Characterised Control Valves with Actuators

advertisement

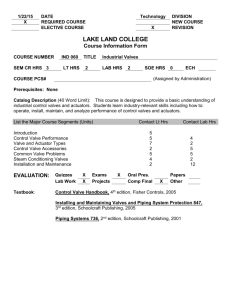

Characterised Control Valves with Actuators Technical Databook Version 5.1 Belimo Asia Pacific Product overview and table of contents Table of contents 2 Control Valves and Actuators Product overview 3 The Belimo Characterised Control Valves 4 The Belimo Characterised Control Valves/Notes 5 The sizing of Ball Valves 6 Characterised Control Valves R2..AC Characterised Control Valves 2-way 7 R6..AO Characterised Control Valves 2-way 8 R3.. Characterised Control Valves 2-way 9 Open/Close Ball Valves R2..AC/R6..AC Open/Close Ball Valves 2-way 10 R3.. Open/Close Ball Valves 3-way 11 Valve dimensions 12 General Rotary Actuators TR.. series Rotary Actuators 12 LRU.. series Rotary Actuators 15 NRU.. series Rotary Actuators 17 SRVU..-5 Rotary Actuators 19 GRVU..-7 Rotary Actuators 21 Dimensions of Mechanical Fail-Safe Rotary Actuators 23 Dimensions/Auxiliary switch adjustment 24 Installation procedures 25 Mechanical Fail-Safe Rotary Actuators TRF.. series Mechanical Fail-Safe Rotary Actuators 28 LRF.. series Mechanical Fail-Safe Rotary Actuators 30 NRFU.. series Mechanical Fail-Safe Rotary Actuators 32 SRFU..-5 Mechanical Fail-Safe Rotary Actuators 34 Dimensions and auxiliary switch adjustment 36 Installation procedures of Mechanical Fail-Safe Rotary Actuators 37 Electronic Fail-Safe Actuators GRKU..-7 Electronic Fail-Safe Actuators 38 Dimensions of GRKU..-7 Electronic Fail-Safe Actuators 43 Installation procedures of Electronic Fail-Safe Rotary Actuators 44 Installation, direction of flow and commissioning 45 CCV-Notes on installation 46 Notes on maintenance and project design 47 2 V5.12.2010•Subject to modification Installation Notes Product Overview Characterised Control Valves and Rotary Actuators for modulating control kv Flow characteristics of Characterised Control Valves Characteristic: equal percentage Rated pressure: 3-way, 4140kPa (DN15...32), 2760kPa (DN32...50) 2-way, 2500kPa (DN15...50), 1600kPa (DN65...150) Y Connection Kvs[m3/h] DN[mm] Internal thread Flange PN16 0.63 1.0 1.6 2.5 4.0 4.0 6.3 6.3 10.0 10.0 16.0 16.0 25.0 25.0 40.0 63 100 140 230 320 15 15 15 15 15 20 20 25 25 32 32 40 40 50 50 65 80 100 125 150 R209AC R210AC R211AC R212AC R213AC R217AC R218AC R222AC R223AC R229AC R231AC R238AC R239AC R248AC R249AC R664AO R679AO R6099AO R6124AO R6149AO 2-way Modulating DV 2(0)...10V Fail-Safe TR24-SR LRU24-SR NRU24-SR SRVU24-SR-5 GRVU24-SR-7 AC/DC 24V TRF24-SR LRF24-SR NRFU24-SR SRFU24-SR-5 GRKU24-MF-7 TR24 LRU24(-S) NRU24(-S) SRVU24(-S)-5 GRVU24-7 AC/DC 24V GRVU230-7 AC 100...240V GRKU24-7 3-point Fail-Safe TR230-3 LRU230(-S) NRU230(-S) SRVU230(S)-5 TR24-2 LF24-3 NRFU(-S2) * SRFU(-S2) Connection 3 Kvs[m /h] DN[mm] 3-way Internal thread 0.63 1.0 1.6 2.5 4.0 4.0 6.3 6.3 10.0 10.0 16.0 16.0 25.0 15 15 15 15 15 20 20 25 25 32 32 40 50 R309 R310 R311 R312 R313 R317 R318 R322 R323 R329 R331 R338 R348 Modulating DV 2(0)...10V TR24-SR LRU24-SR NRU24-SR Fail-Safe TRF24-SR LRF24-SR NRFU24-SR 3-point Fail-Safe TR24 LRU24(-S) NRU24(-S) TR230-3 LRU230(-S) NRU230(-S) TR24-2 LF24-3 NRFU(-S2) Open/Close Ball Valves and Rotary Actuators for shut-off or change-over functions kv Flow characteristics of Open/Close Ball Valves Rated pressure: 3-way, 4140kPa (DN15...32), 2760kPa (DN32...50) 2-way, 2500kPa (DN15...50), 1600kPa (DN65...150) Y Connection Internal thread 3 Flange PN16 Kvs[m /h] 8.6 13 18 31 40 65 120 180 230 390 570 DN[mm] 15 20 25 32 40 50 65 80 100 125 150 R215AC R220AC R225AC R232AC R240AC R250AC R665AO R680AO R6100AO R6125AO R6150AO LRU24(-S) NRU24(-S) SRVU24(-S)-5 GRVU24-7 TR230-3 LRU230(-S) NRU230(S) SRVU230(-S)-5 GRVU230-7 TRF24(-S) LRF24(-S) NRFU(-S2) SRFU(-S2)-5 GRKU24-7 TRF230(-S) LRF230(-S) NRFU(- S2) SRFU(-S2)-5 GRKU24-7 2-way Open/Close TR24 Fail-Safe Connection 3 Internal thread Kvs[m /h] 8.6 21 26 16 32 32 49 DN[mm] 15 20 25 32 32 40 50 R315 R320 R325 R330 R332 R340 R350 3-way V5.12.2010•Subject to modification Open/Close TR24 LRU24(-S) TR230-3 LRU230(-S) NRU24(-S) NRU230(-S) TRF24(-S) LRF24(-S) NRFU(-S2) TRF230(-S) LRF230(-S) NRFU(-S2) Fail-Safe Further contact for more combinations. 3 CCV-The Belimo Characterised Control Valve An ordinary Ball Valve is unsuitable as a control device an ge a ra cter istic In order to ensure good stability of control, a Control Valve must have a flow characteristic that complements the nonlinear characteristic of the heat exchanger in the HVAC system. ci ty ch h rc ch ar ac ter isti c R es ul ta nt th e Typ i rm ca al lh ca ea pa te x 100% Flow rate ge nta rce e al-p Equ 100% Amount of opening An equal-percentage valve characteristic is describled in order to produce a linear relationship between the thermal output and the amount of opening of the control device. This means that the flow rate increases slowly as the valve begins to open. Characteristic in ordinary Ball Valves is severely distorted. The reason for this is that an ordinary Ball Valve has an extremely high flow coefficient (Kvs value) compared with its nominal size, several times that of a comparable globe valve. Characteristic of an ideal Control Valve Therefore, an ordinary Ball Valve is not very suitable for performing control functions: a c it y • Quick-opening flow characteristic • Flow coefficient excessive due to the design • Flow control inadequate in the part-load range Flow rate Re su lt a 100% cap Flo wc haract e ris Ord ti c inary B all V alv e nt th er l ma Amount of opening 100% Characteristic of an ordinary Ball Valve Belimo has added “control” to the Ball Valve an g tic ci al rm he tt ta n ul es R teris pa ca ea lh ca Typ i Flow rate rac ty ch ar ac ra t e cte ris tic ris ed Co ntro l Valv e ch er a ch te x 100% ge nta Cha rce o e p lim alBe Equ Amount of opening Belimo has succeeded in solving the problem of thedistorted flow characteristic of ordinaryBall Valves. A so-called “characterising disc” in the inlet of the Characterised Control Valve converts the valve’s characteristic to the equal-percentage kind. The side of the characterising disc facing the ball is concave and is in contact with the surface of the ball. Thus, the actual flow is regulated by the hole in the ball and by the V-shaped aperture in the characterising disc. The Kvs value is reduced and corresponds approximately to that of a Globe Valve of comparable size. In order to avoid having to fit pipe reducers in the majority of cases, each size of valve is also available with wide choices of different Kvs values. 100% Characteristic of the Belimo CCV Characterising disc 4 • Equal-percentage characteristic • No initial jump in flow on opening • Excellent stability of control thanks to the characterising disc • Kvs values comparable with those of Globe Valves of comparable size • Fewer pipe reducers needed • High rangeability • High close-off pressure • Tight-sealing V5.12.2010•Subject to modification Advantages of the Belimo Characterised Control Valve The Belimo Characterised Control Valve/Notes The elements of the Characterised Control Valve 1 Simple direct attachment with a central screw 2 Square spindle head for form-fit attachment of R2..AC 2 9 7 3 8 2 the Rotary Actuator 1 10 R6..AO 3 Identical mounting flange for all sizes 4 Spindle with O-rings for long service life 5 Ball and spindle made of stainless steel 5 Characterising disc produces equalpercentage flow characteristic 4 6 5 7 Internal screw connection (ISO 7/1) 8 Forged fitting, nickel-plated brass body 9 Vent part to prevent the accumulation of condensation 10 Thermal decoupling of actuator from valve 11 Flange (ISO 7005-2) 12 GG25, polyester coated bod 9 4 12 6 5 11 Optimum choice of Kvs valves of identical size • Better controllability • Lower installation costs The Belimo range of Characterised Control Valves includes 2-way and 3-way types that are available in a variety of sizes and with a choice of Kvs value. A Characterised Control Valve is normally supplied as a unit complete with a suitable Belimo Rotary Actuator. Notes • The control devices described in this publication are intended for use in the closed water circuits of heating, ventilating and air-conditioning system. Use of the control devices in conjunction with other liquid or gaseous fluids is on request. • • Select the Characterised Control Valve according to the valve sizing diagram: page 6. Please pay attention to the notes at operation, mounting, commissioning, maintenance and project design: page 38, 39. Ordering Ordering example* (with LRU24) a) LRU24 Rotary Actuator with R.. valve fitted** -Order code: R..+LRU24 b) LRU24 Rotary Actuator and R.. valve supplied separately -Order code: R../LRU24 c) LRU24 Rotary Actuator packed loose V5.12.2010•Subject to modification -Order code: LRU24 *An order for a R.. valve usually includes an actuator 5 The sizing of Ball Valves Sizing diagram for Characterised Control Valves Legend — p max Maximum permitted pressure difference for long service life across control path A-AB referred to the whole range of opening. 