D6.2.1 Software platform for the integration of the Trans

advertisement

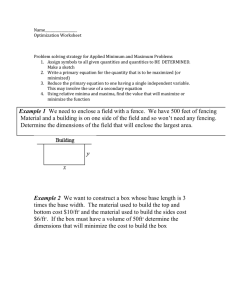

Integrated Trans-IND system Page 1 of 37 Trans-IND integrated process It is well-known that the construction sector is a very traditional one and that every innovation needs an period for acceptance by the end users. Introducing Fiber Reinforced Materials (FRP) in this sector is difficult because the construction process has been optimized for traditional materials (concrete and steel) that are popular within this sector. In order to introduce FRP materials in this sector, this new and advanced material has to gain trust among the people (technical, commercial, architects, etc.) and this will only be possible when they are supported by a design code accepted by the standardization bodies. The integrated Trans-IND system not only deals with FRP, manufacturing components made of FRP, their assembly, but it also goes further. The integrated Trans-IND system tries to optimize the management of the whole construction site from its beginning at the tender stage to its maintenance and demolition. It will be shown that Information and Communication Technologies (ICTs) are very important in this system, and introducing these technologies into the construction sector will also be a challenge, where traditional methods are very difficult to substitute. A scheme (see Figure 2 below) has been prepared in order to show the philosophy of this integrated system with an emphasis on the valid results. 1 Integrated Trans-IND system Page 2 of 37 Figure 2: Influence of the Integrated Trans-IND system on the traditional construction process of transport infrastructure 2 Integrated Trans-IND system Page 3 of 37 Technical solutions of Integrated Trans-IND system Overview and list of the solutions In order to give a better overview of the works that have been performed within the Trans-IND project, the list of specific technical solutions and guidelines was created, Table 1. Each solution is assigned to a different phase of the construction process and described in details. Table 1 List of technical solutions within Trans-IND project. Implementation phase Solutions Design Design of FRP beams FRP deck system Safety barrier system Acoustic barrier system Plug-in joint solutions Catalogue of standardised FRP components Manufacturing process Off-site industrialization process Autonomous navigation system for beam finishing operations Epoxy resin application into the manufacturing system for Trans-IND components Lab-scale modular system for fabrication of composite components (closed shape beam) including software control system Multi-axial UD Crossply machine (material manufacturing process) FRP deck manufacturing process Automation of cross-ply process for DForm® prepreg production Rib mold manufacturing including DForm® technology (Deformable Composite System) Continuous Compression Molding process Automatic Quality Control and NDT procedures Support for optimized design of dimensional and morphological control system for FRP components using laser scanner technology Logistics & Assembly process Conceptual on-site assembly method RFID-based technologies supporting logistics and assembly process Asset management tool for the on-site assembly process QRCodes tool for item tracking and production and assembly support Trans-IND scheduler Intelligent position system based on 3D technology to assist crane movement All phases of construction process Business model for value chain integration Bridge semantic model and rules Testing and certification procedures Recommendation for standardisation Integrated Trans-IND system 3 Integrated Trans-IND system Page 4 of 37 The project intends to deliver integrated package of solutions and techniques that enable to construct a transport infrastructure in a more efficient way. The Trans-IND system contributes with specific solutions to different stages of the construction process from the design to the maintenance of the structure, Figure 9. Only in this way the Integrated system can be obtained and successfully implemented on the market. Figure 9: Components of the Integrated Trans-IND system 4 Integrated Trans-IND system Page 5 of 37 Design phase The solutions for the design phase covers innovative bridge components, Figure 10: – structural parts: deck, beams and plug-in joint system, – secondary elements: Acoustic and safety barriers. Figure 10: Trans-IND bridge system In order to facilitate the work of the architects and civil engineers, a special catalogue with the design bridge components has been prepared. The catalogue includes design models and gives detailed information about element typology, material, dimensions, span, durability and resistance. The paper shows how to integrate the components into the day-to-day design process of transport infrastructure. The catalogue is divided into four chapters: Introduction (History and advantages of use of FRPs), Structural elements (Beams, Decks, Joints), Secondary elements (Acoustic and Safety barriers) and short info about the Trans-IND project. 5 Integrated Trans-IND system Page 6 of 37 FRP beams Description Three types of FRP beams have been designed in order to cover a wide range of combinations of load and span made of polymer composite materials (FRP). The range covered for load and span is from 5 to 9 kN/m2 and from 10 to 40 m respectively. Scheme Figure 11: Open-shaped FRP beam Figure 12: Close-shaped FRP beam Figure 13: U-shaped FRP beam Innovativeness Actors of construction process FRP beams will provide an alternative solution to the existing modular beams made in traditional materials, adding all the advantages of these polymer composite materials, FRP (better reaction to corrosion, long life cycle, lightness, good mechanical properties, etc.). Designer, Structural Engineering, Cost Engineer, Main Contractor, Project Manager 6 Integrated Trans-IND system Page 7 of 37 FRP deck system Description FRP composite bridge deck is a solution for refurbishment of the existing bridges and construction