pdf version - US Bellows

advertisement

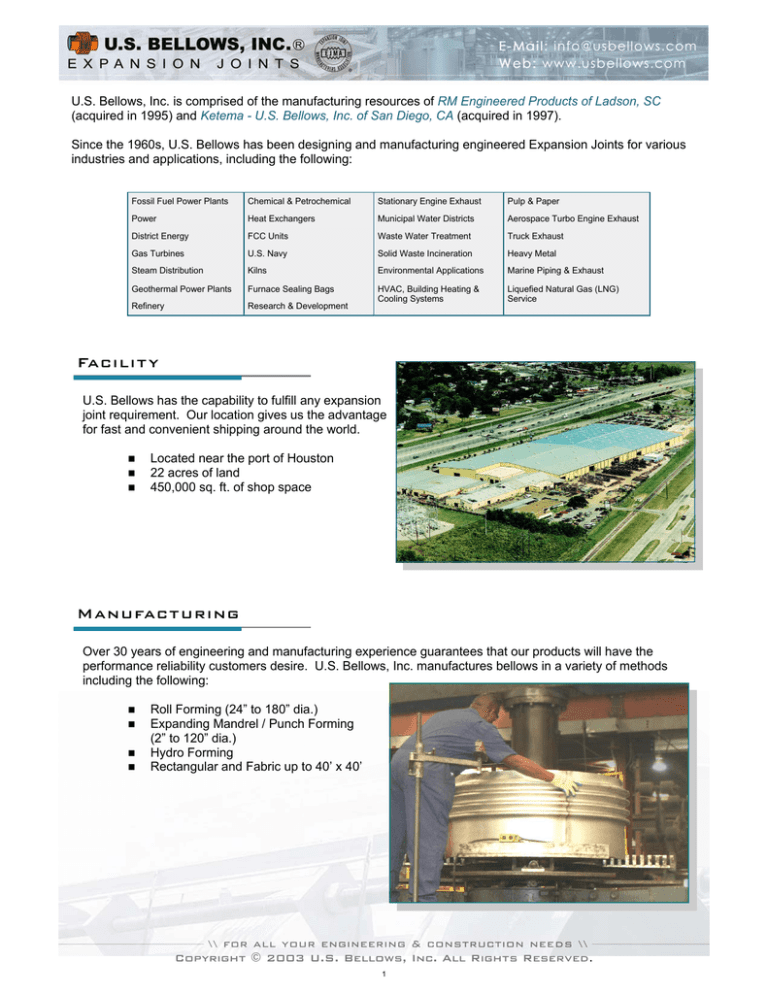

U.S. Bellows, Inc. is comprised of the manufacturing resources of RM Engineered Products of Ladson, SC (acquired in 1995) and Ketema - U.S. Bellows, Inc. of San Diego, CA (acquired in 1997). Since the 1960s, U.S. Bellows has been designing and manufacturing engineered Expansion Joints for various industries and applications, including the following: Fossil Fuel Power Plants Chemical & Petrochemical Stationary Engine Exhaust Pulp & Paper Power Heat Exchangers Municipal Water Districts Aerospace Turbo Engine Exhaust District Energy FCC Units Waste Water Treatment Truck Exhaust Gas Turbines U.S. Navy Solid Waste Incineration Heavy Metal Steam Distribution Kilns Environmental Applications Marine Piping & Exhaust Geothermal Power Plants Furnace Sealing Bags Refinery Research & Development HVAC, Building Heating & Cooling Systems Liquefied Natural Gas (LNG) Service Facility U.S. Bellows has the capability to fulfill any expansion joint requirement. Our location gives us the advantage for fast and convenient shipping around the world. Located near the port of Houston 22 acres of land 450,000 sq. ft. of shop space Manufacturing Over 30 years of engineering and manufacturing experience guarantees that our products will have the performance reliability customers desire. U.S. Bellows, Inc. manufactures bellows in a variety of methods including the following: Roll Forming (24” to 180” dia.) Expanding Mandrel / Punch Forming (2” to 120” dia.) Hydro Forming Rectangular and Fabric up to 40’ x 40’ Copyright © 2003 U.S. Bellows, Inc. All Rights Reserved. 1 Index of Products and Services PAGE INTRODUCTION ……………………………………………………... 1 Facility & Manufacturing ……………………………………………... Engineering ……………………………………………………………. Quality …………………………………………………………………. PRODUCTS …………………………………………………………... Thin-wall Expansion Joints ……………………………………….. 1 Single …………………………………………………………………... Toroidal ….…………………………………………………………….. Universal ………………………………………………………………. Hinged ………………...……………………………………………….. Externally Pressurized ……………………………………………….. Clamshell ………………………………………………………………. Gimbal …………………………………………………………………. In-line Pressure Balanced ……………………..…………………….. Elbow Pressure Balanced ……………………………………………. Refractory Lined …………………..………………………………….. Thick-wall Expansion Joints ………………………………………. 4 2 3 4 - 11 4-8 4 4 5 5 10" Single tied titanium Expansion Joints for a chemical plant in Kingsport, Tennessee 5 6 7 7 8 9 Rectangular Expansion Joints …...………………………………. 9 Slip Type Expansion Joints ……………………………………….. 10 Fabric Expansion Joints ………...…………………………………. 10 Rubber Expansion Joints ………………………………………….. 11 Stock Bellows …..……………………………………………………. 11 EXPANSION JOINT DATA SHEETS - 85 / 150 / 300 PSIG ……... 12 - 14 12” dia. Single Expansion Joint, with 304SS bellows, SA 105 150# RFSO and C/S weld ends. EXPANSION JOINT SPECIFICATION SHEETS ROUND / RECTANGULAR ………………………………………….. 15 - 16 SERVICES ……………………………………………………………... 17 - 18 Engineering U.S. Bellows, Inc. has over 45 experienced engineers on-site to provide you with cost-effective, high quality solutions. Utilizing the latest design software and analysis applications, as well as in-house developed software, U.S. Bellows can design and manufacture specialized custom units as per your specifications. Finite Element Analysis and Pipe Stress Analysis software are used to simulate the loads and resulting stresses that may occur in a design system. These computer programs help determine engineering design specifications to meet load/stress requirements. Gimbal Stress Analysis for 804,242 lbs. Pressure Thrust of a 36" Gimbal ring for a Gimbal Expansion Joint 36" Gimbal Expansion Joint after completion 36" Gimbal Expansion Joint, designed for 680 PSIG and 540 °F, installed at chemical plant Copyright © 2003 U.S. Bellows, Inc. All Rights Reserved. 