280 220 170 140 — p max for low-noise operation — p max pressure difference with Ball Valve fully open V100 Nominal flow rate at Pv100 h Formula for kVS V100 kVS = pV100 100 V100 [m3/h] pV100 [kPa] Definition of ps(Pg6...9) Differential pressure at which the actuator can still seal the valve tightly allowing for the appropriate leakage rate. Sizing table for Characterised Control Valves Kvs[m3/h] 0.63 1 1.6 2.5 4 4 6.3 6.3 10 10 16 16 25 25 40 15 15 15 15 15 20 20 25 25 32 32 40 40 50 50 A209AC A210AC A211AC A212AC A213AC A217AC A218AC A222AC A223AC A229AC A231AC A238AC A239AC A248AC A249AC R309 R310 R311 R312 R313 R317 R318 R322 R323 R329 R331 R338 Kvs[m3/h] 63 100 140 230 320 DN[mm] 65 80 100 125 150 R664AO R679AO R6099AO R6124AO R6149AO DN[mm] 2-way 3-way - R348 - Differential pressure Pv100 [kPa] Flow V100 [m3/h] 6 0.1 1 3 10 Kvs [m3/h] DN [mm] 2-way 0.27 0.86 1.49 2.72 8.6 15 R215AC 0.41 1.3 2.3 4.1 13 20 R220AC 0.57 1.8 3.1 5.7 18 25 R225AC 0.98 3.1 5.4 9.8 31 32 R232AC 1.26 4.0 6.9 12.6 40 40 R240AC 2.06 6.5 11.3 20.6 65 50 R250AC 3.79 12 20.8 37.9 120 65 R665AO 5.70 18 31.2 56.9 180 80 R680AO 7.27 23 39.8 72.2 230 100 R6100AO 12.3 39 67.5 123.3 390 125 R6125AO 18.0 57 98.7 180.2 570 150 R6150AO V5.12.2010•Subject to modification Sizing table for Open/Close Ball Valves R2..AC Characterised Control Valves 2-way 2-way low torque Characterised Control Valves DN15...50 Equal-percentage characteristics for modulating control of cold and hot water Applications • Water-side control of air handling unit in air conditioning systems • Water-side control in heating systems Technical data Flow medium Cold and hot water, water with max. 50% volume of glycol Temperature of medium -5...100°C Rated pressure 2500kPa Flow characteristic Equal percentage Rangeability DN15* Sv>50 DN15...50** Sv>100 Leakage rate 0...0.01% Kvs (ANSI Class IV) Pipe connector Internal thread to ISO7/1 (No leakage when ex-factory) Close-off pressure ps Differential pressure 1400kPa pmax 350kPa (200kPa for low-noise operation) Angle of rotation 90° Installation position Upright to horizontal (in relation to the stem) Maintenance Maintenance-free Materials Body Forged, nickel-plated brass body Ball Stainless steel Seat RPTFE Stem Stainless steel O-ring EPDM Characterising disc PPA *= Kvs up to 2.5 **= DN15 Kvs 4 Product features Mode of operation The Characterised Control Valve is operated by a Rotary Actuator. The actuator is controlled by a standard modulating or 3-point control system and drives the ball of the valve - the throttling device - to the opening position dictated by the control signal. Equal-percentage characteristic Equal-percentage characteristic of the flow rate ensured by the integral characterising disc. V5.12.2010•Subject to modification Manual operation Please refer to page 13...37. 7 R6..AO Characterised Control Valves 2-way 2-way Characterised Control Valves DN65...150 Equal-percentage characteristics for modulating control of cold and hot water Applications • Water-side control of air handling unit in air conditioning systems • Water-side control in heating systems Technical data Flow medium Cold and hot water, water with max. 50% volume of glycol Temperature of medium -5...100°C Rated pressure 1600kPa Flow characteristic Equal percentage Rangeability DN65...80 Sv>50 DN100...150 Sv>100 Leakage rate 0...0.01% Kvs (ANSI Class IV) Pipe connector Flanged ISO 7005-2, PN16 (No leakage when ex-factory) Differential pressure p Close-off pressure pmax 350kPa(200kPa for low-noise operation) DN65...125 700kPa DN150 300kPa Angle of rotation 90° Installation position Upright to horizontal (in relation to the stem) Maintenance Maintenance-free Materials Body GG25, Polyester coated Ball Stainless steel Seat RPTFE Stem Stainless steel O-ring EPDM Characterising disc Stainless steel Product features • • • • Equal-percentage characteristic Manual operation 8 The Characterised Control Valve is operated by a Rotary Actuator. The actuator is controlled by a standard modulating or 3-point control system and drives the ball of the valve - the throttling device - to the opening position dictated by the control signal. Equal-percentage characteristic of the flow rate ensured by the integral characterising disc. Please refer to page 13...37. V5.12.2010•Subject to modification Mode of operation Simplified installation procedure Light weight comparing with same DN size valves Anti-corrosion treatment inside of the valve Solid linkage in insulation design R3.. Characterised Control Valves 3-way 3-way mixing Characterised Control Valves DN15...50 Equal-percentage characteristics for modulating control of cold and hot water Applications • Water-side control of air handling unit in air conditioning systems • Water-side control in heating systems Technical data Flow medium Cold and hot water, water with max. 50% volume of glycol Temperature of medium -5...100°C Rated pressure DN15... 32 4140kPa DN32... 50 2760kPa Flow characteristic Equal percentage Rangeability Leakage rate DN15* Sv>50 DN15...50** Sv>100 Control path A-AB Air bubble-tight (DIN 3230 Part 3) By path B-AB Approximately 1...2% of Kvs value Pipe connector Internal thread to ISO7/1 Close-off pressure ps 1400kPa Differential pressure pmax 350kPa (200kPa for low-noise operation) Angle of rotation 90° Installation position Upright to horizontal (in relation to the stem) Maintenance Maintenance-free Materials Body Forged, nickel-plated brass body Ball Stainless steel Seat PTFE Stem Stainless steel O-ring EPDM Characterising disc TEFZE *= Kvs up to 2.5 **= DN15 Kvs 4 Product features Mode of operation Equal-percentage characteristic V5.12.2010•Subject to modification Manual operation The Characterised Control Valve is operated by a Rotary Actuator. The actuator is controlled by a standard modulating or 3-point control system and drives the ball of the valve - the throttling device - to the opening position dictated by the control signal. Equal-percentage characteristic of the flow rate ensured by the integral characterising disc. Please refer to page 13...37. 9 R2..AC/R6..AO Open/Close Ball Valves 2-way 2-way Open/Close Ball Valves DN15...150 Shut-off function and 2-point controls in cold and hot water circuits Applications For shutting off cold and hot water circuits in heating and ventilation systems on the water side or for 2-point control of these circuits. R2..AC Technical data (for DN15...50) Flow medium Temperature of medium Rated pressure Leakage rate Pipe connector Differential pressure pmax Close-off pressure ps Angle of rotation Installation position Maintenance Materials Body Ball Seat Stem O-ring Cold and hot water, water with max. 50% volume of glycol -5...100°C 2500kPa 0...0.01% Kvs (ANSI Class IV) (No leakage when ex-factory) Internal thread to ISO 7/1 1000kPa (200kPa for low-noise operation) 1400kPa 90° Upright to horizontal (in relation to the stem) Maintenance-free Forged, nickel-plated brass body Stainless steel RPTFE Stainless steel EPDM R6..AOTechnical data (for DN65...150) Flow medium Temperature of medium Rated pressure Leakage rate Pipe connector Differential pressure pmax Close-off pressure ps Angle of rotation Installation position Maintenance Materials Body Ball Seat Stem O-ring Cold and hot water, water with max. 50% volume of glycol -5...100°C 1600kPa 0...0.01% Kvs (ANSI Class IV) (No leakage when ex-factory) Flanged ISO 7005-2, PN16 1000kPa (200kPa for low-noise operation) 700kPa (DN65...125) 300kPa (DN150) 90° Upright to horizontal (in relation to the stem) Maintenance-free GG25, Polyester coated Stainless steel RPTFE Stainless steel EPDM Product features Manual operation 10 The Open/Close Ball Valve is operated by a Rotary Actuator. The Rotary Actuator is controlled by an Open/Close signal. Please refer to page 13...37. V5.12.2010•Subject to modification Mode of operation R3.. Open/Close Ball Valves 3-way 3-way Open/Close mixing Ball Valves DN15...50 Change-over function and 2-point controls in cold and hot water circuits Applications For changing over cold and hot water circuits in heating and ventilation systems on the water side or for 2-point control of these circuits. Technical data Flow medium Cold and hot water, water with max. 50% volume of glycol Temperature of medium -5...100°C Rated pressure DN15... 32 4140kPa DN32... 50 2760kPa Flow rate Bypath B-AB Approximately 50% of Kvs Leakage rate Control path A-AB Air bubble-tight (DIN 3230 Part 3) By path B-AB 1% of Kvs Pipe connector Differential pressure Internal thread to ISO7/1 pmax Close-off pressure ps 1000kPa (200kPa for low-noise operation) 1400kPa Angle of rotation 90° Installation position Upright to horizontal (in relation to the stem) Maintenance Maintenance-free Materials Body Forged, nickel-plated brass body Ball Stainless steel Seat PTFE Stem Stainless steel O-ring EPDM Product features Mode of operation V5.12.2010•Subject to modification Manual operation The Open/Close Ball Valve is operated by a Rotary Actuator. The Rotary Actuator is controlled by an Open/Close signal. Please refer to page 13...37. 