hot dip galvanizing

advertisement

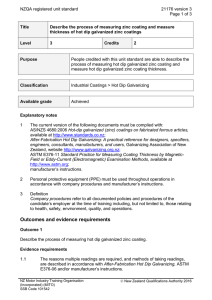

NUCOR FASTENER hot dip galvanizing TECHNICAL DATA SHEET General Hot Dip Galvanizing is one of the oldest methods of zinc coating which involves immersion of a fastener in molten zinc to provide a corrosion protecting finish. This zinc coating provides sacrificial or cathodic protection to the steel. Because zinc is more reactive than iron, the zinc galvanized coating corrodes first, protecting the steel substrate. The appearance of the galvanized surface can vary from shiny silver to a dull matte gray finish depending upon variables such as the steel composition, rate of withdrawal from the molten zinc bath and cooling method. The dark gray matte finish will provide just as much corrosion protection as the shiny appearance. Our domestic sources are qualified and utilize in-process quality systems enabling us to maintain full traceability from raw material to each container of product we ship. Chemical and physical certifications are provided with every shipment. Nucor Fastener is TS16949 and ISO9001 Registered and our laboratory is A2LA Accredited. The Hot Dip Galvanizing Process The hot dip galvanizing process starts by carefully cleaning the surface of the steel to prepare it for galvanizing. After cleaning, the parts are dipped in a flux tank containing (typically) an aqueous solution of zinc ammonium chloride or they are fluxed by passing through a layer of molten zinc ammonium chloride floating on the top of the molten zinc. In the galvanizing tank, the parts are completely immersed in a molten bath consisting of a minimum of 98% zinc. After slowly withdrawing the parts from the molten zinc, the fasteners are spun in a centrifuge while the zinc is still liquid to remove excess zinc. The parts are then either air or water cooled to solidify the zinc and to permit handling. Hot Dip Zinc Coating The resulting coating from Hot Dip Galvanizing consists of a layer of pure zinc on the outside, with layers of zinc-iron alloy underneath, ranging from 6% to 25% iron content, leading to the base metal. The thickness and chemistry of the galvanizing will be principally determined by the bath immersion time, bath withdrawal rate and the chemistry of the steel being coated. Hot Dip Galvanizing of fasteners is typically specified to meet the requirements of ASTM A153, Class C (AASHTO M232, Class C); or to ASTM F2329. The thickness requirements are listed in Table 1. TDS-007A 2-15-08 TABLE 1 – Coating Weight (Thickness) Requirements ASTM A153/AASHTO M232/ASTM F2329 FIGURE 1 – Service Life of Hot Dip Zinc Galvanizing (Source: American Galvanizers Association) Hot Dip Minimum Weight of Galvanizing oz/Ft2 (Thickness) of Surface Thickness of Zinc in Micrometers 11 STANDARD & CLASS OF MATERIAL AVERAGE OF SPECIMENS TESTED ANY INDIVIDUAL SPECIMEN 1.25 oz/Ft2 (.0021") 1.00 oz/Ft2 (.0017") ASTM A153, Class C (AASHTO M232) Fasteners over 3/8" in diameter & Washers 3/16" or 1/4" in thickness 1.00 oz/Ft2 (.0017") 0.85 oz/Ft2 (.0014") ASTM F2329 Fasteners & nuts over 3/8" in diameter Washers 3/16" or 1/4" in thickness 32 43 54 65 75 86 97 ine ar lM e rin Tro e Ma t e ra mp a pic 50 Te Sub .0017" .0015" al 70 Mo 30 .0017" 129 r Ru 40 .0020" 118 80 ASTM F2329 Fasteners & nuts 3/8" diameter & under Washers under 3/16" in thickness 108 60 ASTM A153, Class D (AASHTO M232) Fasteners 3/8" and under in diameter & Washers under 3/16" in thickness 21 de ly ra t e Heav 20 ur b In d y Ind an i ustr al l ustria 10 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 4.2 4.7 5.1 Oz. of Zinc/Sq. Ft. of Surface 0.4 0.8 1.3 1.7 2.1 2.6 3.0 3.4 3.8 Thickness of Zinc in Mills *Service Life is defined as the time to 5% rusting of the steel surface Special Requirements Corrosion Protection Hot Dip Galvanized nuts for structural bolting applications must be heat-treated A563 (AASHTO M291) While the ASTM/AASHTO specifications do not specify corrosion testing, the life of coating in real world Grade DH to provide sufficient thread strength to prevent thread stripping, because the nuts are tapped service will depend upon the actual conditions of the environment. Figure 1 illustrates the typical range of oversize after galvanizing. Our lubricant containing a green colored dye is put on the HDG coated service life that can be realized for a variety of environmental conditions. nuts as a requirement of ASTM/AASHTO specifications to prevent galling during