2 Quality As a member of EJMA, U.S. Bellows, Inc. follows strict quality control procedures to ensure that its products meet industry standards. U.S. Bellows, Inc. is in compliance with the following codes and standards as applicable: ASME Section VIII ANSI B31.1 ANSI B31.3 API 620 AISI EJMA ICBO Each Bellows and Expansion Joint is inspected thoroughly, both during the fabrication process and prior to shipping, to ensure the products are delivered to our customers in optimum condition. U.S. Bellows, Inc. offers the following Performance Assurance Programs: Hydrostatic Testing Liquid Penetrant Inspection Magnetic Particle Radiography Test Ultrasonic Positive Material Identification (PMI) Test Cycle Testing Pneumatic Testing Burst Testing Spring Rate Testing Helium Leak Detection Hydro test on a 30” Rubber Expansion Joint designed for 150 PSIG and 221 °F Cycle Test on a 12" dia. A240-321SS Bellows with 8 convolutions. The bellows has met the EMJA cycle life calculation of 1,000 cycles and failed in the root of the convolutions at 1,285 cycles. Burst Test on a 20" Bellows as per US Army specifications Copyright © 2003 U.S. Bellows, Inc. All Rights Reserved. 3 Products U.S. Bellows, Inc. has extensive experience in designing and manufacturing all types of Metallic and Fabric Expansion Joints. In addition, U.S. Bellows can repair/fabricate replacement and equivalent Expansion Joints manufactured by other suppliers. Thin Wall Metallic — Single Expansion Joint A Single Expansion Joint is a bellows element with end connections that allows movement in any direction or plane. However, the piping must be guided in the same direction of the movement. Single Expansion Joints are the least expensive type available. 30" dia. Expansion Joint, with 2-plies 321SS bellows, designed for 50 PSIG and 650 °F 24" dia. Single Expansion Joint, with 321SS bellows, liner and cover, designed for 50 PSIG and 651 °F Thin Wall Metallic — Toroidal Expansion Joint 92" I.D. Toroidal Bellows Expansion Joint designed for 400 PSIG and 500 °F Thin Wall Metallic — Universal Expansion Joint The universal expansion joint consists of two bellows separated by a pipe section or spool. This arrangement allows the unit to accept large amounts of lateral deflection. The amount of lateral deflection capability can be adjusted by changing the length of the center spool. 47" I.D. x 80" Universal Expansion Joint with SB-443 Round Corners Bellows 24” Tied Universal Expansion Joints designed for 170 PSIG and 450 °F for a chemical plant in Africa Copyright © 2003 U.S. Bellows, Inc. All Rights Reserved. 4 Products Thin Wall Metallic — Hinged Expansion Joint Hinged Expansion Joints contain hinges or pivots which allow the unit to bend in a single plane. These units are designed to restrict axial deflection, either in extension or compression. The hinge mechanism is typically designed to accept full pressure thrust. 