InnovatIve solutIons for ropeway transportatIon

advertisement

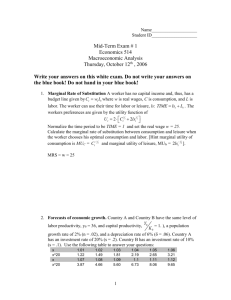

I n n o vat i v e s o l u t i o n s f o r r o p e way t r a n s p o r tat i o n M o u n ta i n Urban I n d u s t ry LST, a company of the Group commitments Integration of LST in the MND Group DEVELOPMENT of innovative technologies FLEXIBILITY for the benefit of our customers LST applies all its skills and industrial and technological facilities to design, manufacture and maintain a range of high-quality products satisfying the requirements of its customers and partners in terms of performance and attractiveness. LST supports its customers with their projects from start to finish with tailored offers. Its after-sales service guarantees technical support available seven days a week during the season. LST is a French company of the MND Group and benefits from its sound distribution network through subsidiaries and distributors for offers and services in our customers’ local area. INTEGRATION OF ER2i Montagne CREATION OF LST Engineering office specialised in ropeway transportation and special lifts 1989 2014 2012 2016 High quality factory welding and assembly Experienced in ropeways technologies CERTIFICATION ISO 9001 (Quality) and 14001 (Environment) LST JOINS THE MND GROUP This membership in the Group has enabled us to quickly find our place among the international market leaders. SUPPORT and quality of service At LST our mission is to supply and install reliable, long-lasting equipment enabling our customers to optimise and improve the conditions under which their infrastructure is operated, thus acting as a real partner for our customers. 02 www.lst.eu merger with GRC-TEC Industrie Distribution subsidiaries: Switzerland, Italy, Spain, Austria, Turkey, Sweden, USA and China. A network of distributors worldwide. Our know-how Over 25 years of experience Over 10% of turnover invested in R&D each year Over 20 engineers and technicians in R&D Over 600 ropeways installed www.lst.eu 03 application areas SUMMARY LST specialises in design and manufacture of tailored ropeways and offers a high-performance and flexible alternative for ropeway transportation and carpets projects for the development of ski areas and tourist sites. M o u n ta i n urban I n d u s t ry SERVICES Thanks to our industrial expertise in ropeway transportation for mountain applications and innovative technologies, LST today offers a unique urban ropeway transportation solution (CABLINE) which fits perfectly into cities, suburbs, airports, etc… The gondolas and funiculars complete the range of urban ropeway transportation. The LST expertise responds to the ropeway transportation needs for industrial applications such as difficult access sites or construction sites, materials transportation or any other application using a rope. Detachable chairlift Detachable gondola Cable car Funicular Fixed grip chairlift Pulsed gondola Surface lift Carpets and Canopies Loading carpets - Gates Bambi Kid Carousel Cabline Detachable gondola Cable car Funicular Pulsed gondola Special lifts Cable car Funicular Materials transportation LST offers all the spare parts for the various types of lifts and provides its expertise in reply to lifts upgrade requests. LST offers service contracts adapted to operators’ needs. After-Sales 04 www.lst.eu www.lst.eu 05 M O U N TA I N NEW GENERATION M O U N TA I N DETACHABLE CHAIRLIFT LST-DG-10 detachable grip • New patented flexion detachable grip, reducing the number of movements in the station by half as compared to a direct clamping grip, • Reduced drag forces, minimising the risk of jamming, • Designed to facilitate frost clearance during operation, • Sized for a 6- or 8-places chair or gondola LST-DC6-Comfort 6-seater chair LST has designed and developed a new range of detachable lifts from 6 to 12-pERSONS both chairlifts and gondolas All the components (stations, line, grips and vehicles) have been specially developed to offer a new generation of detachable lift, the aim of which is to ensure maximum safety, significantly optimising operating costs (improved durability, reduced energy consumption, reduced