15 Appendix 15 – Notes on periodic inspecting and testing

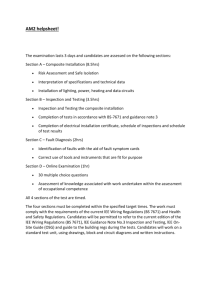

advertisement

Guide to the Wiring Regulations 15 15.1 Appendix 15 – Notes on periodic inspecting and testing Introduction scope and statutory requirements After an electrical installation is constructed, commissioned and put into service it must be maintained to keep it in a safe condition. The statutory requirements for health and safety at work are covered by the Health and Safety at Work etc. Act 1974, and through this act the Electricity at Work Regulations 1989 (EWR) provides the basic statutory framework for electrical safety in the workplace (but they do not apply to domestic installations). The EWR are not voltage dependant and cover all electrical systems from battery operated torches to the national grid. There are some terms that are central to the understanding of these requirements, and for ease of reference they are listed below. Most are from the EWR, but some are supplemented by Part 2 of BS 7671: 2008 and are as follows: Duty holder A person on whom statutory or other duties are imposed by statutory regulations or other (usually contractual) requirements. (The duty holder may or may not be a ‘competent person’). Competent person A person who possesses sufficient technical knowledge and experience for the nature of the electrical work undertaken, and is able at all times to prevent danger, and where appropriate injury, to themselves and others. Danger Risk of injury. Injury Death or personal injury from electrical shock, electric burn, electrical explosion or arcing, or from fire or explosion initiated by electrical energy, where any such death or injury is associated with the generation, provision, transmission, transformation, rectification, conversion, conduction, distribution, control, storage, measurement or use of electrical energy. System An electrical system in which all the electrical equipment is, or may be, electrically connected to a common source of electrical energy, and includes such source and such equipment. (It includes all the electrical installations, switchgear, luminaires, equipment, accessories, fittings, appliances and controls etc.). 15 34 Appendices Electrical equipment Any item for such purposes as generation, conversion, transmission, distribution or utilisation of electrical energy, such as machines, transformers, apparatus, measuring instruments, protective devices, wiring systems, accessories, appliances and luminaires. Regulation 4(2) of the Electricity at Work Regulations requires: ‘As may be necessary to prevent danger, all systems shall be maintained so as to prevent, so far as is reasonably practicable, such danger.’ Someone must be responsible for an electrical installation. For a domestic installation, this is the householder and for an electrical installation at a place of work, the responsible person is usually a nominated person (the duty holder). Often no one is specifically nominated, but someone must have control (e.g. the office manager or other manager who gets an electrical contractor in to do some work) and this person or these persons will assume the position, usually by default, and the law will presume that they are duty holders. It is for the installation duty holder to decide, by a risk assessment, as to what danger can arise and what maintenance is required to prevent danger. The statutory obligation to maintain at work arises only if danger would otherwise result, although there is the practical reason to maintain to keep a building in good condition. The quantity and frequency of statutory maintenance should be sufficient to prevent danger so far as is reasonably practicable. There is no statutory duty to maintain in a domestic environment, but insurers may not pay claims if they can show that an installation was not safe. 15.2 BS 7671: 2008 requirements On the electrical installation certificate of a new installation advice is given for the time period at which the installation should have its first periodic inspection and test. This is based on the considered advice from a number of parties, as identified in Chapter 34 of BS 7671: 2008 which states: • •• • An assessment is to be made of the frequency and quality of maintenance of the reasonable expectation of the installation The responsible person shall be consulted Periodic inspection and testing as well as maintenance and repairs shall be considered The assessment shall consider the effectiveness of the protective measures 35 15 Guide to the Wiring Regulations 15.3 Information and records Before any periodic inspection and testing work can be undertaken (or even priced), the scope of the installation and the required work must be identified. There should be several existing sources of information about the electrical installation, but if necessary the inspector must survey the building and identify the installation arrangement and circuits before any meaningful inspection and testing work can be undertaken. 15.3.1 Operation and maintenance documents When commissioned and set to work operation and maintenance documentation, including record drawings and an electrical installation certificate is issued for a new installation. BS 7671: 2008 lists the information that should be available in section 514 and these amount to circuit diagrams. For most commercial installations a single line diagram is usually essential. Statutory legislation including the Construction Design and Management Regulations 1994 (revised 2007) and the Building Regulations (England and Wales) require adequate health and safety, operation and maintenance, and record drawings documents be provided by the installer. In essence the information that should be available should allow the safe and proper operation and maintenance of the building and its services. These health and safety requirements do not apply to domestic installations, which are usually a lot simpler, but the Building Regulations and NHBC guidance still require adequate records, and the requirements of section 514 of BS 7671: 2008 still apply. The new Home Information Packs may also contain a Home Condition Report as an optional document, which will give details about the physical condition of a dwelling. At the time or writing, it was not clear if this report would contain electrical information, but if it does sellers, buyers and lenders will be able to rely on it as an accurate document. An electrical installation certificate must accompany each new work in a commercial building and if it is ‘notifiable’ (see 15.3.2 below), the required CDM Health & Safety file, as well as general Operation & Maintenance and record information. The CDM H&S file must be retained by the building owner, for the life of the building, and thus this provides a valuable source of information for building modifications and inspections. Unfortunately, this information is not always available when required! 