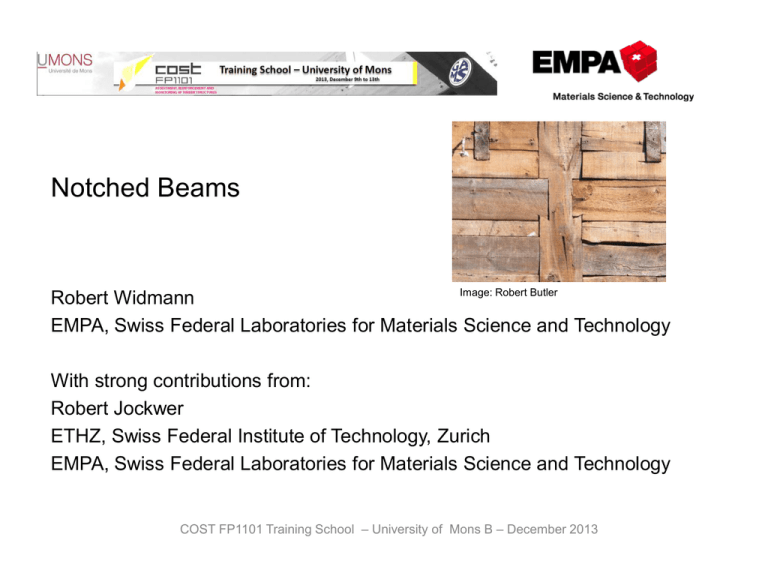

Notched Beams

advertisement

Notched Beams Image: Robert Butler Robert Widmann EMPA, Swiss Federal Laboratories for Materials Science and Technology With strong contributions from: Robert Jockwer ETHZ, Swiss Federal Institute of Technology, Zurich EMPA, Swiss Federal Laboratories for Materials Science and Technology COST FP1101 Training School – University of Mons B – December 2013 Outline Introduction Principals Types of notches Design of notches Shear design Reinforcement perpendicular to grain SIA 265 and EN 1995-1-1:2004 (German Version) Example Research Inclined reinforcements Conclusions COST FP1101 Training School – University of Mons B – December 2013 2 Introduction Notches at the support of beams Reduced depth of the beams at the support Connection of members Jockwer 2012 COST FP1101 Training School – University of Mons B – December 2013 3 Introduction - Principals Notches at the support of beams Reduced depth of the beams Connection of members High stresses perpendicular to the grain Stress concentrations at notch edge Notches should be avoided or strengthened ! Vd Tension perpendicular to the grain: high low Scholten, American Lumberman, 1935 COST FP1101 Training School – University of Mons B – December 2013 4 Introduction - Types of Notches Rectangular Rounded / Tapered Drawings from: www.harzerstatik.de COST FP1101 Training School – University of Mons B – December 2013 5 Introduction - Types of Reinforcements Bonded Straps Fully threaded screws Glued-in profiled rods Drawings from: www.harzerstatik.de COST FP1101 Training School – University of Mons B – December 2013 6 Outline Introduction Principals Types of notches Design of notches Shear design Reinforcement perpendicular to grain SIA 265 and EN 1995-1-1:2004 (German Version) Example Research Inclined reinforcements Conclusions COST FP1101 Training School – University of Mons B – December 2013 7 Design of Notches (SIA 265:2012) VEd h Calculation of shear stresses d 1.5 VEd kred fv ,d b hef hef i1 Δ hef c b A) A) A) B) Reduction of shear strength B) General conditions: (c ≤ 0.4 h und hef ≥ 0.5 h ) Δh0 For rounded / inclined notches with inclinations ≤ 1:10 the influence of stress concentrations can be neglected (kred = 1,0). 25mm for solid timber from softwood 45mm for glulam from softwood COST FP1101 Training School – University of Mons B – December 2013 8 Design of Notches (SIA 265:2012) 1.2 Calculation of shear stresses VEd kred fv ,d 1 b hef Reduction factor kred Abminderungsfaktor kred [-] d 1.5 0.8 VEd h SIA 265:2012 hef EN 1995-1-1:2004 Δ hef DIN 1052:1988 b Scholten i1 c A) 0.6 A) A) 0.4 B) Reduction of shear strength 0.2 General conditions: (c ≤ 0.4 h und hef ≥ 0.5 h ) Δh0 0 B) 25mm for solid timber from softwood 45mm for glulam from softwood 1 0.9 0.8 0.7 0.6 0.5 Notchwith ratioinclinations hef / h hef≤ /1:10 h [-] For rounded / Ausklinkungsverhältnis inclined notches the influence of stress concentrations can be neglected (kred = 1,0). COST FP1101 Training School – University of Mons B – December 2013 9 Flowchart for notch design - DIN EN 1995-1-1:2010 Notched bending member Notch in tension zone Notch in compression zone Inclination i < 10 Inclination i ≥ 10 Notch same side as support Notch opposite side to support x ≥ hef x < hef for LVL for solid timber for glulam COST FP101 Training School – University of Mons B – December 2013 10 Notch design - DIN EN 1995-1-1:2010 Shear capacity as function of inclination i, a= 0.8, h = 600mm, x = 100mm Glulam Solid Shear capacity as function of notch ratio a, i = 0, h = 600mm, x = 100mm LVL 80 60 40 20 0 Glulam 100 Shear Capacity [%] Shear