maintenance costs, etc…). Many patents on various innovations regarding stations, grips, vehicles. Drive and return stations • Acceleration and deceleration belts, removing the need for difficult-to-maintain tire beams, which are subject to heavy wear and offer variable reliability. • Contours provided by solid tires, motorised in 3 zones to facilitate spacing and storage of vehicles in the stations. • Loading and/or unloading available as a standard in the axis of the line or in the contour. • Acceleration and deceleration belts driven by electrical motors, VFD controlled, without taking the motion from the rope. • Emergency drive is provided by an electric motor directly connected to the bullwheel, powered by a diesel generator. All the functions are therefore operational in case of evacuation. • The maintenance cost is reduced four-fold and the energy saving on vehicles transfer around 15%. • Stations access is easier and safer for operators via stairs at the rear of the contour, avoiding crossing the chairs path, thus avoiding any risk of collision. Option • Grip maintenance area at the rear of the station contour. 06 www.lst.eu • Streamlined design with a simple vibration dampener for good load distribution, • Comfortable seat for users of all sizes thanks to an ergonomically-shaped back rest, • Shaped and differentiated seats for the comfort and safety of even the youngest users. Openwork back rest to reduce wind effects, • Restraining bar with individual two-level footrests to suit adults and children and assure the user’s safety (optional restraining bar with 3 double footrests for snowboarders and handicapped-ski chairs). Line • Available sheave trains: 6 / 8 / 12 support or compression, 4+4 double effect, • Support sheaves with diameter 500 mm, maximum load 750 kg, • Compression sheaves with diameter 420 mm, maximum load 600 kg (to improve passenger comfort and reduce stress on the vehicles), • Over-sized sheave bearings for a longer lifetime, • Over-sized sheave battery axles, designed to be turned by a quarter turn, • Line safety assured by break forks fitted on the rope axis and protected against ice and snow, • Sheave jamming detection system. Electrical equipment • Electrical architecture entirely designed by LST, based on SIEMENS components (safety PLCs, variable frequency drives, motors and gear motors). • Electrical equipment built by a SIEMENS-approved industrial systems integrator specialised in the design of automated safety systems and available seven days a week in France and abroad for repair and maintenance operations. Options • Supervision of lift operation with remote access for maintenance • Load simulation system • Safety radio remote control for operators • Safety radio remote control for maintenance platform. www.lst.eu 07 CABLE CAR FUNICULAR M O U N TA I N © design by carvatech M O U N TA I N Our funicular engineering expertise is recognised around the world The experience of ER2i Montagne, which has now joined LST, permits us to design or renovate all types of cable car Services Services Design engineering, 3D design, sizing and optimisation of machinery, operating procedures for interventions, renovation work. The experience of ER2i and its teams means we can now carry out even the most ambitious renovation work and design entire new cable car lines. Design engineering, 3D design, sizing and optimisation of machinery, operating procedures for interventions, renovation work, handling work, major inspections. Key product references: Key product references: > Cable car at the Grande Motte glacier - TIGNES - Customer: STGM -2013 Installation of a rescue cable car (design, manufacture, installation) > Pomb du Cantal cable car - LE LIORAN - Customer: Conseil Général du Cantal 2013 Saddle shoes replacement (design, manufacture, installation) > ST LARY cable car - Customer: Seirel - 2013 Replacement of the entire drive train > SHEM service cable car - Pont de Camps - Customer: SHEM - 2013 Stations renovation (design, manufacture, installation) > EDF service cable car at Naguilhes - Customer: EDF - 2012 Large-scale renovation (design, manufacture, installation) > SHEM