Watertight Cover Gasket Replacement Instructions

advertisement

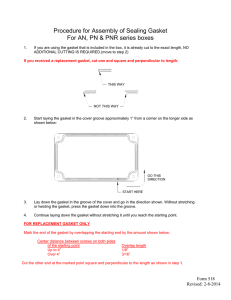

Watertight Cover Gasket Replacement Instructions 1. GENERAL 1.1. Follow these instructions when replacing a Xerxes watertight cover gasket. Watertight Cover Gasket 3.4.2. Beginning with this end, press the gasket into the groove. Do Replacement Instructions 1. GENERAL 1.1.You Follow thesethe instructions 1.2. will need following when items:replacing a Xerxes watertight cover gasket. • replacement gasket from Xerxes • tube of sealant (100% silicon) items: 1.2. You will need the following • replacement gasket from Xerxes • trim knife • tube of sealantspirits, (100%paint silicon) • solvent (mineral thinner, etc.) • trim knife • clean rags(mineral spirits, paint thinner, etc.) • solvent • clean rags 1.3. The replacement gasket has an adhesive backing with a protective paper strip. The adhesive very aggressive and will stick 1.3. The replacement gasket has anisadhesive backing with a protectightly to anything withadhesive which it comes in contact. and Use will carestick in tightly tive paper strip. The is very aggressive to anything with which it comespaper in contact. care init in handling handling and remove only enough backingUse to place the and remove only at enough groove 2-3 inches a time.paper backing to place it in the groove 2-3 inches at a time. not stretch the gasket into place. If you do, it may pull away from the cover over time. 3.4. Install the gasket into the groove by following these steps: 3.4.3. Continue to press the gasket into place, removing the backing as you workleading your way around the groove. Stopinches whenofthere 3.4.1. At the end, peel back about 3-4 the is paper approximately 6 inches of gasket remaining. backing. 3.5. Beginning Leaving the backing paper in place, lay the remaining 6 inches 3.4.2. with this end, press the gasket into the groove. Do of notgasket stretchover thethe gasket intoend place. you maytopull away leading andIfcut thedo, tailitend match thefrom leading theend, cover over time. allowing for 1/4-inch of overlay. 3.4.3. removing 3.6. Continue Once the to tailpress end the cut gasket is madeinto andplace, you are sure ofthe thebacking fit, the as backing you workpaper your way around the groove. when is approxcan be removed. Do notStop install thethere remaining imately 6 inches of groove gasket remaining. gasket into the at this time. 3.5. Leaving the backing paper in place, lay the remaining 6 inches of gasket over the leading end and cut the tail end to match the leading When usingforsolvents, read and follow the manufacturer safety end, allowing 1/4-inch of overlay. warnings on the labels. 2. REMOVING THE OLD GASKET 2. REMOVING THE OLD GASKET 2.1. 2.1.Remove Removethe theold oldgasket. gasket. 2.2. thethe groove, including oldold ad2.2.Remove Removeallallforeign foreignmaterial materialfrom from groove, including adhesive residue, oils and dirt. hesive residue, oils and dirt. 3.6. Once the tail end cut is made and you are sure of the fit, the 3.7. Apply thin be coat of sealant silicon) to remaining the tip of the tail backing papera can removed. Do(100% not install the gasket groove at this time. end ofinto the the gasket. 3.8. Butt the tail end against the leading end and hold the two ends 2.3. groove solvent asasneeded 2.3.Wash Washout outthe the groovewith with solvent neededand andwipe wipeit itdry. dry. together whilesolvents, pushing the remaining gasket the into the groove. When using read and follow manufacturer safety warnings on the labels. 3.3.INSTALLING INSTALLINGTHE THENEW NEWGASKET GASKET 3.1. Dry fit the gasket groove (placeit itloosely looselyininthe thegroove groove 3.1. Dry fit the gasket ininthethegroove (place upside down). upside down). to Apply ensurea athin complete 3.7. coat ofbond. sealant (100% silicon) to the tip of the tail end of the gasket. 3.2.Cut Cutthe thegasket gaskettotoaalength lengthequal equalto tothe theamount amountofofgasket gasket needed needed 3.2. to fit in the groove plus 2 inches of slack. to fit in the groove plus 2 inches of slack. 3.3.Cut Cut leading end into a squareshape. shape.(See (SeeFIGURE FIGURE 1-1.) 3.3. thetheleading end into a square 1-1.) 3.9. Using your fingers, knead the gasket in place all the way around 3.10. Allow the seam joint to cure completely before installing the cover. times vary.the Refer to theend instructions on the 3.8. Butt Cure the tail end will against leading and hold the twosealant ends together while pushing the remaining gasket into the groove. container. 3.9. Using your fingers, knead the gasket in place all the way around to ensure a complete bond. 3.10. Allow the seam joint to cure completely before installing the cover. Cure times will vary. Refer to the instructions on the sealant container. Squarecut cut Square to fit tight at seam FIGURE 1-1 Figure 1-1 3.4. Install the gasket into the groove by following these steps: 3.4.1. At the leading end, peel back about 3-4 inches of the paper backing. 7901 Xerxes Avenue South, Minneapolis, MN 55431-1288 952-887-1890 www.xerxes.com 7901 Xerxes Avenue South, Minneapolis, MN 55431-1288 (952) 887-1890 Fax (952) 887-1882 www.xerxescorp.com xwg11/04ih © Xerxes Corporation 2004 xwg11/04ih © 2004 Xerxes Corporation