11 Valve dimensions Dimensions R2..AC 2-way Ball Valves DN mm Thread Rp Weight [Kg] L H 15 70 43.5 0.38 R217AC/R218AC/R220AC 20 77 46 0.48 R222AC/R223AC/R225AC 25 R229AC/R231AC/R232AC 32 R238AC/R239AC/R240AC 40 R248AC/R249AC/R250AC 50 R209AC/R210AC/R211AC R212AC/R213AC/R215AC lmp Dimensions [mm] 1 85 47.6 0.63 94 51 0.84 1 104 53.5 1.1 2 116.5 58.1 1.6 Disc for Characterised Control Valve R3.. 3-way Ball Valves Dimensions [mm] DN Valve type mm Weight [Kg] L H M 15 67.4 45.15 36.3 0.45 R317/R318/R320 20 77.9 47.4 41.6 0.6 R322/R323/R325 25 87.6 47.4 44.9 R329/R330 32 105.4 47.4 55.4 1.2 R331/R332 32 105.4 51.9 55.4 1.5 R338/R340 40 110.5 51.9 56 1 1.5 R348/R350 50 124.6 57.65 67.8 2 2.4 R309/R310/R311 R312/R313/R315 lmp Thread Rp 1 0.9 Disc for Characterised Control Valve R6..AO 2-way Ball Valves Dimensions [mm] DN Valve type mm A D H L N-M 65 105 145 86 93 4- 18 R679AO/R680AO 80 125 160 94.5 108 8- 18 6.5 R6099AO/R6100AO 100 148 180 104 120 8- 18 10.5 R6124AO/R6125AO 125 174 210 118.5 142 8- 18 13.0 R6149AO/R6150AO 150 204 240 136.5 170 8- 22 19.5 R664AO/R665AO lmp Weight [Kg] H1 N-M 4.3 H D PN16 DN GG25 A L H1 N-M D Disc for Characterised Control Valve 12 V5.12.2010•Subject to modification H TR.. series Rotary Actuators • General Rotary Actuators for: • • • Torque: Modulating control: Open/Close and floating control: 2-way Ball Valves DN15...25 3-way Ball Valves DN15...20 2Nm TR24-SR (AC/DC 24V) TR24 (AC/DC 24V) TR230-3 (AC 230V) Technical data Basic technical data TR24-SR TR24 V5.12.2010•Subject to modification TR230-3 Connection cable 1m, 0.75mm2 Torque 2Nm Angle of rotation 95° Sound power level 35dB(A) Degree of protection IP40 EMC CE according to 89/336/EEC Ambient temperature -5...+50°C Non-operating temperature -5...+80°C Temperature of medium -5...+100°C Humidity test To EN 60730-1 Maintenance Maintenance-free Power supply range AC 19.2...28.8V; DC 21.6...28.8V Power consumption 1.0W Transformer sizing 1.0VA Control signal DC 2(0)...10V @ 100kΩ input impedance Protection class III (safety low voltage) Running time 90s Weight 0.3kg Power supply range AC 19.2...22.8V; DC 21.6...22.8V Power consumption 0.5W Transformer sizing 0.5VA Protection class III (safety low voltage) Running time 100s Weight 0.3kg Power supply range AC 198...264V Power consumption 1.0W Transformer sizing 1.0VA Low voltage directive CE according to 73/23/EEC Protection class II (Totally insulated) Running time 105s Weight 0.3kg 13 TR..series Rotary Actuators Product features Simple direct mounting Simple direct mounting on the Ball Valve using only one screw. Manual operation Manual operation by lever (the gearing latch remains disengaged as long as the self-resetting lever is pressed). Wiring digrams Modulating control ~ T - + AC 24V DC 24V TR24-SR Y DC 2(0)...10V Control signal Notes: ! 1 2 3 T • Other actuators can be connected in parallel. ~ • Connection via safety isolating transformer. Y Please note the performance data. TR24-SR Floating control Open/Close control T ~ TR24 - + AC 24V DC 24V T + ~ - - + AC 24V DC 24V 0 Notes: • Connection via safety isolating transformer. ! • Other actuators can be connected in parallel. 1 2 3 1 2 3 Please note the performance data. TR24 TR24 Open/Close and Floating control L1 N AC 230V TR230-3 0 Notes: • Caution: Power supply voltage! ! 1 2 3 14 V5.12.2010•Subject to modification TR230-3 LRU.. series Rotary Actuators • General Rotary Actuators for: • • • Torque: Modulating control: Open/Close and floating control: 2-way Ball Valves DN32...40 3-way Ball Valves DN25...32 5Nm LRU24-SR (AC/DC 24V) LRU24(-S) (AC/DC 24V) LRU230(-S) (AC 100...240V) Technical data Basic technical data Connection cable 1m, 0.75mm2 Torque 5Nm Angle of rotation 90° Running time 90s Sound power level Max. 35dB(A) Position indication Mechanical Direction of rotation Selectable by switch (covered): Factory preset change to LRU24-SR LRU24(-S) to reverse the direction of rotation Degree of protection IP54 in any direction EMC CE according to 89/336/EEC Ambient temperature -5...+50°C Non-operating temperature -5...+80°C Temperature of medium -5...+100°C Humidity test To EN 60730-1 Maintenance Maintenance-free Nominal voltage range AC/DC 19.2...28.8V Power consumption 1.5W @ running/0.4W @ holding Transformer sizing 3VA Control signal DC 2(0)...10V(input impedance) 100kΩ Feedback signal DC 2...10V, max. 1mA Protection class III (safety low voltage) Weight 0.55kg Nominal voltage range AC/DC 19.2...22.8V Power consumption 1.5W @ running/0.2W @ holding Transformer sizing 2VA Protection class III (safety low voltage) Auxiliary switch(LRU24-S) 1XSPDT, 1mA...3(0.5)A, AC 250V 0...100%adjustable V5.12.2010•Subject to modification LRU230(-S) Weight 0.55kg Nominal voltage range AC 85...265V Power consumption 2.0W @ running/0.5W @ holding Transformer sizing 4VA Low voltage directive CE according to 73/23/EEC Protection class II (Totally insulated) Auxiliary switch(LRU230-S) 1XSPDT, 1mA...3(0.5)A, AC 250V 0...100%adjustable Weight 0.60kg 15 LRU.. series Rotary Actuators Product features Simple direct mounting Simple direct mounting on the Ball Valve using only one screw. Manual operation Manual operation by pushbutton when necessary. High function reliability The actuator is overload-proof, needs no limit switches and stops automatically at the end stops. Wiring digrams Modulating control AC 24V - + DC 24V Y DC 2(0)...10V ~ T LRU24-SR U DC 2...10V Notes: 1 2 T ~ ! • Connection via safety isolating transformer. 3 5 • Other actuators can be connected in parallel. - Y U + LRU24-SR Open/Close control ~ T - T LRU24(-S) Floating control AC 24V DC 24V + ~ Please note the performance data. - AC 24V DC 24V + 0 Notes: • Connection via safety isolating transformer. ! 1 • Other actuators can be connected in parallel. 2 3 S1 S2 S3 1 2 3 S1 S2 S3 Please note the performance data. LRU24-S 0...100% 0...100% LRU24 1 1 Auxiliary switch S1 S2 S3 0 0 Open/Close control L1 N LRU24 1 S1 S2 S3 0 LRU24-S Floating control N L1 AC 100V...240V AC 100V...240V 0 LRU230(-S) 1 2 3 S1 S2 S3 1 2 3 S1 S2 S3 Notes: ! • Caution: Power supply voltage! LRU230-S 0...100% 0...100% LRU230-S Please note the performance data . LRU230 1 1 Auxiliary switch 0 16 1 S1 S2 S3 S1 S2 S3 0 0 LRU230 V5.12.2010•Subject to modification • Other actuators can be connected in parallel. NRU.. series Rotary Actuators • General Rotary Actuators for: • • • Torque: Modulating control: Open/Close and floating control: 2-way Ball Valves DN50 3-way Ball Valves DN32...50 10Nm NRU24-SR (AC/DC 24V) NRU24(-S) (AC/DC 24V) NRU230(-S) (AC 100...240V) Technical data Basic technical data Connection cable 1m, 0.75mm2 Torque 10Nm Angle of rotation 90° Running time 90s Sound power level Max. 45dB(A) Position indication Mechanical Direction of rotation Selectable by switch (covered): Factory preset change to NRU24-SR NRU24(-S) to reverse the direction of rotation Degree of protection IP54 in any direction EMC CE according to 89/336/EEC Ambient temperature -5...+50°C Non-operating temperature -5...+80°C Temperature of medium -5...+100°C Humidity test To EN 60730-1 Maintenance Maintenance-free Nominal voltage range AC/DC 19.2...28.8V Power consumption 2.5W @ running/0.4W @ holding Transformer sizing 5VA Control signal DC 2(0)...10V(input impedance) 100kΩ Feedback signal DC 2...10V, max. 1mA Protection class III (safety low voltage) Weight 0.85kg Nominal voltage range AC/DC 19.2...22.8V Power consumption 2.0W @ running/0.2W @ holding Transformer sizing 4VA Protection class III (safety low voltage) Auxiliary switch(NRU24-S) 1XSPDT, 1mA...3(0.5)A, AC 250V 0...100%adjustable V5.12.2010•Subject to modification LRU230(-S) Weight 0.85kg Nominal voltage range AC 85...265V Power consumption 3.0W @ running/0.6W @ holding Transformer sizing 7VA Low voltage directive CE according to 73/23/EEC Protection class II (Totally insulated) Auxiliary switch(NRU230-S) 1XSPDT, 1mA...3(0.5)A, AC 250V 0...100%adjustable Weight 0.90kg 17 Product Overview/Contents Product features Simple direct mounting Simple direct mounting on the Ball Valve using only one screw. Manual operation Manual operation by pushbutton when necessary. High function reliability The actuator is overload-proof, needs no limit switches and stops automatically at the end stops. Wiring digrams Modulating control AC 24V - + DC 24V Y DC 2(0)...10V ~ T NRU24-SR U DC 2...10V Notes: 1 2 T ~ ! • Connection via safety isolating transformer. 