24" dia. Single Hinged Expansion Joints designed for 170 PSIG and 580 °F for a water facility in Pennsylvania 36" Single Hinged Expansion Joint designed for 338 °F and 450 PSIG Thin Wall Metallic — Externally Pressurized Expansion Joint Externally Pressurized Expansion Joints contain a bellows and an outer-shell. In this design, the pressure is applied externally to the bellows. These expansion joints will require anchoring of the piping system. Externally Pressurized Expansion Joints for a steam plant in Kent, Ohio. The expansion joints, fabricated with 304 SS bellows and carbon steel shell and flanges, were designed for 150 PSIG and 350 °F for a maximum of 4” compression. Thin Wall Metallic — Clamshell Bellows 14” dia. Clamshell bellows designed for 150 PSIG and 150 °F Copyright © 2003 U.S. Bellows, Inc. All Rights Reserved. 5 Products Thin Wall Metallic — Gimbal Expansion Joint A Gimbal Expansion Joint can accept bending or angulation in two planes. It contains two sets of hinge pins or pivots with the axis of each set perpendicular to the other. Each set of pins is connected to each other with a central gimbal ring, similar to an automobile universal joint. 36" dia. Single Gimbal Expansion Joint, with testable Inco 625 bellows, SA516-70 gimbal rings, designed for 680 PSIG and 270 °F 24" dia. Double Gimbal Expansion Joint, with 321SS bellows, SA516-70 gimbal ring, designed for 130 PSIG and 300 °F 55” O.D. Double Gimbal Universal Expansion Joint for an FCC Unit. The expansion joint is equipped with floating rings and Inco 625 LCF bellows. It is designed for 50 PSIG and 1075 °F. Copyright © 2003 U.S. Bellows, Inc. All Rights Reserved. 6 Products Thin Wall Metallic — In-line Pressure Balanced Expansion Joint In-line Pressure Balanced Expansion Joints consist of three bellows - two In-line bellows on each side and one balancing bellows in the middle. They are typically used when axial & lateral deflections exist and anchoring is impractical for structural or economical reasons. An In-line Pressure Balanced Expansion Joint is a solution to difficult design problems. 24” In-line Pressure Balanced Expansion Joints designed for 175 PSIG and 610 ºF for a petrochemical plant in Venezuela. The bellows are composed of Inco 625 LCF material and the flanges and liners are constructed from SA516 Grade 70 material. Thin Wall Metallic — Elbow Pressure Balanced Expansion Joint The mechanism of the Elbow Pressure Balanced Expansion Joint is similar to that of the In-line pressure balanced expansion joint, except these joints are used in piping systems where there is a change of direction. They are generally used to handle a large amount of lateral movement and a moderate amount of axial movement. The pressure thrust is contained within the tie rods of these expansion joints. 72” Universal Pressure Balanced Expansion Joint designed for 30 PSIG/full vacuum and 200 °F Elbow Pressure-Balanced Expansion Joints designed for 150 PSIG and 450 ºF to allow lateral and axial movements in a 42" steam line Copyright © 2003 U.S. Bellows, Inc. All Rights Reserved. 7 Products Thin Wall Metallic — Refractory Lined Expansion Joint In Process: 56” O.D. Gimbal Hinged Refractory Lined Universal Expansion Joint for a CAT Cracker Application, designed for 57 PSIG and 1300 °F In Process: 55” O.D. Gimbal Hinged Refractory Lined Universal Expansion Joint for a FCC Unit, designed for 60 PSIG and 1020 °F 44" Universal Refractory Lined Expansion Joints designed for 30 PSIG and 1400 °F with Inco 625 LCF bellows and a 4" thk refractory lining per UOP specifications 70” Tied Universal Expansion Joint with a 4” thick Refractory Lining per UOP specifications, designed for 51 PSIG and 1460 °F 36" Double Hinged Expansion Joint, with 2-plies Inco 625 Bellows, 3/4" thk A479-304 Abrasion lining per UOP specifications, designed for 50 PSIG and 1000 °F Copyright © 2003 U.S. Bellows, Inc. All Rights Reserved. 