Capacity [%] 100 [%]kv Capacity Shear Factor Reduction for LVL for structural timber for glulam kv as function of notch ratio Shear a, capacity i = 0, h = 600mm, x = 100mm as function of distance x, i = 0, a= 0.8, h = 600mm Glulam Solid LVL 1 Glulam Solid LVL 100 0.8 80 0.6 60 0.4 40 0.2 20 0 0 0.4 0.5 0.6 0.7 0.8 0.9 1 0 50 100 150 200 250 300 notch ratio a = hef/h Distance x Solid LVL 80 60 40 20 0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Inclination i COST FP101 Training School – University of Mons B – December 2013 0.4 0.5 0.6 0.7 0.8 0.9 1 Notch ratio a = hef/h 11 Flowchart for notch design - DIN EN 1995-1-1:2010 kv as function of notch ratio a, i = 0, h = 600mm, x = 100mm Reduction Factor kv 2.5 2 1.5 1 0.5 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 Notch ratio a = hef/h Shear capacity as function of notch ratio a, i = 0, h = 600mm, x = 100mm Shear Capacity [%] 100 80 60 40 20 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 Notch ratio a = hef/h COST FP101 Training School – University of Mons B – December 2013 12 Variation of strength values F Nordtest method to determine mode 1 fracture energy on 3-point bending SENB-specimens Parameters that influence fracture energy Gf,I hc Force [N] Knots Angle of grain Annual ring structure Cracks 180 160 140 120 100 80 60 40 20 0 G f ,I W 1 W mgu0 hc b u0 2 3 4 5 Displacement [mm] 6 7 Nordtest Method, NT Build 422, Wood: Fracture energy in tension perpendicular to the grain, 1993 COST FP101 Training School – University of Mons B – December 2013 13 Variation of strength values High variation of fracture energy Gf,I 0.12 Probability Density [-] 0.1 Test results Lognormal Probability Density [-] 0.08 0.06 0.04 0.02 0 0.14 0.13 0.12 0.11 0.1 0.09 0.08 0.07 0.06 0.05 0.04 0.03 0.02 0.01 0 Test results Normal Lognormal 2p-Weibull 0 Fracture energy Gf,I [N/m] 4 8 12 16 20 24 28 32 36 40 44 48 Notch Strength A' [Nmm-3/2] Consequence: high variation in notch strength Gustafsson, P.J., A study of strength of notched beams, 1988 Larsen, H.J. and P.J. Gustafsson, The fracture energy of wood in tension perpendicular to the grain, 1990 Riberholt, H., et al., Timber beams notched at the support, 1991 COST FP101 Training School – University of Mons B – December 2013 14 Reinforcement of Notches Unreinforced Notches: Low strength Big variations of strength values Notches have to be reinforced! Types of reinforcements Embedded reinforcements Glued-in rods Fully threaded screws COST FP101 Training School – University of Mons B – December 2013 External reinforcements Bonded wood based panels GFRP and / or CFRP Nail Plates 15 Design of Notches F Ft,90,d F Ft,90,d / VEd [-] 1.2 1 0.8 0.6 0.4 0.2 0 1 αh Ft,90,d Δhef τ h VEd 0.9 0.8 0.7 0.6 Notch ratio a = hef/h [-] 0.5 0.4 Ft ,90,d 1.3 31 a 21 a VEd 2 3 VEd COST FP101 Training School – University of Mons B – December 2013 16 Introduction - Types of Reinforcements Bonded Straps Fully threaded screws Glued-in profiled rods Drawings from: www.harzerstatik.de COST FP1101 Training School – University of Mons B – December 2013 17 Design of reinforced notch 1 Fully threaded screws Glued-in rods with dr 2 Bonded wood based panels Bond line Bond line for glued-in rods Wood based panel COST FP101 Training School – University of Mons B – December 2013 18 Outline Introduction Principals Types of notches Design of notches Shear design Reinforcement perpendicular to grain SIA 265 and EN 1995-1-1:2004 (German Version) Example Research Inclined reinforcements Conclusions COST FP1101 Training School – University of Mons B – December 2013 19 Example for design of reinforced notch Vd = 78kN, fv,g,k = 3.5MPa, kmod = 0.9, gM = 1.3 h = 600mm, hef = 450mm, b = 140mm, c = x = 100mm VEd h hef i1 Δ hef c b COST FP101 Training School – University of Mons B – December 2013 20 Example for design of reinforced notch Vd = 78kN, fv,g,k = 3.5MPa, r,k = 385kg/m3, kmod = 0.9, gM = 1.3 h = 600mm, hef = 450mm, b = 140mm, c = x = 100mm GL24h VEd h hef i1 Δ hef c b Reinforcement with fully threaded screws Pull-out strength R1,k [kN] Pull-out strength R1,k [kN] COST FP101 Training School – University of Mons B – December 2013 21 Example for design of screw reinforced notch COST FP101 Training School – University of Mons B – December 2013 22 Example for design of reinforced notch Vd = 78kN, fv,g,k = 3.5MPa, r,k = 385kg/m3, kmod = 0.9, gM = 1.3 h = 600mm, hef = 450mm, b = 140mm, c = x = 100mm GL24h hef i1 Δ hef c Reinforcement with wood based panel 𝜏𝑒𝑓 ,𝑑 ≤ 0.52 MPa = 0.75 MPa ∙ 𝑙𝑟 ≥ 𝐹𝑡,90,𝑑 2 ∙ h-∙ℎ𝑒𝑓 ∙ 0.52 𝑙𝑟 ≥ VEd h b 0.9 𝑘𝑚𝑜𝑑 = 𝑓𝑘2,𝑘 ∙ 1.3 𝛾𝑀 15.8 ∙ 103 = 101𝑚𝑚 2 ∙ 600-∙450 ∙ 0.52 38mm ≤ 𝑙𝑟 ≤ 75mm 38mm ≤ 101mm ≤ 75mm Requirement not fulfilled, notch can’t be strengthened with wood based panels COST FP101 Training School – University of Mons B – December 2013 23 Outline Introduction Principals Types of notches Design of notches Shear design Reinforcement perpendicular to grain SIA 265 and EN 1995-1-1:2004 (German Version) Example Research Inclined reinforcements Conclusions COST FP1101 Training School – University of Mons B – December 2013 24 Reinforcement of Notches Shear deformations of reinforcement F Jockwer, R. 2012 COST FP101 Training School – University of Mons B – December 2013 25 Reinforcement of Notches Image correlation measurements ARAMIS V Unreinforced notch Strain perpendicular to grain y Shear strain y x x Jockwer, R. 2012 COST FP101 Training School – University of Mons B – December 2013 26 Reinforcement of Notches Image correlation measurements ARAMIS V Reinforced notch: Fully threaded screw 90° Strain perpendicular to grain y Shear strain y x x Jockwer, R. 2012 COST FP101 Training School – University of Mons B – December 2013 27 Reinforcement of Notches Image correlation measurements ARAMIS V Reinforced notch: Fully threaded screw 45° Strain perpendicular to grain y Shear strain y x x Jockwer, R. 2012 COST FP101 Training School – University of Mons B – December 2013 28 Tests on reinforced notches Aim: Determination of influence of inclined reinforcement Glulam Gl28h, 10 beams b/h 90/315 mm Reinforcement: Fully threaded screws: SFS WRT-13 CFRP sheets: SikaWrap d= 13mm t= 1mm l= 400mm b= 50mm 45° and 90° 45° and 90° Shear Stress at failure Residual Cross Section [N/mm2] 3.5 3 2.5 2 1.5 1 0.5 0 unverstärkt Schraube 90°Schraube 45° CFRP CFR 90° Unreinforced Screw 90° Screw 45° 90° CFR 45°45° CFRP Jockwer, R. 2012 COST FP101 Training School – University of Mons B – December 2013 29 Outline Introduction Principals Types of notches Design of notches Shear design Reinforcement perpendicular to grain SIA 265 and EN 1995-1-1:2004 (German Version) Example Research Inclined reinforcements Conclusions COST FP1101 Training School – University of Mons B – December 2013 30 Conclusions Notched members to decrease depth at supports Shear capacity significantly decreases Tension stresses perpendicular to grain are present From mechanical point of view notches should be avoided Rounded / inclined notches have a better performance Notches need to be strengthened / reinforced Most used techniques: bonded wood based panels, fully threaded screws, nail plates and glued-in rods Research shows that strengthening should also be applied for shear Thank you for your attention ! COST FP1101 Training School – University of Mons B – December 2013 31