Infastech Inserts Design Guide

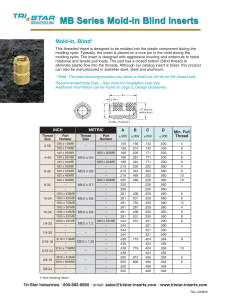

advertisement

Infastech Insert Design Guide Infastech Offices www.infastech.com The characteristics of Knurl and inserts • Crystalline plastics is relatively insensitive to stress, can apply for a variety of inserts. • Non-crystalline plastic is very sensitive to stress, the choice of inserts models should avoid sharp Knurl. For plastics who need to shield plating should be particularly careful, Helix angle the plastics buried inserts can cause serious cracking issue after acid washing process. It is best to plating first, then buried inserts. Knurl • Thermoset plastics does not apply for hot melt and ultrasonic burying, if it’s necessary, you can choose sophisticated and sharp Knurling with compression inserts process. Groove Pitch Lead Plastic characteristics Thermoset Plastics Thermoplastic Plastics Will not soften by heating Will soften by heating High hardness and easy broken Good flexibility Good surface hardness Can be recycled More stable with microstructure Easy for injection molding process Twist-pull relationship with the helix angle Good heat resistance performance Helix angle vs strength Difficulty for injection molding process Pull force Crystalline plastic KN (KN.M) infastech brass inserts The relationship between the plastic and inserts Torque 30 35 40 45 Helix angle Non-Crystalline plastic 50 55 60 Groove and Oriented Inserts materials and surface treatment • Standard Brass C3604 • Low-lead copper in line with the EC ROHS environmental protection requirements • Stainless steel / tin, free cutting iron • Surface Treatment: Under normal circumstances, inserts is not necessary for the particular surface treatment. If a special request, the plating can be used for processing. Lead • The effect-oriented role of lead can enhance the efficiency, at the same time to avoid the deflection and boss hole crack • Make sure the size of D is larger than d 0.03mm at least. Groove can accommodate the plastic to improve the pull force Brass Insert Applications Inner Thread Specification Herringbone For thermoplastic plastics application with ultrasonic and Nominal Size Toleranc e Aiguille dia m.m. Inch Hole dia, GO m.m. Inch Hole dia, NO-GO m.m. Inch M1X0.25 5H 0.77 0.0303 0.75 0.0295 0.785 0.0309 M1.2X0.25 5H 0.97 0.0382 0.95 0.0374 0.985 0.0388 M1.6X0.35 6H 1.3 0.0512 1.25 0.0492 1.321 0.052 M1.7X0.35 6H 1.39 0.0547 1.35 0.0531 1.421 0.0559 M2X0.4 6H 1.64 0.0646 1.61 0.0634 1.679 0.0661 M2.5X0.45 6H 2.12 0.0835 2.058 0.081 2.138 0.0842 M2.6X0.45 6H 2.23 0.0878 2.184 0.086 2.26 0.089 M3X0.5 6H 2.58 0.1016 2.515 0.099 2.599 0.1023 & pull out performance M3.5X0.6 6H 2.97 0.1169 2.926 0.1152 3.01 0.1185 Symmetry II For small plastic products with thin boss hole wall thickness M4X0.7 6H 3.38 0.1331 3.34 0.1315 3.422 0.1347 M5X0.8 6H 4.29 0.1689 4.2 0.1654 4.334 0.1706 Symmetry III For non-crystalline plastic application. Round knurl can avoid M6X1.0 6H 5.08 0.2 5 0.1969 5.153 0.2029 M7X1.0 6H 6.09 0.2398 6 0.2362 6.153 0.2422 M8X1.25 6H 6.83 0.2689 6.75 0.2657 6.912 0.2721 M10X1.5 6H 8.61 0.339 8.5 0.3346 8.676 0.3416 M12X1.75 6H 10.38 0.4087 10.25 0.4035 10.44 0.4111 hot-melt install process. Herringbone