8 Products Thick Wall Metallic Expansion Joint Thick Wall Expansion Joints are used primarily in heat exchangers and large diameter piping systems where Thin Wall Expansion Joints cannot be used. The bellows are typically fabricated from A516 Grade 70 material, with the thickness ranging from 3/16" to 1". Other materials are available to meet different temperature requirements. 44" thick wall SA516-70 flanged and flued Expansion Joints 108" dia. Thick Wall Expansion Joint, with 2 convolutions Rectangular Expansion Joint Rectangular metal expansion joints are used for a variety of applications in power, petrochemical, refining, chemical, and steel industries. Due to the wide range of pressure, temperature, and duct size requirements, each rectangular metal expansion joint is custom-engineered to provide an economical design that will not sacrifice the integrity of the entire system. 71"x143" Round Corner Rectangular Expansion Joint with A240-321 bellows for an oil refinery In India Camera Corner Rectangular bellows 28"x 66" Rectangular Expansion Joint with 321SS bellows and mitered corners for a chemical plant in South Carolina Copyright © 2003 U.S. Bellows, Inc. All Rights Reserved. 9 Products Slip Type Expansion Joint Slip Type Expansion Joints are used to accommodate large axial movement. They are available in various materials for different temperature and pressure requirements. Design details must include selection of packing and sealing materials, as well as the media that flows through the expansion joint. All applications require machine surfaces to minimize abrasive wear. Others may require "wiper" mechanisms to prevent potential clogging in between the two slipping pipes. 30" Slip Type Expansion Joint, designed for 150 PSIG and 412 °F for installation in the hydrocarbon flaring system of a refinery Hydro-testing being performed on a 6" Slip Type Expansion Joint Fabric Expansion Joint Fabric Expansion Joints are often used in ducts which carry hot gases at low pressure. The major design parameters are temperature, pressure and flow rates of the media going through the duct. Layers of different fabrics, insulation, and metal foils can be combined to accommodate different temperatures and pressures in the system. The fabric belt may require periodic replacement. 21’ x 14’ I.D., Fabric Expansion Joint for a power plant in Puerto Rico 48" dia. Fabric Expansion Joint with three layers Copyright © 2003 U.S. Bellows, Inc. All Rights Reserved. 10 Products Rubber Expansion Joint 30" dia. Rubber Expansion Joint, with EPDM reinforced tube and cover, telescoping linear A516-70 flanges, designed for 150 PSIG and 221 °F Stock Bellows U.S. Bellows has created a system of stock bellows for your quick-turn/emergency requirements. We have over 300 stock bellows on the shelf, ranging in size from 1" to 24" in diameter. Using our stock bellows, U.S. Bellows can quickly assemble and ship a variety of expansion joints. Copyright © 2003 U.S. Bellows, Inc. All Rights Reserved. 11 85 PSIG Single and Multi-ply Stainless Steel Expansion Joint Bellows Notes: 1. 2. 3. 4. 5. 6. 7. 8. 