3 5 • Other actuators can be connected in parallel. - Y U + NRU24-SR Open/Close control ~ T - T NRU24(-S) Floating control AC 24V DC 24V + ~ Please note the performance data. - AC 24V DC 24V + 0 Notes: • Connection via safety isolating transformer. ! 1 • Other actuators can be connected in parallel. 2 3 S1 S2 S3 1 2 3 S1 S2 S3 Please note the performance data. NRU24-S 0...100% 0...100% NRU24 1 1 S1 S2 S3 0 0 Open/Close control L1 N NRU24 1 S1 S2 S3 Auxiliary switch 0 NRU24-S Floating control L1 AC 100V...240V N AC 100V...240V 0 NRU230(-S) 1 2 3 S1 S2 S3 1 2 3 S1 S2 S3 Notes: ! • Caution: Power supply voltage! NRU230-S 0...100% 0...100% NRU230-S • Other actuators can be connected in parallel. . NRU230 1 1 0 18 1 S1 S2 S3 S1 S2 S3 Auxiliary switch 0 0 NRU230 V5.12.2010•Subject to modification Please note the performance data SRVU..-5 General Rotary Actuators • • • • General Rotary Actuators for: Torque: Open/Close or 3-point control: Modulating control: DN65...80 CCV 20Nm SRVU24(-S)-5, SRVU230(-S)-5 SRVU24-SR-5 Technical data SRVU24(-S)-5 Nominal voltage Nominal voltage range Power consumption -running -holding For transformer/wiring sizing Connecting cable -Motor -Auxiliary switch(-S) Protection class Weight Manual override SRVU230(-S)-5 Nominal voltage Nominal voltage range Power consumption -running -holding For wiring sizing Connecting cable -Motor -Auxiliary switch(-S) Protection class Weight Manual override SRVU24-SR-5 V5.12.2010•Subject to modification Common technical data Nominal voltage Nominal voltage range Power consumption -running -holding For transformer/wiring sizing Connecting cable Control signal Y Feedback signal U Synchronisation Protection class Weight Manual override Torque Auxiliary switch (SRVU..(-S)-5) Angle of rotation Direction of rotation Sound power level Position indicator Running time Mode of operation Ambient temp. Non-operation temp. Humidity test Degree of protection Low Voltage Directive Maintenance AC 24V 50/60Hz, DC 24V AC/DC 19.2...28.8V 2.5W 0.2W 5.5VA Cable 1m, 3x0.75mm2 Cable 1m, 3x0.75mm2 III (safety low voltage) SRVU24 approximately 1000g,SRVU24-S approximately1050g Gearing disengaged by pressing the push button, manual operate while the button is held depressed AC 100...240V 50/60Hz AC 85...265V 3.0W 0.6W 7VA Cable 1m, 3x0.75mm2 Cable 1m, 3x0.75mm2 II (Totally insulated) 1050g~1100g Gearing disengaged by pressing the push button, manual operate while the button is held depressed AC 24V 50/60Hz, DC 24V AC/DC 19.2...28.8V 2.5W 0.4W 5VA Cable 1m, 4x0.75mm2 DC 2(0)...10V @ input resistance 100kΩ DC 2...10V @ max.1mA 5% III (safety low voltage) 1050g Gearing disengaged by pressing the push button, manual operate while the button is held depressed Min. 20Nm @ nominal voltage 1xSPDT1mA...3(0.5)A, AC 250V 0...100% adjustable Max.90° to close (switch hidden under a label) Pre-setting Max. 45dB(A) Mechanical, remote visible 90s Type 1 (EN 60730-1) -30...+50°C -40...+80°C 95% RH, non condensing (EN60730-1) IP54 in any direction CE according to 89/336/EEC CE according to 73/23/EEC Maintenance-free 19 SRVU..-5 Rotary Actuators Product features the position defined by this signal. The feedback signal U allows the valve position (0...100%) to be electrically indicated and serves as a follow-up control signal for other actuators. Mode of operation Adjustable angle of rotation Adjustable angle of rotation with mechanical end stops. The actuator is overload-proof, requires no limit switches and automatically stops when the end stop is reached. High function reliability Flexible signalisation Flexible signalisation of the SRVU..-S-5 with adjustable auxiliary switch (0...100%). Wiring digrams T ~ T - SRVU24(-S)-5 3-point control ~ Open/Close control AC 24V - + DC 24V AC 24V + DC 24V Notes: 0 ! • Connection via safety isolating transformer. • Other actuators can be connected in parallel. 1 2 1 S1 S2 S3 3 2 3 Please note the performance data. Direction of rotation (factory setting, switch hidden) SRVU24-S-5 0...100% 0(Y1) S1 S2 S3 SRVU24-S-5 0...100% 1(Y2) SRVU24-5 SRVU24-5 1 1 1 S1 S2 S3 Auxiliary switch(-s) S1 S2 S3 0 0 0 3-point control Open/Close control N L1 AC 100V...240V SRVU230(-S)-5 L1 AC 100V...240V N Notes: 0 ! • Connection via safety isolating transformer. • Other actuators can be connected in parallel. 1 Please note the performance data. 2 3 1 S1 S2 S3 2 3 SRVU230-S-5 0...100% S1 S2 S3 0...100% SRVU230-S-5 0(Y1) Direction of rotation (factory setting, switch hidden) 1(Y2) SRVU230-5 SRVU230-5 1 1 1 S1 S2 S3 Auxiliary switch(-s) S1 S2 S3 0 0 Modulating control AC 24V + DC 24V T - Notes: ~ Y DC 2(0)...10V ! U DC 2...10V • Other actuators can be connected in parallel. Please note the performance data. 2 3 T 20 1 ~ 0(Y1) Direction of rotation (factory setting, switch hidden) 5 1(Y2) Y U SRVU24-SR-5 Feedback signal U for position indicating or as master-slave control signal. V5.12.2010•Subject to modification SRVU24-SR-5 • Connection via safety isolating transformer. 0 GRVU..-7 General Rotary Actuators • • • • General Rotary Actuators for: Torque: Open/Close control: Modulating control: DN100...150 CCV 40Nm GRVU24-7, GRVU230-7 GRU24-SR-7 Technical data GRVU24-7 Nominal voltage Nominal voltage range Power consumption -running -holding For transformer/wiring sizing Connecting cable Protection class Weight Manual override GRVU230-7 Nominal voltage Nominal voltage range Power consumption -running -holding For wiring sizing Connecting cable Protection class Weight Manual override SRVU24-SR-5 Nominal voltage Nominal voltage range Power consumption -running -holding For transformer/wiring sizing Connecting cable Control signal Y Feedback signal U Synchronisation Protection class Weight Manual override Common technical data Torque Angle of rotation Direction of rotation Sound power level Position indicator Running time Mode of operation Ambient temp. Non-operation temp. Humidity test Degree of protection Low Voltage Directive V5.12.2010•Subject to modification Maintenance AC 24V 50/60Hz, DC 24V AC/DC 19.2...28.8V 4W 2W 6VA Cable 1m, 3x0.75mm2 III (safety low voltage) approximately 1550g Gearing disengaged by pressing the push button, manual operate while the button is held depressed AC 100...240V 50/60Hz AC 85...265V 4W 2W 7VA Cable 1m, 3x0.75mm2 II (Totally insulated) approximately 1550g Gearing disengaged by pressing the push button, manual operate while the button is held depressed AC 24V 50/60Hz, DC 24V AC/DC 19.2...28.8V 4.5W 2W 6.5VA Cable 1m, 4x0.75mm2 DC 2(0)...10V @ input resistance 100kΩ DC 2...10V @ max.1mA 5% III (safety low voltage) 1550g Gearing disengaged by pressing the push button, manual operate while the button is held depressed Min. 40Nm @ nominal voltage Max.95° to close (switch hidden under a label) Pre-setting Max. 45dB(A) Mechanical, remote visible 150s Type 1 (EN 60730-1) -30...+50°C -40...+80°C 95% RH, non condensing (EN60730-1) IP54 in any direction CE according to 89/336/EEC CE according to 73/23/EEC Maintenance-free 21 GRVU..-7 General Rotary Actuators Product features Manual operation GRVU24-SR-7 is controlled by means of a standard control signal DC 2(0)...10V and travels to the position defined by this signal. The feedback signal U allows the valve position (0...100%) to be electrically indicated and serves as a follow-up control signal for other actuators. Adjustable angle of rotation Adjustable angle of rotation with mechanical end stops. High function reliability The actuator is overload-proof, requires no limit switches and automatically stops when the end stop is reached. Accessories Description Electrical accessories Positioner SG..24 (available on request) Digital position indication ZAD24 Wiring digrams Open/Close control T Notes: ~ GRVU24-7 - + 1 2 AC 24V DC 24V ! • Connection via safety isolating transformer. • Other actuators can be connected in parallel. Please note the performance data. 0(Y1) Direction of rotation (factory setting, switch hidden) 3 1(Y2) GRVU24-7 Open/Close control GRVU230-7 N L1 1 2 Notes: ! • Connection via safety isolating transformer. • Other actuators can be connected in parallel. Please note the performance data. 3 0(Y1) Direction of rotation (factory setting, switch hidden) GRVU230-7 1(Y2) Modulating control T ~ GRVU24-SR-7 - + DC 24V AC 24V Y DC 2(0)...10V Notes: • Connection via safety isolating transformer. ! U DC 2...10V • Other actuators can be connected in parallel. Please note the performance data. Feedback signal U for position indicating or as master-slave control signal. 1 2 3 5 ~ T 22 1(Y2) Y U GRVU24-SR-7 V5.12.2010•Subject to modification 0(Y1) Direction of rotation (factory setting, switch hidden) Dimensions of General Actuators 67 55 69 78 Dimensions[mm]: TR.. 22 84 Dimensions[mm]: LRU.. 167.2 24.5 8.2 94 66 63 64.4 4 6 1 8.2 13.2 19.5 71 56 46.9 11 50 5.2 70.9 50 Dimensions[mm]: NRU.. 172.2 24.7 99 66 8.2 65.9 64.5 19.5 8.6 41.7 4 12.5 74 58.5 48.4 11.5 1 6 83 5.2 50.9 Dimensions[mm]: SRVU.. 117 93 93 V5.12.2010•Subject to modification 21 84 33 70 176 150 23 Dimensions/Auxiliary switch adjustment Dimensions: GRVU.. 44 151 50 97 45° GRVU24-7 GRVU230-7 116 124 6 R10 47.5° 183 59 44 151 97 GRVU24-SR-7 124 50 45° 6 47.5° 69 183 Auxiliary switch adjustment: LRU..