Document

advertisement

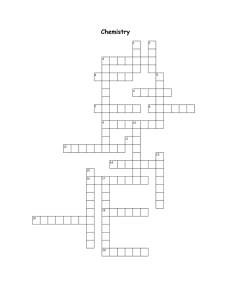

Physical Properties of Materials 1. Electrical Properties 2. Optical Properties 3. Magnetic Properties 1 1. electrical properties 2 (1) electrical conduction in metals classical Model • metallic bonds make free movement of valence electrons possible • outer valence electrons are completely free to move between positive ion cores • positive ion cores vibrate with greater amplitude with increasing temperature • the motion of electrons are random and restricted in absence of electric field no net electron flow • in presence of electric field, electrons attain directed drift velocity that is proportional to the applied field but in the opposite direction 3 Ohm’s law – electric current flow i is directly proportional to the applied voltage V and inversely proportional to resistance of the wire V i = ── R i: electric current (A) V: potential difference (V) R: resistance of wire (Ω) electric resistivity A ρ = R ── l l: length of the conductor A: cross-sectional area of the conductor electric conductivity σ = 1/ ρ 4 conductor σ > 107 (Ω·m)-1 metals insulator σ ~ 10-14 (Ω·m)-1 polymer semiconductor Si, Ge ex. a wire whose diameter is 0.20 cm carries 20 A current, the maximum power is 4 W/m, calculate the minimum allowable conductivity of the wire P = iV =i2R R=ρl/A σ = 1/ρ i2l (20 A)2 × (1 m) σ = ── = ────────2= 3.18 × 107 (Ω·m)-1 PA (4 W) × π(0.001 m) ex. Cu wire conducts 10A of current with maximum voltage drop of 0.4 V/m. what is the minimum diameter? R = V/i ρ = RA/ l = AV / i l σ = i l / AV 5.8 × 107 (Ω·m)-1 = (10 A)(1 m) / A (0.4 V) (10 A)(1 m) -7 m2 A = ────────── = 4.31 × 10 (0.4 V) 5.8 × 107 (Ω·m)-1 d = √4 (4.31 × 10-7)/π = 7.37 × 10-4 m microscopic Ohm's law J=E/ρ or J = σ E J: current density A/m2 E: electric field V/m 5 drift velocity of electrons electrons are accelerated when electric field E is applied and collide with ion cores after a collision, they accelerate again electron velocity varies in a saw tooth manner drift velocity vd = μ E μ: electron mobility m2/(V·s) the electron flow in metal wire depends on the number of electrons per unit volume, the electronic charge (-1.60 × 10-19 C), and the drift velocity of electrons the current density J = nevd direction of current flow is opposite to that of electrons 6 electrical resistivity ρtotal = ρT + ρr ρT thermal component – elastic waves (phonons) generated due to vibration of electron core scatter electrons • resistivity increases with temperature ρT = ρ0oC (1+ αTT) ρ0oC: resistivity at 0oC αT: coefficient of resistivity T: temperature of the metal 7 ex. calculate the electrical resistivity of Cu at 132oC ρT = ρ0oC (1+ αTT) = 1.6 × 10-6 (1 + 0.0039 × 132) = 2.42 × 10-6 Ω·m ρr residual component – due to structural imperfections like dislocations, grain boundaries, impurity atoms • ρr is almost independent of temperature • alloying increases resistivity addition of various elements to Cu 8 (2) energy-band model of electrical conduction valence electrons are delocalized, interact and interpenetrate each other sharply defined energy levels are broadened into wider regions called energy bands ex. Na has 1 valence electron (3s1). there are N Na atoms, there are N distinct 3s1 energy levels in 3s energy band energy bands Na is a good conductor since it has half filled outer 3s band, very little energy is required to 9 produce electron flow energy-band diagrams for Na, Mg, and Al in insulators, electrons are tightly bound to the bonding atoms large energy gap Eg separates lower filled valence band and upper empty conduction band to be available for conduction, the electron should jump the energy gap, which may as much as 6~7 eV (for diamond) 10 (3) intrinsic semiconductors semiconductors – electrical conductivities are between good conductors and insulators. intrinsic semiconductors – pure semiconductors and conductivities are determined by their inherent properties ex. Si and Ge sufficient energy is needed to excite valence electrons away from their bonding position bonding electron becomes a free conduction electron and leaves a hole behind both electrons and holes are charge carriers