Installation Instructions - 56FWL Flush Mounting Wall Light

advertisement

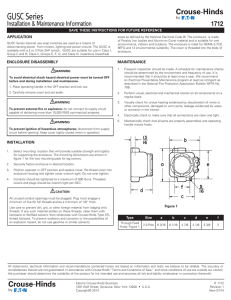

Flush Mounting Wall Light 56FWL Mounting Instructions General Mounting Details 1. Prepare wall for 56FWL unit by cutting a hole 205mm x 110mm to fit enclosure 2. Remove bracket from enclosure (as supplied) and use as template to position mounting points on wall 3. Bring cables through enclosure, wire lamp assembly and reposition in enclosure, refit bracket on enclosure using the two screws provided 4. Connect earthing conductor to the bracket 5. Fix bracket and enclosure to wall by one of the following methods: a. Solid and Cavity Brick Walls - Suitable fixing devices, i.e. through bolts, fibre plugs, etc. In soft or porous brickwork we suggest chemically adhesive anchor fixing b. Panel Type Walls - Suitable hollow wall anchors and if possible mount to building frame, i.e. wooden noggins and studs with suitable wood screws c. Poured Concrete Walls - Position enclosure at correct height on framework. Pour concrete over the enclosure. When cured the lamp assembly can be wired and refitted, then bracket repositioned Enclosure Shown in wall. Note: Ensure top edge of enclosure ends up as close as possible to finished wall face. Lens Assembly Gasket Bracket Lamp Assembly suits PL5-PL7 lamps. Lamps not supplied 6. Place lamp in assembly - test operation 7. Remove adhesive stop sheet from gasket and adhere to inner surface of lens assembly 8. Fit lens assembly to unit and firmly tighten screws to compress gasket and give even seal to wall/bracket. Note: IP Rating is dependent upon method of sealing. When mounting to brick or uneven surfaces ensure all mortar joints or depressions are sealed with suitable caulking compound, to ensure against ingress of water or dust. We suggest sealant is applied around enclosure and bracket, bracket and wall and all areas not filled by gasket. CONDENSATION Over a period of time, moisture may form and collect in the unit and/or associated conduit system. This phenomenon depends on several environmental factors including humidity and variations in temperature and pressure. To help keep the interior of the unit dry, we suggest that during installation, consideration be given to applying suitable mastic between cables and entry and providing small vent facilities at bottom of unit as appropriate. Ensure all joints in the conduit system are properly sealed. Product of Clipsal Australia Pty Ltd A member of Schneider Electric Contact us clipsal.com/feedback National Customer Service Enquiries: Tel 1300 2025 25 Fax 1300 2025 56 F382/02 clipsal.com Clipsal Australia Pty Ltd reserves the right to change specifications, modify designs and discontinue items without incurring obligation and whilst every effort is made to ensure that descriptions, specifications and other information in this catalogue are correct, no warranty is given in respect thereof and the company shall not be liable for any error therein. © Clipsal Australia Pty Ltd. The identified trademarks and copyrights are the property of Clipsal Australia Pty Ltd unless otherwise noted. CLIPCOM 16257 June 2008