Influence of attached mortar content on the properties of recycled

advertisement

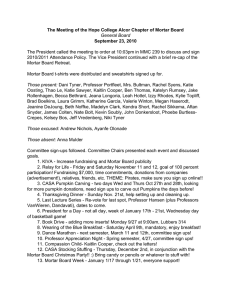

INFLUENCE OF ATTACHED MORTAR CONTENT ON THE PROPERTIES OF RECYCLED CONCRETE AGGREGATE Marta Sánchez de Juan(1), Pilar Alaejos Gutiérrez(2) (1) Laboratorio Central de Estructuras y Materiales (CEDEX). Spain. (2) Laboratorio Central de Estructuras y Materiales (CEDEX). Head of the Material Science Area. Spain. Abstract ID Number: …..346 …….. Author contacts Authors Marta Sánchez de Juan E-Mail Fax Postal address msanchez@cedex.es 34 91 3357422 Laboratorio Central de Estructuras y Materiales C/Alfonso XII, 3 y 5 28014 Madrid Pilar Alaejos Gutiérrez palaejos@cedex.es 34 91 3357422 Laboratorio Central de Estructuras y Materiales C/Alfonso XII, 3 y 5 28014 Madrid Contact person for the paper: Marta Sánchez de Juan Presenter of the paper during the Conference: Marta Sánchez de Juan 1 Total number of pages of the paper (this one excluded): 9 Page 0 INFLUENCE OF ATTACHED MORTAR CONTENT ON PROPERTIES OF RECYCLED CONCRETE AGGREGATE THE Marta Sánchez de Juan(1), Pilar Alaejos Gutiérrez(2) (1) Laboratorio de Estructuras y Materiales (CEDEX). Spain. (2) Laboratorio de Estructuras y Materiales (CEDEX). Head of the concrete technology department. Spain. Abstract Recycled concrete aggregates mainly differ from natural aggregates in that they are composed by two materials of different nature: natural aggregate and cement mortar attached to it. This last material is the origin of the different and worse properties of recycled aggregates. The objective of this study is to relate the attached mortar content to recycled aggregate properties, to establish the mortar content from which aggregate properties essentially get worse. This aspect can be useful for recycling plants as they will be able to adjust the production processes to improve aggregate quality, for example, by means of several crushing processes. The results show that the main properties unfavourably affected by the attached mortar content are density, absorption and Los Angeles abrasion. However, the attached mortar content is not the only determining factor on recycled aggregate properties, also mortar and natural aggregate quality influence them. Keywords: coarse recycled concrete aggregate, attached mortar, recycled aggregate quality. 1. INTRODUCTION Recycled concrete aggregates mainly differ from natural aggregates in that they are composed by two materials of different nature: natural aggregate and cement mortar attached to it. This last material is the cause of the different and worse properties of recycled aggregates: lower density, higher absorption, sulphate soundness and sulphate content. These properties have a negative influence on recycled concrete quality, mainly affecting to properties related with deformation (elasticity, shrinkage, creep), also durability, and to a lesser extent to strength. One aspect that influences on old mortar content is the number of crushing processes in the production plants. Increasing the number of crushing processes, attached mortar content can be diminished, and therefore, aggregate quality can be improved. However, this fact causes an increase of production costs, so that it will be necessary to find a balance between number of stage-crushing processes and aggregate quality required according to each application. Page 1 This study is included into the experimental works carried out by The Central Laboratory of Structures and Materials (CEDEX), aimed to establish the requirements that recycled concrete aggregates should fulfil, in order to guarantee their safe utilization for structural concrete. 