knurl can improve pull-out performance Shoulder For bigger draft angel (8 degree) plastic boss hole application. Groove with taper I For bigger draft angel plastic boss hole application. Diagonal knurl & taper can increase 25% torque & pull out performance Groove with taper II For bigger tolerance plastic boss hole application and provide good performance Symmetry I Fit with Auto install line. And herringbone knurl offer great torque sharp teeth. Rivet For thin plastic plate application Direct Push-in For most of thermoplastic plastics application and needn’t special equipment Full Burial For most of thermoset plastic application with sharp knurl. Outer thread One kind of self-taping insert, use for both thermoset & thermoplastic application. Outer Thread Specification I Internal Inch Direct Push-In Type T Head Thickness Inches H Head Diameter Inches W Insert Diameter Inches N Pilot End Diameter Inches No of Fine Rec.Hole -0.000 +0.004 Inches .157 .018 .189 .147 .123 2 .126 .063 .226 .023 .217 .178 .154 3 .157 .079 M3.5x0.6 .281 .029 .250 .209 .185 4 .189 .094 #8-32 M4x0.7 .321 .035 .281 .240 .218 5 .220 .110 #10-24 - .375 .042 .312 .274 .248 5 .252 .126 #10-32 M5x0.8 .375 .042 .312 .274 .248 5 .252 .128 #1/4-20 M6x1.0 .500 .052 .375 .337 .310 7 .315 .157 T Head Thickness Inches H Head Diameter Inches W Insert Diameter Inches #2-56 M2x0.40 .236 .023 .236 .177 .157-.161 .161-.159 #2-56 #4-40 M2.5x0.45 .236 .023 .236 .177 .157-.161 .161-.159 #4-40 M3x0.5 .236 .023 .236 .197 .177-.181 .181-.189 #6-32 #6-32 M3.5x0.6 .315 .029 .295 .236 .209-.213 .217-.224 #8-32 M4x0.7 .315 .035 .315 .256 .228-.232 .236-.244 .394 .042 .374 .315 .280-.283 .287-.299 #10-24 - Min.Wall Thickness Inches L Insert Length Inches L Insert Length Inches - Rec.Hole Rec.Hole Size Size Thermoplastics Thickness Inches +0.004 Inches Internal Inch Thread Size ISO Metric Evaluate by pre-production tests Thread Size ISO Metric M2x0.40 M2.5x0.45, M3x0.5 Min. Wall Thickness as Inches #10-32 M5x0.8 .394 .042 .374 .315 .280-.283 .287-.299 #1/4-20 M6x1.0 .551 .052 .472 .394 .339-.346 .354-.370 #1/4-28 - .500 .052 .375 .337 .310 7 .315 .157 .591 .052 .472 .394 .339-.346 .354-.370 #5/16-18 M8x1.25 .500 .052 .433 .400 .374 7 .378 .189 .591 .052 .551 .472 .417-.425 .433-.449 #5/16-24 - .500 .052 .433 .400 .374 7 .378 .189 .591 .052 .551 .472 .417-.425 .433-.449 .709 .062 .630 .551 .496-.504 .512-.528 .709 .062 .630 .551 .496-.504 .512-.528 #1/4-28 #5/16-18 M8x1.25 #5/16-24 #3/8-16 M10X1.5 #3/8-24 - Shoulder Type Outer Thread Specification II Internal Inch Thread Size ISO Metric Internal Inch L Insert Length Inches W Insert Diameter Inches Rec.Hole -0.0000 +0.004 Inches Min.Wall Thickness #4-40 #2-56 M20x0.40 .157 .146 .126 .063 #4-40 M2.5x0.45,M3x0.50 .228 .177 .157 .079 #6-32 M3.5x0.60 .283 .209 .189 .094 #8-32 M4x0.70 .323 .242 .220 .110 .374 .272 .252 .126 #10-24 - #10-32 M5x0.80 .374 .272 .252 .126 #1/4-20 M6x1.0 .500 .335 .315 .157 .500 .335 .315 .157 .500 .398 .378 .189 .500 .398 .378 .189 #1/4-28 #5/16-18 #5/16-24 M8x1.25 - #2-56 Thread Size ISO Metric M2x0.40 M2.5x0.45, M3x0.5 L Insert Length Inches T Head Thickness Inches H Head Diameter Inches W Insert Diameter Inches N Pilot End Diameter Inches Rec.Hole -0.000 +0.004 Inches Min.Wall Thickness Inches .157 .021 .187 .141 .123 .126 .051 .226 .024 .218 .181 .154 .157 .063 #6-32 M3.5x0.6 .281 .030 .250 .214 .185 .189 .071 #8-32 M4x0.7 .321 .036 .281 .248 .218 .220 .083 #10-24 - .375 .043 .312 .278 .249 .252 .102 #10-32 M5x0.8 .375 .053 .312 .278 .249 .252 .102 #1/4-20 M6x1.0 .500 .053 .375 . 