-S/NRU..-S/SRVU..-S-5 2. 3. Press the pushbutton and operate manually the universal clamp to favoured switch position. Turn switch pointer to the middle line. When actuator moves clockwise (counter-clockwise) to switch position, switch indicator passes counter-clockwise (clockwise) the middle line. The contact between S1 and S3 is cut off (established) and the contact between S1 and S2 is established (cut off). 2 1 S2 S3 S1 Note: The switching point should be about 5° from the mechanical end stops (1 short step on the scale). 24 S2 S3 S1 V5.12.2010•Subject to modification 1. Installation instructions Installation instructions: TR.. Installation procedures: LRU../NRU.. (DN15...50) 1 3 1 2 2 4 V5.12.2010•Subject to modification 5 25 Installation instructions Installation instructions: SRVU..+DN65...80 CCV 1 2 1 2 0% 3 0% 26 V5.12.2010•Subject to modification 4 Installation instructions Installation procedure: GRVU..+DN100..150 CCV 1 2 0% 0% V5.12.2010•Subject to modification 17 27 TRF..series Mechanical Fail-Safe Rotary Actuators • Mechanical Fail-Safe Rotary Actuators for: • • • • Torque: Modulating control: Floating(3-point) control: Open/Close control: 2-way Ball Valves DN15...25 3-way Ball Valves DN15...20 2Nm TRF24-SR (AC/DC 24V) TRF24-2 (AC/DC 24V) TRF24(-S) (AC/DC 24V) TRF230(-S) (AC 100...240V) Basic technical data TRF24-SR TRF24-2 TRF24(-S) TRF230(-S) 28 Connection cable Torque Angle of rotation Position indication Degree of protection EMC Ambient temperature Non-operation temperature Temperature of medium Humidity test Maintenance Power supply range Power consumption Sound power level For transformer sizing Control signal Feedback signal Direction of rotation Protection class Running time Weight Power supply range Power consumption Sound power level For transformer sizing Direction of rotation Protection class Running time Weight Power supply range Power consumption Sound power level For transformer sizing Direction of rotation Auxiliary switch (TRF24-S) Protection class Running time Weight Power supply range Power consumption Sound power level For transformer sizing Direction of rotation Low voltage directive Auxiliary switch (TRF230-S) Protection class Running time Weight 1m, 3x0.75mm2 Motor: 2Nm; spring return: 2Nm 95° Mechancial IP42 CE according to 89/336/EEC -5...+50°C -5...+80°C -5...+100°C To EN 60730-1 Maintenance-free AC 19.2...28.8V/DC 21.6...28.8V 2.5W @ running/1W @ holding Motor: Max. 45dB(A), spring return: 62dB(A) 4VA DC 2(0)...10V @ 100kΩ input resistance DC 2...10V Motor: reversible with L/R switch Spring return: reversible by mounting L/R III (safety low voltage) Motor: 90s; spring return: < 25s (-5...+50°C) / max. 60s (-30°C) 0.6kg AC 19.2...28.8V/DC 21.6...28.8V 2.5W @ running/1W @ holding Motor: Max. 45dB(A), spring return: 62dB(A) 4VA Motor: reversible with L/R switch Spring return: reversible by mounting L/R III (safety low voltage) Motor: 90s; spring return: < 25s (-5...+50°C) / max. 60s (-30°C) 0.6kg AC 19.2...28.8V/DC 21.6...28.8V 2.5W @ running/1.5W @ holding Max. 45dB(A) 5VA Spring return: reversible by mounting L/R 1XSPDT, 1mA...3(0.5)A, AC 250V , 0...100% adjustable III (safety low voltage) Motor: 40...75s; spring return: <75s 0.6kg AC 85...265V 2.5W @ running/1.5W @ holding Max. 45dB(A) 5VA Spring return reversible by mounting L/R CE according to 73/23/EEC 1XSPDT, 1mA...3(0.5)A, AC 250V , 0...100% adjustable II (Totally insulated) Motor: 40...75s; spring return: <75s 0.6kg V5.12.2010•Subject to modification Technical data TRF..series Mechanical Fail-Safe Rotary Actuators Product features Simple direct mounting Manual operation High function reliability Simple direct mounting on the Ball Valve using only one screw. No manual operation. The actuator is overload-proof, needs no limit switches and stops automatically at the end stops. Wiring diagrams AC 24V T ~ – + DC 24V ! Connection via safety isolating transformer. DC 2(0)...10V DC 2...10V Y U TRF24-SR Modulating control 1 2 3 5 Other actuators can be connected in parallel. Please note the performance data. TRF24-SR AC 24V ~ T a ! Connection via safety isolating transformer. b TRF24-2 Floating control 1 2 3 4 Y1 Y2 Other actuators can be connected in parallel. Please note the performance data. TRF24-2 AC 24V DC 24V ! Connection via safety isolating transformer. N L1 AC 100V...240V ! Caution: Power supply voltage! T – ~ + TRF24(-S) TRF230(-S) Open/Close control 1 2 <x M 1 >x x=0...100% TRF24-S TRF230-S 2 M V5.12.2010•Subject to modification S1 S2 S3 TRF24 TRF230 Other actuators can be connected in parallel. Please note the performance data. 29 L(R)F.. series Mechanical Fail-Safe Rotary Actuators • Mechanical Fail-Safe Rotary Actuators for: • • • • Torque: Modulating control: Floating(3-point) control: Open/Close control: 2-way Ball Valves DN32...40 3-way Ball Valves DN25...32 4Nm LF24-SR,LRF24-SR (AC/DC 24V) LF24-3 (AC/DC 24V) LRF24(-S) (AC/DC 24V) LRF230(-S) (AC 230V) Technical data LF24-SR LRF24-SR LRF24-3 LRF24(-S) LRF230(-S) 30 Connection cable Torque Angle of rotation Sound power level Position indication Degree of protection EMC Ambient temperature Non-operation temperature Temperature of medium Humidity test Maintenance Manual operation LRF.. Lingkage Power supply range Power consumption For transformer sizing Control signal Feedback signal Direction of rotation Protection class Running time Weight Power supply range Power consumption For transformer sizing Direction of rotation Protection class Running time Weight Power supply range Power consumption For transformer sizing Direction of rotation Auxiliary switch (LRF24-S) Protection class Running time Weight Power supply range Power consumption For transformer sizing Direction of rotation Auxiliary switch (LRF230-S) Low voltage directive Protection class Running time Weight 1m, 0.75mm2 Motor: 4Nm; spring return: 4Nm 95° Motor: Max. 50dB(A), spring return: 62dB(A) Mechancial IP54 CE according to 89/336/EEC -5...+50°C -5...+80°C -5...+100°C To EN 60730-1 Maintenance-free By manual override key (Only when power supply is disconnected for LRF24-SR) Lingkage included in LRF.. AC 19.2...28.8V/ DC 21.6...28.8V 2.5W @ running/1W @ holding 5VA DC 2(0)...10V @ 100kΩ input resistance DC 2...10V Motor: reversible by L/R switch; spring return: reversible by mounting L/R III (safety low voltage) Motor:<150s; spring return: ~20s (-5...+50°C) / max. 60s (-30°C) 1.4kg AC 19.2...28.8V/DC 21.6...28.8V 2.5W @ running/1W @ holding 5VA Motor: reversible by L/R switch; spring return: reversible by mounting L/R III (safety low voltage) Motor:40...75s; spring return: ~20s (-5...+50°C) / max. 60s (-30°C) 1.4kg AC 19.2...28.8V/DC 21.6...28.8V 5W @ running/2.5W @ holding 7VA Spring return: reversible by mounting L/R 2XSPDT, 1mA...3(0.5)A, AC 250V , fixed at 10° , 85° III (safety low voltage) Motor:40...75s; spring return: ~20s (-5...+50°C) / max. 60s (-30°C) 1.4...1.54kg AC 198...264V 5W @ running/3W @ holding 7VA Spring return: reversible by mounting L/R 2XSPDT, 1mA...3(0.5)A, AC 250V , fixed at 10° , 85° CE according to 73/23/EEC II (Totally insulated) Motor:40...75s; spring return: ~20s (-5...+50°C) / max. 60s (-30°C) 1.55...1.68kg V5.12.2010•Subject to modification Basic technical data L(R)F.. series Mechanical Fail-Safe Rotary Actuators Product features Simple direct mounting Simple direct mounting on the Ball Valve using only one screw. Manual operation LRF.. have manual operation with integral position stop. High function reliability The actuator is overload-proof, needs no limit switches and stops automatically at the end stops. Wiring diagrams T ~ – + ! AC 24V DC 24V Connection via safety isolating transformer. CCW Y DC 2(0)...10V Control signal U DC 2...10V Position feedback signal L(R)F24-SR Modulating control Mounting side CW 1 1 .8 .8 .6 .6 .4 .4 .2 .2 0 0 R L Reversible switch 1 2 5 3 R L Y=0 ~ T + – Y U Z L R Y=0 Y=0 Y=0 L(R)F24-SR MP Other actuators can be connected in parallel.Please note the performance data. T ~ – + AC 24V DC 24V Connection via safety isolating transformer. ! Mounting side CCW CW 1 1 .8 .8 .6 .6 .4 .4 .2 .2 0 0 R L b a Reversible switch 1 2 3 T ~ LF24-3 Floating control Y1 Y2 - + 4 a b (Y1) (Y2) R L R L Stop Stop Stop Stop LF24-3 Other actuators can be connected in parallel.Please note the performance data. T ~ 1 2 AC 24V DC 24V ! Connection via safety isolating transformer. T + ~ LRF24(-S) Open/Close control – – + AC 24V DC 24V 1 2 S1 S2 S3 S4 S5 S6 LRF24 M M ! Connection via safety isolating transformer. <10° <85° LRF24-S <85° LRF230-S Other actuators can be connected in parallel.Please note the performance data. N L1 N L1 AC 230V ! V5.12.2010•Subject to modification LRF230(-S) Open/Close control 1 Caution: Power supply voltage! 