321 S.S. Bellows with Welding Aide Monel and Inconel available on request ND (in) 3/4 1 1 1/2 2 2 1/2 3 4 5 6 8 10 12 14 16 18 20 22 24 9. Max. Axial Movement (in) Max. Lateral Movement (in) Max. Angular Movement (deg) S007050C 0.59 0.47 L007050C 0.79 0.71 S010050C 0.59 L010050C Pressure Range: Vacuum to 50 PSIG for 3/4" to 1.1/2", 2", and over 85 PSIG Temperature Range: -20F to 800F Rated cycle life is 3000 cycles per EJMA for any one tabulated movement Maximum axial extension movement is 50% of the tabulated axial movement Rated extension movement is equal to rated axial movement provided the bellows is pre-compressed the amount of design extension Maximum test pressure: 1.5x design pressure Materials: Bellows: ASTM A240-T321SS Welding Aides: ASTM A240-T321SS Flanges or weld ends can be attached to the bellows 1/16" thk (min.) Welding aide. For more details request our Expansion Joint Catalog O.A.L. (in) Weight Each (lbs) Axial Spring Rate (lbs/in) Lateral Spring Rate (lbs/in) Angular Spring Rate (in/lbs/deg) 13 3.50 0.08 392 95 3 17 4.31 0.09 302 39 3 2.19 9 2.94 0.10 386 274 3 10 3.00 13 3.75 0.12 269 90 3 0.24 10 2.38 10 3.13 0.15 515 622 3 0.94 0.59 10 3.63 16 4.38 0.19 325 151 3 US-2-8-85S 0.64 0.24 10 3.00 8 5.00 0.50 191 230 3 US-2-12-85L 0.95 0.53 10 4.50 12 6.50 1.00 281 151 4 US-2.5-8-85S 1.33 0.39 10 3.00 8 5.00 1.00 113 215 3 US-2.5-12-85L 1.12 0.50 10 4.50 12 6.50 1.00 218 184 5 US-3-8-85S 0.71 0.17 10 3.00 8 5.00 1.00 403 1075 14 US-3-12-85L 1.07 0.40 10 4.50 12 6.50 1.00 269 319 9 US-4-8-85S 0.96 0.18 10 3.00 8 5.00 1.00 260 1138 15 US-4-12-85L 1.45 0.42 10 4.50 12 6.50 2.00 173 337 10 US-5-8-85S 0.95 0.15 10 3.00 8 5.00 1.00 325 2075 27 US-5-12-85L 1.42 0.34 10 4.50 12 6.50 2.00 217 615 18 US-6-8-85S 1.10 0.19 10 4.00 8 6.00 3.00 536 2735 64 US-6-12-85L 1.65 0.44 10 6.00 12 8.00 4.00 358 810 42 US-8-8-85S 1.07 0.15 10 4.00 8 6.00 3.00 707 5824 136 US-8-12-85L 1.61 0.34 10 6.00 12 8.00 5.00 471 1725 90 US-10-8-85S 1.99 0.45 10 8.00 8 10.00 6.00 548 1737 162 US-10-12-85L 2.38 0.82 10 12.00 12 14.00 10.00 729 1027 215 US-12-8-85S 2.09 0.40 10 8.00 8 10.00 9.00 711 3177 296 US-12-12-85L 3.14 0.91 10 12.00 12 14.00 13.00 474 941 197 US-14-8-85S 2.05 0.36 10 8.00 8 10.00 10.00 783 4163 388 US-14-12-85L 3.08 0.81 10 12.00 12 14.00 14.00 522 1234 258 US-16-8-85S 2.04 0.31 10 8.00 8 10.00 16.00 1034 7213 671 US-16-12-85L 3.06 0.71 10 12.00 12 14.00 22.00 689 2137 448 US-18-8-85S 2.03 0.28 10 8.00 8 10.00 18.00 1168 10146 944 US-18-12-85L 3.05 0.63 10 12.00 12 14.00 25.00 779 3006 630 US-20-8-85S 2.01 0.25 10 8.00 8 10.00 20.00 1302 13782 1283 US-20-12-85L 3.02 0.57 10 12.00 12 14.00 28.00 868 4084 855 US-22-8-85S 2.28 0.26 10 8.00 8 10.00 23.00 1067 13668 1272 US-22-12-85L 3.42 0.58 10 12.00 12 14.00 33.00 712 4050 848 US-24-8-85S 2.26 0.23 10 8.00 8 10.00 25.00 1167 17615 1640 US-24-12-85L 3.39 0.53 10 12.00 12 14.00 36.00 778 5219 1093 B.F.L. (in) Number Of Corrugation 10 2.75 10 3.56 0.27 10 0.87 0.59 S015050C 0.59 L015050C Part Number Phone: (713) 731-0030 Fax: (713) 731-8640 Toll Free: (800) 787-5914 Plant Address: 3701 Holmes Rd, Houston, TX 77051 Mailing Address:Copyright P.O. Box 34506, TX 77234-4506 © Houston, 2003 U.S. Bellows, Inc. All Rights Reserved. 12 150 PSIG Single and Multi-ply Stainless Steel Notes: 1. Pressure Range: Vacuum to 150 PSIG Expansion Joint Bellows 2. Temperature Range: -20F to 800F 3. 4. 5. 6. 7. 8. 9. 