of new ones. FRP deck system can be applied to different types of composite beams: open-shaped beam, close-shaped beam and U-shaped beam. The basic materials for the deck are: glass fibre, epoxy resin and concrete. The depth of the deck is 0,35 cm (including concrete slab) and the ideal span varies between 2-3 m. Scheme Figure 14: Scheme of FRP deck system Figure 15: Scheme of FRP deck system installed on FRP beams Innovativeness Actors of construction process FRP deck system brings the advantages of the composite materials. The benefits of solutions are: durability, light weight, high strength, rapid installation, lower or competitive life-cycle cost, high quality manufacturing process under controlled environments, long service life. Designer, Structural Engineering, Cost Engineer, Main Contractor, Project Manager 7 Integrated Trans-IND system Page 8 of 37 Safety barrier system Description Two typologies of safety barriers have been developed in Trans-IND project, according to the European Standards EN 1317-2: simple safety barriers and safety barriers with foam. Both types of Trans-IND safety barriers have the same geometrical dimensions and consist of the same main elements: two closed cap FRP profiles (single and double) supported by steel posts. The only difference is the foam within the closed cap profiles. A detailed description of the elements and the materials that compose the safety barrier are shown on Figure 16 and 17. Scheme Figure 16 Scheme of the safety barrier 8 Integrated Trans-IND system Figure 17: Cross-section of the safety barrier The use of closed cap profiles in FRP supported by posts in traditional material is a new solution in the field of the safety barriers, usually made of steel elements. The innovation is based on the following concept: the FRP profiles provide the needed resistance to a potential impact and the support in steel profiles ensure the necessary ductility to the barrier, according to the European Standards (EN1317-2). Innovativeness Actors process of Page 9 of 37 construction Designer, Structural Engineering, Cost Engineer, Main Contractor, Project Manager, Supplier, off-site manufacturer 9 Integrated Trans-IND system Page 10 of 37 Acoustic barrier system Description The acoustic barrier system covers five configurations of the barriers. Based on the performance regarding the efficiency of five designs of acoustic barriers using advance composite materials (GFRP) it was concluded that the most interesting, innovative, and most effective design, is the option #5, which consisted of a sandwich of two layers of rock wool between two veils of polyvinyl alcohol nano-particles and an exterior cover of a plane and a curved layer of GFRP. Although the most suitable acoustic barrier is option #1, from an economical point of view, if aesthetic and environmental factors are considered, the best option is clearly option #3. Scheme Figure 18: Different configuration of acoustic barriers Innovativeness Actors of construction process Figure 19: On the left detail of the simple acoustic barrier design (option #1), on the right detail of the curved acoustic barrier design (option #5) The results obtained regarding the efficiency of the acoustic barriers with composite revealed a significant increase in the noise reduction index when GFRP is included in all the designs developed. The best results in this sense were obtained for design #5, the curved acoustic barrier. This increment in the efficiency combined with an innovative design (both options #3 and #5) makes this system an attractive option for future acoustic barriers in the transport infrastructure. Designer, Structural Engineering, Cost Engineer, Main Contractor, Project Manager, Supplier, off-site manufacturer 10 Integrated Trans-IND system Page 11 of 37 Plug-in joint solutions Description Three types of structural joints between the beams and the deck have been designed and tested. The open-shape (U and V) beams are connected to the FRP deck through shear rods. These connectors are placed and glued in holes previously drilled on the upper flange of the FRP beams. The close-shape beams are connected to the FRP deck through T shape steel plates (Perfobond) or steel sheeting glued to the top surface of the beam. Transverse reinforcing bars are placed through those metallic elements to increase their interaction with the concrete layer. The main advantages of the solutions are: They do not interfere in the manufacture of the beam They are easy to install / assemble on - site They are commercial or mass-produced items Scheme Innovativeness Actors of process construction Figure 20: Scheme of the joints between beam and deck There are no standard joints for FRP structures. The proposed ones allow connection between beams and decks in bridges and other structures. They are in line with the objectives of Trans-IND project regarding the on-site assembly and cost reduction strategies. The joining systems are original from the concrete-steel composite structures. They have been redesigned under the working mode of the FRPs. The analytical estimations of the mechanical capacities have been validated through experimental tests. Designer, Structural Engineering, Cost Engineer, Main Contractor, Project Manager, Supplier, offsite manufacturer 11 Integrated Trans-IND system Page 12 of 37 Catalogue of standardised FRP components Description Trans-IND Catalogue is a collection of the main composite components developed in the Trans-IND project for designing transport infrastructures. The Catalogue includes both structural and secondary elements: Beams: Open-shaped beams, Closed-shaped beams, U-shaped beams Deck solutions for: Open-shaped beams, Close-shaped beams, U-shaped beams Joints solutions for: Open-shaped beams, Close-shaped beams, U-shaped beams Safety Barriers: Simple safety barriers, Safety barriers with foam Acoustic Barriers: Simple acoustic barriers, Curved acoustic barriers, Acoustic barriers with vegetation Furthermore, a general overview of the main characteristics and properties of the