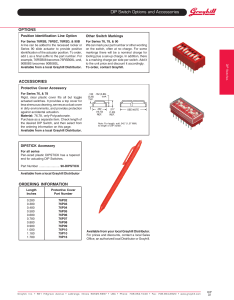

Rotary Switches

advertisement