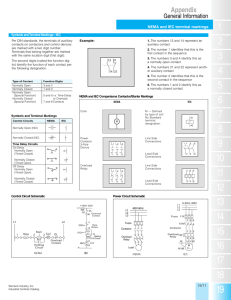

Standards

advertisement