assembly. The visible dye is a requirement to enable visual confirmation of the presence of a lubricant. The green color of Nucor Black Kegs are really “Green”! With an Average Recycled Content of 99%, Nucor Fastener products Nucor Fastener’s Hot Dip Galvanized nuts distinguishes them from our blue dye lubricated Mechanical qualify for “Green Building” applications or LEED® rated projects. Just as you would expect from Nucor, the Galvanized nuts to help prevent mixing. There shall be no mixed coating types on structural bolt/nut largest recycler in North America. It’s our Nature! combinations per the specifications. Nucor Fastener has the equipment, quality, systems, expertise, sources & people to meet your specifications. Testing/Certification Requirements Testing for the mechanical properties of the fasteners including proof load, wedge tensile strength, TODAY, THAT LITTLE “n” MEANS BIG THINGS! and hardness must be done after galvanizing in accordance with the ASTM A325 specification. ASTM A490, ASTM A490M, ASTM F1852 and ASTM F2280 Structural Products are not permitted to be Hot Dip Galvanized. This Technical Data Sheet is subject to change without prior notification. TABLE 1 – Coating Weight (Thickness) Requirements ASTM A153/AASHTO M232/ASTM F2329 FIGURE 1 – Service Life of Hot Dip Zinc Galvanizing (Source: American Galvanizers Association) Hot Dip Minimum Weight of Galvanizing oz/Ft2 (Thickness) of Surface Thickness of Zinc in Micrometers 11 STANDARD & CLASS OF MATERIAL AVERAGE OF SPECIMENS TESTED ANY INDIVIDUAL SPECIMEN 1.25 oz/Ft2 (.0021") 1.00 oz/Ft2 (.0017") ASTM A153, Class C (AASHTO M232) Fasteners over 3/8" in diameter & Washers 3/16" or 1/4" in thickness 1.00 oz/Ft2 (.0017") 0.85 oz/Ft2 (.0014") ASTM F2329 Fasteners & nuts over 3/8" in diameter Washers 3/16" or 1/4" in thickness 32 43 54 65 75 86 97 ine ar lM e rin Tro e Ma t e ra mp a pic 50 Te Sub .0017" .0015" al 70 Mo 30 .0017" 129 r Ru 40 .0020" 118 80 ASTM F2329 Fasteners & nuts 3/8" diameter & under Washers under 3/16" in thickness 108 60 ASTM A153, Class D (AASHTO M232) Fasteners 3/8" and under in diameter & Washers under 3/16" in thickness 21 de ly ra t e Heav 20 ur b In d y Ind an i ustr al l ustria 10 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 4.2 4.7 5.1 Oz. of Zinc/Sq. Ft. of Surface 0.4 0.8 1.3 1.7 2.1 2.6 3.0 3.4 3.8 Thickness of Zinc in Mills *Service Life is defined as the time to 5% rusting of the steel surface Special Requirements Corrosion Protection Hot Dip Galvanized nuts for structural bolting applications must be heat-treated A563 (AASHTO M291) While the ASTM/AASHTO specifications do not specify corrosion testing, the life of coating in real world Grade DH to provide sufficient thread strength to prevent thread stripping, because the nuts are tapped service will depend upon the actual conditions of the environment. Figure 1 illustrates the typical range of oversize after galvanizing. Our lubricant containing a green colored dye is put on the HDG coated service life that can be realized for a variety of environmental conditions. nuts as a requirement of ASTM/AASHTO specifications to prevent galling during assembly. The visible dye is a requirement to enable visual confirmation of the presence of a lubricant. The green color of Nucor Black Kegs are really “Green”! With an Average Recycled Content of 99%, Nucor Fastener products Nucor Fastener’s Hot Dip Galvanized nuts distinguishes them from our blue dye lubricated Mechanical qualify for “Green Building” applications or LEED® rated projects. Just as you would expect from Nucor, the Galvanized nuts to help prevent mixing. There shall be no mixed coating types on structural bolt/nut largest recycler in North America. It’s our Nature! combinations per the specifications. Nucor Fastener has the equipment, quality, systems, expertise, sources & people to meet your specifications. Testing/Certification Requirements Testing for the mechanical properties of the fasteners including proof load, wedge tensile strength, TODAY, THAT LITTLE “n” MEANS BIG THINGS! and hardness must be done after galvanizing in accordance with the ASTM A325 specification. ASTM A490, ASTM A490M, ASTM F1852 and ASTM F2280 Structural Products are not permitted to be Hot Dip Galvanized. This Technical Data Sheet is subject to change without prior notification. PO Box 6100 | St. Joe, Indiana 46785 | ph: (800) 955-6826 or (260) 337-1726 | fax: (260) 337-1726 | www.nucor-fastener.com