FIO EZ - Pietro Fiorentini

advertisement

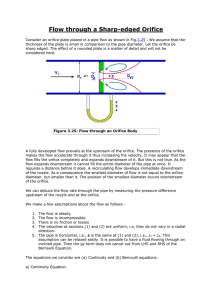

FIO EZ Un-Pressurized Orifice Fittings FIO EZ Classification and Application Fields The FIO EZ un-pressurized Orifice Fitting is a device that houses, and accurately positions, an orifice plate for measuring flow within a pipe or tube. When placed in the FIO EZ un-pressurized Orifice Fitting, an orifice plate will produce a differential pressure by abruptly constricting the medium flowing through it. The differential pressure is measured across the plate through two taps located on the FIO EZ un-pressurized Orifice Fitting in the vicinity of the constriction. The FIO EZ un-pressurized Orifice Fitting single chamber design allows for the inspection and the replacement of orifice plates without removing the FIO EZ from the flow line. Use of the FIO EZ un-pressurized Orifice Fitting eliminates the effort required to remove and inspect an orifice plate housed in conventional orifice flange installations. Pietro Fiorentini designs and manufactures all FIO EZ units to A.G.A. 2000 recommendations. The FIO EZ un-pressurized Orifice Fitting is designed and manufactured in strict accordance with all applicable ANSI, ASME, ASTM and ISO 5167 specifications. Products bearing the “CE” mark are designed and manufactured in compliance with the European Union Pressure Equipment Directive (PED) 97/23/EC. Fig.1 2 FIO EZ Features and Benefits FIG. 945 179 Electroless Nickel Plated Provides Life-time Protection against corrosion 190 Three Points of Contact Metal-to-metal contact ensures meeting internal concentricity tolerances of ANSI 14.3 181 O-Ring Seal - Easily assembled at job-site - Reuseable many times during operating life - Body and bonnet metal-to-metal contact does not change the eccentricity of the orifice plate as may be possible with designs utilizing gaskets 178 AISI 316 Screw Provides Life-time Protection against corrosion and future maintenance is easier 180 Electroless Nickel Plated Provides Life-time Protection against corrosion All Pietro Fiorentini “FIO EZ” un-pressurized orifice fittings are designed and manufactured to current ISO 5167/API/AGA 14.3 standards. Alternate fittings are available in socket weld, threaded and weld ends upon request. 3 Providing Solutions for Oil and Gas TECHNICAL DATA FIG. 945 ROUGHNESS OF INTERNAL BODY SURFACES API/AGA 14.3 Report N°3 Body bore diameter D gap X B Seal diameter SECTION: 2.5.1.1 300 microinches per Beta ≤ 0.6 200 microinches per Beta > 0.6 ORIFICE PLATE API/AGA 14.3 Report N°3 - SECTION: 2.5.1.4 SEALING PLATE RING The orifice plate surfaces ‘B’ must not protrude into the bore ‘D’. BODY FITTING API/AGA 14.3 Report N°3 - SECTION: 2.5.1.4.2 In all Pietro Fiorentini pressurized orifice fittings, the distance ‘X’ is less than 0.25 inches. Temperature limits: -20° F +250° F ➀➁ TEST PRESSURE IN ACCORDANCE TO HYDROSTATIC TEST API 6D PNEUMATIC TEST CLASS ➀ BODY AND BONNET ➁ BODY ➂ PLATE 150 425 80 2.9 300 1100 80 2.9 600 2175 80 2.9 psi psi psi ➀➁ The test pressures listed are NOT valve operating pressure ratings. 4 BODY ➂ BLIND ORIFICE PLATE TECHNICAL DATA FIG. 945 THREE POINTS OF CONTACT This system enables the fitting to meet internal concentricity tolerances of the orifice plate as required by ISO 5167/API/ AGA 14.3 standards. max (ε) ECCENTRICITY FOR 0,75 BETA (β) SIZE Dm API/AGA 14.3 Report N°3 Section: 2.6.2.1 ECCENTRICITY (ε) API/AGA 14.3 εmax = Report N°3 Section: 2.6.2.1 where: εmax 2 2.066 0.005905 3 3.068 0.009055 4 4.025 0.011811 6 6.066 0.018110 0.0025 Dm 0.1+2.3 (βmax)4 Allowable plate bore eccentricity measured parallel to the axis of the pressure taps; Dm is the mean bore diameter; β is the maximum beta max ratio of the diameters used. inches 5 Providing Solutions for Oil and Gas CONSTRUCTION MATERIALS FIG. 945 X 178 180 179 181 277 279 222 278 220 14 190 1 13 X Sec. XX POS. 1 13 14 178 179 180 181 190 220 222 277 278 279 DESCRIPTION BODY DRAIN PLUG PLUG SCREW BONNET CLAMP O RING PLATE CARRIER SCREW WASHER WASHER ORIFICE PLATE SEALING PLATE MATERIALS ASTM A 216 WCB ASTM A 105 ASTM A 105 AISI 316 AISI 1035 AISI 1035 BUNA-N AISI 316 CARBON STEEL CARBON STEEL AISI 316 AISI 316 BUNA-N NOTES 2 2 1 1 2 2 Tab.2 Three-dimensional control NOTES 1 ENP (Electroless Nickel plated). 2 Zinc coated. 6 OVERALL DIMENSIONS FIG. 945 ORIFICE PLATE S S Butt-Welding End According to ANSI ASME B16.25 1/16” Ø D H B 1/2° 37 1” 1” RF+BW = Flange Facing According to ANSI ASME B16.5 R = FIG. 945-1 ND 2 3 4 6 CLASS 150 RF-BW 71/4 71/2 9 101/4 D* 2.067 3.068 4.026 6.065 B 3 4 47/8 6 H 45/8 51/8 55/8 73/8 S 45/8 51/4 53/4 63/4 R 1/8 1/8 1/8 1/8 pounds Inches FIG. 945-3 ND 2 3 4 6 CLASS 300 RF-BW 71/4 71/2 9 101/4 D* 2.067 3.068 4.026 6.065 B 3 4 47/8 6 H 45/8 51/8 55/8 73/8 S 45/8 51/4 53/4 63/4 R 1/8 1/8 1/8 1/8 WEIGHT 42 54 80 130 pounds Inches FIG. 945-6 ND 2 3 4 6 WEIGHT 41 49 68 114 CLASS 600 RF-BW 8 9 10 111/2 D* 2.067 3.068 4.026 6.065 B 3 4 47/8 6 H 45/8 51/8 55/8 73/8 S 45/8 51/4 53/4 63/4 WEIGHT 47 72 98 160 pounds Inches * Bore tolerance “D” ± 0.002” R 1/8 1/8 1/8 1/8 Other bores are available on special request ORIFICE PLATE DIAMETER Dp 2.437 3.437 4.406 6.437 R 1/8 1/8 1/8 1/8 Ø Dp ND 2 3 4 6 R (Thickness) Inches 7 Providing Solutions for Oil and Gas www.fiorentini.com The data are not binding. We reserve the right to make changes without prior notice. CT-s 635-US May 16