composite materials is specified in the introduction together with a description of the advantages of using FRP composite materials in civil construction. Moreover, since the Catalogue is a tool for the dissemination of the Trans-IND project results, a final section is dedicated to a brief summary of the project objectives and an overview of the TransIND Consortium Partners. Scheme 12 Integrated Trans-IND system Figure 21: Catalogue of standardised Trans-IND components The Trans-IND Catalogue makes designing easier thanks to the collection of the technical information about the main transport infrastructures’ components, materials, standards and some solutions to solve typical design problems. Innovativeness Actors of process Page 13 of 37 construction Designer, Structural Engineering, Cost Engineer, Main Contractor, Project Manager, 13 Integrated Trans-IND system Page 14 of 37 Manufacturing process An integral part of the project is the development of the automated off-site manufacturing process for modular FRP transport infrastructure components, Figure 22. This new process is characterised by a high automation level and at the same time is highly flexible and agile for coping with different sizes and quantities of FRP components. It is important that the system allowed to control the flow of materials and components and also to manage human security issues and the available human resources. Due to the fact that the manufacturing concept is directly adapted for the FRP components and their properties, planning, time and cost efficiency can be achieved. Integral part of the manufacturing process is the development of the machinery for FRP transport infrastructure that utilize the process of filament winding, pre-preg production and advanced pultrusion. Figure 22: General concept of the overall manufacturing process As a consequence, it can be concluded that the manufacturing system based on new systems, will be able to significantly improve the existent methods, and bring important benefits in terms of: - Time reduction with respect to the current manufacturing processes for equivalent FRP components, - Labour cost reduction, - Energy cost reduction, - Increase competitiveness of the FRP components with respect to concrete, - Improvement of job quality and workers satisfaction because of a safer, cleaner and easier process. 14 Integrated Trans-IND system Page 15 of 37 Off-Site Industrialisation Process Description Conceptual design of the off-site industrialisation process deals with the design of the planning layout for the automated industrialisation process, and therefore the definition of the logistics and process planning activities for the most suitable production process in terms of cost-effectiveness, flexibility, efficiency and productivity. The resulting process features a high automation level and at the same time is highly flexible and agile for coping different sizes and quantities of FRP components. These features allow the resulting system to control the flow of materials and components and also to manage human security issues and the available human resources. Finally, energy efficiency issues as well as RFID technological aspects are considered in this phase of conceptual design. Scheme Innovativeness Actors of process construction Figure 23: Off-site industrialisation concept Manufacturing processes on a high automation level and, at the same time, high flexibility and agility for coping with different sizes and quantities of FRP components. Adapting the manufacturing system regarding different product types and quantities to variable market demands. In terms of performance, this result can be seen as a specified and adopted manufacturing concept for FRP components. Therefore it can save planning and modelling time and also costs. Quality control officer, Main Contractor, Safety Control Officer, Procurement Officer, Supplier, offsite manufacturer 15 Integrated Trans-IND system Page 16 of 37 Autonomous navigation system for mobile platforms Description An autonomous navigation system for a mobile platform has been developed and tested. It will help to increase the automation level of the finishing operations done on composite beams or other large structures. Once the navigation algorithms are implemented in the appropriate mobile system, the platform can move in a safe way along the beam and can carry and position necessary equipment for finishing operations with high precision. The main advantages of the solution are Beam is used as support and guiding. Compact and autonomous system, low space required. Flexibility in beam size within the crawler frame. Fast deployment and quick referencing. Scheme Figure 24: Scheme autonomous navigation system for a mobile platform Innovativeness Actors of process construction With the help of the developed navigation system, some of the finishing operations that nowadays are done manually, such as drilling or sanding, could be performed automatically, assuring process quality, and reducing the tack time of this operation. Although these operations could also be made by traditional large machine tools, the main advantages of the proposed solution are that the investment is lower, the system is compact and autonomous, and it is more versatile and transportable from one side of the manufacturing floor to another. Quality control officer, Main Contractor, Safety Control Officer, Procurement Officer, Supplier, offsite manufacturer 16 Integrated Trans-IND system Page 17 of 37 Epoxy resin application into the manufacturing system for Trans-IND components Description In the Trans-IND project, thermosets resins will be processed via filament winding (beam production) and pultrusion (deck production). Those 2 processes as well as the requirements needed for the resins when using those processes are described and suitable epoxy resin systems are proposed. Filament Winding: Scheme Pot-life (100g, 23°C) (Process) Initial mix viscosity (mPa.s) Tg (°C) (properties) Cure cycle (Energy consumption) Araldite®LY1135-1/Aradur® 917/ Accelerator 960-1 Araldite®3585 / Aradur® 3486 Araldite®LY 556/ Aradur ® 22962 56 - 62 h 480 - 580 min 110 - 150 min 600 - 1000 500 - 650 400 - 600 132 -138 100 - 110 130 - 140 4h/80°C + 4h/120°C 2h/100°C 15 min/120°C + 2h/150°C Pultrusion: Araldite® LY1135-1/ Aradur® 917/ Araldite® DY 070 95 – 115 h Innovativeness Actors of process construction Araldite® LY 1568 / Aradur® 917/ Araldite® DY070 40 - 50 h Pot-life (100g, 23°C) (Process) Initial mix viscosity (mPa.s) 600 – 900 500 - 700 Tg (°C) (properties) 140 -150 140-150 Cure cycle 4h/80°C + 4h/140°C 4h/80°C + 4h/140°C (Energy consumption) Automated lamination of large parts with the lowest cost and energy consumption possible with having the required mechanical properties for infrastructures of bridges. Main Contractor, Procurement Officer, Supplier, off-site manufacturer 17 Integrated Trans-IND system Page 18 of 37 Lab-scale modular system for fabrication of composite components (closed shape beam) including software control system Description New automated and flexible system for producing FRP components (close-shape beam) with combination of two technology processes: Filament winding process and Tape laying process. Specially developed software control system based on specific requirements associated with the structure of composite components. Scheme Innovativeness Actors of process construction Figure 25: System for producing FRP components Designed equipment for production of close-shape beam has the possibility to use two technologies, Filament Winding and ATL technology. For both technologies, two independent software packages are prepared. All equipment parts with specially defined delivery tools are designed in order to achieve full automation of manufacturing process of this type of beams. Result allows to increase productivity, reduction of time; use the different types of materials in production process. Main Contractor, Supplier, off-site manufacturer 18 Integrated Trans-IND system Page 19 of 37 Multiaxial Crossply Machine Description The Multiaxial Crossply Machine enables the reel-to-reel production of laminates consisting of two or more UD layers with cross layers varying in orientation from 45 to 90 o. In this way both technical textile and composite laminates can be produced efficiently from rolls of UD-material consisting of various fibres and matrices. UDs based on thermoset - as well as thermoplastic matrix materials can be laminated by this machine, although latter category is favourable because of its efficient processing to building components by means of welding or thermoforming. Scheme Figure 26: Multiaxial Crossply Machine Innovativeness Actors of process construction Current production processes for technical textile and composites are rather slow because they consist of a weaving/winding and coating/impregnation step, while in case of UD & Crossply technology, both are integrated. Besides, the option to vary the orientation of the UD layers in the laminate in comparison with the 0/900geometry of a fabric, the reinforcement of the resulting textile/composite can be optimized for its specific application. Main Contractor, Supplier, off-site manufacturer 19 Integrated Trans-IND system Page 20 of 37 FRP deck manufacturing process Description The result is an optimized manufacturing process which will allow us to manufacture deck parts, in a continuous and, therefore, cost-effective way. Scheme 4 1 2 3 1- Raw material storage 4- Pulling device Innovativeness Actors of process construction 5 2- Fiber impregnation 3- Pultrusion die 5- Cutting device Figure 27: Scheme of deck manufacturing process After studying and testing various methods for impregnating and guiding the fibres, optimized way to get the fibres impregnated and guided for manufacturing the bridge deck was developed. Quality control officer, Main Contractor, Safety Control Officer, Procurement Officer, Supplier, offsite manufacturer 20 Integrated Trans-IND system Page 21 of 37 Automation of cross-ply process for DForm® pre-preg production Rapid molding with DForm allowing unidirectional pre-preg to be formed over complex shapes including double curvatures and tight radii, this technology is established and patented but current production methods are slow and labour-intensive; automation will significantly reduce the material costs while improving the life of the material, this will be particularly important for low temperature curing resin systems such as the Umeco LTM series of tooling resins. Description Scheme Innovativeness Actors of process construction Figure 28: Schematic of the automated cross-plying process for DForm The innovation in this result is the automation of a crucial stage in the manufacture of the DForm pre-preg which requires crossplying in order to render the material practical. Sub-contractor, Supplier, off-site manufacturer 21 Integrated Trans-IND system Description Page 22 of 37 Rib mold manufacturing including DForm® technology (Deformable Composite System) Rapid molding with DForm allowing unidirectional pre-preg to be formed over complex shapes including double curvatures and tight radii; this technology will be demonstrated through the production of a rib tool and component. Current methods include woven fabric pre-preg which is much more labour-intensive to lay up and dry pre-form infusion which has limitations in achievable fibre content and resin properties Scheme Innovativeness Actors of process construction Figure 29: CAD schematic of DForm rib tool Previously tooling for this type of component would be manufactured using conventional woven fabric-based pre-preg which takes much more skill and time to make a tool skin; DForm has not previously been used in the construction sector and it is anticipated that this will show a measurable improvement in cost effective manufacture of the tool and the components made using the tool. Sub-contractor, Supplier, off-site manufacturer 22 Integrated Trans-IND system Page 23 of 37 Continuous Compression Molding process Description Continuous Compression Molding (CCM) is