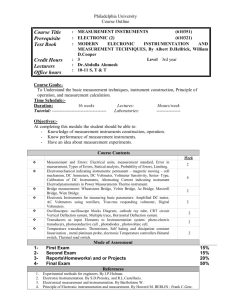

ELECTRICAL / ELECTRONIC INSTRUMENTATION I

advertisement