2 M 1 LRF230 2 M S1 S2 S3 S4 S5 S6 <10° Other actuators can be connected in parallel.Please note the performance data. 31 NRFU.. series Mechanical Fail-Safe Rotary Actuators • Mechanical Fail-Safe Rotary Actuators for: • • • Torque: Modulating control: Open/Close control: 2-way Ball Valves DN50 3-way Ball Valves DN32...50 10Nm NRFU24-SR (AC/DC 24V) NRFU,NRFU-S2 (AC 24...240V) (DC 24...125V) Technical data NRFU24-SR NRFU NRFU-S2 Connection cable Torque Angle of rotation Sound power level Position indication Degree of protection EMC Ambient temperature Non-operation temperature Temperature of medium Humidity test Maintenance Manual operation Lingkage Power supply range Power consumption For transformer sizing Control signal Feedback signal Protection class Running time Weight Power supply range Power consumption For transformer sizing Direction of rotation Protection class Running time Weight Power supply range Power consumption For transformer sizing Direction of rotation Auxiliary switch Low voltage directive Protection class Running time Weight 32 3x1m, 0.75mm2 (NRFU..) 4x1m, 0.75mm2(NRFU24-SR) Motor: 10Nm; spring return: 10Nm 90° Motor: Max. 50dB(A), spring return: ~62dB(A) Mechancial IP54 CE according to 2004/108/EEC -30...+50°C -40...+80°C -5...+100°C To EN 60730-1 Maintenance-free By manual override key Lingkage included in NRFU.. AC 19.2...28.8V/ DC 21.6...26.4V 5.5W @ running/3W @ holding 9VA DC 2(0)...10V @ 100kΩ input resistance DC 2...10V III (safety low voltage) Motor:150s; spring return:<20s (-5...+50°C) / max. 60s (-30°C) Approx. 2kg AC 19.2...264V/DC 20.4...126.5V 6W @ running/2.5W @ holding 9.5VA Motor: reversible by L/R switch; spring return: reversible by mounting L/R III (safety low voltage) Motor:<75s; spring return: ~20s (-20...+50°C) / max. 60s (-30°C) Approx. 1.7kg AC 19.2...264V/DC 21.6...143V 6W @ running/2.5W @ holding 9.5VA Spring return: reversible by mounting L/R 2XSPDT, 1mA...3(0.5)A, AC 250V One fixed at 10° , one adjustable 10°...95° CE according to 2006/95/EC II (Totally insulated) Motor:<75s; spring return: ~20s (-20...+50°C) / max. 60s (-30°C) Approx. 1.7kg V5.12.2010•Subject to modification Basic technical data NRFU.. series Mechanical Fail-Safe Rotary Actuators Product features Simple direct mounting Manual operation High function reliability Simple direct mounting on the Ball Valve using only one screw. NRFU..have manual operation with integral position stop. Only when power supply is disconnected for NRFU24-SR. The actuator is overload-proof, needs no limit switches and stops automatically at the end stops. Wiring diagrams ~ T – + ! AC 24V DC 24V Connection via safety isolating transformer. NRFU Open/Close control 1 2 NRFU M Other actuators can be connected in parallel. Please note the performance data. N L 1 2 NRFU-S2 Open/Close control S1 S2 S3 S4 S5 S6 M 10%...90% 10% ! adjustable Connection via safety isolating transformer. ~ T – + Y U NRFU24-SR Modulating control DC 0...10V DC 2...10V Control signal Position feedback signal 1 2 3 5 V5.12.2010•Subject to modification NRFU24-SR 33 SRFU..-5 Mechanical Fail-Safe Rotary Actuators • • • • • Mechanical Fail-Safe Rotary Actuators for operation of: Torque: Open/Close control: Modulating control: DN65...80 CCV 20Nm SRFU-5, SRFU-S2-5 (AC 24...240V) (DC 24V...125V) SRFU24-SR-5 (AC/DC 24V) Technical data SRFU-S2-5 SRVU24-SR-5 Common technical data Nominal voltage Nominal voltage range Power consumption For transformer/wiring sizing Connection Nominal voltage Nominal voltage range Power consumption For transformer/wiring sizing Connection -Motor -Auxiliary switches Nominal voltage Nominal voltage range Power consumption For transformer/wiring sizing Connection Control signal Position feedback Position Accuracy Torque -Motor -Spring return Auxiliary switch (SRFU-S2-5) Angle of rotation Sound power level Position indicator Manual override Running time -SRFU-S25,SRFU-5 -SRFU24-SR-5 Ambient temp. Non-operation temp. Humidity test Degree of protection EMC Low Voltage Directive Maintenance Weight 34 AC 24...240V, 50/60Hz, DC 24...125V AC 19.2...264V/ DC 21.6...126.5V 7.0W @ running / 3.5W @ holding 7.0VA @ AC 24V 8.5VA @ AC 120V 18.0VA @ AC 240V Cable 1m, 2x0.75mm2 AC 24...240V, 50/60Hz, DC 24...125V AC 19.2...264V/ DC 21.6...126.5V 7W @ running / 3.5W @ holding 7.0VA @ AC 24V 8.5VA @ AC 120V 18.0VA @ AC 240V Cable 1m, 2x0.75mm2 Cable 1m, 6x0.75mm2 AC 24V, 50/60Hz, DC 24V AC 19.2...28.8V/ DC 21.6...28.8V 5W @ running / 3W @ holding 7VA Cable 1m, 2x0.75mm2 DC 2(0)...10V @ 100kΩ input resistance DC 2...10V @ max.0.5mA 5% Min. 20Nm @ nominal voltage Min. 20Nm 2xSPDT, 1mA...3(0.5)A, AC 250V One fixed at 10%, one adjustable 10%...90% Max.95° by means of adjustable mechanical end stops Max. 45dB(A), spring ≈ 62dB(A) Mechanical Hex crank Motor ≈75s, spring return Max. 20s @ -20..+50°C Motor ≈150s, spring return Max. 20s @ -20..+50°C -30...+50°C -40...+80°C 95% RH, non condensing IP54 CE according to 2004/108/EC CE according to 2006/95/EC Maintenance-free Approx. 2.2kg V5.12.2010•Subject to modification SRFU-5 Product Overview/Contents Product features Simple direct mounting Manual operation Adjustable angle of rotation Simple direct mounting on the butterfly valve. Manual operation is possible with the manual override key Adjustable angle of rotation with mechanical end stops. High function reliability The actuator is overload-proof, requires no limit switches, and stops automatically when the end stop is reached. Mode of Operation The actuator is controlled with a standard of DC 2(0)...10V and moves the butterfly valve to the operating position at the same time as tensioning the return spring. The butterfly valve is turned back to the emergency position by spring force if the supply voltage is interrupted. Wiring diagrams T • Caution: Power supply voltage! – + • Other actuators can be connected in parallel. Please note the performance data. ~ Notes: AC 24...240V DC 24...125V SRFU-5 Open/Close control 1 2 SRFU-5 M Notes: ~T • Caution: Power supply voltage! – + AC 24...240V DC 24...125V • Other actuators can be connected in parallel. Please note the performance data. SRFU-S2-5 Open/Close control l S1 S2 S3 S4 S5 S6 1 2 M A=10° SRFU-S2-5 <A° <B° >A° >B° B=10...90° adjustable Notes: ~ • Caution: Power supply voltage! T • Other actuators can be connected in parallel. – + AC 24V DC 24V Please note the performance data. Y U SRFU24-SR-5 Modulating control DC 2(0)...10V Control signal DC 2...10V Position feedback signal 1 2 3 5 V5.12.2010•Subject to modification SRFU24-SR-5 35 Dimensions and auxiliary switch adjustment Dimensions[mm] min.70 151 115 L(R)F.. 221 40 103 min.40 27 101 NRFU.. 98 min.40 87.5 57 25 min.70 81 TRF.. 155 59 80 min.40 min.70 61 21.5 Adjusting A..-S auxiliary switches 1 2 3 Initial situation: Actuator in safety position 36 V5.12.2010•Subject to modification 3mm (1/8’’) hexagonal key not included with the actuator Installation instructions of General Actuators Installation instructions: TRF.. NC NO 2 2 1 AB B A 1 AB B A % B=0 % A–A B=100 B–A 00 % B=1 A –A B = 0 % B –A Installation instructions: LF../LRF.. 1 NC NO .8 0 .2 .4 .6 .8 .6 1 .4 .2 .8 0 0 .2 .4 .6 R R M R Made in Switzland Made in Switzland M 1 .8 .6 .4 .2 L 0 .2 1 .6 1 .8 .4 .6 .2 .4 .8 0 M a d R e in S w n in d e M d la a itz M R S w it zl a n d R M AB AB B A B A % 100 B= A–AB = 0 % B–A 0 %% B= A–A B = 1 00 B–A Installation instructions: NRFU../SRFU NC NO 65)$ 1 4 1 4 .9 .8 .7 V5.12.2010•Subject to modification .9 .8 .7 6 6 3 3 SRFU NRFU $$% %$% $$% %$% $ $ % $% % $% 37 GRKU..-7 Electronic Fail-Safe Actuators • • • • Electronic Fail-Safe Actuators for operation of: Torque: Open/Close control: Modulating control: DN100...150 CCV 40Nm GRKU24-7 GRKU24-MF-7 Technical data GRKU24-7 Nominal voltage AC 24V, 50/60Hz / DC 24V Nominal voltage range AC 19.2...28.8V/DC 21.6...28.8V Power consumption GRKU24-MF-7 -running 12W @ norminal torque -holding <3W For wiring sizing ≤21VA Connecting cable Cable1m, 2x0.75mm2 Protection class III (safety extra- low voltage) Weight Approx. 2200g Nominal voltage AC 24V, 50/60Hz / DC 24V Nominal voltage range Power consumption AC 19.2...28.8V/DC 21.6...28.8V -running 12W @ norminal torque -holding <3W For wiring sizing ≤21VA (1max 20 A @ 5ms) Connecting cable Cable1m, 4x0.75mm2 Control signal Y DC 2(0)...10V @ input impedance100kΩ Position feedback U DC 0.5...10V@ max. 0.5mA Sychronisation Common technical data 5% Protection class III (safety extra- low voltage) Weight Approx. 2200g Torque ≤ 40Nm Direction of rotation Max. 90° At switch position Angle of rotation Max. 95° , can be limited at both ends with 1or 0 , respectively adjustable mechanical end stops Sound power level Max. 61dB(A) Position indicator Mechanical, pluggable Manual override Gearing disengaged by pressing the pushbutton Running time -Standard operation 150s/95° 38 35s @ 0...50 °C Type 1.AA Ambient temp. -30...