a semi-continuous process in which several pressing tools are included in one press. These tools are arranged in a row and the material is transported through them. But the use of one continuous tool is also possible. This tool is attached to only one press and is fed with a certain amount of material. The main objective of the Continuous Compression Molding process is to separate the heating and the cooling zone of the tool in order to realize high heating and cooling rates. This means that the impregnation and the solidification take place in different parts of the tool. In the heated section at the beginning the material is impregnated and consolidated and then it is still consolidated and also solidified in the cooling section. Scheme Innovativeness Actors of process construction Figure 30: Scheme of Continuous Compression Molding (CCM) Within the Trans-IND project several production trials for the manufacturing of the safety barriers by use of continuous compression molding process were performed. The aim of this study was to evaluate the feasibility of the production of closed cap profiles in one single step that can be used as safety barriers afterwards. As suitable process, the continuous compression molding process was identified. Main Contractor, Sub-contractor, Supplier, off-site manufacturer 23 Integrated Trans-IND system Page 24 of 37 Inspections for NDT procedures The main objective of “Automatic quality control and NDT (Non-destructive testing) procedures” Description is to develop and optimize dedicated techniques for the quality and integrity control of new FRP components for Trans-IND project. Main issues like the large size, high thickness and complex shape have been addressed. The optimal NDT techniques and configurations for the different Trans-IND components have been identified and described. In particular a new configuration of the ultrasonic technique has been developed to overcome the current limit in inspecting sandwich elements with high thickness and low density core. The system developed meets the requirements of easiness and flexibility for a further implementation in the production site. Scheme Contact emitter, ultrasound probe Non-contact receiver, ultrasound probe Figure 31: On the left NDT inspection with hybrid configuration on sandwich structure, on the right C-Scan inspection result Defect Innovativeness Actors of process construction Figure 32: On the left NDT inspection with ultrasound in pulse echo mode on curved panel, on the right C-Scan inspection result The inspection of the structural integrity of composite components with complex shapes (high thickness, complex profiles, sandwich structure) for civil construction and infrastructures are very challenging for NDT at the state of the art. Moreove,r the flexibility of these solutions allow to inspect a large area automatically. An accurate inspection reduces the risk of cracks, accident and cost of maintenance. Quality control officer, Quality Surveyor, Main Contractor, Sub-contractor, Supplier, off-site manufacturer, Service Provider 24 Integrated Trans-IND system Page 25 of 37 Support for optimized design of dimensional and morphological control system for FRP components using laser scanner technology. Description Innovativeness Actors of process construction The quality control of FRP components is certainly an important phase of the off-site production to guarantee the respect of the engineering specifications and tolerances. The result is focused on the development of methods and procedures based on laser scanner technology dedicated to design, Hw and Sw configuration and set up of the most appropriate “dimensional and morphological control system” for the FRP products and processes. Developed methods and procedures will be used by ITIA to provide an integrated service focused on dimensional and morphological control. The integrated consultancy service concerns the study, the design and the set-up of the best solution – according to the specific set of requirements - for the dimensional and morphological control of FRP components and it will be fully customized to customer’s needs. An integrated service dedicated to design, configuration and set-up of the most adequate control system is a new service that we consider innovative and unique. Main Contractor, Sub-contractor, Supplier, off-site manufacturer, Service Provider 25 Integrated Trans-IND system Page 26 of 37 Logistics and Assembly process The new approach to logistics and on-site assembly process enable to obtain shortened installation process and what is important to limit traffic disturbance, that frequently provoke many problems during construction of transport infrastructure. The flexible process that can be used in different climatic conditions covers new technologies like: tracing the elements by RFID system and intelligent positioning system. As a result, on just-in-time delivery of the components can be achieved, which enables construction on the space-limited sites. The RFID could help monitoring the structural components, equipments, tools or even staff during the FRP bridge and its elements construction, Figure 33. It would mean an improvement in the traceability of the process. There are two main fields in which the RFID can be used: – Logistics: This involves mainly tracking and tracing (controlling, monitoring) and also security and safety (theft, accident, loss of fright). – Working site: This involves mainly tracking and tracing, resource management (human resource management, machine management, asset management and site management), installation through a semi-automated process (beam installation, deck panel installation, etc.), supporting the demolition process and maintenance. Tag Chip Data Antenna Reader Middleware Application server Figure 33: Scheme of RFID system The role of the intelligent positioning system is to improve the positioning of large elements such as a beam, Figure 34. The aim is to position a beam in a correct place with the highest precision possible. Figure 34: Scheme of intelligent