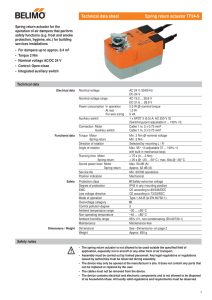

Characterised Control Valves with Actuators

advertisement