service cable car - Eget - Customer: SHEM - 2012 Complete replacement of the cabin carriage (design, manufacture, installation) Compliant with European Norms, with safety devices certified in accordance with European Directive 2000/9/CE. 08 Our engineers can design new systems or renovate even the oldest equipment. www.lst.eu > Montmartre funicular - PARIS - 2016/2018 Complete renovation of the two machineries and major inspection of the two vehicles > Portillon EDF Funicular - LUCHON - (EDF) - 2014 Renovation of the machinery, winding drum, hauling rope, vehicle carriage,… (design, manufacture, installation) > TAKAMAKA service funicular - La Réunion (EDF) - 2011 Vehicle renovation (useful load 11 tons), recalculation of structures, design of a new powertrain, and replacing the rope tie > HAVRE Funicular - 2010 Renovation and installation of a tele transmission system between the two vehicles and the top drive station, on board energy, power rails > PAU funicular - 2010 main engine replacement, and installation of a tele transmission system between the two vehicles and the top drive station, on board energy, power rails > Capucin funicular - LE MONT DORE - 2009 Vehicles major inspection, tele transmission system between the two vehicles and the top drive station, on board energy, power rails, replacement of brake clutch systems. (Design, manufacture, installation) > Noyant funicular - La Mine Bleue - 2007 Replacement of the existing hydraulic motorisation with continuous current motor and renovation of the winding drum axis. Compliant with European Norms, with safety devices certified in accordance with European Directive 2000/9/CE. www.lst.eu 09 M O U N TA I N FIXED GRIP CHAIRLIFT Compact, Easy to operate, Maintainability Technical specifications Transport capacity Maximum speed without loading carpet Maximum speed with loading carpet Line gauge Drive station tension Return station tension DoubleQuad up to 1440 p/h up to 2400 p/h up to 2.5 m/s up to 2.3 m/s up to 2.8 m/s up to 2.6 m/s 4 m 4.8 m up to 40 t up to 60 t up to 50 t up to 60 t Standard version Wind version Comfort version 3 TYPES OF SEAT FOR DIFFERENT REQUIREMENTS TOWERS GRIPS Grip type Cable diameter Ø Shaft diameter Type of lift Grip’s duckbills 2- OR 4-SEATER COMPACT STATION Fixed grip 2- or 4-seater compact chairlifts to reduce assembly time, maintenance and environmental impact. FK1 26 -36 mm 50 mm Double Plastic FK2 36 -45 mm 75 mm Quad Plastic Key features Features Advantages SHEAVE BATTERIES • Pre-assembled stations at the factory in three parts • Simplified assembly on-site • Hydraulic, electrical and mechanical components accessible from the ground • Easier maintenance for the operator without requiring work at height Wide range of sheave batteries to cover all transport requirements. • Hydraulic tensioning and breaking units at the front of the station in a closed room • Accessible for operation and maintenance • Hydraulic unit with manual back-up pump (tension and brake) • Used to evacuate the lift in the event of hydraulic system failure • Emergency drive directly coupled to the bullwheel (optional) • Used to evacuate the line in the event of a gearbox and/or motor malfunction • Vehicles guided through the terminal • Improved passenger comfort • Carefully designed gear-motor housing • Low noise level around the station and protection from adverse weather Assembly system allowing adjustments in all directions. Support sheave load up to 7.5 kN Compression sheave load up to 7 kN Sheave diameter 400 mm Number of sheaves – S or C type 2 to 12 Number of sheaves - type 4SC 4S/4C Sheave type Aluminium body and steel disc Sheave bearings Permanently lubricated bearings Compliant with European Norms, with safety devices certified in accordance with European Directive 2000/9/EC. 10 www.lst.eu www.lst.eu 11 M O U N TA I N SURFACE LIFT Meets requirements, Easy to operate, Maintainability Technical specifications Euro Hydro 470 Hydro 550 Drive station Fixed Tensioning TensioningFixed Electrical motor Up to 22 kW Up to 45 kW Brake ElectromechanicalElectromechanical Electromechanical Electromechanical plus mechanical plus