positioning system 26 Integrated Trans-IND system Page 27 of 37 Conceptual on-site assembly method Result description Conceptual on-site assembly method describes new possibilities for assembly process that are available for the FRP infrastructure components e.g. use of light cranes and plug in joints. New technologies like: tracing the elements by RFID system and intelligent positioning system. The goal of the application of new technologies is to obtain shortened installation process and limit traffic disturbance. Moreover conceptual on-site assembly focuses on just-in-time delivery, which enables construction on space-limited sites. Scheme Figure 35: Scheme of intelligent positioning system Innovativeness Actors process of construction In comparison with traditional installation scheme, the Trans-IND method utilizes innovative solutions that until now were successfully used in other sectors. Example of the new technologies are: tracing the element by RFID system and intelligent positioning system that is based on 3D vision technology. Quality control officer, Quality Surveyor, Trainer, educator, Main Contractor, Project Manager, Safety Control Officer, Sub-contractor 27 Integrated Trans-IND system Page 28 of 37 RFID-based technologies supporting logistics and assembly process Description RFID-based technologies support the logistic and assembly processes by providing a contactless and correct identification of the FRP bridge components. To satisfy the requirements made for different RFID application scenarios a strategy was proposed regarding all relevant aspects influence the selection of certain RFID devices. Here, the starting point for the selection process is formed by the components to be tagged, the concrete application and the environment RFID is used. Based on these boundary conditions certain criteria can be derived allowing the analysis of RFID product catalogues. The result of this strategy is the most appropriate RFID system (reader, transponder and middleware). Scheme Components Element Type Beam-Element, DeckElement,… Individual Elements: Beams, decks, ... Conditions Application Case Constr. Phase, Maintenance Phase,… Selection Process Selection Criteria Manuf acturer Tag name functio nality Tag Mount orientation Dectag DecTagFlex Read/ Wirte Horizontal Confid ex Confidex Carrier Pro Readonly Horizontal GAO Tag- Flex N/A optional Frick Foam Backed Tag Read/ write Horizontal Proposed Readers Reader Manufacturer Name Nordic ID PL3000 Mobile Motorola System Temperature, Precipitation,… Manufacturer Info RFID Tracking, Documentation ,… Pallets Single Element, Pallet,… Application Application Type RFID Product Catalogues Boundary Condition Off-Site, On-Site, Shipment Element Level of Detail Environment Location Proposed Transponders Stationary • • • • Transponder Characteristics Transponder Fixing Method Reader Characteristics Communication Transponder/Reader/Middleware • Economic criteria Impinj speedway Alien MC9090-G R-220 or R420 ALR-9900 Middleware Open source Fosstrak EPCIS Repository Figure 36: RFID technologies for logistic and assembly Innovativeness Actors of construction process The proposed RFID system represents an appropriate solution for timely identification of FRP bridge components in different application scenarios. It is flexible to apply in different construction process phases and reuse again in other projects. It also provides information accessible to all project partners, can be extended to include other ID-technology (Barcode, QRcode) for further applications and offers common interfaces to use the gathered data for further processing e.g. in the intended KMT (Knowledge Management Tool). Project Managers, Main Contractor, Quality Control Officers, Sub-Contractors, Quality Surveyors, Suppliers, Off-Site Manufacturers ,Service Provider (logistics),Tester. 28 Integrated Trans-IND system Page 29 of 37 Asset management tool for the on-site assembly process Description Software functionalities included into the integrated Trans-IND software platform allow to: uniquely identify physical bridge parts by means of RFID and/or QRCode tags; associate information to the parts: manufacturing and test reports, handling, safety and assembly instructions; track the location of these physical parts; providing up-to-date information of the location of the parts of a bridge; access part information and main assembly instructions from anywhere using the identifier of the part. Scheme Innovativeness Actors of process construction Figure 37: Asset management tool Parts logistics and on-site will benefit from up-to-date and remotely available information about parts, including: exact location of parts involved in assembly steps, access to handling and mounting instructions, access to 3D views of the parts, access to animations of the mounting steps. This interactive information retrieval will contrast with current situation where most of it is paper-based. Project Managers, Main Contractor, Service Provider (logistics), Tester. 29 Integrated Trans-IND system Page 30 of 37 QRCodes tool for item tracking and production and assembly support Description This tool for item tracking and provision of on-site information support is based on a unique QR code tag attached to each part of a bridge, which identifies the part, allows geo-positioning of the part, and provides on-line link to extended part and project information. The application consists of two software modules: the Smart-phone Client and the Information Centre Web Application, which are communicated through the Knowledge Management Tool (KMT application), which in turn provides a set of web services facilitating full duplex part information retrieval and/or update. The Smartphone Client allows to scan the QR coded identification of a part via the camera integrated on the device and uses the GPS functionality available on the smart-phone for positioning the scanned item. It also provides an interface for on-site access to graphical and textual information on part properties, montage instructions, project specifications, quality procedures and guidelines, or any further details available on the knowledge base, as well as real time messages created by the Information Centre operator. The Information Centre Web Application allows tracking of parts on a map and information exchange with the user on-site. Scheme Figure 38: Scheme of the work of QRCodes tool Innovativeness Actors of process On-site crews rarely have access to the internet, but a Smartphone with a camera, internet connection and positioning capability are becoming a standard. QR codes scanning and processing combined with positioning and wireless networking technologies are used to develop innovative solutions which allow architectural, engineering and construction companies to do daily on-site jobs more efficiently. construction Project Managers, Main Contractor, Service Provider (logistics), Tester. 