15 36 Appendices 15.3.2 Health and safety files The CDM Health and Safety Files are the means by which health and safety information is recorded and kept for future use at the end of a construction project. The Construction (Design & Management) Regulations 1994 and 2007 require that the file includes adequate information about any aspect of the structure or materials used which might affect the health or safety of anyone carrying out construction, maintenance, cleaning or demolition work or of anyone who may be affected by such work. The file will contain information necessary for future construction, maintenance, refurbishment or demolition to be carried out safely, and is retained by the client or any future owner of the property. (Where a client gets non-notifiable work done, and a health and safety file already exists for the premises, it should be updated if necessary). The file should be a useful and valuable document for the client and any persons with a professional interest in the building, and since 1994 should provide the required information on the building. Work undertaken by a local authority or a domestic householder is exempt from the CDM Regulations. For any notifiable project under the CDM Regulations (defined as projects where the production stage on site will exceed 30 days or 500 person days) a health and safety file must be prepared at the completion of the works and retained by the owner of the works. When the project is finished and the health and safety file has been handed over by the planning supervisor, the client should keep it available for those who need to use it. Usually this will include maintenance contractors, the planning supervisor and contractors preparing or carrying out future construction work. Its purpose is to provide the end user with information about the risks that have to be managed during maintenance, repair, renovation or demolition. This file must be made available to anyone doing any future work on the structure. Guidance to the regulations recommends that the file include: • •• •• ‘record’ or ‘as built’ drawings and plans used and produced throughout the construction process; the design criteria; general details of the construction methods and materials used; details of the equipment and maintenance facilities within the structure; maintenance procedures and requirements for the structure; 37 15 Guide to the Wiring Regulations • • manuals produced by specialist contractors and suppliers which outline operating and maintenance procedures and schedules for plant and equipment installed as part of the structure; details of the location and nature of utilities and services, including emergency and fire-fighting systems. Ideally, the health and safety file should be kept available for inspection on the premises to which it relates. It may be useful to store the health and safety file so that it is in two parts. One part will be more relevant for day-to-day use, e.g. operational and maintenance manuals. The other part will be for longer-term use, e.g. drawings that will only be required when major alteration work is carried out. The health and safety file could be stored electronically but it should be easily accessible in whatever form it is stored, and for a big project the documentation could run to many volumes but the system must be searchable. Over the course of time an installation will be modified, extended or perhaps parts replaced due to changes in use of parts of the building. O&M documentation and drawings must be kept up to date or supplemented as the building changes over time, or it will be useless. 15.4 Competence of personnel The individual(s) carrying out the electrical inspection and testing must be competent and experienced in electrical installation work, and especially in the type of installation being inspected and tested. The subject of competence is complicated but it is important to realise that periodic inspecting and testing is an area often underestimated in terms of an individual’s competence. Although outside the scope of this book, the subject of quoting for and the forming of a contract for an inspection and test can be quite involved. For simple installations, a City and Guilds 2392 qualification is usually accepted as the required technical standard for electrical operatives carrying out inspection and testing work to the requirements of BS 7671: 2008. Often for larger commercial installations, electrical technicians or electrical engineers should be employed. It should perhaps be remembered that the competence should be at a level where the quantity of tests and samples as in Tables 15.2 and 15.3 to be applied can be routinely considered by the individual. 