321 S.S. Bellows with Welding Aide Monel and Inconel available on request Max. Axial Movement (in) Max. Lateral Movement (in) Max. Angular Movement (deg) B.F.L. (in) S007150C 0.33 0.14 10 L007150C 0.47 0.25 10 S010150C 0.39 0.12 L010150C 0.53 1 1/2 S015150C Rated cycle life is 3000 cycles per EJMA for any one tabulated movement Maximum axial extension movement is 50% of the tabulated axial movement Rated extension movement is equal to rated axial movement provided the bellows is pre-compressed the amount of design extension Maximum test pressure: 1.5x design pressure Materials: Bellows: ASTM A240-T321SS Welding Aides: ASTM A240-T321SS Flanges or weld ends can be attached to the bellows 1/16" thk (min.) Welding aide. For more details request our Expansion Joint Catalog O.A.L. (in) Weight Each (lbs) Axial Spring Rate (lbs/in) Lateral Spring Rate (lbs/in) Angular Spring Rate (in/lbs/deg) 7 2.38 0.06 734 633 13 10 2.94 0.07 510 218 13 6 2.31 0.08 582 930 13 1.94 8 2.69 0.09 437 392 13 10 1.75 7 2.50 0.13 739 1815 13 0.19 10 2.38 10 3.13 0.15 515 622 13 0.34 0.12 10 3.00 8 5.00 0.50 1206 1451 19 0.51 0.28 10 4.50 12 6.50 1.00 804 430 13 0.69 0.20 10 3.00 8 5.00 1.00 327 620 8 US-2.5-12-150L 0.78 0.34 10 4.50 12 6.50 1.00 536 452 13 US-3-8-150S 0.66 0.16 10 3.00 8 5.00 1.00 403 1075 14 US-3-12-150L 0.82 0.31 10 4.50 12 6.50 1.00 411 472 14 US-4-8-150S 0.70 0.13 10 3.00 8 5.00 1.00 635 2780 36 US-4-12-150L 1.05 0.30 10 4.50 12 6.50 2.00 423 824 24 US-5-8-150S 0.69 0.11 10 3.00 8 5.00 2.00 794 5068 66 US-5-12-150L 1.03 0.25 10 4.50 12 6.50 3.00 529 1502 44 US-6-8-150S 0.83 0.15 10 4.00 8 6.00 3.00 1074 5477 127 US-6-12-150L 1.25 0.34 10 6.00 12 8.00 4.00 716 1623 85 US-8-8-150S 0.81 0.11 10 4.00 8 6.00 4.00 1415 11661 271 US-8-12-150L 1.22 0.26 10 6.00 12 8.00 6.00 943 3455 181 US-10-8-150S 1.48 0.33 10 8.00 8 10.00 9.00 1379 4463 415 US-10-12-150L 2.22 0.75 10 12.00 12 14.00 13.00 919 1322 277 US-12-8-150S 1.54 0.29 10 8.00 8 10.00 16.00 1832 8417 784 US-12-12-150L 2.31 0.66 10 12.00 12 14.00 23.00 1222 2494 522 14 US-14-8-150S 1.53 0.26 10 8.00 8 10.00 18.00 2020 11011 1025 US-14-12-150L 2.30 0.60 10 12.00 12 14.00 25.00 1347 3262 683 16 US-16-8-150S 1.52 0.23 10 8.00 8 10.00 20.00 2321 16184 1506 US-16-12-150L 2.28 0.52 10 12.00 12 14.00 29.00 1547 4795 1004 US-18-8-150S 1.50 0.20 9 8.00 8 10.00 23.00 2621 22765 2119 US-18-12-150L 2.26 0.47 10 12.00 12 14.00 32.00 1747 6745 1413 US-20-8-150S 1.49 0.18 8 8.00 8 10.00 26.00 2922 30924 2879 US-20-12-150L 2.24 0.42 10 12.00 12 14.00 36.00 1948 9163 1919 US-22-8-150S 1.49 0.17 8 8.00 8 10.00 28.00 3223 40831 3801 US-22-12-150L 2.23 0.38 10 12.00 12 14.00 39.00 2149 12098 2534 US-24-8-150S 1.47 0.11 5 8.00 8 10.00 31.00 3524 52653 4901 US-24-12-150L 2.21 0.26 8 12.00 12 14.00 43.00 2349 15601 3267 ND (in) 3/4 1 2 Number Of Corrugation 1.63 2.19 10 1.56 0.19 10 0.41 0.10 L015150C 0.59 US-2-8-150S US-2-12-150L Part Number 2 1/2 US-2.5-8-150S 3 4 5 6 8 10 12 18 20 22 24 Phone: (713) 731-0030 Fax: (713) 731-8640 Toll Free: (800) 787-5914 Plant Address: 3701 Holmes Rd, Houston, TX 77051 Mailing Address:Copyright P.O. Box 34506, TX 77234-4506 © Houston, 2003 U.S. Bellows, Inc. All Rights Reserved. 13 300 PSIG Single and Multi-ply Stainless Steel Notes: 1. Pressure Range: Vacuum to 300 PSIG Expansion Joint Bellows 2. Temperature Range: -20F to 800F 3. 4. 5. 6. 7. 8. 9. 