IQ OQ PQ PM PM PM PM

advertisement

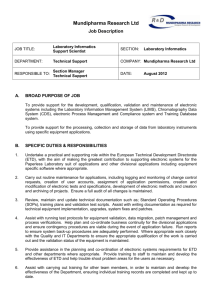

PRODUCT REVIEW Biacore® C: compliant concentration analysis of biopharmaceuticals Fredrik Sundberg, Biacore AB, Uppsala Sweden Biacore® C is the world’s first automated surface plasmon resonance (SPR)-based system specifically designed for GxP (GCP, GLP, GMP) applications. The validated system is optimized for regulated concentration analysis of biopharmaceuticals. C omputerized analytical instruments operating in a regulated environment must comply with the requirements of Good Clinical Practice (GCP), Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP). The end user is ultimately responsible for ensuring compliance with current regulations. Due to the high degree of automation and the complex systems used in today’s laboratory, technology and validation support are needed from specialized vendors. The on-going qualification processes in the GxP laboratory. PQ OQ IQ VENDOR QUALIFICATIONS AND ON-SITE AUDITS PM Qualification Approval PAGE 12 DEFINITION OF VALIDATION AND CRITICAL POINTS FOR REGULATORY COMPLIANCE One of the most important ways of maintaining the safety and effectiveness of a drug or pharmaceutical product is to maintain control over the instrumentation used in analysis. Validation is a necessary exercise for product approval and should provide evidence of control. According to the US Food and Drug Administration (FDA), the definition of process validation is: “Establishing documented evidence which provides a high degree of assurance that a specific process will consistently produce a product meeting the predetermined specifications and quality attributes” (1). A company producing therapeutic drugs is expected to validate software programs and analytical instruments used in drug development and manufacturing quality control (QC) or in-process control (IPC). PM PM PM Preventive Maintenance (PM) & Re-Qualification A validation plan should include a vendor audit program to select the preferred vendor. The preferred vendor should be: • Technically competent • Commercially qualified to supply and support the proposed system • Experienced and have knowledge of current validation requirements Qualifications of selected vendors should be verified through on-site evaluations, focusing on the vendor’s quality system. For software-based Biacore Journal – Number 2 2002 PRODUCT REVIEW Modifications to sample evaluations are tracked in Biacore® C software with computer generated, time-stamped audit trails. systems, the Software Quality Assurance System (SQAS) should be a major factor in evaluating the capability of the vendor. SYSTEM DEVELOPMENT LIFE CYCLE AND SOFTWARE VALIDATION For successful validation and maintenance of computerized systems the software programs controlling the instrument should be developed to support the GxP regulated working process. To build in quality, effectiveness and functions meeting with current regulations, validation should be considered part of the complete life cycle of a computer system, including all stages of planning, specification, programming, testing, commissioning, documentation, operation, monitoring and modification (2). A System Development Life Cycle (SDLC) approach can be applied to software used to control analytical instruments. This model facilitates effective software development of safe products and ensures adequate validation of software being developed. Truly validated software programs are verified in-house by the vendor to conform with, and function according to specification, with documented evidence of testing available on request. It is usually not realistic for the user to perform this type of structural testing of software, as testing for source code accuracy can be timeconsuming. However, regardless of how and when the testing is performed, the user must be responsible for understanding and evaluating these tests. MEETING 21 CFR PART 11 REQUIREMENTS IN THE GXP LABORATORY Appropriate security and backup measures must be designed into computerized systems. For example, both physical and logical access should be controlled and restricted to authorized personnel only (3). Biacore Journal – Number 2 2002 Every significant modification to validated systems should be carefully evaluated and documented according to defined procedures. Systems not meeting U.S. FDA guidelines for 21 CFR Part 11 (Electronic Records; Electronic Signatures) must be brought into compliance, or replaced with new, compliant systems. During recent years, FDA has put more emphasis on enforcing the regulation and is increasingly issuing warnings. The industry is now faced with the administrative and technical burden of applying the rule to legacy systems without totally shutting down today’s operations. EQUIPMENT QUALIFICATION Regulatory authorities expect that a company producing therapeutics will qualify their analytical instruments prior to use in the laboratory. Equipment qualification is the process by which it is ensured that a system is appropriate for its intended use. Equipment qualification is commonly broken down into design, installation, operational, and performance qualification. Design qualification (DQ) relates to all procedures