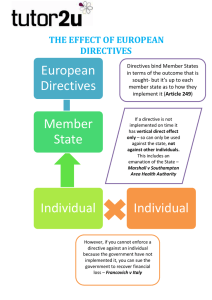

Understanding the Machinery Directive

advertisement