341 .312 .315 .130 #1/4-28 - .500 .053 .375 .341 .312 .315 .130 #5/16-18 M8x1.25 .500 .053 .437 .403 .374 .378 .177 #5/16-24 - .500 .053 .437 .403 .374 .378 .177 #3/8-16 M10x1.50 .500 .063 .551 .494 .465 .469 .236 #3/8-24 - .500 .063 .551 .494 .465 .469 .236 Symmetry Type Single Groove with Taper Thread Size Inch Thread Size Metric Overall Length L Insert Diameter W Pilot Diameter N Recommended d +/_.001 D Hole Size +/_.001 S Minimum Wall Thickness Internal Inch Thread Size ISO Metric L Insert Length Inches T Head Thickness Inches H Head Diameter Inches W Insert Diameter Inches N Pilot End Diameter Inches Rec.Hole -0.000 +0.004 Inches Min.Wall Thickness Inches #2-56 M2x0.40 .115 .136 .115 .123 .118 .080 #4-40 M2.5x0.45 .135 .172 .157 .159 .153 .093 #2-56 M2x0.40 .155 .020 .187 .137 .123 .126 .055 #6-32 M3x0.50 .150 .220 .203 .206 .199 .116 #4-40 M2.5x0.45,M3x0.5 .228 .023 .217 .174 .154 .157 .071 - M3.5x0.6 .150 .220 .203 .206 .199 .116 #6-32 M3.5x0.6 .281 .029 .250 .206 .185 .189 .083 #8-32 M4x0.7 .185 .250 .230 .234 .226 .133 #8-32 M4x0.7 .320 .035 .280 .239 .218 .220 .094 #10-24 - .225 .296 .272 .277 .267 .159 #10-24 - .374 .042 .312 .270 .249 .252 .110 #10-32 - .225 .296 .272 .277 .267 .159 #10-32 M5x0.8 .374 .042 .312 .270 .249 .252 .110 - M5x0.8 .265 .328 .308 .315 .303 .171 #1/4-20 M6x1.0 .500 .052 .375 .333 .312 .315 .142 #1/4-20 M6x1.0 .300 .375 .354 .363 .349 .194 #1/4-28 - .500 .052 .375 .333 .312 .315 .142 #1/4-28 - .300 .375 .354 .363 .349 .194 #5/16-18 M8x1.25 .500 .052 .437 .393 .375 .378 .197 #5/16-18 M8x1.25 .335 .469 .439 .448 .431 .245 #5/16-24 - .500 .052 .437 .393 .375 .378 .197 .335 .469 .439 .448 .431 .245 H Head Diameter Inches W Insert Diameter Inches N Pilot End Diameter Inches #5/16.24 #3/8-16 M10x1.50 .375 .563 .530 .540 .523 .293 #3/8-24 - .375 .563 .530 .540 .523 .293 Full Burial Type Twins Groove with Taper Internal Inch Thread Size Inch Thread Size Metric Overall Length L Insert Diameter W Pilot Diameter N Recommended d +/_.001 D Hole Size +/_.001 S Minimum Wall Thickness #2-56 Thread Size ISO Metric M2x0.40 M2.5x0.45,M3x0.50 L Insert Length Inches T Head Thickness Inches Rec.Hole -0.000 +0.004 Inches Min.Wall Thickness Inches .162 .020 .187 .131 .117 .122 .063 .208 .023 .217 .165 .146 .150 .079 #2-56 M2x0.40 .188 .136 .115 .123 .107 .080 #4-40 #4-40 M2.5x0.45 .219 .172 .144 .159 .141 .093 #6-32 M3.5x0.60 .247 .029 .250 .196 .178 .181 .098 #6-32 M3x0.5 .250 .220 .190 .206 .185 .116 #8-32 M4x0.7 .292 .035 .281 .228 .209 .213 .098 - M3.5x6 .250 .220 .212 .206 .185 .116 #10-24 - .326 .042 .312 .259 .241 .244 .098 #8-32 M4x0.7 .312 .250 .251 .234 .208 .133 #10-32 M5x0.8 .326 .042 .312 .259 .241 .244 .098 #10-24 - .375 .296 .251 .277 .246 .159 #1/4-20 M6x1.0 .362 .052 .375 .322 .304 .307 .110 #10-32 - .375 .296 .283 .377 .246 .159 #1/4-28 - .362 .052 .375 .322 .304 .307 .110 - M5x.8 .438 .328 .332 .315 .278 .171 #5/16-18 M8x1.25 .362 .052 .437 .383 .365 .366 .150 #1/4-20 M6x1.0 .500 .375 .332 .363 .321 .194 #5/16-24 - .362 .052 .437 .383 .365 .366 .150 #1/4.28 - .500 .375 .406 .363 .321 .194 #3/8-16 M10x1.50 .362 .062 .551 .499 .481 .484 .197 #5/16-18 M8x1.25 .562 .469 .406 .448 .401 .245 #3/8-24 - .362 .062 .551 .499 .481 .484 .197 #5/16-24 - .562 .469 .439 .448 .401 .245 #3/8-16 M10x1.50 .625 .563 .493 .540 0.488 .293 #3/8-24 - .625 .563 .493 .540 0.488 .293 Plastic Hole Size and Wall Thickness Slotted Type Internal Inch Thread Size ISO Metric #2-56 M2x0.4 #4-40 L Insert Length Inches M2.5x0.45,M3x0.5 T Head Thickness Inches H Head Diameter Inches W Insert Diameter Inches Recommended -0.000 +0.004 Inches Minimum Wall Thickness Inches .155 .017 .187 .124 .126 .094 .186 .020 .218 .156 .157 .126 #6-32 M3.5x0.6 .249 .026 .250 .186 .189 .142 #8-32 M4x0.7 .312 .032 .281 .217 .220 .157 #10-24 - .371 .039 .312 .249 252 .189 #10-32 M5x0.8 .371 .039 .312 249 .252 .189 #1/4-20 M6x1.0 .497 .049 .375 .311 .315 .236 #1/4-28 - .497 .049 .375 .311 .315 .236 #5/16-18 M8x1.25 .497 .049 .437 .374 .378 .276 #5/16-24 - .497 .049 .437 .3744 .378 .276 Production Process L1= insert length L2= min. hole depth W= wall thickness T= draft angle Plastic Hole - Taper L1= insert length L2= min. hole depth W= wall thickness T= draft angle Plastic Hole Contour Production Process Design Engineering QA Final Inspection Tool Fabrication Move to Package Area Raw Material Packing Cutting Shipping Washing Part Final Audit Drying Note: Under normal circumstances, inserts has oriented segment , do not need bevel on the plastics Permanent Weld Removable Assembly Permanent Weld Removable assembly • Adhesive connection • Welding - Ultrasonic Welding - Friction welding - Hot-melt welding • Self-drive screw clip • Plastic thread • Metal Insert - Forming mold - Secondary burial (thermography, ultrasound) Plastic Hole Depth Note: Depth of plastic design, plastic overflow space must be considered, under normal circumstances is between 0.5-1.5mm Plastic Conjugation Line Insert Outside Diameter and Plastic Hole factor Outside Diameter (Body) Note: the location of the plastic boss hole should be advised not to set up onconjugation line, to avoid the breakdown of the plastic hole with stress • Fit into the hole • Length (Body) • Fit into the hole depth Knurling length (Performance Consideration) • Knurl • Pitch • Number of knurl division Thread Inserts Application • The relationship between outline of the inserts and boss hole • The relationship between size of the inserts and boss hole • Installation method of insert • Application information of insert • Performance test of insert • Design of Blind hole • Quality of inserts Insert Figure and Plastic Hole Factor Pilot lead-in: • Tapered Hole (8 degrees): With ribs lead in hole • Straight Hole: With a Flat head lead in hole Knurls provide: • The performance function (torque ,tensile) - Diamond Knurl (Raised/ Inverted) - Diagonal Knurl ( Single knurl/ Opposing knurl) - Straight Knurl (Increases Torque Performance) Undercut: • Allows plastic to flow into grooves for higher pullout resistance Flange: • To eliminate direct contact of plastic with mating parts • Increases push