prior to installation of the system in its selected operating environment. Installation qualification (IQ) involves verifying complete arrival of the system as purchased, with a list of components, instruments, and required specifications to be checked and signed off. Operational qualification (OQ) includes procedures for testing the system in its selected environment. Performance qualification (PQ) is documented verification that a method works for a specific system according to its routine usage. The pharmaceutical producer usually carries out this phase and ongoing performance tests to ensure that PAGE 13 PRODUCT REVIEW the system is maintained in a validated state. The ongoing qualification process is supported by periodic preventive maintenance (PM) visits, calibrations and re-qualifications that keep the system in a validated state. Modifications to validated systems do not always require a fullblown re-qualification. Instead after initial risk analysis, modifications can be managed with change control procedures. Change control needs to be in-place for all stages in the life cycle of the system. Points to consider for compliance when qualifying equipment include: • On-site performance of IQ/OQ/PQ to take environmental factors into consideration (temperature, voltage, operating procedures, etc.) • Use calibrated instruments for the qualification exercise • Work with GMP-trained personnel • Document everything – while doing it! The qualification protocols generated should be stored in a safe location and be easily retrieved. The end user is responsible for providing documentation when the system is inspected. the initial IQ/OQ, continuous follow-up with preventive maintenance and re-qualifications are included in the service. The system is thus suitable to be applied across a broad range of assays in pre-clinical and clinical trials and manufacturing QC and IPC. FULLY AUTOMATED CONCENTRATION ANALYSIS USING BIACORE® C Increasing speed and quality of concentration analysis, while still meeting stringent regulatory requirements is essential for ensuring success in regulated manufacturing QC and IPC. Key advantages are: • 21 CFR Part 11 compliance for electronic records and enhanced data security • Label-free, real-time sample analysis and minimal usage of limiting reagents • Validation support & services meeting worldwide regulatory expectations • Cost-efficient active concentration detection To maintain systems in a validated state, Biacore also offers a maintenance re-qualification service (PM GxP). PM GxP is preventive maintenance adapted for a regulated environment, with fully documented and extended system functionality tests included. TTM FOR THERAPEUTIC DRUGS AND OUTSOURCING VALIDATION The first product that is released for a particular indication often gains most of the market share. Time to Market (TTM) can be shortened by: • Working with a vendor with knowledge of validation requirements • Assembling and developing the proper documentation in a shorter time frame • Using experienced and GMP-trained personnel. Vendors are usually the most qualified party to assemble an installation and operational qualification protocols. Costs can be cut if validation documents are assembled quickly by personnel specifically trained in GMP. LEADING-EDGE TECHNOLOGY IN DRUG DEVELOPMENT AND MANUFACTURING Biacore® C software is designed to support the GxP-regulated working processes in the laboratory. The user-friendly software interface guides the user through assay development as well as daily routine analysis. Regulatory demands on data security, traceability and 21 CFR Part 11 are also supported in the software. Authorized users can be defined into three different access levels in the system. As support for the overall system validation process, Biacore provides access to design-validation documentation from system development and Equipment Qualification services meeting worldwide regulatory expectations. This service includes Installation Qualification (IQ) and Operational Qualification (OQ) performed by qualified Service Engineers. After PAGE 14 CONCLUSION • A validation life cycle applied to a computerized system will keep the system in a state-of-control during the entire product life cycle, until its retirement. • Analytical systems must be brought into compliance with 21 CFR Part 11, or be replaced with new, compliant systems. • Working with vendors providing validated systems and outsourcing the equipment qualification effort can drastically cut the Time-toStart-up for instruments and process equipment, accelerating TTM for new therapeutics. • Biacore® C has been designed for GxP regulated areas of drug development and manufacturing processes, geared to accelerating QC and IPC of biopharmaceuticals. References 1. General guidelines for process validation, U.S. FDA (1987). 2. Good manufacturing practices, Medicinal products for human and veterinary use, European Commission, Directorate General III - Industry, Pharmaceutical and cosmetics. Computerised systems, Annex 11, Vol. 4 (1998). 3. 21 Code of Federal Regulations Part 11, Subpart B - Electronic records, Section 11.10 Controls for closed systems, U.S. FDA. Biacore Journal – Number 2 2002