construction of property line manholes are completed in time to allow Company to build the necessary ducts before the embargo periods. Experience has shown that High Tension projects typically take one to three years or more to be completed, depending on the complexity of the Customer’s design. Early submission and close coordination are critical to ensure the Customer’s desired service date is met. Reference 1. EO-2022 “General Specification for High Tension Service”. - High Tension Service Customer Guide: September 2010 - 7