321 S.S. Bellows with Welding Aide Monel and Inconel available on request Max. Axial Movement (in) Max. Lateral Movement (in) Max. Angular Movement (deg) B.F.L. (in) S007300C 0.23 0.10 10 L007300C 0.35 0.25 10 S010300C 0.29 0.12 L010300C 0.43 1 1/2 S015300C Rated cycle life is 3000 cycles per EJMA for any one tabulated movement Maximum axial extension movement is 50% of the tabulated axial movement Rated extension movement is equal to rated axial movement provided the bellows is pre-compressed the amount of design extension Maximum test pressure: 1.5x design pressure Materials: Bellows: ASTM A240-T321SS Welding Aides: ASTM A240-T321SS Flanges or weld ends can be attached to the bellows 1/16" thk (min.) Welding aide. For more details request our Expansion Joint Catalog O.A.L. (in) Weight Each (lbs) Axial Spring Rate (lbs/in) Lateral Spring Rate (lbs/in) Angular Spring Rate (in/lbs/deg) 7 2.38 0.07 1607 1394 13 11 3.13 0.09 1025 358 13 8 2.69 0.13 1387 1647 13 2.75 12 3.50 0.17 1226 487 13 10 2.38 10 3.13 0.22 2279 2733 13 0.29 10 4.06 15 4.81 0.29 1518 806 13 0.32 0.12 10 3.00 8 5.00 0.50 1206 1451 19 0.48 0.27 10 4.50 12 6.50 1.00 804 430 13 0.77 0.30 10 4.00 8 6.00 1.00 733 782 18 US-2.5-12-300L 0.89 0.52 10 6.00 12 8.00 2.00 1252 594 31 US-3-8-300S 0.57 0.19 10 4.00 8 6.00 2.00 2318 3477 81 US-3-12-300L 0.85 0.42 10 6.00 12 8.00 3.00 1545 1030 54 US-4-8-300S 0.77 0.20 10 4.00 8 6.00 3.00 1435 3534 82 US-4-12-300L 1.16 0.45 10 6.00 12 8.00 4.00 957 1047 55 US-5-8-300S 0.74 0.16 10 4.00 8 6.00 4.00 1795 6443 150 US-5-12-300L 1.11 0.36 10 6.00 12 8.00 5.00 1197 1909 100 US-6-8-300S 0.84 0.15 10 4.00 8 6.00 5.00 1576 7903 184 US-6-12-300L 1.26 0.34 10 6.00 12 8.00 6.00 1051 2342 123 US-8-8-300S 0.82 0.11 10 4.00 8 6.00 6.00 2075 16871 393 US-8-12-300L 1.23 0.26 10 6.00 12 8.00 8.00 1383 4999 262 US-10-8-300S 1.52 0.38 10 9.00 8 11.00 18.00 3102 7932 934 US-10-12-300L 2.28 0.87 10 13.50 12 15.50 26.00 2068 2350 623 12 US-12-8-300S 1.57 0.33 10 9.00 8 11.00 32.00 4141 15031 1771 US-12-12-300L 2.36 0.76 10 13.50 12 15.50 45.00 2761 4454 1181 14 US-14-8-300S 1.55 0.30 10 9.00 8 11.00 36.00 4566 19662 2316 US-14-12-300L 2.32 0.68 10 13.50 12 15.50 50.00 3044 5826 1544 US-16-8-300S 1.53 0.26 10 9.00 8 11.00 41.00 5245 28900 3405 US-16-12-300L 2.30 0.60 10 13.50 12 15.50 57.00 3496 8563 2270 US-18-8-300S 1.53 0.23 9 9.00 8 11.00 46.00 5924 40653 4789 US-18-12-300L 2.29 0.53 10 13.50 12 15.50 64.00 3949 12045 3193 US-20-8-300S 1.51 0.21 8 9.00 8 11.00 51.00 6604 55223 6506 US-20-12-300L 2.27 0.48 10 13.50 12 15.50 71.00 4403 16362 4337 US-22-8-300S 1.40 0.16 6 8.00 8 10.00 55.00 7284 92281 8590 US-22-12-300L 2.11 0.36 10 12.00 12 14.00 76.00 4856 27343 5727 US-24-8-300S 1.60 0.15 6.85 8.00 8 10.00 64.00 5835 88059 8197 US-24-12-300L 2.41 0.35 10 12.00 12 14.00 90.00 3890 26092 5465 ND (in) 3/4 1 2 Number Of Corrugation 1.63 2.38 10 1.94 0.27 10 0.35 0.13 L015300C 0.51 US-2-8-300S US-2-12-300L Part Number 2 1/2 US-2.5-8-300S 3 4 5 6 8 10 16 18 20 22 24 Phone: (713) 731-0030 Fax: (713) 731-8640 Toll Free: (800) 787-5914 Plant Address: 3701 Holmes Rd, Houston, TX 77051 Mailing Address:Copyright P.O. Box 34506, TX 77234-4506 © Houston, 2003 U.S. Bellows, Inc. All Rights Reserved. 14 Round Expansion Joint Specifications Customer: Date: Project: Prepared By: Page: Applicable Codes and Standards: Item or Tag Number: Quantity Size Style or Type End Connections Thickness / Flange Rating Material Design Pressure Operating Test Design Temperature Operating Installation Media Media Flow Velocity Flow Direction Axial Extension Axial Compression Installation Lateral Angular Movements Number of Cycles Axial Extension Axial Compression and Design Lateral Angular Number of Cycles Axial Extension Life Cycle Axial Compression Operating Lateral Angular Number of Cycles Bellows Materials Liner Cover Overall Length Dimensions Maximum O.D. Minimum I.D. Maximum Axial Spring Rate Spring Rates Maximum Lateral Spring Rate Maximum Angular Spring Rate Bellows Long.Seam Weld Quality Assurance Bellows Attachment Weld Piping U-2 Forms Phone: (713) 731-0030 Fax: (713) 731-8640 Toll Free: (800) 787-5914 Plant Address: 3701 Holmes Rd, Houston, TX 77051 Mailing Address:Copyright P.O. Box 34506, TX 77234-4506 © Houston, 2003 U.S. Bellows, Inc. All Rights Reserved. 