mechanical plus mechanical plus mechanical brakebrake brake brake Speed Up to 2.5 m/s Up to 3.5 m/s Up to 3.5 m/s Up to 3.5 m/s Line gauge 2 m 2.5 or 3 m 2.5 or 3 m 2.5 or 3 m Tower height 6 m 7 or 8 m 7 or 8 m 7 or 8 m Type of hanger Comfort or Comfort Comfort Comfort light platter or T-bar or T-bar or T-bar Return station TensioningFixed Fixed Tensioning Tensioning system CounterweightHydraulic Hydraulic Counterweight Maximum tension Up to 4.5 T Up to 5 T Up to 9 T Up to 25 T Tensioning system travel 1.5 m 1.5 m 2.5 m 3m Up to 75 kW LA Up to 200 kW A FULL RANGE OF SURFACE LIFTS Key features • Station bolted onto concrete foundations or metal support • Station with cross-arm for sheave battery • Electrical motor controlled by variable frequency drive • Suspended motor and anti-rollback ratchet system on gearbox • Ø250mm sheaves for silent operation and minimum wear • Galvanised steel structure • Optional angle station on the uphill side available Compliant with European Norms, with safety devices certified in accordance with European Directive 2000/9/EC. 12 www.lst.eu www.lst.eu 13 SURFACE LIFT M O U N TA I N EURO HANGERS Economical solution specially developed for the requirements of small lifts up to 22kW, using simple but robust components combined with our usual LST high-quality engineering. Compact fixed drive station and return with counterweight, requiring no maintenance. This model is only available with platter hangers. LST 200 MAGNETIC The LST200 magnetic spring box offers a level of comfort normally only achieved with larger models. Our spring boxes, fitted with a magnetic brake, provide a smooth progressive start-up for skiers and snowboarders, which is a real bonus for beginners. The LST200 has a robust design to withstand adverse weather conditions. The LST200 has no wear parts (except for the cord) and requires no maintenance. Rope length Cord diameter Type of hanger Stick length 5 to 9 m 5 mm Platter 0,65 to 2 m LST 260 HYDRO HYDRO 470 & HYDRO 550 The tried and tested LST 260 Hydro springbox, with its hydrodynamic brake, provides a progressive start-up for skiers and snowboarders, which is a real bonus for beginners. Thanks to the electrically controlled hydraulic tensioning system, the compact Hydro drive and tensioning station combined with the no-maintenance fixed return are the ideal combination for all medium-sized surface lifts requirements up to 75 kW. The LST260 has a robust design to withstand adverse weather conditions. This model is available with platter or T-bar hangers. Rope length Internal rope diameter Type of hanger Stick length 5 to 9,5 m 6 mm T-bar / Platter / Sledge 0,75 / 0,9 / 1,5 m key features LA The LA surface lift is the ideal choice for longer, steeper lines. Our friction-free hydrodynamic brakes require no maintenance 100% compatible with all hangers on the market (with or without adapter) Forged steel hanger head Galvanised steel structure Sledges can be installed on the LST260 to transport pedestrians and tubing Compact fixed drive station up to 200 kW with a no-maintenance counterweight return. This model is available with platter or T-bar hangers. 14 www.lst.eu www.lst.eu 15 M O U N TA I N CARPET Accessible to all, Comfort, Safety Technical specifications • Rubber band useful widths: 600, 760, 900 or 1200 mm • Adjustable speed from 0.2 to 0.7 m/s (option up to 1.2 m/s) • Transport capacity 1680-4320 p/h • Integrated electrical cabinet with variable frequency drive • Linear and modular elements 3 metres long • Hydraulic tensioning • Quick and easy to install • Touchscreen control • Compliant to the directive EN15700 Options • Automatic restart after temporary stop (light beams, trap) • Remote control console • Lateral or bi-lateral unload at 0.9 m/s or 1.2 m/s • Straight exit at 1.2 m/s with double safety trap • Belt heating system over the entire line • Bottom station heating system • Top station heating system • Rubber band with non-slip surface for maximum adhesion • Manual tensioning for conveyors up to 4 kW • PVC tarpaulin for side cover • PVC tarpaulin for summer top cover • Motorised brush for additional belt cleaning • Presence detection