hole is attracted to negative terminal, electron to positive terminal 11 the motion of a hole in an electric field energy-band diagram for an intrinsic semiconductor such as pure Si (Eg = 1.1 eV) quantitative relationship of electrical conduction current density J = nqvn* + pqvp* n: number of conduction electrons per unit volume p: number of conduction holes per unit volume q: absolute value of electron or hole charge (1.6 x 10-19C) 12 vn, vp: drift velocities of electrons and holes J=σE pqvp* J nqvn* σ = ─ = ─── + ─── E E E vn/E: electron mobility μn vp/E: hole mobility μp σ = nqμn + pqμp for intrinsic semiconductor n = p = ni σ = niq(μn + μp) ex. calculate the number of Si atoms per m3 (d = 2.33 Mg/m3, atomic mass: 28.08) 6.023 × 1023 atoms 1 2.33 × 106 g (────────)(─────)(──────) mol 28.08 g/mol m3 = 5.00 × 1028 atoms/m3 ex. calculate the electrical resistivity of Si at 300 K σ = niq(μn + μp) = (1.5 × 1016 m-3) × (1.6 × 10-19 C) × (0.135 + 0.048 m2/V·s) = 4.39 × 10-4 Ω-1·m-113 ρ = 1/σ = 2.28 × 103 Ω·m effect of temperature on intrinsic semiconductors • the conduction band is completely empty at 0oK • at higher temperatures, valence electrons are excited to conduction bands • conductivities increase with increasing temperature ni ∞ e-(Eg – Eav)/kT ni: concentrations of electrons having energy to enter conduction band. Eg: energy gap Eav: average energy across gap k: Boltzmann's constant T: temperature Eav = Eg/2 ni ∞ e-(Eg)/2kT σ = σ0 e-(Eg)/2kT σ0: constant depending on the mobility Eg ln σ = ln σ0 - ── 2kT Eg can be determined from the slope of the plot of ln σ vs. 1/T for intrinsic semiconductor 14 ex. plot of ln σ vs. 1/T for Si ex. electrical resistivity of pure Si is 2.3 × 103 Ω·m at 27oC, calculate its conductivity at 200oC (Eg = 1.1 eV, k =8.62 × 10-5 eV/K) Eg ln σ = ln σ0 - ── 2kT σ473 1.1 eV 1 1 ln ── = ───────── (── ──) σ300 2 (8.62 × 10-5 eV/K) 300 473 = 7.777 σ473 = e7.777σ300 = 2385(1/2.3 × 103) = 1.04 Ω-1·m-1 15 (4) extrinsic semiconductors have impurity atoms (100-1000 ppm) that have different valance characteristics (i) n – type extrinsic semiconductors – impurities donate electrons for conduction ex. group VA atoms (P, As, Sb) added to Si only 0.044 eV of energy is required to remove the excess electron from its parent nucleus 16 (ii) p-type extrinsic semiconductors – group IIIA atoms when added to silicon, a hole is created since one of the bonding electrons is missing when electric field is applied, electrons from the neighboring bond move to the hole boron atom gets ionized and hole moves towards negative terminal B, Al, Ga provide acceptor level energy and are hence called acceptor atoms 17 doping – impurity atoms (dopants) are deposited into silicon by diffusion at 11000C (iii) effect of doping on carrier concentration the mass action law at constant temperature np = ni2 ni : intrinsic concentration of carriers in a semiconductor and a constant at a given temperature n, p : concentration of electrons or holes since the semiconductor must be electrically neutral Na + n = Nd + p Na and Nd are concentrations of negative acceptor ions and positive donor ions in a n-type semiconductor, Na = 0 and n >> p hence nn ≈ Nd pn = ni2/nn ≈ ni2/Nd 18 for p-type semiconductor np = ni2/pp ≈ ni2/Na typical carrier concentrations in intrinsic and extrinsic semiconductors Si at 300 K ni = 1.5 × 1016 carriers/m3 for extrinsic Si doped with As at a typical concentration of 1021 impurity atoms/m3 nn = 1021 electrons/m3 pn = 2.25 × 1011 holes/m3 ex. Si wafer doped with 1021 P atoms/m3 calculate (a) the majority-carrier concentration, (b) the minority-carrier concentration, (c) the electrical resistivity of this n-type semiconductor at room temperature (assume complete ionization of the dopant atoms; and ni = 1.5 × 1016 m-3, μn = 0.135 m2/V·s, μp = 0.048 m2/V·s) (a) nn = 1021 electrons/m3 (b) pn = (1.5 × 1016 m-3)2 /1021 m-3 = 2.25 × 1011 holes/m3 (c) 1 1 ρ = —— = ——————————————— (1.6 × 10-19 C)(0.135 m2/V·s)(1021 m-3) qnnμn = 0.0463 Ω·m 19 ex. P-doped Si wafer has an electrical resistivity of 8.33 × 10-5 Ω·m at 27oC. assume μn = 0.135 m2/V·s, μp = 0.048 m2/V·s, (a) what is its majority-carrier concentration