Component acceptability for CE product Safety

advertisement

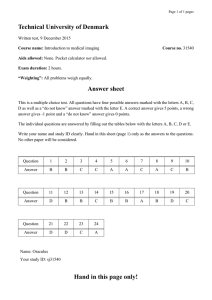

Component acceptability for CE product Safety Technical Note 37 The following component status table applies to the general approval of electrical or electronic safety critical components (e.g. transformers, motors, fuses, mains cables, etc) for use in equipment that is CE marked in accordance with a EU product safety directive (e.g. LVD, R&TTE). Separate rules may apply, in addition, for qualification of the fire resistance of such components – see relevant equipment standard for details. Status 2 3 4 Risk to CE compliance Third party certified to a relevant EN/IEC standard by a recognised EU body (e.g. FI, VDE, TUV). Supplied with supporting reports or certificates (including conditions of use/acceptability, where appropriate). CE marked. Minimum Tested in application by TRaC. CE marked. Minimum Third party tested to a relevant EN/IEC standard by a recognised body (i.e. UKAS or equivalent ISO17025/ISO guide 25 laboratory or an EU Notified Body operating such a laboratory). Supplied with supporting reports or certificates (including conditions of use/acceptability, where appropriate). CE marked. Third party certified or tested to a foreign standard by a recognised body (e.g. UL, CSA) with demonstrable equivalence to a relevant EN/IEC standard. Supplied with supporting reports or certificates (including conditions of use/acceptability, where appropriate). CE marked with declaration of conformity to relevant EN standard. Low Low Marked as certified by a recognised EU body (e.g. TUV, VDE, BSI). CE marked with declaration of conformity to relevant EN standard. Medium 6 Tested to a relevant EN/IEC standard by the manufacturer or other unaccredited test laboratory. Supplied with detailed test reports. CE marked with declaration of conformity to relevant EN standard. Medium 7 Marked as certified to a foreign standard by a recognised body (e.g. UL, CSA). CE marked with declaration of conformity to relevant EN standard. 8 CE marked with declaration of conformity to relevant EN standard. 9 CE marked only. No CE mark. High Very high Not acceptable Probably illegal to use. 10 (worst) Med./high Possible to CE mark on the basis of a report stating that insufficient data was available to confirm compliance. 5 Notes Acceptable for a fully compliant test report. CE mark fully supported by independent data. 1 (best) Explanation of requirements to achieve status Note that acceptability is dependent upon a component being rated and tested to the level required for the particular application in the equipment (e.g. input voltage (230Vac), operating temperature, cooling requirements), as determined by the equipment standard. Guidelines for selection of safety critical components What is safety critical? Components that are critical to the safety of equipment are known as “safety critical components”. Safety critical components perform functions that protect against electric shock, explosion, mechanical hazards, fire, etc. Examples of safety critical components would include mains cable, mains switches, transformers, X and Y capacitors, power supplies, fuses and fuse holders. As a general rule, all mains connected parts with some form of insulating or special protective function are considered to be safety critical components. However, a component does not have to be mains connected to be safety critical. Examples would be PTC devices or fuses in secondary circuits or interlocked door switches. Why does a safety critical component need to be approved? A safety critical component is essential to the compliance of your equipment. You therefore need to be sure that it will perform its safety function reliably when it is required to do so. Independent, third party testing or certification to a recognised standard ensures that the component will satisfy this requirement. Note that testing by the manufacturer alone may not ensure compliance and therefore for many certification and test schemes a certificate from a recognised third party is required. Certified components are not only independently tested but benefit from regular and independent audit of the manufacturing process. How do I know that the component is approved? An approved component is normally marked with the “mark” of the third party certification body. In addition there will be a certificate detailing the limits of the approval (e.g. voltage. temperature, etc) and a full supporting test report. In some cases the component may not be marked but will be supported by a certificate or report. It is essential that you obtain the approval certificate to ensure that the parameters of the approval are suitable for your application. You cannot assume that the “mark” covers all of the rated values of the component nor that the component standard encompasses all of the requirement of the equipment standard. A list of common safety approval marks issued by EU bodies and suitable for demonstrating CE compliance are shown later in this document. Will a “CE approved” component be enough to demonstrate EU compliance? The CE Marking should not be included here in dealing with safety marks because it is not a safety mark. This is because it is not (generally) necessary to use an independent third party body to attest to the safety performance of the product. It is also illegal to sell many electrical components without a CE mark and therefore “de facto” all components (good or bad) carry this mark. Hence the mark is not a useful guide to compliance. Where there is no independent third party evidence of compliance then a CE mark with accompanying declaration of conformity may be the best that you can obtain. Under these circumstances you may opt to CE mark but you should be aware of the increased risk of following this route. Can I use my UL or CSA approved component to demonstrate EU compliance? Not normally. It is important to be aware that safety markings relating to foreign (i.e. non EU standards - UL, CSA) have little or no relevance in the EU because: • • • the operational conditions are different; the local history of hazards are different, and; there are significant technical differences between the European and non-European standards. Notwithstanding this general rule, there are some standards that have been harmonised between North America and the EU. Where an equivalence can be established then the foreign approval may in some cases be acceptable. Some examples of foreign approval marks (including some from the USA and Canada) are shown at the end of this document. Can I use my EU approved component for UL, CSA or NRTL approval? No. For the same reasons as above, EU approvals have little or no relevance in the USA or Canada. In addition, equipment approval is mandatory for many product areas and hence specifically approved UL or CSA approved components are often required. The same principal of course applies for CE marked components. Apart from the standards, an important difference between US/Canadian approval schemes is the requirement for regular inspection of the manufacturing process as part of the certification scheme. These inspections can be up to four times per year – a factor not common in EU approval programmes. Can I use a foreign certified safety critical component to demonstrate EU compliance? Many foreign certification bodies work to international (IEC) standards that are technically equivalent to an EN standard (in fact many EN standards are identical to their equivalent IEC). Also, many of these foreign certification bodies are members of the international CB scheme. For this reason, where the certification body is recognised and operates under an ISO17025/IEC Guide 25 quality system, then an IEC certificate may be acceptable for use in equipment tested for EU compliance. Additional supporting documents may be required to ensure that all EU deviation shave been addressed. Examples of safety approval marks issued by EU bodies Examples of safety approval marks issued by EU bodies (continued) Examples of safety approval marks issued by foreign certification bodies