radar for belt start-up • Canopy THE EASIEST WAY TO TRANSPORT PEOPLE Key features Usage • Skiers • Pedestrians • Sledges • Tubing • Pushchairs • Wheelchairs 16 www.lst.eu www.lst.eu 17 M O U N TA I N CANOPY FOR CARPETS Protection, Attractive look, Comfort Technical specifications • Gallery with aluminium and polycarbonate structure • Polycarbonate panels with anti-UV protection • Compatible with all existing carpets • Compliant to the directive EN15700 Options • Wood structure • Ends fitted with flexible or rigid doors • Rigid or flexible emergency exits • Fire detection system • Video surveillance • Lighting DESIGNED TO START UP THE CARPET AS QUICKLY AS POSSIBLE AND PROTECT USERS FROM ADVERSE WEATHER Specially designed to avoid the need for snow clearance and improve comfort by protecting users from adverse weather and to protect the carpet during the summer. 18 www.lst.eu www.lst.eu 19 M O U N TA I N LOADING CARPET Comfort, Performance, Safety ENTRY GATES M O U N TA I N Comfort, performance, safety FACILITATES LOADING BY REDUCING THE RELATIVE SPEED BETWEEN CHAIR AND USERS AND INCREASES THE SPEED OF THE LIFT USED TO MANAGE USER ACCESS TO THE LIFT Easy positioning of users for loading on detachable chairlifts. Technical specifications Technical specifications • LC2, LC3 and LC4 for 2-, 3- and 4-seater fixed grip chairlifts • LCA4 and LCA6 for 4- and 6-seater chairlifts • Complete supply including passengers entry gates • Maximum speed 1 m/s • Power 11 kW • With heated pit, minimum height 80 cm • 2,3,4,6,8 for 2-,3-,4-,6, 8-seater fixed grip or detachable chairlifts • Grouped motorisation (2+2, 2+2+2), power 120 kW • Ground-mounted or pit-installation for easy re-location Options • User counter cell • Individual motorisation of gates Options • User counter cell • Electrical cabinet Compliant with European Norms, with safety devices certified in accordance with European Directive 2000/9/EC. 20 www.lst.eu Compliant with European Norms, with safety devices certified in accordance with European Directive 2000/9/EC. www.lst.eu 21 M O U N TA I N BAMBI-KID Simple, Economic solution, Safety CAROUSEL M O U N TA I N Simple, Economic solution, Safety A fun way to take those first steps on the snow at any age Specially designed for children’s gardens. Economic rope tow for beginners Particularly suitable for junior ski schools. Technical specifications Safety features • Rope tow with no intermediate support, no hanger and no handle • Easy operation, minimum maintenance • Maximum length: 150 m • Maximum slope: 15% • Power: 2.2 kW (three-phase 380V) • EC electrical cabinet • Fixed speed: 1 m/s • Spliced plastic rope diameter 22 mm • Galvanised metal parts • Reversible up-line direction • Adjustable height and angle for drive and return terminals • No concrete foundation: pegged into the ground • Quick to install (1/2 day) • Double safety gate the first with automatic reset the second with manual reset • Drive and return bullwheels with groove designed to avoid the rope twisting • Drive and return bullwheels covered, preventing hands being inserted into the mechanism Track preparation • The ground must be even, straight up to 100 m and concave up to 150 m • Option: top drive Compliant with European Norms, with safety devices certified in accordance with European Directive 2000/9/EC. 22 www.lst.eu Technical specifications • Diameter: 7000 mm • Height: 1650 mm • Adjustable arms height: 800 mm • Rotation speed: adjustable between 1 and 2.6 rpm • Maximum capacity: 12 people • Power: 1.5 kW (220 V) • Noise level: < 70 dB(A) • Safety cover • Arms lifting system to facilitate slope grooming Options • Fastening ropes for skiers • Supply of inflatable tubings or vehicles in specific shapes (trains, cars, animals, etc.) • Arms with swings for summer use Compliant with European Norms, with safety devices certified in accordance with European Directive 2006/42/EC. www.lst.eu 23 URBAN PULSED GONDOLA Reduced investment, Compact, Easy operation, Maintainability COMPACT STATION Stations design is entirely based on our standard quad chairlift lines. On site, the compact design considerably reduces assembly time, maintenance