Timken Ball Bearing Catalog

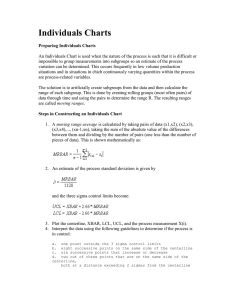

advertisement