2. EXPERIMENTAL OUTLINE In this study, a periodical control along one year of fifteen samples coming from a stationary recycling plant in Madrid (TEC REC Tecnología y Reciclado) has been done. The plant produces recycled aggregates for bulk fills, bases and subbases for road construction. There is a visual inspection of the incoming waste materials, that allows to classify them according their nature and to establish separated stockpiles (concrete, masonry and asphalt). The processing consists of a double crushing with impact crushers and vibrating screens. It also has systems to remove metallic elements by a magnetic conveyor belt and a manual separation of big impurities, such as plastics, papers, glass and so on. The batched samples were graded at the Laboratory selecting 4/16 mm fraction prior testing, and were divided into two new fractions, 4/8 mm and 8/16 mm, in order to establish aggregate size influence on aggregate quality. Properties of 4/16 mm fraction, have been obtained as an average, according to each sample grading. In addition to mortar content, other properties required to natural aggregate for structural concrete, according to Spanish Specification EHE(1), and that are related to mortar content, have been studied. These properties are: density, absorption, Los Angeles abrasion and sulphate content. All the tests have been carried out for the fourteen samples, except chemical tests, that have been done only for several samples. Furthermore, in each sampling at the recycling plant, four cores were extracted from several concrete blocks stocked, and compressive strength tests were made. This will allow to asses if mortar content and original concrete quality are related. 3. ATTACHED MORTAR CONTENT As we mentioned before, recycled concrete aggregate is composed by natural aggregate and cement mortar attached to it. Photograph 1 shows the appearance of these components, that can be found separately or together. Mortar Aggregate+mortar Aggregate Figure 1: Detail of recycled concrete aggregate Page 2 3.1 Test method As there is not any standardized method to quantify attached mortar content in recycled aggregate, we have valued those found in bibliography, which are described below: -Treatment with a solution of hydrochloric acid(2): This method consists on the dissolution of cement paste attached to stone particles when recycled aggregate is immersed in a solution of hydrochloric acid. The problem is that it can not be used with limestone, because acid also attacks this kind of natural aggregate. -Production of a new concrete(3): This method consists on the production of a new concrete made with recycled aggregate and new coloured cement, so you can determine, in several slices, the mortar surface by the different colour from both natural aggregate an new mortar. -Thermal treatment(4): This method has been developed by the Universidad Politécnica of Barcelona, and consists on a treatment including a soaking and drying of the aggregate. The thermal treatment has been chosen in this study, as it can be used for all kind of aggregates (including limestone), it is easier to do and its results are very accurate. Next, a more detailed explanation of this method is included. 70 60 50 40 30 M-XIV M-XII M-XIII M-X M-XI M-IX M-VII M-VIII M-V M-VI M-III M-IV M-I 20 M-II One factor that mainly affects the mortar content is the aggregate size. Attached mortar content is generally higher in the fine fraction than in the coarse one. The fine fraction 4/8 mm had a mortar content between 33% and 55%, while in coarse fraction, it ranged from 23% to 44%. Graphic 1 shows these results. Attached mortar content (%) 3.2 A recycled aggregate sample (mi) is prepared, having previously removed all kind of impurities as bricks, asphalt, plastics, wood, etc. (Photo 2). The sample is immersed in water for two hours, so that attached mortar saturates but not the natural aggregates (Photo 3). Next, the sample is dried in a muffle, at a temperature of 500ºC for two hours (Photo 4), to achieve the evaporation of the water included into the mortar pores. This causes stress into the mortar so that it can be easily removed. From the muffle, the sample is immersed into water (Photo 5). After these operations, some mortar usually remains