and environmental impact. Moreover, the return station has a very small footprint, thus ensuring optimum architectural integration. Technical specifications © design by carvatech • Cabins with 6 or 8 seats • Pulsed movement or jig-back version The most economical gondola transport solution Key features Features Advantages • Pre-assembled stations at the factory in three parts • Simplified assembly on-site • Hydraulic, electrical and mechanical components accessible from the ground • Easier maintenance for the operator without requiring work at height • Hydraulic tensioning and breaking units at the front of the station in a closed room • Accessible for operation and maintenance • Hydraulic unit with manual back-up pump (tension and brake) • Used to evacuate the lift in the event of hydraulic system failure • Emergency drive directly coupled to the bullwheel (optional) • Used to evacuate the line in the event of a gearbox and/or motor malfunction • Vehicles guided through the station • Improved passenger comfort • Carefully designed gear motor housing • Low noise level around the station and protection from adverse weather Compliant with European Norms, with safety devices certified in accordance with European Directive 2000/9/EC. 24 www.lst.eu www.lst.eu 25 URBAN CABLINE SPECIAL ROPEWAYS Design, Product, Renovation The CABLINE is an innovative urban ropeway transportation system LST can design or renovate all types of industrial ropeways: blondin (cable car for materials and equipment transportation), inclined elevators, etc... With vehicles circulating above the ropes, it provides speed, comfort and accessibility to people with reduced mobility. The vehicle is well lit and gives a good view. An efficient system allowing specific obstacles to be crossed (railways, rivers, roads, etc.). I N D U S T RY Services Design engineering, 3D design, sizing and optimisation of machinery, operating procedures for interventions, full renovation work, and handling work. Technical specifications • Maximum capacity: 4000 pphpd, • Speed: 45 km/h • Reduced installation time • Line composed of over-sized carrying ropes to minimise the sag • Wide gauge (3m) with hauling ropes in the centre of the line • Compact stations • Availability : 2018 26 Main applications > Access to outlying areas > Services supplementing urban networks > Airport access > Main artery where it is impossible to insert a tramway www.lst.eu Key product references: > Renovation of the blondin and inclined lift at the Portillon EDF hydroelectric power plant at Luchon (Haute Garonne) 2015 > Flaine inclined elevator (design, replacement, pitch maintenance) 2013 > Grande Motte glacier cable car: Installation of a rescue cable car. www.lst.eu 27 SERVICES SERVICES - AFTER-SALES «Relocate, modify, modernise the ropeways» LST provides its expertise to satisfy all your requirements for the modernisation of ropeways. > Personalised design > Components engineering > Supply of adapted and special components > Project management from design to start-up Committed to quality «A spare parts catalogue containing over 3,000 parts» The after-sales service provides all the spare parts, wear parts and safety part for all types of ropeway. Catalogue available on www.lst.eu LST provides adapted support contracts to satisfy the specific requirements of his customers: • Summer maintenance contracts • Winter technical support • Periodical maintenance ...choose the best contract for you. Technical assistance contract Reactivity 28 «A turnkey package» www.lst.eu www.lst.eu SAV > Large stock > Shipments within 72 hours for stored parts > Competitive prices > Catalogue 2016 available - Compac Carpet - LST Carpet - LST Surface Lift 29 subsidiaries and dealers AUSTRIA - GERMANY MND Austria Hans-Maier-Str. 9 6020 Innsbruck Contact: Roderich Urschler roderich.urschler@mnd-group.com Günther Praxmarer guenther.praxmarer@mnd-group.com Tel.: +43 512 343839 JAPAN SAKAE KATO 380-0815 Room 306 Amenity-18 2406 Tsurugatamachi Nagano city Contact: Sakae Kato sakae2278@gmail.com Tel.: +81 90 1404 2278 BULGARIA EWCG 81 Bulgaria Blvd BG-2000 Samokov Contact: Ivan Bogev office@ewcg.eu