15 38 Appendices 15.5 Basic principles of periodic inspecting and testing The following principles should be noted relevant to a BS 7671 periodic inspecting and test: •• • The periodic inspection and test forms a condition report for the installation The periodic inspection and test is not intended to cover 100% (indeed this would almost always be impractical if not impossible). Thus sampling will be required the nature of which will need to be set by the person carrying out the periodic inspection and test. The inspection and test method should follow the principles highlighted in the latest Edition of BS 7671. However, many installations will not have been installed to this latest standard. This will generally not be a problem as it was safe at the time of installation. Comments or recommendations on any ‘upgrades’ can be provided but these comments should be separated from any issues that make the installation unsafe (often, this will not be due to an issue with a previous Edition of BS 7671). This is an example where the experience of the individual(s) is important. Generally, inspection and testing is carried out as a prerequisite to any maintenance to establish the condition of electrical systems. There is no specific required frequency for periodic inspection and testing, and it depends solely on the age, use and condition of the system, and to assess its suitability for continued use. Guidance on inspection periods is given in Table 15.1 but it must be understood that the periods proposed are suggested maximum periods, and each installation will be different and must be considered individually on its merits. Table 15.1 Recommended Initial Inspection Frequencies of Electrical Installation Type of installation Maximum period between inspections and testing as necessary Domestic Change of occupancy/10 years All Commercial i.e. shops offices, hospitals and labs, etc. Change of occupancy/5 years Industrial 3 years Places subject to entertainment licence 1 year 1,2 Public swimming pools, caravan parks 1 year 1,2 Notes: 1 2 Reference (see notes below) 1 See also Electricity at work Regulations 1989 This is normally a requirement of local licensing organisations 39 15 Guide to the Wiring Regulations If the duty holder is continuously aware of the condition of the system there is no need for any formal inspection and testing regime. The frequency of periodic inspection and testing of an installation must be determined having regard to the type of system, its use and operation, the frequency and quality of maintenance and the external influences to which it is subjected. Not all parts of the system may require the same frequency of inspection and testing. BS 7671: 2008 Chapter 62 gives guidance on the requirements for periodic inspection and testing of fixed electrical installations. It advises that periodic inspection testing of an electrical installation should be carried out to determine, so far as is reasonably practicable, whether the installation is in a satisfactory condition for continued service. The statement so far as is reasonably practicable must be clarified, and attempts to bring a balance against the time, trouble, cost and physical difficulty of doing something and the risk to safety of not doing it. If these resources are so disproportionate to the risk that it would be unreasonable to expect any employer to have to incur them to prevent it, the employer is not obliged to do so unless there is a specific requirement that he does. Some EWR requirements are ‘absolute’ and must be complied with regardless of cost (e.g. providing an earth connection), but some can be compared to cost and maintenance is an example of where costs must be considered. A duty holder should identify all the circumstances in which persons could be at risk whilst at work, and all the circumstances in which anyone else could be at risk as a result of anything done in his work, and determine the level of resource that is needed to manage each risk effectively taking account of the level of risk. Only by directing and applying a level and effectiveness of resource that is commensurate with the risk can the employer perform his general duties so far as is reasonably practicable. The greater the risk, the more likely it is that it is reasonable to go to very substantial expense, trouble and invention to reduce it. But if the consequences and extent of a risk are small, insistence on great expense would not be considered reasonable. It is important to remember that the judgment is an objective one and the size or financial positions of the employer are immaterial. Inspection of an installation and electrical equipment comprising careful scrutiny should be carried out with dismantling as required, together with appropriate tests as discussed in the other sections. It must be realised however that to disassemble or disconnect something already in service for 15 40 Appendices physical inspection or testing always carries with it the risk of introducing new faults to the equipment during this work. The scope of the periodic inspection and test, should be set by a competent person. This is usually the duty holder, although he can ‘sub-contract’ this duty. The scope should take into account availability of records and the use, condition and nature of the installation. This inspection and testing should provide, so far as is reasonably practicable, for: • • • • 15.6 the safety of persons and livestock against the effects of electric shock and burns protecting against damage to property by fire and heat arising from an installation defect, and confirming that the installation is not damaged or deteriorated so as to impair safety, and the identification of installation defects and non-compliance with the requirements of the Regulation which may give rise to danger. Establishing sample and scope of inspection and test Sampling of both the visual inspecting and testing facets of the inspection and test is key and this is where experience counts. Inspection and testing is a complex process and time consuming and costly to do fully, and some proposals are always made to reduce the work, but one must ensure that in consequence the installation safety is not reduced. The person inspecting and testing the installation will provide a report on the condition of the installation and its safety and suitability for continued use. The installation owner and users are usually not technical, and will rely on the conclusions of the report so it is vital