15 Rectangular Expansion Joint Specifications Customer: Date: Project: Prepared By: Page: Applicable Codes and Standards: Item or Tag Number: Quantity Size (specify inside or outside duct dimensions) Orientation (horizontal / vertical / inclined) Style or Type Corner Type End Connections Pressure (in. water) Thickness/Angle Flange Size Material Design Operating Design Temperature Operating Installation Media Flow Velocity Media Flow Direction Axial Extension Axial Compression Movements Lateral (parallel to short side) Lateral (parallel to long side) Angular (parallel to short side) Angular (parallel to long side) Bellows Materials Liner Cover Dimensions Overall Length Axial Lateral (parallel to short side) Maximum Spring Rates Lateral (parallel to long side) Angular (parallel to short side) Angular (parallel to long side) Quality Assurance Bellows Corner Welds Bellows Attachment Weld Phone: (713) 731-0030 Fax: (713) 731-8640 Toll Free: (800) 787-5914 Plant Address: 3701 Holmes Rd, Houston, TX 77051 Mailing Address:Copyright P.O. Box 34506, TX 77234-4506 © Houston, 2003 U.S. Bellows, Inc. All Rights Reserved. 16 Services On-Site Field Services U.S. Bellows, Inc. has extensive experience providing on-site services for Expansion Joints which include the following: Installation guidance Field survey and inspection Problem resolution and repair Replacement Expansion Joints for any quick-turn or emergency situation We provide you with the most comprehensive program available. U.S. Bellows is available on a 24x7 basis to fulfill any emergency/quick-turn requirement that might arise. With a system of stock bellows, U.S. Bellows can quickly assemble and ship products for any quick-turn/emergency situation. Friday, 5:30pm Emergency call from a customer regarding a deformed 48” expansion joint 42" x 26" Fabric Expansion Joint, with telescoping liners, and a 2" thk insulation pillow Sunday The 48" dia. Expansion joint is installed at customer’s location in Alaska Saturday The 48" dia. Expansion Joint is manufactured and ready for shipment For the quickest response, please complete the Emergency Service Request Form at www.usbellows.com/emergency. U.S. Bellows On-call Engineering Team GUARANTEES a 30-minute response time to your request. Copyright © 2003 U.S. Bellows, Inc. All Rights Reserved. 17 Services Customer Desktop U.S. Bellows utilizes the latest web/internet technology to serve its customers at any time, anywhere: Online Order Status Expansion Joint Online Store Online Quotation Requests Online Catalogs Online Discussion Forum Visit us at www.usbellows.com 32” Tied Universal Expansion Joints designed for 150 PSIG and 380 °F for an oil refinery in China Rectangular Fabric Expansion Joints designed for a furnace application at a chemical plant in Texas Dye penetrant test on the bellow’s attachment weld of a 40” I.D. Single Coded Clamshell Expansion Joint Pneumatic and Vacuum test between piles at 15 PSIG/14 PSIG for a 56” O.D. Gimbal Hinged Refractory Lined Universal Expansion Joint Copyright © 2003 U.S. Bellows, Inc. All Rights Reserved. 18