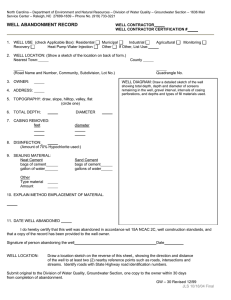

state oil and natural gas regulations designed to protect water

advertisement