attached (Photo 6), so it is necessary to remove it by means of a rubber hammer or scratching the surface (Photos 7 and 8). When all the mortar has been removed, the sample is screened by 4 mm sieve, obtaining the coarse aggregate weight (mf). Mortar content is calculated as follows: m − mf % attached mortar = i ⋅ 100 mi Results Samples 4/8 mm fraction Total (4/16 mm) 8/16 mm fraction Graphic 1: Attached mortar content. Page 3 Figure 2 Figure 3 Figure 4 Figure 5 Figure 6 Figure 7 Figure 8 Figure 9 Figure 10 4. RELATIONSHIP BETWEEN AGGREGATE PROPERTIES MORTAR CONTENT AND OTHER As we said before, attached mortar unfavourably affects the properties of recycled aggregate, as mortar is a porous material, and has lower density and higher absorption. Other properties affected are Los Angeles abrasion and sulphate content. Table 1 summarizes the test methods and the Spanish specifications for each property. Table 1: Test methods PROPERTY Attached mortar (%) Apparent specific gravity (kg/dm3) Water saturated surface dry density (kg/dm3) Water absorption (%) Los Angeles abrasion (%) Total sulfur content as SO3= (%) Rc of tested cores (N/mm2) Ref. 4 Spanish Specification (EHE) - UNE 83134:98 ≥2 UNE 83134:98 - UNE 83134:98 UNE-EN 1097-2:99 UNE-EN 1744-1:99 UNE 83.304:84 ≤5 ≤40 ≤1 - Test method Page 4 4.1 Density Bulk specific density (kg/m3) 2500 D= -8,8175x + 2546,4 R = 0,73 2400 2300 2200 2100 2000 20 30 40 50 Attached mortar (%) 4/8 mm fraction Lineal (all results ) 60 8/16 mm fraction Graphic 2: Relationship between mortar content and bulk specific density 4.2 Saturated surface-dry density (kg/m3) Bulk specific density of recycled aggregate ranged from 2.010 kg/m3 to 2.300 kg/m3 in fraction 4/8 mm, and from 2.100 kg/m3 to 2.400 kg/m3 in fraction 8/16 mm. On the other hand, the ranges for saturated surface-dry density were 2.240-2.420 kg/m3 and 2.330-2.470 kg/m3, respectively. Graphics 2 and 3 show the relationship between mortar content and density. The correlations show that the higher amount of attached mortar, the lower the density is. If we consider the intersection points of the these correlations with axis of coordinates (x=0), we can obtain the average value of bulk specific density and saturated surface-dry density of natural aggregate, set on 2.546 kg/m3 and 2.579 kg/m3 respectively. In a same way, the points when all recycled aggregate is mortar (x=100%), give the average values of bulk specific density and saturated surface-dry density of a normal mortar, set on 1.600 kg/m3 and 2.000 kg/m3. These results are coherent with the real experimental values usually obtained. DSS = -5,6283x + 2579,3 R = 0,72 2500 2400 2300 2200 20 30 40 50 Attached mortar (%) 4/8 mm fraction Lineal (all results) 60 8/16 mm fraction Graphic 3: Relationship between mortar content and saturated surface-dry density Absorption Water absorption of recycled aggregates was found to be in the range of 5,1% to 11,5% in 4/8 mm fraction, and in the rage of 4,2% to 8,8% in 8/16 mm fraction. Graphic 4 gives the relation between the amount of attached mortar and water absorption of recycled aggregate. It shows that when mortar content increases, water absorption increases too, specially in the finer fraction 4/8 mm. The dispersion of results, as in the case of density, points out that water absorption of recycled aggregate is affected by others factors than original mortar amount, as original mortar quality. Page 5 4.3 y = 0,177x + 0,36 R = 0,71 12 Absorption (%) To satisfy Spanish specification regarding water absorption, fixed in 5%, mortar content should be very low, less than 26%. This value is hardly reached, at least by the more coarse fractions. According this correlation, the average water absorption of natural aggregate (x=0%) would be 0,36% (lower than the usual one), while mortar absorption would be placed in 18%. 