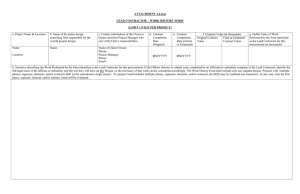

MD Anderson Project No. FPDC-160012 ZAYED PHASES 2b, 2c

advertisement