+50°C Non-operation temp. -40...+80°C Humidity test 95% RH, non condensing Degree of protection IP54 NEMA 2, UL Enclosure Type 2 EMC CE according to 2004/108/EC Maintenance Maintenance-free V5.12.2010•Subject to modification -Emergency setting position Mode of operation GRKU..-7 Electronic Fail-Safe Actuators Technical data (continued) Dimensions Dimensions See «Dimensions» on page 6 Safety notes • The actuator is not allowed to be used outside the specified field of application, especially • in aircraft or in any other airborne means of transport. It may only be installed by suitably trained personnel. Any legal regulations or regulations ! issued by authorities must be observed during assembly. • • • The device may only be opened at the manufacturer’s site. It does not contain any parts that can be replaced or repaired by the user. The cable must not be removed from the device. The device contains electrical and electronic components and is not permitted to be disposed of as household refuse. All locally valid regulations and requirements must be observed. Product features Mode of operation Pre-charging time (start up) The actuator is controlled with a standard modulating signal of DC 0 ... 10 V and travels to the position defined by the control signal. The measuring voltage U serves for the electrical display of the damper position 0 ... 100%. The capacitor actuators require a pre-charging time. This time is used for charging the capacitors up to a usable voltage level. This ensures that, in the event of a voltage interruption, the actuator can be moved at any time from its current position into the preset emergency setting position (POP). The duration of the pre-charging time depends mainly on the following factors: –Duration of the voltage interruption –PF delay time (bridging time) Typical pre-charging times 30 30 PF delay 10 s PF delay [s] Duration of voltage interruption [Days] 0 1 2 7 ≥10 0 5 8 10 15 19 2 6 9 11 16 20 5 8 11 13 18 22 10 12 15 17 22 26 Pre-charging time[s] Pre-charging time [s] 25 5s 2s 0s 20 25 20 15 15 10 10 5 5 0 0 2 4 6 8 Duration of voltage interruption [Days] 10 0 12 Calculation example: In the event of a voltage interruption of 3 days and a set bridging time (PF) of 5 s, the actuator requires a pre-charging time of 14s (see graphic on page 2) after the voltage has been reconnected. Delivery condition (capacitors) The actuator is completely discharged after delivery from the factory, which is why the actuator requires approximately 20 s pre-charging time before initial commissioning in order to bring the capacitors up to the required voltage level. High operational reliability The actuator is overload-proof, requires no limit switches and automatically stops when the end stop is reached. V5.12.2010•Subject to modification Home position / Start The clamp of the actuator is set ex-works to 0° After the supply voltage has been applied, the actuator moves into the position defined by the control signal. 39 GRKU..-7 Electronic Fail-Safe Actuators Product features (continued) The «Emergency setting position» rotary button can be used to adjust the desired emergency setting position (POP) between 0 and 100% in 10% increments. The rotary button applies only to the adapted angle of rotation range of between 30 and 95° . No minimum or maximum set values are taken into account. In the event of a voltage interruption, the actuator will move into the selected emergency setting position, taking into account the bridging time. Emergency setting position (POP) rotary button Settings The rotary button must be set to the «Tool» position for retroactive settings of the emergency setting position with the BELIMO service tool MFT-P. Once the rotary button is set back to the range 0 … 100%, the manually set value will have positioning authority. Bridging time (PF) Voltage interruptions can be bridged up to a maximum of 10 s. In the event of a voltage interruption, the actuator will remain stationary in accordance with the set bridging time. If the voltage interruption is greater than the set bridging time, then the actuator will move into the selected emergency setting position (POP). The bridging time set ex-works is 2 s. This can be modified at the site of operations with the use of the BELIMO service tool MFT-P. Settings The rotary button must not be set to the «Tool» position! Only the values need to be entered for retroactive adjustments of the bridging time with the BELIMO service tool MFT-P. Accessories Description Electrical accessories Data sheet Auxiliary switch S..A.. S..A.. Feedback potentiometer P..A.. P..A.. Wiring diagrams Open/Close control ~ GRKU24-7 T – + Notes: ! • Caution: Power supply voltage! • Other actuators can be connected parallel. Please note the performance data. 1 2 Cable colors: 1=black 2=red Open/Close control T ~ Y U Note: – + ! 2 3 5 Cable colors: 1=black 2=red 3=white 5=orange U 1 T – 40 2 + 3 5 Y U V5.12.2010•Subject to modification 1 ~ Connect via safety isolation transformer. Control signal Measuring voltage T + ~ GRKU24-MF-7 – GRKU..-7 Electronic Fail-Safe Actuators Electrical installation T ~ – + Y U1 1 2 UX Wiring diagram for parallel operation 5 1 2 Y 3 5 1 Actuator 2 C T Cable lengths 3 Actuator 1 ~ Notes: • A maximum of eight actuators can be connected in parallel. • Parallel operation is permitted only on separated axes. • It is imperative that the performance data be observed with parallel operation. U 2 3 5 Actuator X A = Actuator C = Control unit L1 = Belimo connection cable, 1m (4x 0.75mm2) L2 = Customer cable Ltot = Maximum cable length L2 Ltot Cross section L2 ┴/~ When several actuators are connected in parallel, the maximum cable length must be divided by the number of actuators. AC DC ≤40m ≤20m 1m (L1) + 19m (L2) 1.00mm2 ≤50m ≤30m 1m (L1) + 29m (L2) 0.75mm 1 2 3 5 A 1.50mm 2 2.50mm2 N Example for DC 2 L1 Note: Max. cable length Ltot = L1+ L2 ≤80m ≤45m 1m (L1) + 44m (L2) ≤130m ≤80m 1m (L1) + 79m (L2) L AC 230V C T AC 24V Y U A = Actuator C = Control unit L1 = Belimo connection cable, 1m (4x 0.75mm2) L1 Note: There are no special restrictions on installation if the supply and data cable are routed separately. 1 2 3 5 V5.12.2010•Subject to modification A 41 GRKU..-7 Electronic Fail-Safe Actuators Operating controls and indicators 1 GRKU24-MF 0 1 Direction of rotation switch 1 2 Cover, POP button 3 POP button 4 Scale for manual adjustment 5 Position for adjustment with tool 6 Tool socket 7 Disengagement switch 2 0.5 0.1 7 0 5 3 POP 0.9 1 4 TOOL 8 9 Status Power Adaption LED displays 6 yellow 9 Off Illuminated Illuminated Off 8 green Meaning / function Operation OK / without fault Fault Off Off Illuminated Illuminated Adaptation procedure running Not in operation Blinking Illuminated Communication with programming tool Operating controls and indicators R Setting the POP Power Off position GRKU24-MF 0.5 0.1 0.9 0 1 TOOL POP % 0...100 0.5 0.9 0 1 TOOL 42 POP > PC- Tool V5.12.2010•Subject to modification 0.1 Dimensions of GRKU..-7 Electronic Fail-Safe Actuators Dimensions [mm] 44 174 V5.12.2010•Subject to modification GRKU24-MF-7 97 GRKU24-7 43 Installation procedures of Electronic Fail-Safe Rotary Actuators 3 1 10Nm 10 F05 F07 22Nm 13 2 0% 0% 4 PO n tio ec dir P ec n tio P dir PO dir ec P n tio 44 M PO B M V5.12.2010•Subject to modification A Installation, direction of flow and commissioning Standard directions of flow kv Y Characterised Control Valves AB A 2-way R2..AC, R6..AO Closed Open 3-way R3.. AB A A-AB Open A-AB Closed B B kv Open 2-way R2..AC, R6..AO Closed Y Open/Close Ball Valves A A AB 3-way R3.. AB A-AB Open A-AB Closed B B Spindle position for corresponding valve flow For 2-way and 3-way Ball Valves Actuator position corresponding to ball valve flow direction Flow characteristics of Charactersied Control Valves Between 0° and 12.5° angle of rotation, 2way and 3-way Characterised Control Valves function as tight-sealing shut-off devices. Between 12.5° and 90° angle of rotation, Control Ball Valves operate kv/kvs 2-way Characterised Control Valve 3-way Characterised Control Valve 100% 100% B- AB 0 10° 90° Angle of rotation 0 12.5° 70° Note: Due to its spherical design, the 3-way Characterised Control Valve is of limited application for conventional supply temperature control systems only. Therefore, it is recommended that supply temperature control systems are of the double-mixing circuit type (see diagram below). There are no restrictions when using mixing-type circuits for air preheaters and for injection circuits. M A- 70% AB kv/kvs as regulating devices. In case of the 3-way Characterised Control Valve, the bypass flow rate (B-AB) is 70% of the nominal flow rate (A-AB). 