if complete ionization is assumed? (b) what is the ratio of P to Si atoms in this semiconductor? (a) this is an n-type semiconductor, the majoritycarrier is electron and the resistivity 1 1 ρ = ——— hence nn = ——— qnnμn ρ q μn 1 nn = —————————————————— -5 -19 2 (8.33 × 10 Ω·m)(1.6 × 10 C)(0.135 m /V·s) = 5.56 × 1023 electrons/m3 (b) pure Si contains 5 × 1028 atoms/m3 P/Si ratio = 5.56 × 1023/ 5 × 1028 = 1.11 × 10-5 (iv) effect of total ionized impurity concentration as the concentration of impurities increase, mobility of carriers decrease 20 ex. Si is doped with 1.4 × 1016 B atoms/cm3 + 1.0 × 1016 P atoms/cm3 at 27oC. Calculate (a) the equilibrium electron and hole concentrations, (b) the mobilities of electrons and holes, and (c) the electrical resistivity (ni = 1.5 × 1010 cm-3) (a) majority-carrier concentration pp ≈ Na – Nd = 1.4 × 1016 - 1.0 × 1016 = 4 × 1015 holes/cm3 minority-carrier concentration np = ni2/pp = (1.5 × 1010)2 / 4 × 1015 = 5.6 × 104 electrons/cm3 (b) total impurity concentration = 2.4 × 1016 atoms/cm3 check figure 14.26 find μn = 900 cm2/V·s μp = 300 cm2/V·s (c) electrical resistivity 1 1 ρ = —— = ——————————————— qppμp (1.6 × 10-19 C)(300 cm2/V·s)(4 × 1015 cm-3) = 5.2 Ω·cm 21 (v) effect of temperature on electrical conductivity extrinsic range – electrical conductivity increases with temperature as more and more impurity atoms are ionized exhaustion range – temperature at which donor atom becomes completely ionized for n-type semiconductor saturation range – acceptor atoms become completely ionized for p-type semiconductor beyond these ranges, temperature does not change conductivity substantially further increase in temperature results in intrinsic conduction becoming dominant 22 and is called intrinsic range to provide an exhaustion (or saturation) range at about room temperature is important since it provides temperature range that have essentially constant electrical conductivity ex. (a) As-doped Si (b) B-doped Si 23 (5) semiconductor devices (a) pn junction – n-type and p-type silicon semiconductors are joined together • formed by doping a single crystal of silicon first by n-type and then by p-type material • majority carriers cross over the junction and recombine but the process stops later as electrons repelled by negative ions giving rise to depletion region • under equilibrium conditions, there exists a barrier to majority carrier flow there is no net current flow 24 (b) biased – an external voltage is applied to a pn junction reverse biased – n-type is connected to the positive terminal of battery, electrons of ntype material and holes of p-type material move away from junction current resulting from majority carriers does not flow leakage current (of the order of μA) flows due to minority carriers 25 forward biased – n-type is connected to the negative terminal and p-type to positive majority carriers are repelled to the junction and recombine and considerable current flows 26 (c) application of pn junction diode rectifier diodes – converts alternating voltage into direct voltage (rectification) when AC signal is applied to diode, current flows only when p-region is positive and hence half way rectification is achieved signal can be further smoothed out by using other electronic devices breakdown diodes (zener diodes) in reverse bias, small leakage currents flow upon breakdown voltage is reached, reverse current increases rapidly electrons gain sufficient energy to knock more electrons from covalent bonds these are available for conduction in reverse 27 bias (d) bipolar junction transistor (BJT) • BJT consists of two pn junctions occurring sequentially on a single crystal • can serve as current amplifier ex. npn BJT emitter – emits electrons base – controls flow of charge (0.1mm thick) collector – collects electrons emitter base junction is forward biased and collector base junction is reverse biased small base current can be used to control large collector current 28 (6) microelectronics thousands of transistors on a “chip” of Si about 5 mm2 and 0.2 mm thick (a) microelectronic planar bipolar transistors ex. planar bipolar npn transistor • relatively large island of