in performance • Thread standard • Chips Brass Insert Installation • Ultrasonic Installation • Thermal/Heat Installation • Mold-In Installation • Press-In Installation Ultrasonice Installation Installation Principle: Ultrasonic installation uses electrical energy to create high frequency vibration. The vibration creates friction and thus melts the plastic material around the insert. The insert is forced into the plastic and the plastic flows around the insert body. Once the plastic material cools the insert is locked in-place. Notes: Ultrasound can release energy instantaneously during installation, the great impact is easy to damage the insert during the process, specially on thread area. Suggest to not use the process for M1.6 or smaller brass insert Electric Heating Installation Principle: Heating the inserts to certain temperature and then force the insert into the plastic and the plastic flows around the insert body. Once the plastic material cools the insert is locked inplace. Molded In Installation Method Plastic Material Principle: • Thermoplastic plastics: PC/ABS ..…. Usually used in mobile phone industry. Preferred insert installation method: ultrasonic and hotmelt. • Thermoset plastics: Can not be used for the installation of ultrasonic and hot-melt. Preferred insert installation method: Mold-in; Threaded in & Press-in • Knurl - Straight knurl: Provides maximum torque out performance - Diamond/ Diagonal knurl: To increase the torque out and pull out resistance • Use Molding Pin as fixture • Counter bore design for accurate alignment of the insert to the plastic part • Blind Insert • Blind-end or closed-end inserts help prevent plastic ingress Notes: • In order to improve the accuracy of the thread, all the thread tolerances should follow with the old version of the ISO standard screw holes regulation. • Attention to the choice of moulding point in order to avoid inserts displacement caused by the plastic flow. • The tolerances of pin must be strictly controlled, the specific parameters should reference the old version of the ISO standard. (Should be less than the under limitation about 0.01-0.03mm) Brass Insert Performance Testing Torque Thermal/Heat Installation Force Pull Force Temperature is too high Temperature wall up Plastic hole is scrap Plastic spillover surface Not in place Temperature is too low Plastic hole crack Lower pull and torsional Plastic hole scrap Nut scrap Under the better burial process, there will be plastics on the surface when pull out the inserts from the plastic hole Blind Hole Design Guide Brass Inserts Testing Contents •General Boss Design Information •Hole Depth = “L” +0.9mm •Hole Diameter = “C”+0.1~0.15mm •Boss Outer Diameter = “C” x 2~2.5 curve of torque under the assembly Torque Fastener Specifications Material: Brass Finish: Cleaning Thread: Class 2B, per ASME B1.1, 6H ISO Metric Installed with heat or molded in. Designed for use in straight holes. Flange provides a large loading surface • Turns Pull Torque force Indirect torque Indirect tensile Installation Type Plastic Family Thermo-Plastic Thermoset Ultrasonic • Thermal/Heat • Pre-Molded Hole • Performance Normal • Normal Mold-In • Good Threaded-In • • Bad Press-In • • Bad