90° Angle of rotation V5.12.2010•Subject to modification Mounting, installation and commissioning Separate supply When Ball Valve and Rotary Actuator are supplied separately, they can be assembled on-site. Recommended mounting positions The Ball Valves maybe mounted vertical (Fig. 1) or horizontal (Fig. 2). However, mounting the Ball Valves with the spindle pointing downwards, i.e. upside down (Fig. 3), is not recommended. No special tools are needed for assembly. Instructions will be found packed with the valve and actuator. Fig.1 Fig.2 Commissioning Must not be carried out until the Ball Valve and Rotary Actuator have been assembled in accordance with the instructions. Fig.3 45 CCV-Notes on installation DN15...50 CCV 1. Clean pipe by compress air or steam 2. Teflon tape or other sealing filler is recommended for pipe and valve thread end, pipe dope is not allowed on thread 3. Make sure the correct wrench position (fig.1) 4. Support pipeline to avoid pipe distortion (fig.1) DN15...50 CCV 1. Clean the joint 2. Insert the gasket Put two or three screws (loose) 3. Insert the rest of the bolts, tighten all of the bolts evenly by the cross-over method to eliminate concentrated stresses. 7 V5.12.2010•Subject to modification 4 2 5 6 3 1 8 46 Notes on maintenance and project design Maintenance • Ball Valves and Rotary Actuators are both maintenance free. • Before any kind of service work is carried out on control devices of this type, it is essential to isolate the actuator from the power supply (by unplugging the power lead). Any pumps in the particular part of the piping system concerned must also be switched off and the appropriate isolating fittings closed (also allow everything to cool down first if necessary and reduce the pressure in the system to atmospheric). The systems must not be returned to service until the Ball Valve and the Actuator have been properly re-installed and connected and the pipe work has been refilled in the proper manner. Disposal When a control device (Ball Valve and Actuator) has come to the end of its service life, the two parts must be dismantled and sorted into different materials before being disposed of. Subsequent removal In the case of applications where subsequent removal of Ball Valve will be necessary, it is advisable to make appropriate preparations before hand. Project design Installing R2..AC, R6..AO CCV, 2-way The R2.. Characterised Control Valve is a throttling device, installed in the return line of systems in order to ensure less thermal stress on the seals of the device. The direction of flow specified must be adhered to. Dirt filters recommended Characterised Control Valves are relatively sensitive control devices and in order to ensure that they give long service life, the fitting of dirt filters is recommended. PV100 with Characterised Control Valves full open PV100R2..AC, R6..AO Characterised Control Valves, 2-way Injection circuit with throttling device Throttling circuit PV100 > Correct rating and sizing In order to ensure that the control device (Characterised Control Valve and Rotary Actuator) achieves a long service life, it is essential for the valve to be rated for the correct differential pressure PV100 across the valve, i.e. with adequate valve authority (Pv>0.5). The differential pressure PV100 depends on the type of hydraulic circuit in which the valve is being used. Water quality requirements The water quality requirements specified in VDI2035 must be adhered to. Installing R3.. CCV, 3-way The R3.. Characterised Control Valve is a mixing device. Whatever type of installation is employed, it is essential to adhere to the directions of flow specified. Whether a valve is installed in the supply or the return of a system depends on the type of Differential pressures Sufficient isolating valves It is essential to ensure that sufficient isolating valves are provided. hydraulic circuit being employed. No balancing valve is needed in the bypass line of a diverting circuit because of the reduced flow in the bypass. PVR/2 PV100 > Typical values: 15kPa > PV100 > 150kPa PVR/2 PV100 R3.. Characterised Control Valves, 3-way Diverter circuit PV100 > Typical values: 10kPa > PV100 > 100kPa PMV Typical values: 5kPa > PV100 > 50kPa Mixing circuit PV100 > PMV Typical values: PV100 > 3kPa(unpressurise manifold). For other mixing 3kPa > PV100 > 30kPa Injection circuit with 3-way Characterised Control Valve PMV1 + PMV2≈0 Typical values: PV100 < 3kPa Geographic Presentation PMV PMV2 PMV1 VL VL P P VR RL RL VL VL RL RL VL VL VL VR VL PMV2 ≈0 VL RL VL Synoptic Presentation PMV1 PMV PVR V5.12.2010•Subject to modification RL PMV ≈0 PVR RL RL RL PMV2 RL Legend Characterised Control Valve, 2-way with Rotary Actuator PVR Differential pressure across specified section at rated load Characterised Control Valve, 3-way with Rotary Actuator PMV Pump Differential pressure across variable-flow section at rated load (e.g. heat exchanger) Non-Return Damper Balancing throttle VL — Supply RL…Return Note: Dirt traps and isolating fittings are not shown. 47 Market Asia Pacific Trade Selection by Belimo Asia Pacific Headquarters and Shanghai Office: Belimo Actuators (Shanghai) Trading Ltd. 479 Chun Dong Road, Building C-2 Xin Zhuang Industry Park Shanghai 201108, P.R. China Tel: +86 21 5483 2929 Fax: +86 21 5483 2930 E-mail: info.asiapacific@belimo.ch E-mail: info.shanghai@belimo.ch INDIA Mumbai Office: Belimo Actuators India Pvt. Ltd. 204 Jaisingh Business Center, Parsiwada Sahar Road, Andheri (East) Mumbai 400099, India Tel: +91 22 6733 2525 / 6733 2501 Fax: +91 22 2822 2643 E-mail: info.india@belimo.ch New Delhi Office: AUSTRALIA Melbourne Office: Belimo Actuators Pty. Ltd. 12 Enterprise Court Mulgrave Business Park Mulgrave, VIC 3170, Australia Tel: +61 (0)3 9545 0844 Fax: +61 (0)3 9545 0855 E-mail: info.australia@belimo.ch Sydney Office: Belimo Actuators Pty. Ltd. Suite 2.20, 32 Delhi Road North Ryde, NSW 2113 Australia Tel: +61 (0)2 9805 1777 Fax: +61 (0)2 9805 1722 E-mail: info.australia@belimo.ch GREATER CHINA Beijing Office: Belimo Actuators (Shanghai) Trading Ltd. Beijing Branch Office Room 605, Hai Chang Edifice 44 Liang Ma Qiao Road Beijing 100016, P.R. China Tel: +86 10 6462 1382 Fax: +86 10 6462 1383 E-mail: info.beijing@belimo.ch Guangzhou Office: Belimo Actuators (Shanghai) Trading Ltd. Guangzhou Branch Office Room 1202, Skyline Plaza 644 Tong Fu East Road, Haizhu Area Guangzhou 510240, P.R. China Tel: +86 20 3435 1860 Fax: +86 20 3435 1870 E-mail: info.guangzhou@belimo.ch Belimo Actuators India Pvt. Ltd. A-230, Okhla Phase I New Delhi 110020, India Tel: +91 11 2637 1644 Fax: +91 11 2637 1699 E-mail: info.india@belimo.ch Bangalore Office: Belimo Actuators India Pvt. Ltd. 60/1, 1st Floor, Coles Road, Frazer Town Bangalore 560001, India Tel: +91 80 2558 0421 / 6565 6978 Fax: +91 80 2558 0422 E-mail: info.india@belimo.ch JAPAN Belimo Actuators Ltd. 7th Floor, Honjo-Azumabashi DJ Building 4-19-3, Honjo, Sumida-ku Tokyo 130-0004, Japan Tel: +81 3 6823 6961 Fax: +81 3 3626 3911 E-mail: info.japan@belimo.ch MALAYSIA Belimo Actuators Ltd. 12-1, Jalan PJS 10/2, Subang Indah 46000 Petaling Jaya Selangor, Malaysia Tel: +603 5631 2188 Fax: +603 5638 2189 E-mail: info.malaysia@belimo.ch SINGAPORE Belimo Actuators Ltd. 1 Tannery Road #08-04, One Tannery Singapore 347719 Tel: +65 6842 1626 Fax: +65 6842 1630 E-mail: info.singapore@belimo.ch Chongqing Office: Belimo Actuators (Shanghai) Trading Ltd. Chongqing Branch Office Room 4, 9th floor, Unit 7, Luoma Jiari Garden No. 36, QingLong Road, Nan’an District Chongqing 400060, P.R. China Tel: +86 23 6275 3155 Fax: +86 23 6280 3380 *519 E-mail: info.chongqing@belimo.ch Hong Kong Office: Belimo Actuators Ltd. Room 207, 2/F, New Commerce Center 19 On Sum Street, Shatin, N.T., Hong Kong Tel: +852 2687 1716 Fax: +852 2687 1795 E-mail: info.hongkong@belimo.ch Taiwan Office: Belimo Actuators Ltd. 7F-2, No. 343, Jhonghe Road, Yonghe City Taipei County 234, Taiwan Tel: +886 2 2922 8805 Fax: +886 2 2922 8806 E-mail: info.taiwan@belimo.ch THAILAND Belimo Actuators Ltd. 90/2 Pensiri Place Soi Phaholyothin 32, Phaholyothin Road Chandrakasem, Jatujak Bangkok 10900, Thailand Tel: +662 9415582-3 Fax: +662 9415584 E-mail: info.thailand@belimo.ch Innovation, Quality and Consultancy: A partnership for motorising HVAC actuators www.belimo.com Belimo regional head offices EU BELIMO Automation AG Brunnenbachstrasse 1 8340 Hinwil, Switzerland Tel: +41 43 843 61 11 Fax: +41 43 843 62 68 E-mail: info@belimo.ch Or contact your nearest Sales Representative AP BELIMO Actuators (Shanghai) Trading Ltd. 479 Chun Dong Road, Building C-2 Xin Zhuang Industry Park Shanghai 201108, P.R. China Tel: +86 21 5483 2929 Fax: +86 21 5483 2930 E-mail: info.asiapacific@belimo.ch US BELIMO Aircontrol (USA), Inc. 43 Old Ridgebury Road Danbury, CT 06813-2928, USA Tel: +800 543-9038 / 203 791-9915 Fax: +800 228-8283 / 203 791-9919