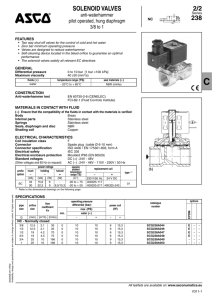

SOLENOID VALVES FOR VALVE AUTOMATION Delivering

advertisement