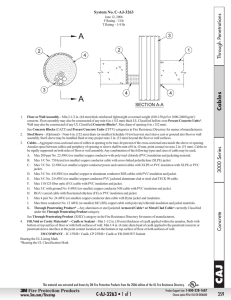

xlpe insulated power cable

advertisement