30 Integrated Trans-IND system Page 31 of 37 Trans-IND scheduler Description Trans-IND scheduler is a tool for planning and management of construction projects. It helps to plan the integrated transport process and installation of bridge facility elements. The tool has easy-to-operate graphic user interface combined with suitable description. The construction works completion schedule set by the application can be presented in a graphic form - a Gantt chart, or in a text form - dates of commencement/completion of particular construction works. Application of a fast algorithm approximated to the scheduling of construction projects allows to obtain high-quality solutions (in the sense of values of the objective function) in a short time. Scheme Figure 39: Trans-IND scheduler programme window Innovativeness Actors of process construction The tools help to plan and manage the transport and installation process of the FRP bridge components. Trans-IND project not only focus on the innovative material solution but also provides products for easier and more efficient work scheduling. Project Managers, Main Contractor, Service Provider (logistics), Tester 31 Integrated Trans-IND system Page 32 of 37 Intelligent position system based on 3D technology to assist crane movement Description An application based on 3D vision technology that localizes and helps positioning of a beam with respect to a target position has been developed and tested. The developed algorithms can be used with any camera that provides a point cloud as output data. The precision obtained with the positioning system is due mainly to the camera chosen. The application can be configured for different types of beams, by including beams features on the system, so that it recognises the new geometry as the beam to be localised. Scheme Figure 40: Scheme of intelligent positioning system Innovativeness Actors of process construction The developed application will improve the assembly procedure on site by guiding crane operator with the help of vision technology. As a consequence, it will bring a decrease of the necessary time during assembly operation and reduction of human resources during assembly. Quality control officer, Project Managers, Main Contractor, Safety Control Officer, Sub-contractor 32 Integrated Trans-IND system Page 33 of 37 Intelligent positioning system: Manual Guidance Device for on-site assembling and disassembling activities of FRP barriers Description The result is focused on the development of a tool, called a manual guidance device – dedicated to intuitive robot programming during assembly and disassembly activities, enhancing productivity. The Manual Guidance Device (MGD) is a tool to intuitively move a manipulator. No specific skill or previous training is needed to perform pick and place operations reducing in that way the programming effort and so increasing assembly working time. It’s suited to guide robots dedicated to FRP barriers and small FRP components assembly Scheme Innovativeness Actors of process construction Figure 41: Example of the called manual guidance device scheme Manual Guidance (MG) technology is an innovation in itself and even more in the construction sector, where manual work is still prevalent. The introduction of such a technology could significantly improve productivity. Quality control officer, Project Managers, Main Contractor, Safety Control Officer, Sub-contractor 33 Integrated Trans-IND system Page 34 of 37 Management of the integrated construction process The Trans-IND project delivers solutions that help to manage/administer the whole construction process of FRP transport infrastructure. Such results can be used in different stages of the process and are adjusted to the needs of the main actors of the process. In order to obtain innovative approach within construction process, the existing projects, solutions from other sectors, lean manufacturing practices were investigated and best techniques were adapted to the special features of FRP transport infrastructure. An important part of the Integrated Trans-IND system is a new business model to overcome the existing market and legal barriers, especially concerning the fragmentation problem in the construction sector. Physically, it will allow companies to create new and profitable revenue streams, and find competitive advantage. The new business model is geared towards the large-scale implementation of FRP in civil infrastructure projects across the EU. Its main aspects are: – Industrialised value-chain integration (including demand and supply chains) instead of one-off project strategy, – Performance-based instead of lowest-price procurement. The new business model is built upon the knowledge of: current and future market potentials; characteristics of the current business models; innovative asset management concept; and feasibility analysis supported by real case studies from different EU countries. 