that the inspection and testing is properly carried out. Samples should be selected to be representative of installation and will thus be dependent upon records. The sample size may need regular adjustment throughout the process. The samples must be representative and chosen by experience, judging each installation on its merits. It can be argued that large well maintained buildings (e.g. offices etc.) would have the scope for reduced sample sizes over other less wellmaintained buildings. Samples tables are provided for in this appendix for visual inspections as well as physical tests but the following summary applies: 41 15 Guide to the Wiring Regulations • •• Sampling criteria depends on size, age, complexity, condition of records and frequency of routine maintenance. Small domestic installations will tend to a fuller sampling approach Large installations will have to implement a low sample approach Generally, samples of less than 10% are not recommended. For very large installations where it is established that the installation is consistent by say, inspection of records or similar, the sample size may be reduced below 10%. 15.7 The visual inspection Often, the value of the visual inspection facet of the inspection and test is undervalued but it usually depicts a much better indication about the condition of an installation than the testing facet. As discussed previously, the inspector must be very experienced in working on the type of installation being inspected. Precautions must be taken to ensure that inspection and testing does not cause danger to persons or livestock and does not cause damage to property and system even if the circuit or equipment is defective. During the inspection any damage, deterioration, defects, dangerous conditions which may give rise to danger, and any non-compliance with the requirements of the current edition of the IEE Regulations, together with any limitations of the inspection shall be recorded. The inspector must utilise all of the senses (sight, touch, smell etc.) to form a judgment of the condition of various parts of the installation, and must make an opinion of the condition, use and suitability for future safe use of the installation including: •• •• •• •• • Safety Wear and tear Corrosion Damage Excessive loading (overloading) Age of equipment External influences Suitability Heat, temperature and burning The sampling provided in Table 15.2 is recommended but needs to be set by a competent person 15 42 Appendices Table 15.2 Range samples for visual inspection Visual inpection Suggested minimum sample (see note 1) Check for single line diagram 100%, i.e. it/they must be present Signs of overheating, aging, check tightness. Main switchgear outside inspection 100% Signs of overheating, aging, check tightness. Internal sections and cable terminations 100% Signs of overheating, aging, check tightness. Internal inspection of circuit breaker connections and control sections (large switchgear) 100% small installations 10% large installations Signs of overheating, aging, check tightness. Sub-main swtichgear Ideally 100% of connections reducing to 10% of connections. This may need reducing for very large installations. Signs of overheating, aging, check tightness. Final circuit distribution boards Ideally 100% of connections reducing to 10% of connections. This may need reducing for very large installations. Signs of overheating, aging, check tightness. Final circuits joints in cables Sample circuits of 10% Signs of overheating, aging, check tightness. Final circuits accessories Samples on above Damage, signs of overheating Main equipotential bonding 100% Presence Typical checks Note 1. Although generally samples of 10% are not recommended, for very large installations where it is established that the installation is consistent by say inspection of records, the sample size may be reduced. Overheating is a common problem, whether caused by overloading, poor ventilation or whatever, and an inspection must pay particular attention to signs of overheating and identify their possible causes. Many installations are now surveyed with infrared thermographic cameras, which can provide a useful non invasive aid to inspection, especially in installations that cannot be easily switched off (e.g. computer facilities), but care must be taken to understand the results obtained. Not all electrical equipment is thermally ‘transparent’, and if thermographic pictures are used over time to look at possible changes in an installation one must ensure that pictures are taken with the same loads, environment and circumstances. 43 15 Guide to the Wiring Regulations Depending on the type of building, especially if it has areas in it accessible to the general public (school, hospital etc.), it may be necessary (or at least wise) to carry out regular inspections of the accessible electrical equipment and accessories outside the formal periodic inspection and testing programme. 15.8 The testing Testing should be considered to supplement the visual inspection part of the periodic inspection and test process. This section provides an overview of samples and general notes on testing. The test methods detailed in Chapter F of the book can all generally be used with necessary modifications. This section provides an overview of samples and general notes on testing. 15.8.1 Sample sizes Testing in a periodic inspection and test programme is different from that at the commissioning of a new installation as one may well be working in an occupied building and it may not be possible to isolate all the electrical systems, or carry out all the tests (e.g. there may be local flammable products stored that cannot be moved). Any limitations on the testing must be clearly identified in the report. Although generally samples of 10% are not recommended, for very large installations where it is established that the installation is consistent by say, inspection of records or from the visual inspection, the sample size may be reduced. 