n-type silicon is formed first in a p-type Si substrate • smaller island of p and n type silicon are created on larger n type island 29 (b) microelectronic planar field-effect transistor MOSFET (metal oxide semiconductor field effect transistor) NMOS – n-type MOSFET PMOS – p-type MOSFET ex. NMOS overall structure cross-sectional view • two islands of n-type silicon are created in a substrate of p-type silicon • source – the contact where electrons enter drain – the contact where electrons leave 30 • gate – third contact, a layer of polysilicon • no voltage is applied to the gate, only a few electrons are attracted to the drain • when a positive voltage is applied to the gate, electrons will flow between source and drain if there is positive voltage difference between them • MOSFET is capable of current amplification • MOSFET technology is the basis for most LSI digital memory circuits 31 (c) fabrication of microelectric integrated circuits laying out IC network photolithographic mask chrome mask emulsion mask 32 (i) photolithography – the process by which microscopic pattern is transferred from a photomask to the silicon wafer surface step 2 wafer is coated with photoresist step 3 then exposed to UV light through photomask step 4 pattern of photoresist is left where mask is transparent step 5 wafer is immersed in hydrofluoric acid step 6 photoresist pattern is removed by other chemicals 33 (ii) diffusion technique • impurity atoms are diffused into Si wafers at about 1000 ~ 1100oC • thin silicon dioxide patterns serve as masks to prevent dopant atoms from penetrating into silicon • high concentration of dopant is deposited near surface in predeposit step • in drive-in diffusion step, the wafers are placed in high temperature furnace and necessary concentration of dopant atoms at particular depth is attained. 34 (iii) ion implantation technique • carried out at room temperature • dopant atoms are ionized and accelerated to high energies through a high potential difference of 50-100 KV • on striking, ions embed in Si • photoresist or SiO2 is used to mask desired regions • damage to Si lattice is caused but can be healed by annealing 35 (iv) MOS integrated circuit fabrication step 1 deposition of SiN4 by CVD boron ions are implanted to suppress unwanted conduction SiO2 layer is grown in inactive regions step 2 SiN4 is removed by etchants step 3 insulating layer is deposited on wafer by CVD step 4 Al is deposited on wafer step 5 protective layer is deposited on entire surface 36 (v) NMOS integrated circuits fabrication 37 (vi) complimentary metal oxide semiconductor (CMOS) devices circuits containing both types of MOSFETs – NMOS and PMOS • made by isolating all NMOS devices with islands of p-type material. • used in LSI circuits in microprocessors and computer memories. 38 (7) compound semiconductors MX semiconductors are major compound semiconductors IIIA-VA and IIA-VIA electrical properties of intrinsic semiconductors at room temperature Eg μn μp Group Material eV m2/(V·s) m2/(V·s) IV A Si 1.10 0.135 0.048 Ge 0.67 0.390 0.190 IIIA - GaP 2.25 0.030 0.015 V A GaAs 1.47 0.720 0.020 GaSb 0.68 0.500 0.100 InP 1.27 0.460 0.010 InAs 0.36 3.300 0.045 InSb 0.17 8.000 0.045 IIA - ZnSe 2.67 0.053 0.002 VI A ZnTe 2.26 0.053 0.090 CdSe 2.59 0.034 0.002 CdTe 1.50 0.070 0.007 lattice ni constant carrier/m3 5.4307 1.5 × 1016 5.257 2.4 × 1019 5.450 5.653 1.4 × 1012 6.096 5.869 6.058 6.479 1.35 × 1022 5.669 6.104 5.820 6.481 39 • as molecular mass increases energy band gap decreases and electron mobility increases • increasing ionic bonding character energy band gap increases and electron mobility decreases gallium arsenide (GaAs) is the most important of all compound semiconductors advantages: higher mobility better radiation resistance ex. (a) calculate the intrinsic electrical conductivity of GaAs at room temperature (b) what fraction of the current is carried by the electrons in GaAs at 27oC? (a) σ = niq(μn + μp) = (1.4 × 1012)(1.60 × 1019)(0.072 + 0.002) = 1.66 × 10-7 (Ω·m)-1 (b) σn niqμn 0.072 ── = ───── = ───── = 0.973 σ niq(μn + μp) 0.072 + 0.002 40 (8) electrical properties of ceramics • used for electrical insulators