34 Integrated Trans-IND system Description Innovativeness Actors of construction process Page 35 of 37 Business model for value-chain integration A new business model that is a part of the coherent operation strategy of Trans-IND to overcome the existing market and legal barriers, especially concerning the fragmentation problem in the construction sector. Physically, it will allow companies to create new and profitable revenue streams, and find competitive advantage. The new business model is geared towards the large-scale implementation of FRP in civil infrastructure projects across the EU. Its main aspects are (1) industrialised value-chain integration (including demand and supply chains) instead of one-off project strategy and (2) performance-based instead of lowest-price procurement. The new business model is built upon the knowledge of: current and future market potentials; characteristics of the current business models; innovative asset management concept; and feasibility analysis supported by real case studies from different EU countries. The new business model will transform a resources-based and supply-driven construction sector into a sustainable performance-driven sector, which is user-oriented, flexible, creative, innovative, effective and efficient in the whole life-cycle of the civil infrastructures. Moreover, it will encourage large-scale applications of FRP in transport infrastructures. The new construction process and the new business model creates added values through horizontal and vertical value-chain integration (citizens - social acceptance, end-users, regulatory and standardization bodies, clients - public and PPP, civil engineers, construction companies, materials manufacturers, components manufacturers/suppliers, equipment manufacturers, service suppliers, etc.) to solve the fragmentation problems in the construction sector. For this purpose, a full value re-engineering that integrates the demand and supply chains in civil infrastructure projects is carried out. The focus is given on facilitating the multi-party and multi-disciplinary collaboration processes for smart design, manufacturing and assembly of industrialised components. Investor/Client, Main Contractor, Supplier, off-site manufacturer 35 Integrated Trans-IND system Page 36 of 37 Recommendation for standardization Description Recommendations for standardization of FRP (based on Trans-IND infrastructure elements, processes...) are to be developed through collection of existing standards on FRP field, assessment, sorting, through detailed study of literature on procedures of manufacturing, design, testing, assembly, maintenance. The study revealed blank spots and barriers. Recommendations for standardization will gather or develop new procedures for design, production, testing and certification. Recommendation for standardization could help in development of Eurocode of FRPs - wider use and easier design, production, testing, education. Scheme Trans-IND (1) GENERAL (2) BASIC OF DESIGN 2.1. DESIGN VALUES 2.2. DESIGN REQUIREMENTS 2.2.1. General 2.2.2. Ultimate limit states 2.2.3. Serviceability limit states 2.3. ANALYSIS 2.3.1. ULS 2.3.2. SERVICEABILITY ANALYSIS (3) MATERIALS 3.1. REINFORCEMENT 3.1.1. Fibres 2.4.2. Rovings 2.4.3. Mats 3.1.4. Woven rovings (WR) 3.1.5. Fabrics 3.1.6. Prepregs 3.2. RESINS 3.2.1. Polyester resins 3.2.2. Vinyl ester resins 3.2.3. Modified acrylic resins 3.2.4. Phenolic resins 3.2.5. Epoxy resins (4) LAMINATE DESIGN 4.1. LAMINA DESIGN 4.2. LAMINATE design 4.3 Test Methods (5) DURABILITY 5.1. CREEP 5.2. FATIGUE (6)ELEMENT CALCULATION 6.1. ULTIMATE LIMIT STATE DESIGN 6.1.1.BASIC CONDITIONS 6.1.2 Innovativeness Actors of process construction Document Recommendations for standardisation-CONTENTS: 6.1.3 MEMBERS IN COMPRESSION 6.1.4 MEMBERS IN FLEXURE 6.1.5 MEMBERS IN SHEAR 6.1.6 COMBINATION 6.2 SERVICEABILITIY LIMIT STATE DESIGN 6.2.1 BASIS CONDITIONS 6.2.2 DEFLECTIONS 6.2.3 STRESSES AND STRAINS (7) JOINTS 7.1. GENERAL 7.1.1. Partial safety factors 7.2. MECHANICAL JOINTS 7.2.1. BOLTED AND RIVETED JOINTS IN SHEAR 7.2.1.1. General 7.2.1.2. Design 7.2.2. BONDED JOINTS 7.2.2.1. General 7.2.2.2. Adhesives 7.2.2.3. Design of lap and strap joints 7.2.2.4. Design of angle joints 7.2.2.5. Design of tee joints 7.2.3. COMBINED JOINTS 7.2.3.1. Bonded-bolted joints 7.2.3.2. Bonded-riveted joints (10) QUALITY CONTROL 10.1.CONTROL OF DESIGN 10.2.CONTROL OF PRODUCTION 10.3.CONTROL OF CONSTRUCTION 10.4.REGULAR INSPECTIONS (11) REPAIR OF DAMAGES (12) COMPLIANCE TESTING 12.1.1. During production 12.1.2. On site (13) REFERENCE LIST 10 MEMBERS IN TENSION Figure 41: Content of the recommendations for standardisation The end result will increase the use of FRPs. Price of construction of FRP will decrease, FRPs will be more competitive to conventional materials. FRPs will more often be applied together with some of conventional materials like concrete. Designer, Structural Engineering, Main Contractor, Certification Authority, Supplier, off-site manufacture 36 Integrated Trans-IND system Page 37 of 37 Integrated Trans-IND system The Integrated Trans-IND system is a cost-effective integrated construction process that will enable the maximum capability of industrialization of components for transport infrastructures (deck, beam, joints, secondary elements) using Fibre Reinforced Polymer. Trans-IND system incorporates DFMA (Design for Manufacture and Assembly) in order to achieve reduction in the total costs by decreasing manufacturing and assembling efforts. Description Scheme Innovativeness Actors of process construction Figure 42: Main phases of the Trans-IND construction process The Integrated Trans-IND system tends to introduce innovative solutions in every phase of the construction process i.e. planning, design, manufacturing, on-site assembly, maintenance, renovation and demolition. The system combines new: materials like FRP, ICT solutions like RFID system and intelligent positioning system, approach to design, manufacturing and assembly: DFMA method and appropriate business models. Investor/Client, Legal officer, Designer, Structural Engineering, Main Contractor, Certification Authority, Supplier, off-site manufacture, Cost Engineer, Trainer, educator, Service Provider, Sub-contractor, Safety Control Officer, Quality control officer 37