15.8.2 Preparation Precautions must be taken to ensure that inspection and testing does not cause danger to persons or livestock and does not cause damage to property and system even if the circuit or equipment is defective. Safety is particularly important – especially safety of the public in an occupied building. Switchrooms, risers, distribution boards etc. are normally kept locked, and when work access is required safety barriers and warning signs must be put up at the workplace to keep people away from electrical equipment. 15 44 Appendices Table 15.3 Testing to be carried out where practicable on existing installations Test (note 1) Recommendations Earth fault loop impedance At the following positions: • Origin of the installation • Distribution boards (may be sampled see note 2) • Accessible socket-outlets and extremity of radial circuits (may be sampled see note 1) Protective conductors continuity • Bonding conductors continuity • Main bonding conductors • All necessary supplementary bonding conductors (may be sampled see note 2) Insulation resistance If tests are to be made: • Between live conductors and Earth at all final distribution boards (may be sampled see note 2) Earth electrode resistance Test each earth rod or group of rods separately, with the test links removed, and with the installation isolated from the supply source Functional tests RCDs Circuit-breakers, isolators and switching devices Tests as required by Regulation 713–13–01, followed by operation of the functional test button (may be sampled see note 2) Manual operation to prove that the devices disconnect the supply (may be sampled see note 2) Polarity (note 4) At the following positions: • Origin of the installation • Distribution boards • Accessible socket-outlets • Extremity of radial circuits Ring circuit continuity (note 4) Where there are proper records of previous tests, this test may not be necessary. This test should be carried out where inspection/documentation indicate that there may have been changes made to the ring final circuit (may be sampled see note 2) Accessible exposed-conductive-parts of current-using equipment and accessories (requires sampling see notes 2 & 3) Notes: 1 The person carrying out the testing is required to decide which of the above tests are appropriate by using their experience and knowledge of the installation being inspected and tested and by consulting any available records. 2 Where sampling is applied, the percentage used is at the discretion of the tester, see section 15.6. Generally samples of less than 10% are not recommended. For very large installations where it is established that the installation is consistent by say, inspection of records or from the visual inspection, the sample size may be reduced below 10%. 3 The earth fault loop impedance test may be used to confirm the continuity of protective conductors. 4 These tests will often not be required if appropriate records for the existing installation are confirmed. Generally, live working is not safe and is not allowed unless it can be justified by unusual circumstances (see the EAWR). Some testing must be done live, (e.g. earth loop impedance) but that does not mean the tester or occupiers should be exposed to any risk, and work must be properly planned to ensure that equipment can be isolated so that there is no access to live parts. 45 15 Guide to the Wiring Regulations 15.8.3 Tests The test methods detailed in Chapter F of this book can all be generally applied to a periodic test. The individual performing the tests must be aware of the results expected to be obtained and able to interpret them and decide on their adequacy. Knowledge and experience is required in applying the tests and interpreting the results. Insulation resistance in an old installation is unlikely to equal the high values of a new installation, but it must still be adequate. It is not practice to carry out this test between live and testing between neutral and earth is nearly always impractical. With some electronic equipment in circuits it may not be possible to carry out a full insulation resistance test as the equipment may be damaged and tests will often need to be carried out at 250 V and noted on the test paperwork. If the duty holder is continuously aware of the condition of the system there is perhaps no need for any formal periodic inspection and testing regime. In the case of a system under effective supervision in normal use, BS 7671: 2008 allows that periodic inspection and testing may be replaced by an adequate regime of continuous monitoring and maintenance of the installation by competent skilled persons. Full records must be kept for the installation and all works to show that appropriate maintenance management procedures have been followed at all times. There is however no specific guidance as to what this requires, but the duty holder must be able to show that the installation complies at all times with the requirements of the EAWR. Some installations cannot easily be switched off, and so inspection and testing can be rather limited, and ways have been proposed to continuously monitor such installations to identify possible faults before they interfere with the operation of the installation. Infra-red thermography has already been mentioned, and it can prove very useful so long as the installation is designed to accommodate it (thermally transparent switchgear etc.), and the information gathered is properly understood. Another method gaining popularity is to continuously measure earth leakage current. This is generally very small but relatively stable, and it can be monitored at several points in an installation and any changes may signify impending equipment breakdown that can be attended to before it happens. 