Optical Isolation of EIA-232 Serial Communications

advertisement

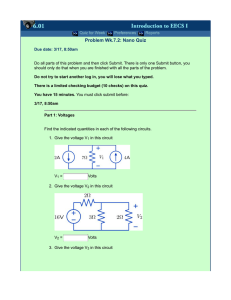

Optical Isolation of EIA-232 serial communications The optical isolator is implemented with a light- emitting-diode and transistor . The phototransistor can "see" the diode and develops a current which is related to the amount of light. it sees . . . which, in related to the amount of current passing through the light emitting The two are sufficiently insulated to allow a 5000 volt difference . a photocollector turn, is diode . The PS2501 is designed to function as a switch . Thus the phototransistor is either cut-off (0 collector current) or saturated (nearly 0 collector-emitter voltage) . The relationship between LED current and light and light and phototransistor collector current are not linear . But because we seek only two states, cut-off and saturation, and thus can model the output as a switch which is open or closed, we need only to specify a range of LED currents which will guarantee those conditions . Linear optical isolators are manufactured. Usually they include a second, matched photo-transistor sensing the same LED which is used in a feedback arrangement to control the current of the matched phototransistor . Operation of a phototransistor is pretty much similar to that of a normal bipolar NPN silicon transistor except that the collector current is controlled by light . . . which in turn is controlled by current through a light-emittingdiode . There is connection to the "base" . Carriers are generated by photons . . .so the device tends to be slow in turning off . The control curves are shown in the data sheet . A family of curves is plotted for fixed values of the LED forward current, IF . We want to design a circuit in which the phototransistorwill be either "on" or "off" (saturated or cutoff) . Consider the following circuit in which an serial data transmitter providing levels specified by the ETA-232 standard is used to power the LED and that the phototransistor is developing a voltage which is sensed by a EIA-232 receiver . The circuit uses two isolators in a "spdt" switch configuration . One switch is on while the other switch is off . This configuration provides low source impedance to both the "off" switch and the load. It can be easily modified for inverting or non-inverting operation . In this example, the excitation voltage for ISO-1 is provided by the circuit which houses it and powers the EIA-interface . Power for ISO-2 is derived from TD1 and DIR1, the transmitter data and data-terminal-ready signals . z.LX_ vz~=D-, 4RYnr-/ 1d interface between EIA-232 port and EIA-232 port implemented with MAX-232 transceiver figure 1 EIA-232 says that a transmitter, transmi tting a "space" will supply a maximum of 10 mA to a short circuit and that it must be able to develop at least +5 volts with a 3K load. So we know that the range of currents we can get with a EIA-232 transmitter is 5/3 < i < 10 ma. Let's plan on the worst and assume we can get 5/3 = 1 .67 mA to drive the optical coupler's LED . This is what will produce saturation an the phototransistor . Cutoff can be produced by reducing the LED current to 0 . The ETA-232 transmitter produces at least -5 volts for a "mark" . This will reverse-bias the LED and develop no light . In fact, we must protect the LED with a signal diode to absorb this current . Taking a look at the specifications for the PS2501 we discover that the current transfer ratio, CTR, ranges from 0 .8 to 1 .6 . Then IF = 1 .67 mA results in CRT x IF = .8 x 1 .67 = 1 .3 mA = Ic So we must design the output to draw less than 1 .3 mA in the worst case . All this current is available to drive the receiver . . . which has in . input impedance 3k < Zin < 7k . This doesn't quit meet EIA-232 but it is easily within the specification of the MC1489 or MAX-232 integrated circuits used to implement the receiver . ? LO ., Z2me v,. = ~ . l t ,= ve- ~~dN~t V 14- EIA transmitter During "mark" EIA transmitter EIA receiver During "space" figure 2 Let's use the EIA-232 Receiver to sense the state of the phototransistor, remembering that we are limited to 1 .3 mA or less through the phototransistor . The receiver input looks like a resistance, 3K < RI < 7K. It will interpret an input, VR as a "low" correctly if V,, < 0 .8 volts and as a "high" if Va, > 2 .4 volts . The input has "hysteresis", 0 .2 < V, < 1 .0 volts . Hysteresis is a history-dependent difference in the input threshold voltage . What it says here is that we must, in the worst case, always have signals greater that 1 .0 volt . . . the maximum hysteresis voltage . For our worst-case, assuming the saturated phototransistor looks like a short circuit compared with 3k then we develop 1 .3 x 3k = 3 .9 volts for a space and -3 .9 volts for a mark. . . easily satisfying the hardware requirements of the receivers . Mark and Space levels, Vi- and Vl+, meeting ETA-232 are derived from TD1 and DTR1 of the incoming communications port . Diodes D1-D4 and capacitors C1 and C2 convert the AC "signal" to corresponding levels . If they are good enough to send, then they are good enough to receive . Resistors R1 and R2 allow enough voltage drop so that TD1 and I7TRl are never less than 5 volts The interface between the optical isolator and the PC is a bit different . We are building the circuit with the MAX-232 so we have access to its power supply . . . and we could draw 1 or 2 mA from V+ and V- as well . These sources are not available at the back of a PC . Why use the MAX-232 between the optical isolator and the TIL logic that it communicates with? "Takes less thinking" is the simple answer . If we interface directly to the TIL logic, then we must understand the internal workinVs of the logic . . . signal levels, currents, etc . The following circuit is a direct interface to our TIL logic . . . but we are responsible for understanding it . OT-ctl The circuit is marginal in the worst case . It cannot use the transmitted data operating at minimum levels and guarantee that it can produce a return signal which is not diminished . We wouldn't want to fly to the moon with this interfacing our rocket engine . And things Vet worse as the components age . . . notice that the CTR degrades to 80% of its initial performance after 105 hours at 60°C . . . not impossible conditions in a medical environment! If we use a more sensitive optical isolator (CTR > 1 .2) then the circuit is not marginal in the worst case at &0 °C for 105 hours! This is not a problem for the IC's we have specified, but it places us further from meeting EIA-232 Good design demands that you consider all realistically possible condition . . . extremes of power supplies, temperature, component values, etc . This example is a first cut at good design . Take a look at the example shown in figure 18 of the MAX-232 data sheet . There are a bunch of potential problems with it . A 22K resistor to a 5 volts supply biases the receiving phototransistor . When the transistor is off (cut off) and if you are using a typical MAX-232 receiver (input resistance = 5K) then the receiver input is sitting at 0 .93 volts . . .which the receiver will likely interpret as a low . The specifications for the receiver say that the lowest voltage that will be correctly interpreted as a "high" is typically 1 .7 volts . So I would guess the circuit shown in figure 18 won't work . Now before thinking "what crocks!!! . . ." about the designer and the application note, realize that the idea of using the isolator is sound and the engineer who wrote the note probably built it and it worked . Just because something works once, don't believe it will always work . And don't blindly follow applications notes . Writing applications notes is often a "first-job" for new engineers at component manufacturers .