Tel.: +3 59 722 66 492 KAZAKHSTAN Alma Alpine Engineering www.aae.kz Republic of Kazakhstan, 149 Dubok-2 Microdistrict 050052 Almaty Contact: Andrey Obyskalov a.s.obyskalov@mail.ru Tel.: +77 017 110 757 CHILE Asesoria Tecnica Pucara S.A. www.pucara-sa.cl Avenida Francisco Bilbao 523 Providencia, Santiago, Chile Contact: Jorge SAEZ jsaez@pucara-sa.cl Tel.: +56 2 223 6167 CHINA MND Beijing Technology Limited Office A1107, Floor 11, 1# Building, Sanlitun SOHO, No.8 Workers’ Stadium North Road, Chaoyang District, Beijing 100027, P.R.China Contact: Emanuel Morin emanuel.morin@mnd-group.com Tel.: +86 10 57037394 CZECH REPUBLIC Lubomir Rek www.lubomir-rek.cz Brnenska 1146/30 CZ-591 01 Zdar nad Sazavou Contact: Tomas Rek sufag@lubomir-rek.cz Tel.: + 42 056 662 0600 KOREA HTI Corporation Room No. 202, YangJi Bldg., #41, Gangam-daero 95-gil, Seocho-gu, Seoul 137-904 Contact: Jong Chan Hong jchong@htic.co.kr Tel.: +82 2 540 3648 SERBIA – MONTENEGRO - ALBANIA Mountain Manager D.O.O Internacionalnih brigada 1, 11000 Beograd Contact: Vladimir Spasojevic mountain.manager.balkan@gmail.com Tel.: +38 163 339 449 ITALY MND Italia Via Camillo Golgi, 10 25064 Gussago (BS) Italia Contact: Mauro Sorba mauro.sorba@mnd-group.com Tel.: +39 366 47 88 848 30 A network of distributors worldwide LST Parc d’Activités Alpespace 74, voie Magellan 73800 Sainte Hélène du Lac - France Tel. : +33 (0)4 79 65 08 90 E-mail : contact@lst.eu www.lst.eu Sales Department Contact : Marc HUTTER Tel. : +33 (0)6 75 69 97 65 After-Sales Services Contact : Camille BOUCHET-MARQUIS Tel. : +33 (0)6 12 59 09 76 services@lst.eu NORWAY Skiheis Service www.skiheis.as Postboks 325 3300 Hokksund Contact: Stein Strand post@skiheis.as Tel.: + 47 - 32 82 91 11 GREECE 4SD Messoghion 535 Aghia Paraskevi Athen Attiki 15343 Contact: Caroline Barelle 4SDconsulting@gmail.com Tel.: +30 69 71 75 15 84 IRAN Simaron Pardaz Corporation Unit 11m No, 10, Shahid Hosseini Rad St (Eftekhar), Larestan St. Motahari Ave. Teheran PC : 1595954534 Contact: Soheil Mardani s.mardani@simaron.com Tel.: +98 21 8891 3629 TURKEY MND Turkey Oguzlar Mah. 1364.Sok 2 10 Balgat Ankara Contact: Ernesto Bassetti ernesto.bassetti@mnd-group.com Tel.: +39 348 708 0605 FRANCE AND OTHER COUNTRIES MACEDONIA Elteh D.O.O Ul. Ivo Lola Ribar 132 1000 Skopje Contact: Borche Janevski b.janevski@elteh.com.mk Tel.: +38 970 221 734 RUSSIA GT CENTER www.gtcenter.ru Dmitrovskoe Road 100 k2 Moscow Contact: Michail Payol payol@gtcenter.ru Tel.: +79 265 827 419 INDIA Metro Cable Contact: Harshad Shah harshad@metrocable.in Tel.: +91 981 010 3586 Distribution subsidiaries for offers and services in our customers’ local area UNITED STATES MND America PO Box 2167 063 Eagle Park East Dr-Eagle CO 81631 Contact: Jay Bristow jay.bristow@mnd-group.com Tel.: +1 724 710 0222 FINLAND Vintertec Offshore Ltd www.vintertecoffshore.fi Hirsalantie 20420 Contact: Olof Rytövaara vinser@vintertecoffshore.fi Tel.: +35 84 00 44 1778 ICELAND Gudmundur Karl Jonsson Huldugil 70 603 Akureyri Iceland Contact: Guðmundur Karl Jónsson gudmundk@akureyri.is Tel.: 462-2280 SWITZERLAND MND Swiss Route du Grand St Bernard 8b 1933 Sembrancher Contact: Marco Toniolo marco.toniolo@mnd-group.com Tel.: +41 79 695 68 98 SLOVENIA – CROATIA - BOSNIA Editrade D.O.O Kidriceva 14e 1236 Trzin Contact: Edward Jerak edward.jerak@editrade.si Tel.: +38 641 760 990 SLOVAKIA VND Železni 1005 05801 Poprad Slovaquia Contact: Vladislav Novýsedlák vladislav.novysedlak@mnd-group.com Tel.: +421 52 77 21 649 SPAIN – ANDORRA - PORTUGAL MND Iberia Avenida Saloria Nº59 La seu d´urgell (25700) Lerida España Contact : Joan Meno joan.meno@mnd-group.com Tel. : +34 664 221 508 I NTERNAT I ONALE PRESEN C E SWEDEN MND Sverige Nifsåsvägen 11 83152 Östersund Contact : Magnus Engstrom magnus.engstroem@mnd-group.com Tel. : +4670-2102094 www.lst.eu www.lst.eu 31 Une création Design by EVE I n n o vat i v e s o l u t i o n s f o r r o p e way t r a n s p o r tat i o n Parc d’Activités ALPESPACE - 74 Voie Magellan - 73800 Sainte Hélène du Lac - FRANCE Tél. : + 33 (0)4 79 65 08 90 - Fax : + 33 (0)4 79 65 08 91 - E-mail : contact@lst.eu www.lst.eu DISTRIBUTOR LST, a company of the Group