10 8 6 4 2 20 30 40 Attached mortar (%) 4/8 mm EHE limit 50 8/16 mm Lineal (Todos) Graphic 4: Relationship between mortar content and absorption Los Angeles abrasión Los Angeles abrasion coeficient (%) Los Angeles abrasion loss percentage of recycled aggregate ranged from 35% to 42%. In Los Angeles abrasion test, all the attached mortar is removed, besides the abrasion suffered by natural aggregate. For this reason, both properties are expected to be related. Graphic 5 shows that when attached mortar content is high, 50 Los Angeles abrasion is high too. Although correlation is not y = 0,19x + 31,6 45 R = 0,60 good enough, it obtains an average loss for natural aggregate (x=0) of 40 32%, and for a 100% attached mortar of 50%, that can be 35 considered coherent values. 30 Conforming to Spanish 44 50 20 30 40 specification, Los Angeles abrasion Attached mortar (%) loss should be lower than 40%. All samples with an attached mortar Experimental content lower than 44% fulfil this limit. Graphic 5: Relationship between mortar content and Los Angeles abrasion Additionally, if those samples with an amount of mortar higher than 44% are rejected, according to Graphic 2, the rest of samples have a density higher than 2.160 kg/m3 and an absorption lower than 8% (Graphic 4). 4.4 Sulphate content Recycled aggregates can have a higher sulphate content due, among other causes, to sulphate compounds from cement of attached mortar. According to Spanish Instruction for Cement (RC-03)(5), sulphate content in cements has to be lower than 4%. For an usual concrete dosage, this maximum sulphate content, referred to concrete, would be set on 0,5%, and referred to mortar, on 1%. To estimate concrete and mortar weight, combined water has been considered the 23% of the cement weight. Page 6 Usual dosage: 1300 kg. 600 kg. 275 kg. 180 l. coarse aggregate sand cement water Sulphate content (%) % SO3= (in y = 0,088x 0,473 R = 0,60 1 0,8 0,6 0,4 0,2 0 20 30 40 50 60 Mortar content (%) 4/8 mm 8/16 mm Experimental results have ranged between 0,35-0,75%, so we can consider that all sulphate content is provided by cement paste. Graphic 7 confirms this relation, and shows that those samples with a higher mortar content have higher sulphate content, and that for 0% and 100% of mortar content, SO3= would be set on 0% and 0,8% respectively. Furthermore, the mortar content of this dosage is: %mortar content= P o tencial (A ll samples) Graphic 7: Relationship between mortar content and sulphur content 4.5 0.04 * 275 = 1,2% 600 + 275 + ( 0.23 * 275 ) 0.04 * 275 concrete)= = 0 ,5% 1300 + 600 + 275 + ( 0.23 * 275 ) % SO3= (in mortar)= 600 + 275 + ( 0 ,23 ⋅ 275 ) = 42% 1300 + 600 + 275 + ( 0 ,23 ⋅ 275 ) The sulphate content that corresponds to this value, according Graphic 7 would be 0,52%, close to the estimated value of 0,5% of % SO3= in concrete. Alkalis content Although experimental tests have not been finished, a theoretical calculation can be made as follows. Maximum alkalis content in recycled aggregate, provided by cement, can also be estimated with a similar analysis as before (when we suppose that natural aggregates do not provide alkalis). Alkalis content in Spanish cements is usually lower than 1%, so that referred to concrete, the maximum alkalis content will be 0,12% and referred to mortar will be 0,29%. 1300 kg. 600 kg. 275 kg. 180 l. Coarse aggregate sand cement water % 0,658K2O+Na2O (in concrete)= % 0,658K2O+Na2O (in mortar)= 0.01 * 275 = 0 ,12 % 1300 + 600 + 275 + ( 0.23 * 275 ) 0.01 * 275 = 0 ,29% 600 + 275 + ( 0 ,23 ⋅ 275 ) Therefore, to use a coarse recycled aggregate with a maximum alkalis content of 0,12%, in a new concrete with the same dosage, would be equivalent to use a cement with an additional alkalis content of ( 0 ,12 ⋅1300 ) = 0 ,56% . 