for low- and high- voltage electric currents • application in various types of capacitors • piezoelectrics (a) basic properties of dielectrics (i) dielectric constant parallel-plate capacitor q = CV or C = q/V C: capacitance (farad = coulomb/volt) area dimension A >> distance d A C = ε0── d permittivity of free space ε0 = 8.854 × 10-12 F/m a dielectric fills the space between plates κε0 A C = ─── κ : dielectric constant41 d the energy stored in a capacity of a given volume at given voltage is increased by the factor of dielectric constant (ii) dielectric strength • a measure of the ability of the material to hold energy at high voltage • defined as voltage per unit length • the maximum electric field that the dielectric can maintain without electrical breakdown • commonly measured in volts/mil (1 mil = 0.001 in) or kilovolts/mm (iii) dielectric loss factor κ tan δ dielectric loss angle δ ex. a parallel-plate capacitor made to store 5.0 × 10-6 C at a potential of 8000 V separation distance = 0.30 mm, calculate the area of the plates if dielectric is (a)42a vacuum (κ = 1) and (b) aluminum (κ = 9) κε0 A Cd (5.0 × 10-6/8000)(3 × 10-4) C = ─── A = ── = ────────── d κε0 k (8.85 × 10-12) (a) κ = 1 A = 0.021 m2 (b) κ = 9 A = 2.35 × 10-3 m2 (b) ceramic insulator materials electrical and mechanical properties make ceramic materials suitable for insulator applications (i) electrical porcelain • 50% clay (Al2O3.2SiO2.2H2O) + 25% silica (SiO2) + 25% feldspar (K2O.Al2O3.6SiO2) • good green-body plasticity and a wide firing temperature • disadvantage: high power-loss factor (ii) steatite porcelain • 90% talc (3MgO.4SiO2.H2O) + 10% clay • good electrical insulator due to low powerloss factor, low moisture absorption, and good impact strength 43 (iii) fosterite • chemical formula: Mg2SiO4 • has high resistivity and low electrical loss with increasing temperature • has lower-loss dielectrica properties at high frequencies (iv) alumina ceramic • Al2O3 as the crystalline phase bonded with a glassy matrix • has relatively high dielectric strength and low dielectric loss and relatively high strength 44 (c) ceramic materials for capacitors • most common type: disk ceramic capacitors, consist mainly of BaTiO3 and other additives dielectric constant 325 2100 6500 formulation BaTiO3 + CaTiO3 + low% Bi2Sn3O9 BaTiO3 + low% CaZrO3 and Nb2O5 BaTiO3 + low% CaZrO3 or CaTiO3 + BaZrO3 steps in manufacture: (i) after firing ceramic disk (ii) after applying Ag electrodes (iii) after soldering Pb (iv) after applying dipped phenolic coating 45 (d) ceramic semiconductors • thermistor (thermally sensitive resistor) is used for temperature measurement and control • negative temperature coefficient (NTC) – resistance decreases with increasing temperature, as the temperature increases, the termistor becomes more conductive • most commonly used for NTC thermistors: oxides of Mn, Ni, Fe, Co, Cu ex. Fe3O4 mixed with MgCr2O4 to adjust the resistivity 46 (e) ferroelectric ceramics ferroelectric – ionic crystalline materials have unit cells that do not have a center of symmetry and contain small electric dipole industrially important material: BaTiO3 • > 120oC regular cubic symmetrical perovskite structure • < 120oC (the Curie temperature) Ti4+ and O2- ions shift slightly in opposite directions the crystal structure changes from cubic to slightly tetragonal formation of ferroelectric domain 47 the piezoelectric (PZT) effect an effect by which mechanical forces can produce an electrical response, or electrical forces a mechanical response • an excess of positive and negative charges at two ends in piezoelectric material • when compressive stresses are applied, the length of the sample is reduced and the distance between the unit dipoles are reduced the overall dipole moment is reduced and the voltage difference between the ends is changed • an electric field is applied across the ends, the charge density at each end will be changed it causes the change in dimensions in the48 direction of the applied field examples of industrial applications • compression accelerator mechanical → electrical • ultrasonic cleaning transducer electrical → mechanical 49