Buck Combined Cycle Station

advertisement

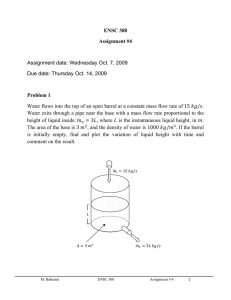

Environmental benefits Combined cycle technology is one of the most environmentally friendly forms of fossil fuel generation available. The station burns low-sulfur natural gas for fuel. Exhaust gases from the natural gas turbines pass through an SCR system to remove a majority of NOx, and an oxidation catalyst removes significant amounts of CO and VOCs. Water usage ¡¡The station’s cooling towers use ambient air for steam condenser cooling, which minimizes intake and discharge impacts to the Yadkin River ¡¡Maximum flow requirements from the Yadkin River are approximately 5 percent of the water used by Buck’s coal-fired units 3 and 4 ¡¡No heated water is discharged to the Yadkin River Site facts ¡¡Site preparation began in 2008 ¡¡Site excavation and backfill required more than 60,000 cubic yards of dirt ¡¡5.6 miles of underground pipe ¡¡1,961 tons of structural steel ¡¡25,191 ¡¡177 ¡¡A cubic yards of concrete miles of cable 20-inch pipeline supplies natural gas to the site ¡¡Commercial operation began in November 2011 ¡¡At full load, each gas turbine consumes approximately 76,400 lbs/hour of natural gas, roughly equivalent to a gas grill-sized tank of natural gas per second ¡¡The 620-MW station has approximately twice the capacity of Buck Steam Station’s original 369-MW rating ¡¡Power augmentation systems: ¡¡HRSG duct burners – At full load each HRSG duct burner system consumes approximately 26,800 pounds per hour of natural gas ¡¡Additional heat input is capable of adding up to 65 MW of additional generating capacity from the steam turbine generator ¡¡Inlet air chilling – Two 6,000-ton chiller plants capable of cooling the inlet air to each gas turbine to 45 degrees Fahrenheit. This allows us to recover lost MW due to elevated temperatures and humidity during summer months. ¡¡Employs Buck Combined Cycle Station approximately 40 people ©2013 Duke Energy Corporation 130977 10/13 130977-buck-combined-cycle-brochure-FINAL.indd 1 10/29/13 9:58 AM Located in Rowan County, N.C., Duke Energy’s Buck Combined Cycle Station utilizes one of the most efficient and flexible fossil generation technologies available. The 620-megawatt (MW) station incorporates two natural gas-fired combustion turbine generator sets, two heat-recovery steam generators and a steam turbine generator set to produce electricity. The major components 1Two General Electric 7FA gas turbine generator sets rated at 170 MW at 18 kV each. 2Two Vogt HRSGs capture exhaust heat from the combustion turbine to heat water inside a series of tubes, producing steam. Gas burners are used to increase the steam temperature and pressure. Buck Combined Cycle Station can go from “cold shutdown” to full capacity in approximately four hours, ramp up and down based on system demand or run 24 hours a day. This flexibility helps Duke Energy manage its generation fleet cost-effectively. 3A selective catalytic reduction (SCR) system removes a significant amount of the nitrogen oxide (NOx) from the combustion process. An oxidation catalyst removes most of the carbon monoxide (CO) and volatile organic compounds (VOCs) produced. Buck Combined Cycle Station shares a strong connection to Duke Energy’s early history and tradition of utilizing the latest, most efficient technology to meet customer demand for electricity. Just a few hundred yards away stands the Buck Steam Station, which generated electricity and served the community for more than 80 years. 4Water vapor leaves the stacks, and continuous emissions monitoring equipment ensures air quality regulations are met. 5One GE D11 steam turbine generator set produces 280 MWs at 18 kV. This ‘traditional” turbine generator uses steam from the HRSGs to produce electricity, increasing plant efficiency. Buck Steam Station In 1926, Buck Steam Station entered commercial operation with two units, the first in the South to use pulverized coal. Named after James Buchanan “Buck” Duke, co-founder of Southern Power Company, the station had four additional units operating by the 1950s. Units 1 and 2 retired from service in 1979, followed by units 3 and 4 in 2011 and units 5 and 6 in 2013 as part of Duke Energy’s continuing efforts to modernize its generating fleet. 6A 10-cell cooling tower uses ambient air to dissipate heat from the condenser cooling water, avoiding the need to discharge heated water to the Yadkin River. 7Three ABB main step-up transformers take voltage from their respective generator at 18 kV and step it up to 230 kV prior to being pushed to the power grid. Adjacent to the station, Duke Energy established and maintained Dukeville Village as housing for employees and their families well into the 1950s. Employees paid rent, and their children attended a school located on Dukeville Road. How does combined cycle technology work? A natural gas combined cycle generating facility efficiently combines two energy production processes – gas combustion turbines and a steam turbine – to convert natural gas fuel to electricity. First, natural gas is burned in Combustion two combustion turbines to heat compressed air. The expanding Turbine air turns a turbine with mechanical energy that is converted to electric power by the generator. For increased 1 efficiency, the hot exhaust gases from the natural gas combustion process are then routed through Main Step-up two 93-foot-tall heat recovery steam generators (HRSGs), which heat water to produce steam. Transformers The steam turns a steam turbine generator to create additional electricity. Combined cycle 7 plants have high operational flexibility, high thermal efficiency and significantly reduced emissions. Heat Recovery Steam Generator 2 Selective Catalytic Reduction 3 Stack 4 Steam Turbine 5 Cooling Tower 6 The Buck Combined Cycle Station can generate 620 MW of electricity. 130977-buck-combined-cycle-brochure-FINAL.indd 2 10/29/13 9:58 AM