275 5. RELATIONSHIP BETWEEN MORTAR CONTENT AND COMPRESSIVE STRENGHT OF ORIGINAL CONCRETE The influence of original concrete quality on attached mortar content has been evaluated for the same crushing process. In Graphic 9, mortar content of recycled aggregate and compressive strength of each four cores are compared. If concretes with a compressive strength below 25 N/mm2 are rejected, we select samples that have an attached mortar percentage lower than 44%. However, with this strength criterion, some samples with low mortar contents will also be rejected. Anyway, these three samples with reduced mortar percentages, gave a high absorption and low density. In any case, strength criterion rejects samples with high mortar content or low mortar quality. Page 7 Compressive strength of original concrete (N/mm2) 55 50 45 40 35 30 25 M- IX, X, XI 20 15 M-VI, VIII, XII 10 26 28 30 32 34 36 38 40 42 44 46 48 Mortar content (%) M-II M-III M-IV M-V M-VI M-X M-XI M-XII M-XIII M-XIV M-VII M-VIII M-IX Graphic 9: Relationship between attached mortar content and compressive strength of original concrete 6. - - - - - CONCLUSIONS Quality of recycled concrete aggregate is lower than natural aggregate quality, due to the mortar which remains attached to natural aggregate. Usual mortar content is about 23-44% for 8/16 mm fraction and 33-55% for 4/8 mm fraction. Generally, amount of mortar attached to fine fraction is higher than to coarse fraction. The main properties unfavourable affected by mortar content are absorption, density and Los Angeles abrasion. To limit mortar content to 44% is considered appropriate, as the coarse fraction of recycled concrete aggregate can fulfil Spanish specification of Los Angeles abrasion loss percentage (40%). With this criterion, recycled aggregate are expected to have absorption lower than 8% and density higher than 2.160 kg/m3. Other properties, as sulphate content or alkalis content are also related to mortar content, so aggregates with a high mortar content seem to have higher sulphate and alkalis content. For the same processing, the methods to reduce mortar content of recycled aggregates are: o To limit size fraction of recycled aggregate, as fine fraction has poor quality due to it higher mortar content. For this reason, it is not recommended to use fine recycled concrete aggregate for most applications, specially for production of new concrete. o To limit original concrete quality; though to a lesser extent, original concrete quality also have influence on recycled aggregate quality, and generally, the lower the strength of the original concrete, the lower will be the quality of the recycled aggregate. A solution to control recycled aggregate quality for production of structural concrete could be to control original concrete, rejecting those concretes with compressive Page 8 strength lower than 25 N/mm2. With this criterion, samples of coarse recycled aggregate with a high mortar content (more than 44%) or samples with a low mortar quality should be rejected. ACKNOWLEDGEMENTS This experimental work has been supported by the General Direction of Quality and Environmental Evaluation of the Ministry of Environment. Recycled aggregate samples have been collected thanks to the collaboration of the company TEC REC Tecnología y Reciclado S.R.L. Thanks to General Directions of CEDEX for initiatives to promote postgraduate training and development of doctoral thesis. Thanks to College of Civil Engineer for all the support at all stages during the preparation of this experimental study. REFERENCES [1] EHE. Instrucción de Hormigón Estructural. Ministerio de Fomento. 2000. [2] Yagishita, F., Sano, M., Yamada, M.: "Behaviour of reinforced concrete beams containing recycled coarse aggregate”. Demolition and Reuse of Concrete. Edited by Erik K. Lauritzen. Rilem. p. 331-342. 1994. [3] Ravindrarajah, R.S., Tam, C.T.: “Properties of concrete made with crushed concrete as coarse aggregate”. Magazine of Concrete Research: Vol 37, Nº130. March 1985. pp.29-38. [4] Barra, M.: “Estudio de la durabilidad del hormigón de árido reciclado en su aplicación como hormigón estructural”. Tesis doctoral. Universidad Politécnica de Cataluña. 1996. [5] RC-03. Instrucción para la Recepción de Cementos. Ministerio de Fomento. 2003. Page 9