Szczecin, Poland

advertisement

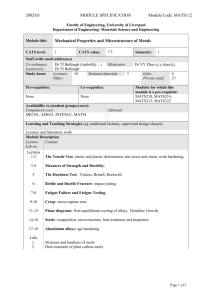

Szczecin, Poland APPLYING MICROHARDNESS TO MICROSTRUCTURE ANALYSIS Małgorzata Garbiak West Pomeranian University of Technology in Szczecin Institute of Materials Science and Engineering malgorzata.garbiak@zut.edu.pl LMV’09 - Telć 11-13.11.2009 Presentation plan ¾ Hardness „finger prints” ¾ Indentation load ¾ Material tested – characteristics ¾ Measurements ¾ Analysis of results ¾ Histogram or direct aiming measurements ¾ Conclusions M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Hardness „finger prints” Hardness density distribution for a single phase material M.Garbiak „Applying microhardness to microstructure analysis” Hardness density distribution for a two-phase material. LMV’09 - Telć Hardness density distribution analysis Cast alloy #4 Pk=Gauss Amp 6 Peaks Phase A r 2 =0.999834 0.005 μ− structure A 2 0.0045 Hardness density distribution SE=1.52802e-05 F=169492 0.004 274.6 μ− structure A 1 0.0035 0.003 μ− structure A 3 0.0025 0.002 0.0015 Phase B or μ− structure B 374 0.001 0.0005 160.1 694.9 Phase C or μ− structure C 500 μ− structure D 944.2 1330 0 0 Phase D or 1000 1500 Hardness [HV] Christodoulou P., Garbiak M., Piekarski B.: Mat.Sc.Eng. A, 457(2007)350–367 M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Average hardness and volume fraction of the matrix and precipitates 1 2 3 4 5 9 7 8 9 As Cast MVf MH [HV] MH [HV] [%_weight] Weighed_Avg Avg 86,3 289,5 238,9 97,7 284,4 231,1 97,1 232,9 243,1 90,3 304,3 269,5 97,0 298,9 279,8 77,9 297,0 203,6 90,7 253,9 239,1 96,0 340,3 263,3 88,6 273,4 228,6 MVf MH PVf - Heat Treated [%_weight MVf MH [HV] MH [HV] ] [%_weight] Weighed_Avg Avg 13,7 90,7 289,2 258,8 2,3 93,3 252,3 225,3 2,9 92,8 248,9 187,8 9,7 70,8 340,6 299,1 3,0 99,0 233,7 231,5 22,1 71,4 350,6 228,8 9,3 88,3 337,1 310,2 4,0 94,1 311,5 302,5 11,4 94,5 312,1 257,1 PVf [%_weight] 9,3 6,7 7,2 29,2 1,0 28,6 11,7 5,9 5,5 Matrix total volume fraction Matrix hardness Precipitates total volume fraction M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Alloy 3 - load 10G 8.9 μm 10 μm Indentation load Alloy 2 - load 5G 5.5 μm Alloy 2 - load 10G 7.9 μm 10 μm 10 μm M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Indentation load The smaller the indentation load the more measured values of hardness of single phase components M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Material tested Austenitic Cast Steel – 0.3%C-18%Cr-30%Ni Alloy no 1 2 3 4 5 6 7 8 9 Ti 0.83 1.00 0.05 0.70 0.03 1.07 0.53 0.30 0.68 Nb 1.75 0.03 1.84 3.00 0.03 1.59 2.80 0.55 2.06 Si 1.69 1.82 1.82 4.00 1.69 4.26 3.54 1.57 1.76 23 41 Stop Alloy 51 23 Ti Ti 1 mm mm DAS, mm Nb Nb 35 25 15 0.06 1.03 1.87 2.58 (Nb + Ti), wt% M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Microstructure Heat treated 6 As-cast 2 900oC 300 h 3 900oC 300 h 10 μm 8 M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Matrix M23C6 10 μm precipitates dislocations M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Primary and eutectic precipitates MC Ni16(Ti,Nb)6Si7 + M23C6 Alloy 2 M23C6 G TiC G M23C6 1 μm M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Microhardness of phase constituents HV0.05 TiC 3000 (Nb,Ti)C 2800 2500 G 2000 M23C6 1500 1000 matrix 1400 1100 770 500 345 0 Average value of 10 measurements Alloy 6 M.Garbiak „Applying microhardness to microstructure analysis” 10 μm LMV’09 - Telć Distinguishing of phases by their hardness 3000 HV 1500 1200 2200 1300 1000 1100 800 1400 TiC vs (Nb,Ti)C (Nb,Ti)C vs G phase G phase vs M23C6 TiC vs matrix 800 HV 600 Average Standard deviation Standard deviation * 1.96 400 M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Random indentations 100 indentations under a load of 5G on cross sections of as-cast and heat treated alloys As - cast BINARY HISTOGRAMS Heat-treated no changes occurred reduce of hardness increase of hardness M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Examples Matrix – 294 HV 225HV – 14% 300HV – 67% 375HV – 7% M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Average weighted hardness of matrix Alloy no 1 2 3 4 5 6 7 8 9 as-cast 294 277 246 291 291 310 260 343 272 annealed 295 247 247 353 252 331 318 315 280 Δ HV 1 -30 1 62 -39 21 58 -28 8 Changes in matrix microhardness ΔHV versus alloy chemistry: ΔHV = -93.3+32.Si+19.7.Nb+45.4.Ti–22.4.Si.Ti R2 = 0.999, F = 2902 M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Influence of Nb and Ti on changes of matrix hardness ΔHV M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Matrix hardness – how the average hardness value obtained from direct aiming measurements can lead to misleading results 10 matrix indentations Alloy no 1 2 3 4 5 6 7 8 9 as-cast 276 225 225 249 313 344 266 326 287 annealed 278 245 213 336 203 346 258 339 286 ΔHV 2 20 -12 87 -110 2 -8 13 -1 weighted matrix hardness as-cast 294 277 246 291 291 310 260 343 272 annealed 295 247 247 353 252 331 318 315 280 ΔHV 1 -30 1 62 -39 21 58 -28 8 + 23-89 HV M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć Conclusions The random measurements of microhardness under the small loads enable, among others, the following: ¾ determination of mean matrix hardness and then evaluation of the effect of alloy chemistry on changes of the matrix hardness due to annealing, ¾ tracing changes in microstructure caused by phase transformations and the processes of secondary precipitation through analysis of a quantitative increase in the value of HV, corresponding to other phase constituents. A possibility also exists to use hardness distribution as a tool for quantitative evaluation of the phase constitutents present in alloy microstructure. Increasing the sensitivity of measurements to improve the detectability of individual phases seems to be a key problem ¾Due to high hardness of phases present in the examined cast steel and their relatively small content, the applied method of microhardness measurements not allows for further reduction of the load value and plotting a multimodal histogram in which all the phase constituent would be described. A solution might be here the random nanoindentation measurements M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć THANK YOU FOR ATTENTION M.Garbiak „Applying microhardness to microstructure analysis” LMV’09 - Telć