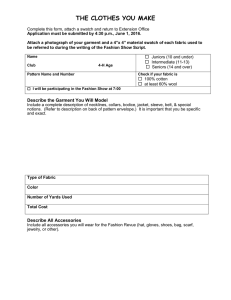

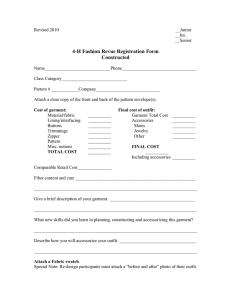

Body Measurements: Garment Technology Unit

advertisement