15 46 Appendices 15.9 Electrical equipment As discussed at the beginning of this appendix, electrical equipment is defined as any item for the generation, conversion, transmission, distribution or utilisation of electrical energy, and as such covers fixed wiring as well as appliances. The EWR cover safety requirements for all electrical systems and equipment used at work, regardless of voltage levels, and it must be understood that the requirements for periodic inspection and testing apply to the fixed installation only. The installation duty holder should be notified of the fact that the ‘clients’ equipment, for example portable and transportable equipment, is not included in a BS 7671 periodic report. This is quite clear for equipment supplied via a plug and socket outlet. However, for other equipment such items as luminaires, chillers, electric motors and boilers etc., the subject is not so clear. Whilst these all fall within the EAW requirements they do present a problem. It is recommended to visually inspect such equipment in the course of the periodic inspection and test process and to highlight any equipment that requires a fuller inspection. In similar fashion, sampling will need to be applied to this process. The IET Code of Practice for the In-service Inspection and Testing of Electrical Equipment gives guidance on the inspection and testing of electrical equipment. 15.10 Reports Following a periodic inspection and testing a Periodic Inspection Report, together with a schedule of inspections and a schedule of test result is to be produced by the person or company carrying out the inspection and testing works. A copy of the ECA Periodic Inspection Report, taken from BS 7671: 2008 is provided in Appendix 17. BS 7671: 2008 suggests that the report is to be ‘given to the person ordering the inspection’. This is rather literal, and realistically the report and schedules must be received by someone in authority (e.g. the duty holder) who is able to do something about any dangers or safety problems identified in the report. The schedules of inspection results and test results will record the result of the appropriate inspections and test carried out. Copies of reports and schedules and records of maintenance works including test results should preferably be kept throughout the working life of an electrical system, and this will enable the condition of the equipment and the effectiveness of maintenance policies to be monitored. Without effective monitoring duty holders cannot be certain that the requirement for maintenance has been complied with. 47 15 Guide to the Wiring Regulations There is a section on the report ‘extent and limitations’ which identifies and describes the parts or areas of an installation covered by a report, and any limitations on the work carried out, e.g. lack of access to certain parts or unable to isolate some equipment for testing. The periodic report is to be completed by an experienced and competent person who was involved in the inspection and testing work, and in the report there is a space to indicate when it is advised that the next periodic inspection and test should be undertaken. This gives a continuity of advice from the guidance on the initial electrical installation certificate as to when inspection and testing of an installation should be undertaken. The most important part of the report is the observations and recommendations section, which identifies any dangers and remedial work required. The requirements are given a coding or categorisation from 1 to 4: •• •• Code 1 – Requires urgent attention Code 2 – Requires improvement Code 3 – Requires further investigation Code 4 – Does not comply with BS 7671: 2008 Only one code should be given to each observation. If more than one code could be applied, only the most serious recommendation should be given. Where an immediate danger is observed Code 1 must be used. Where one or more observations are given a Code 1 recommendation the overall assessment of the installation must be stated to be unsatisfactory. Code 3 indicates that the inspector was unable to reach a conclusion about a certain aspect of the installation, or that the observation was outside the agreed extent or limitations of the inspection, but has come to the inspector’s attention during the inspection and testing. Code 4 indicates items that have been identified as not complying with the requirements of BS 7671: 2008, but that the item is not of any danger. It is entirely a matter for the competent operative doing the inspection and testing to decide on the recommendation code to be given to any fault or observation. The operative’s own judgment as a competent person should not be influenced by his employer or the client or their requirements. The persons signing the report are responsible for its content. 15 48 Appendices 15.11 Repairs and maintenance Installations and equipment must be maintained for safety, long life and efficient performance, and regular inspection and testing and condition monitoring is a necessary part of such maintenance. BS 7671: 2008 is not really concerned with maintenance or energy efficient operation, but such things are now a part of everyday life. As noted above a periodic inspection and test may identify dangers and faults in an electrical installation and these must be repaired in a reasonable time. Any Code 1 items should be seen to immediately they are found, to minimise possible dangers, and if not it can be argued that an inspector could immediately disconnect the supply to that item due to the possible danger. The presence of any Code 2 items is also unacceptable and these should be attended to as soon as realistically possible. Code 3 items may require further work by the inspector and a way forward should be agreed. Code 4 items may not need any action as long as persons are aware of them, but they could be attended to when any new work is being carried out. Generally upon receipt of a report it is advisable to set a programme to ensure that all the Code 1, 2 and 3 items are resolved in an acceptable period, and to have the inspector return to check that they have been completed satisfactorily. Maintenance policies and provisions vary widely depending on the equipment or system, and outcomes required, and such details cannot be discussed here, but must be fully understood by the operational staff. 49 15